Académique Documents

Professionnel Documents

Culture Documents

Bsi Complete PDF

Transféré par

JanekTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bsi Complete PDF

Transféré par

JanekDroits d'auteur :

Formats disponibles

BSI – The ‘keystone’ of PSA Multiplexing

Introduction

What is Multiplexing?

PSA Multiplex layout

BSi structure

Data sharing

Diagnostic interface

Introduction

Most technicians have heard of the term ‘BSi’ when fault finding on Peugeot and

Citroen vehicles but how many actually know what it is?

The term BSI stands for ‘Built-in Systems

interface’ and was introduced by the PSA

group in the year 2000. In simple terms it

is a central controller or interconnection

unit that allows the sharing and

management of information across the

ECU’s fitted to a vehicle.

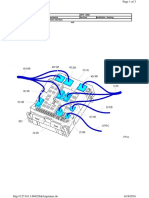

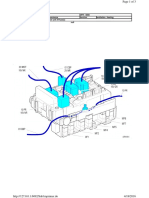

BSi Module

What is Multiplexing?

Multiplexing, or MuX, is the conveying of several pieces of information between various

electrical or electronic components on a single channel or ‘Data-Bus’. With each piece

of data carrying both a unique ‘ID’ and its ‘data’ any controller connected to the ‘Data-

Bus’ can request the information when required. The use of such networks became

something of a necessity when the number of ECU’s found on a vehicle rose

drastically. The days of having only 2 or 3 ECU’s on a vehicle have long gone and it is

quite common to find in excess of 10 ECU’s on entry level vehicles rising to an

astounding 50 plus on top end models. Multiplexing enables manufacturers to simplify

wiring harnesses and connectors which saves space, weight and of course money.

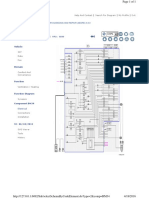

PSA Multiplex layout

Before explaining how the BSI fits into the system and the role it plays it is necessary to

understand the architecture developed by PSA when the BSi was introduced.

PSA multiplexed vehicles are equipped with 3 separate networks each linked by a

single (central) interconnection unit, the BSI.

o Powertrain network – Incorporating Engine management, Transmission, ABS and

suspension.

o Comfort network– Incorporating Instrument cluster, Climate control and Radio.

o Body network – Incorporating Safety and Security devices such as SRS and Alarm /

Immobiliser.

Comfort Multiplex network

Radio / CD

ECU

Instruments Climate

ECU Control ECU

BSI

Transmission Engine Man. Security SRS / Airbag

ECU ECU ECU ECU

ABS / ESP Switch Pack

ECU ECU

Powertrain Multiplex network Body Multiplex network

BSi structure

The BSI takes the form of a fuse panel and power distribution unit; its connector

sockets allowing both power distribution and data transfer between itself and the many

controllers (ECU’s) connected to it. With its own ‘on-board’ microprocessors it is able to

handle data and power distribution at speed, its ‘intelligent’ design also has the ability

to give priority to safety systems if needed. For example; a stability control system

would be given precedence over the Radio ECU requirements in the event of heavy

braking.

These processors also undertake more

routine applications when user intervention

demands. With driver requests collected

by the electronic switch module below the

steering column (the COM2000 /

COM2002 switch pack) these

requirements are relayed via the ‘Body’

network to the BSI where devices such as

the wipers or lights are managed

accordingly.

BSi Module in situ.

Data Sharing

Taking ‘Vehicle Road Speed’ data as an example it is easy to see how a single input is

used by various controllers (ECU’s) to good affect.

Vehicle road speed is still measured as normal by the ABS wheel speed sensor(s) with

the information being sent to the ABS control unit. The collected data would then be

sent along the ‘Data-Bus’ to the BSI where any other controllers on the Powertrain

Multiplex network could request it if needed. This road speed data would also be

available to modules outside of the Powertrain network via the BSi. With systems such

as Security, Radio, Navigation, Climate and Instruments needing this data as well as

Engine, Transmission and ABS it soon becomes obvious why Multiplexing is used.

Diagnostic interface

With the BSI playing such an important ‘central’ role its well being is paramount to

vehicle operation. The use of dedicated diagnostic equipment is therefore essential for:

1) Fault diagnostics

With so many modules being connected to the BSI it is sometimes difficult to

determine whether the fault lies within the interconnection unit or one of the

satellite systems connected to it. By using serial test equipment it is possible to

carry out system tests to help pin point the cause of any reported fault

accurately. BSI diagnostic routines include:

o DTC reading to extract stored fault codes

o Activation procedures to check component actions

o System configuration information for verification.

2) System configuration

With the BSI handling so many inputs and outputs throughout the vehicle it is

necessary to have the exact vehicle configuration programmed into the

processor. Information such as what alarm system the car has and whether a

CD player is fitted along with how many doors there are and whether the car has

15” or 16” wheels is required. As much of this information is subject to change

over the life of the vehicle it is necessary for this data to be changed when

required. For example; if you have just bought a 12 month old Citroen and want

to add a set of optional front fog lamps the configuration must be amended to

reflect this before they will work.

3) Programming replacement units

The programming of a BSI unit following replacement involves much the same

level of data to be input as is required during configuration but with a few extras.

When a new BSI is fitted certain details about the vehicle are ‘hard’ programmed

into the unit, the chassis (VIN) number being an obvious example.

Conclusion

The BSI is just another module on an ever increasing list of those fitted to modern

vehicles, the fact that a certain degree of technology and information is needed before

tackling its diagnostic or configuration requirements should not put you off. Bearing in

mind the percentage of PSA models that occupy the roads, or more importantly the

workshops of Europe can you really afford to ignore its existence?

Vous aimerez peut-être aussi

- Saab 9-5 2004 Can Bus Ver 2.0 EngDocument9 pagesSaab 9-5 2004 Can Bus Ver 2.0 EngMarkPas encore d'évaluation

- ECU MAGNETI MARELLI 6LP - Sensors & WiringDocument25 pagesECU MAGNETI MARELLI 6LP - Sensors & WiringGrizono MassimoPas encore d'évaluation

- Magneti Marelli Rt6 ManualDocument3 pagesMagneti Marelli Rt6 ManualRenato M Faria0% (4)

- 307 Bsi PinoutDocument5 pages307 Bsi Pinoutmohhizbar0% (1)

- Citroen Picasso Bsi NecDocument2 pagesCitroen Picasso Bsi NecNestor MansipePas encore d'évaluation

- Citroen Berlingo Bsi Nec PDFDocument2 pagesCitroen Berlingo Bsi Nec PDFhskv20025525Pas encore d'évaluation

- Psa Modules Wiring Diagrams: Obd2 DB9Document9 pagesPsa Modules Wiring Diagrams: Obd2 DB9simooo32Pas encore d'évaluation

- HF100 Ver.1.6.pdf Service Manual WebridgedDocument28 pagesHF100 Ver.1.6.pdf Service Manual WebridgedErnesto AcostaPas encore d'évaluation

- Engine PDFDocument254 pagesEngine PDFtipo333194% (18)

- BSI1 Built in Systems Interface CON INSTALATIONDocument3 pagesBSI1 Built in Systems Interface CON INSTALATIONMohd Ropi Abdullah75% (4)

- Xsara Picasso ManualDocument8 pagesXsara Picasso ManualFabricio Simões100% (1)

- Citroen Xsara Bsi From 2002Document2 pagesCitroen Xsara Bsi From 2002manutecPas encore d'évaluation

- Bar CargoDocument1 pageBar CargoJanekPas encore d'évaluation

- BSI - The Keystone' of PSA MultiplexingDocument3 pagesBSI - The Keystone' of PSA MultiplexingCelia Thomas100% (1)

- Vehicle: 206 (Full Mux) OPR: 9713 Domain General Points Function Multiplexed Network Interconnection Component BM34 Engine Slave Unit 34 Fuse(s) NullDocument3 pagesVehicle: 206 (Full Mux) OPR: 9713 Domain General Points Function Multiplexed Network Interconnection Component BM34 Engine Slave Unit 34 Fuse(s) Nullluis vilela100% (1)

- CitroenDocument23 pagesCitroenyayayalPas encore d'évaluation

- CitroenDocument6 pagesCitroengrikis2000Pas encore d'évaluation

- BM34 Engine Slave Unit 34 Fuse(s) - CONNNECTORDocument3 pagesBM34 Engine Slave Unit 34 Fuse(s) - CONNNECTORMohd Ropi Abdullah100% (2)

- Table 1. Encrypt/Decrypt: Decoded Hexval Decoded Hexval Decoded Hexval Decoded HexvalDocument5 pagesTable 1. Encrypt/Decrypt: Decoded Hexval Decoded Hexval Decoded Hexval Decoded Hexvaldusko ivanPas encore d'évaluation

- Citroen Berlingo Bsi NecDocument2 pagesCitroen Berlingo Bsi NecDario GomezPas encore d'évaluation

- BM34 Engine Slave Unit 34 Fuse(s)Document3 pagesBM34 Engine Slave Unit 34 Fuse(s)Mohd Ropi AbdullahPas encore d'évaluation

- BSI1 Built in Systems Interface CON CIRCUITDocument3 pagesBSI1 Built in Systems Interface CON CIRCUITMohd Ropi AbdullahPas encore d'évaluation

- Citroen Berlingo 2010 BsiDocument2 pagesCitroen Berlingo 2010 BsiKaku Carlos Cuello50% (2)

- BSI1 Built in Systems Interface CON CODEDocument4 pagesBSI1 Built in Systems Interface CON CODEMohd Ropi AbdullahPas encore d'évaluation

- Peugeot 206CC 2003Document4 pagesPeugeot 206CC 2003Kael ArialPas encore d'évaluation

- BSM Peugeot Can BusDocument5 pagesBSM Peugeot Can BusAlexanderAlexisOñaPas encore d'évaluation

- Psa Modules Wiring Diagrams: Obd2 DB9Document9 pagesPsa Modules Wiring Diagrams: Obd2 DB9uğur yıldırımPas encore d'évaluation

- 3008 Lama BsiDocument3 pages3008 Lama BsiDani SaefudinPas encore d'évaluation

- Identification: Built-In Systems Interface: N.B.: Replacement Parts Will Supply The Top-Of-The-Range BSIDocument13 pagesIdentification: Built-In Systems Interface: N.B.: Replacement Parts Will Supply The Top-Of-The-Range BSIvik_md80% (5)

- Peugeot 407 Bsi From 2006 95128Document1 pagePeugeot 407 Bsi From 2006 95128Sergio David Padron JorgePas encore d'évaluation

- PSA BSI Tool User Manual (English) - V1.1Document21 pagesPSA BSI Tool User Manual (English) - V1.1Diego FilicePas encore d'évaluation

- Component BM34Document1 pageComponent BM34Mohd Ropi AbdullahPas encore d'évaluation

- Citroen Manual Inmo PDFDocument17 pagesCitroen Manual Inmo PDFjorge luis guevara martinez100% (2)

- Bosch m7.4.4 Polaris 1033Document2 pagesBosch m7.4.4 Polaris 1033ddf_dedo100% (2)

- Info Diag 160Document13 pagesInfo Diag 160Koliko TogaPas encore d'évaluation

- Psa 23123Document2 pagesPsa 23123Anonymous SfX0iv12WLPas encore d'évaluation

- Renault Imo OffDocument20 pagesRenault Imo OffAn IaPas encore d'évaluation

- Pin Out PeugeotDocument5 pagesPin Out PeugeotCüneyt AtayPas encore d'évaluation

- BSI ResetDocument3 pagesBSI ResetAndrzej SobczakPas encore d'évaluation

- Peugeot 307Document5 pagesPeugeot 307BogdanBalea50% (2)

- Gateway 2007+Document16 pagesGateway 2007+48884Adam AdamPas encore d'évaluation

- Cluster 206 PDFDocument5 pagesCluster 206 PDFecutronicssPas encore d'évaluation

- CR - Vii Peugeot Diagnostics List (Note:For Reference Only) : Vehicle System ECU Type Functions YearDocument74 pagesCR - Vii Peugeot Diagnostics List (Note:For Reference Only) : Vehicle System ECU Type Functions YearEko hari PrasetyoPas encore d'évaluation

- SCHEMA Citroen C3 PDFDocument4 pagesSCHEMA Citroen C3 PDFMani Fekkar (LuXar)Pas encore d'évaluation

- Peugeot 206Document3 pagesPeugeot 206Asep Ridwan Setiawan100% (1)

- ManualDocument1 pageManualEko hari PrasetyoPas encore d'évaluation

- BoschME7.4.4 & EOBDDocument65 pagesBoschME7.4.4 & EOBDBerniSomex SomexemosPas encore d'évaluation

- Manual Tableros MultimarcaDocument675 pagesManual Tableros MultimarcaAudio-elipse De Ruben PPas encore d'évaluation

- Mk2 Punto Bosch ME7.3H4 Immo OffDocument1 pageMk2 Punto Bosch ME7.3H4 Immo Offkamaleon dorado50% (2)

- Peugeot 206 FusesDocument2 pagesPeugeot 206 FusesThomas Gunawan100% (3)

- Iot Psa Bsi DiagramDocument9 pagesIot Psa Bsi DiagramgandjiPas encore d'évaluation

- Peugeot Diagnostics List4 PDFDocument21 pagesPeugeot Diagnostics List4 PDFlag100% (1)

- Data Explorer Engine Ecu Decoding Version 6.0Document7 pagesData Explorer Engine Ecu Decoding Version 6.0Beniamin CociorvanPas encore d'évaluation

- Psa Modules Wiring Diagrams: Obd2 DB9Document9 pagesPsa Modules Wiring Diagrams: Obd2 DB9Oscar GonzalezPas encore d'évaluation

- STM32F103ZET6 Development BoardDocument10 pagesSTM32F103ZET6 Development BoardpiramidonPas encore d'évaluation

- Use: Diagnostic SocketDocument3 pagesUse: Diagnostic SocketCarlosFernandesPas encore d'évaluation

- Xprog USB User ManualDocument24 pagesXprog USB User ManualSavo Bikic100% (2)

- Peugeot PDFDocument71 pagesPeugeot PDFJorge Antonio Guillen0% (1)

- Continental Sid807evo Irom TC1797 VolvoDocument8 pagesContinental Sid807evo Irom TC1797 VolvoAlpine Lee100% (1)

- Peugeot All Models Wiring Diagrams - GeneralDocument32 pagesPeugeot All Models Wiring Diagrams - GeneralFitra AhmadPas encore d'évaluation

- Psa Group Bsi-2Document3 pagesPsa Group Bsi-2andi vlog'sPas encore d'évaluation

- Risc Assessment Security Countermeasures Vehicular Instrument ClustersDocument8 pagesRisc Assessment Security Countermeasures Vehicular Instrument Clustersinesboumaiza293Pas encore d'évaluation

- Audi Service Training Audi Data Bus TechnologiesDocument10 pagesAudi Service Training Audi Data Bus Technologiesterry100% (32)

- Oleje JCB PDFDocument211 pagesOleje JCB PDFJanek100% (1)

- Oleje JCB PDFDocument211 pagesOleje JCB PDFJanek100% (1)

- Genie S40 ManualDocument246 pagesGenie S40 ManualJanekPas encore d'évaluation

- Wiring Diagrams Fig. 1: Engine Compartment & Headlights (Grid 1-3)Document1 pageWiring Diagrams Fig. 1: Engine Compartment & Headlights (Grid 1-3)JanekPas encore d'évaluation

- Milkytracker Guide: Milkytracker Manual Milkytracker Video Tutorial by Simon WesselDocument9 pagesMilkytracker Guide: Milkytracker Manual Milkytracker Video Tutorial by Simon WesselPavlowPas encore d'évaluation

- TPH 1 R 403 NLDocument9 pagesTPH 1 R 403 NLNelsonSotoPas encore d'évaluation

- Chipanalog-CA-IF4820HS C2846827Document21 pagesChipanalog-CA-IF4820HS C2846827Mudassar RafiqPas encore d'évaluation

- Power Distribution and Utilization - Updated2020 - Spring 2021Document4 pagesPower Distribution and Utilization - Updated2020 - Spring 2021Ahad MunawarPas encore d'évaluation

- Motor Protection 7SK82 - 7SK85. Technical Data. Extract From Manual C53000-G5040-C024-7, Chapter 11. Energy AutomationDocument182 pagesMotor Protection 7SK82 - 7SK85. Technical Data. Extract From Manual C53000-G5040-C024-7, Chapter 11. Energy AutomationDrafter Technical SupportPas encore d'évaluation

- Electronic Inclinometer: Danei-300Document2 pagesElectronic Inclinometer: Danei-300insinyurPas encore d'évaluation

- Thermogravimetry (TG) : 1. Isothermal Thermogravimetry 2. Quasi-Isothermal Thermogravimetry 3. Thermogravimetry DynamicDocument19 pagesThermogravimetry (TG) : 1. Isothermal Thermogravimetry 2. Quasi-Isothermal Thermogravimetry 3. Thermogravimetry DynamicZUL KAMARUDDIN100% (1)

- Laboratory 7Document4 pagesLaboratory 7Priyamdas123Pas encore d'évaluation

- DUO Castellini PDFDocument148 pagesDUO Castellini PDFKhaled MAMMAR KOUADRI100% (1)

- EPAK TVRO Manual PDFDocument32 pagesEPAK TVRO Manual PDFChandan NaikPas encore d'évaluation

- 1996-03-A Comparison of Theoretical and Empirical Reflection Coefficients For Typical Exterior Wall Surfaces in A Mobile Radio EnvironmentDocument11 pages1996-03-A Comparison of Theoretical and Empirical Reflection Coefficients For Typical Exterior Wall Surfaces in A Mobile Radio EnvironmentabdelPas encore d'évaluation

- Led LCD TV: Owner'S ManualDocument85 pagesLed LCD TV: Owner'S ManualJni Ta PrzPas encore d'évaluation

- Ee2428j - Question - Part 1 - Epo622 - Feb2022Document10 pagesEe2428j - Question - Part 1 - Epo622 - Feb2022MOHD ENDRA SHAFIQPas encore d'évaluation

- KACO 02xi BlueplanetDocument2 pagesKACO 02xi BlueplanetKirsten HernandezPas encore d'évaluation

- S202P-C40 Miniature Circuit Breaker - 2P - C - 40 A: Product-DetailsDocument6 pagesS202P-C40 Miniature Circuit Breaker - 2P - C - 40 A: Product-DetailsBilalPas encore d'évaluation

- F40 Filmetrics SOP - REV DDocument7 pagesF40 Filmetrics SOP - REV DsaranyaPas encore d'évaluation

- Common Rail Engine Diagnostic/Repair Kit: Tier Ii CompliantDocument14 pagesCommon Rail Engine Diagnostic/Repair Kit: Tier Ii CompliantYamil AguilarPas encore d'évaluation

- Amateur Radio Guide To DMRDocument28 pagesAmateur Radio Guide To DMRIeħor Biss100% (1)

- Product Data Sheet: Relayaux - Fast Trip and Lockout Relay - 8 C/O - Pick-Up Time 10 Ms - 220 V DCDocument3 pagesProduct Data Sheet: Relayaux - Fast Trip and Lockout Relay - 8 C/O - Pick-Up Time 10 Ms - 220 V DCKuenley TiNy OndePas encore d'évaluation

- Pass Transistor Logic PDFDocument25 pagesPass Transistor Logic PDFTejas KumbarPas encore d'évaluation

- OVL ReferenceDocument222 pagesOVL ReferenceKrishna ParthajePas encore d'évaluation

- ML4824 Power Factor Correction and PWM Controller Combo: General Description FeaturesDocument16 pagesML4824 Power Factor Correction and PWM Controller Combo: General Description FeaturesTaras100% (1)

- 96722599-B68L-54 Quick Start - (V100R001 01, En, SI, L)Document20 pages96722599-B68L-54 Quick Start - (V100R001 01, En, SI, L)Marco Alejandro Flores BarrazaPas encore d'évaluation

- Fara Dimensiuni Transformator 2D 3D NatasaDocument30 pagesFara Dimensiuni Transformator 2D 3D NatasaFazacas DanielPas encore d'évaluation

- User Friendly Smart Energy System Using IOTDocument4 pagesUser Friendly Smart Energy System Using IOTInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Wireless Data Encryption and Decryption Using RFDocument4 pagesWireless Data Encryption and Decryption Using RFsanthosh100% (1)

- Intermediate FrequencyDocument2 pagesIntermediate FrequencySharif ShahadatPas encore d'évaluation

- Implementation of Modified P&o-Mppt AlgorithmDocument8 pagesImplementation of Modified P&o-Mppt AlgorithmVaralakshmi SeerapuPas encore d'évaluation