Académique Documents

Professionnel Documents

Culture Documents

AC Thermal Load Calculation

Transféré par

Anish Mangalathu MohananDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

AC Thermal Load Calculation

Transféré par

Anish Mangalathu MohananDroits d'auteur :

Formats disponibles

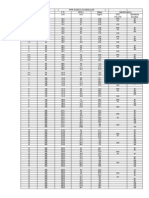

KEY PLAN

SCHEDULE OF CONDENSING UNITS:

Ser. Cooling Capacity

Description Input Power

No. TYPE QTY ( KW ) SERVICE AREA INDOOR UNITS

KW TMBH SMBH

SPLIT DUCTED UNITS SCHEDULE ( INDOOR UNIT GROUND FLOOR ) 1 CU 01 60.3 205.7 156.8 VRV OR VRF 1 22 WORKSHOP GROUND FLOOR G ( 1:10 )

Ser. Cooling Capacity Air Flow Rate 2 CU 02 47.4 161.7 123.2 VRV OR VRF 1 16 WORKSHOP GROUND FLOOR G ( 11:16 )

Description Input Power

No. QTY ( KW ) SERVICE AREA Notes GENERAL NOTES :

KW TMBH SMBH CFM

NOTES:

1 G -1 5.6 19.1 14.6 572 1 0.2 PAINT STORE 1.

2. COOLING CAPACITIES OF UNITS ARE SELECTED ON COIL TEMPERATURE AT 76 F DB / 63 F WB.

2 G-2 3.6 12.3 9.4 335 1 0.2 ELEC. ROOM 3. THE CONTRACTOR SHALL BE SIZED THE REFRIGERANT PIPING ACCORDING TO MANUFACTURER'S

RECOMMENDATION AND ACTUAL UNIT LOCATION.

4. ELECTRICAL DATE OF THE UNIT 3 / 415 / 50 OR ACCORDING TO MANUFACTURER'S RECOMMENDATION

3 G-3 2.2 7.5 5.7 200 1 0.2 STORE 5. REFRIGERANT TO BE ECO FRIENDLY PREFERRED R410A.

4 G - (4,5) 7.1 24.2 18.5 720 2 0.2 TIRES STORE

5 G -6 5.6 19.1 14.6 572 1 0.2 TIRES MACHINE

ROOM

IN LINE EXHAUST FAN SCHEDULE

6 G - (7,8,9,10) 7.1 24.2 18.5 720 4 0.2

Ser. Input Power

STORE Description Air Flow QTY SERVICE AREA Notes

7 G -11 2.2 7.5 5.7 200 1 0.2 No. ( KW )

CFM

8 G - 12,13 4.5 15.4 11.7 370 2 0.2 STORE-OIL TANK

1 EXF-01 1050 1 1.5 TOILETS-STORE INLINE FAN

9 G - 14 7.1 24.2 18.5 720 1 0.2 TURNERY AND OIL

2 EXF-02 1050 1 1.5 TOILETS INLINE FAN

ENGINE REPAIRING

GEAR REPAIRING

10 G -15,16,17,18 5.6 19.1 14.6 572 4 0.2 PADDING ROOM NOTES:

COMPRESSOR

ROOM 1) E.S.P FOR THE FAN TO BE CALCULATED BY THE CONTRACTOR.

2) ALL EXTRACT FAN SHOULD HAVE STATUS MONITORING PANEL CONNECTED TO BMS

NOTES: SYSTEM WITH LIGHT INDICATION AND SOUNDER.

1. AIR FLOW CAPACITY IS SELECTED AT MEDIUM SPEED.

2.

3. COOLING CAPACITIES OF UNITS ARE SELECTED ON COIL TEMPERATURE AT 76 F DB / 63 F WB.

4. ALL DUCTED SPLIT UNIT TO BE WITH 3 SPEED.

5. ESTIMATED E.S.P 300 PA FOR UNITS AND ,CONTRACTOR SHALL CALCULATE ACTUAL EXTERNAL STATIC PRESSURE

AND SUBMIT THE CALCULATIONS TO ENGINEER FOR APPROVAL.

VENTLATION FAN SCHEDULE

6. THE CONTRACTOR SHALL BE SIZED THE REFRIGERANT PIPING ACCORDING TO MANUFACTURER'S

RECOMMENDATION AND ACTUAL UNIT LOCATION. Ser. Input Power

Description Air Flow QTY SERVICE AREA Notes

7. ELECTRICAL DATE OF THE UNIT 1 / 220-240 / 50 OR ACCORDING TO MANUFACTURER'S RECOMMENDATION No. ( KW ) REFERENCE DRAWING

CFM

DRAWING NO. TITLE

WORKSHOP 30 INCH VENTILATION FAN WALL

1 VE.F-A 6000 14 0.2 BAYS MOUNTED

LEGENDS :

SPLIT DUCTED UNITS SCHEDULE ( INDOOR UNIT GROUND FLOOR ) SCHEDULE OF CONDENSING UNITS:

Ser. Cooling Capacity Air Flow Rate Ser. Cooling Capacity

Description Input Power Description Input Power

No. QTY ( KW ) SERVICE AREA Notes No. TYPE QTY ( KW ) SERVICE AREA INDOOR UNITS

KW TMBH SMBH CFM KW TMBH SMBH

1 M - ( 01:05 ), 10 7.1 24.2 18.5 720 6 0.2 1 CU 03 60.3 205.7 156.8 VRV OR VRF 1 22 WORKSHOP FIRST FLOOR M ( 1:10 )

2 M - 06 5.6 19.1 14.6 572 1 0.2

NOTES:

1.

3 G - 07:09 2.8 9.6 7.3 250 3 0.2 2. COOLING CAPACITIES OF UNITS ARE SELECTED ON COIL TEMPERATURE AT 76 F DB / 63 F WB.

3. THE CONTRACTOR SHALL BE SIZED THE REFRIGERANT PIPING ACCORDING TO MANUFACTURER'S

RECOMMENDATION AND ACTUAL UNIT LOCATION.

NOTES: 4. ELECTRICAL DATE OF THE UNIT 3 / 415 / 50 OR ACCORDING TO MANUFACTURER'S RECOMMENDATION

1. AIR FLOW CAPACITY IS SELECTED AT MEDIUM SPEED. 5. REFRIGERANT TO BE ECO FRIENDLY PREFERRED R410A.

2.

3. COOLING CAPACITIES OF UNITS ARE SELECTED ON COIL TEMPERATURE AT 76 F DB / 63 F WB.

4. ALL DUCTED SPLIT UNIT TO BE WITH 3 SPEED. Drawn up Checked Approved

REV DATE DESCRIPTION

5. ESTIMATED E.S.P 300 PA FOR UNITS AND ,CONTRACTOR SHALL CALCULATE ACTUAL EXTERNAL STATIC PRESSURE

AND SUBMIT THE CALCULATIONS TO ENGINEER FOR APPROVAL. CLIENT :

EMIRATES TRANSPORT

6. THE CONTRACTOR SHALL BE SIZED THE REFRIGERANT PIPING ACCORDING TO MANUFACTURER'S

Dubai - Alramool HQ P.O.Box 5757 Dubai

RECOMMENDATION AND ACTUAL UNIT LOCATION.

7. ELECTRICAL DATE OF THE UNIT 1 / 220-240 / 50 OR ACCORDING TO MANUFACTURER'S RECOMMENDATION

IN LINE EXHAUST FAN SCHEDULE United Arab Emirates (U.A.E.)

CONTRACTOR : (Third party )

Ser. Input Power

Description Air Flow QTY SERVICE AREA Notes

No. ( KW )

CFM

DESIGN CONSULTANT :

TOILETS & ALTORATH CONSULTING ENGINEERS

1 EXF-01 450 1 0.5 ABLUTION INLINE FAN

United Arab Emirates (U.A.E.)

NOTES: This document contains CONFIDENTIAL and PROPRIETARY information of ALTORATH. This

1) E.S.P FOR THE FAN TO BE CALCULATED BY THE CONTRACTOR. information is not to be used, disclosed or reproduced in whole or in part to anyone outside of

ALTORATH and subsidiaries, except pursuant to a written agreement with ALTORATH

2) ALL EXTRACT FAN SHOULD HAVE STATUS MONITORING PANEL CONNECTED TO BMS

SYSTEM WITH LIGHT INDICATION AND SOUNDER. PROJECT :

SCHOOL BUS STATION , AUCTION CENTER

& TECHNICAL SERVICES CENTER

GUAIZA'A - SHARJAH

PLOT NO. 3096

DRAWING TITLE :

(WORKSHOP)

REV. SCALE:

DRAWING NO.

EE-04-101 N.T.S

SHEET:

00 A1

VIPIN

Vous aimerez peut-être aussi

- Fan Motor Manual: Operation and MaintenanceDocument13 pagesFan Motor Manual: Operation and MaintenanceYoussef AdnanePas encore d'évaluation

- Part 1. Load Estimating - Chapter 4. Solar Heat Gain Thru GlassDocument3 pagesPart 1. Load Estimating - Chapter 4. Solar Heat Gain Thru Glasskiran raghukiranPas encore d'évaluation

- Jaquar Plumber Guide Editable1Document52 pagesJaquar Plumber Guide Editable1sandeep0975Pas encore d'évaluation

- Wavin AS Product & Technical Guide PDFDocument68 pagesWavin AS Product & Technical Guide PDFnamPas encore d'évaluation

- Newage Price List 18.02.2023Document1 pageNewage Price List 18.02.2023Muhamm AHMADPas encore d'évaluation

- Description QTY U-Price Non Vat U-Price W/ Vat Item No. Total Price Non VatDocument2 pagesDescription QTY U-Price Non Vat U-Price W/ Vat Item No. Total Price Non VatlanPas encore d'évaluation

- Booster PDSDocument3 pagesBooster PDSsunii19847908Pas encore d'évaluation

- Abstract of CPWDDocument5 pagesAbstract of CPWDabhishek kumarPas encore d'évaluation

- RMGF (Repair & Maintenance of Government Facility) ProjectsDocument65 pagesRMGF (Repair & Maintenance of Government Facility) ProjectsJong DrilonPas encore d'évaluation

- Sectional WeightsDocument1 pageSectional WeightsradhakrishnangPas encore d'évaluation

- Busbar RatingsDocument1 pageBusbar RatingsRa ArPas encore d'évaluation

- Water Feature Design ManualDocument8 pagesWater Feature Design ManualShweta Arora VijPas encore d'évaluation

- Wdrive BoostersDocument72 pagesWdrive BoostersAnonymous 7lcVBaOPNgPas encore d'évaluation

- Ismc Isma: Input Running Meter To Obtain Output in KilogramDocument9 pagesIsmc Isma: Input Running Meter To Obtain Output in KilogramAKASH CHAUHANPas encore d'évaluation

- Tariff Advisory Committee Manual PDF Scribd - Google SearchDocument2 pagesTariff Advisory Committee Manual PDF Scribd - Google SearchVimal RajanPas encore d'évaluation

- DADEX Flow Line Price List Mar '21Document2 pagesDADEX Flow Line Price List Mar '21Jugno ShahPas encore d'évaluation

- Hydro Booster SystemsDocument12 pagesHydro Booster SystemsGrundfosEgyptPas encore d'évaluation

- Tuttle and Bailey CircularDocument2 pagesTuttle and Bailey CircularTalha BaigPas encore d'évaluation

- HT Cable Voltage Drop CalculationDocument9 pagesHT Cable Voltage Drop CalculationPaul Goh Yngwie100% (1)

- Ec Axial Fan W3g800gu2501 EngDocument5 pagesEc Axial Fan W3g800gu2501 EngmacmottaPas encore d'évaluation

- Fire Pump Test Meter (6.8)Document2 pagesFire Pump Test Meter (6.8)Luigi CasamassimaPas encore d'évaluation

- DB GF1 L1 Load ScheduleDocument15 pagesDB GF1 L1 Load Schedulepsn_kylmPas encore d'évaluation

- ResourcesFrictionLossData PDFDocument4 pagesResourcesFrictionLossData PDFhmid007Pas encore d'évaluation

- Doha ASHRAE 2017 FundamentalsDocument2 pagesDoha ASHRAE 2017 FundamentalsAhmed LabibPas encore d'évaluation

- ASHRAE Table9 Hot Water DemandDocument1 pageASHRAE Table9 Hot Water DemandTerrence Redd100% (1)

- I Beam DrawingDocument1 pageI Beam DrawingOlivia JacksonPas encore d'évaluation

- Code of Practice On Sewerage and Sanitary WorksDocument15 pagesCode of Practice On Sewerage and Sanitary WorksSteven PohPas encore d'évaluation

- BOQ For Pipe Fittings For Compressed Air PDFDocument1 pageBOQ For Pipe Fittings For Compressed Air PDFsppatilPas encore d'évaluation

- Quantity Take-Off Septic Vault:1 Lot Items Qty UnitDocument24 pagesQuantity Take-Off Septic Vault:1 Lot Items Qty UnitnathanieldagsaPas encore d'évaluation

- Calculation of Water Flow Rates For Different Pipe Sizes - US UnitsDocument4 pagesCalculation of Water Flow Rates For Different Pipe Sizes - US UnitsRyan KanePas encore d'évaluation

- Solar Panel Design (14.1.14)Document8 pagesSolar Panel Design (14.1.14)south adventurePas encore d'évaluation

- Pricelistsalitems (3) of PipeDocument12 pagesPricelistsalitems (3) of PipeRakesh Paraliya100% (1)

- Bajaj LuminairesDocument51 pagesBajaj LuminairesNagesh Rao100% (1)

- OASE FT Catalogue EnglishDocument260 pagesOASE FT Catalogue Englishckyprianou100% (1)

- Eterna CW: Kirloskar Brothers LimitedDocument2 pagesEterna CW: Kirloskar Brothers Limitedudiptya_papai2007100% (1)

- Plan & Profile of RodDocument1 pagePlan & Profile of RodDeepak_pethkarPas encore d'évaluation

- Liquid Press Drop in PipeDocument4 pagesLiquid Press Drop in PipePanner2009Pas encore d'évaluation

- Pipe Schudle ChartDocument2 pagesPipe Schudle Chartsachinshirnath100% (1)

- Clarke 100e Mig WelderDocument18 pagesClarke 100e Mig WelderplainmanPas encore d'évaluation

- Babcock & Wilcox Steam TablesDocument5 pagesBabcock & Wilcox Steam Tablesnum0067Pas encore d'évaluation

- Mohammad Al Mazroui Villa (Plot#8) : Storm Water Calculation SummaryDocument1 pageMohammad Al Mazroui Villa (Plot#8) : Storm Water Calculation Summaryroula abi rachedPas encore d'évaluation

- Street LightingDocument28 pagesStreet Lightinganon_688386444Pas encore d'évaluation

- Code of Practice For Installation of Septic Tanks - Part 1 - Design Criteria and Construction - Bureau of Indian Standards - 1986Document21 pagesCode of Practice For Installation of Septic Tanks - Part 1 - Design Criteria and Construction - Bureau of Indian Standards - 1986lagnajit dasPas encore d'évaluation

- Furutec HP-ES (FT (ES) @2012-08) PDFDocument40 pagesFurutec HP-ES (FT (ES) @2012-08) PDFramadani bimaPas encore d'évaluation

- FEB08 Economic Thickness of Insulation For Hot Pipes 1993 Rep 1996 PDFDocument55 pagesFEB08 Economic Thickness of Insulation For Hot Pipes 1993 Rep 1996 PDFAfrizal Albar RamadhanPas encore d'évaluation

- Lazy River Design ListDocument1 pageLazy River Design ListJason MaPas encore d'évaluation

- Technical Details of 1 Ton Jute BoilerDocument12 pagesTechnical Details of 1 Ton Jute BoilerPial KhanPas encore d'évaluation

- Plumbing Data SheetDocument2 pagesPlumbing Data SheetzhobeysPas encore d'évaluation

- Circuit BreakerDocument6 pagesCircuit BreakerAkhilesh KumarPas encore d'évaluation

- 24x7 InvoiceDocument1 page24x7 InvoiceArul SankaranPas encore d'évaluation

- Boq-Compressed Air (Rev1) (Cut & Bend Rajhi Steel)Document3 pagesBoq-Compressed Air (Rev1) (Cut & Bend Rajhi Steel)Luis Gabriel BautistaPas encore d'évaluation

- Patton Line Size - 2014Document6 pagesPatton Line Size - 2014Rocky James AsildoPas encore d'évaluation

- Pipe Sizes and ScheduleDocument2 pagesPipe Sizes and Schedulechupacid0% (1)

- External Building DrainageDocument11 pagesExternal Building Drainagevelayuthan_s9168Pas encore d'évaluation

- Four Season Hotel - Dubai Water Canal Voltage Drop Calculation SheetDocument1 pageFour Season Hotel - Dubai Water Canal Voltage Drop Calculation SheetSha Sameer NizamiPas encore d'évaluation

- Data Sheet FOR Gear Box (Api 613) : B 25.11.15 A 15.06.15 Comments Incorporated Issued For InformationDocument5 pagesData Sheet FOR Gear Box (Api 613) : B 25.11.15 A 15.06.15 Comments Incorporated Issued For Informationritoh8657Pas encore d'évaluation

- WPT - Woll Ds M 0001 1 IpDocument4 pagesWPT - Woll Ds M 0001 1 IpParag ThakkarPas encore d'évaluation

- MMTC - Chiller Equipment Schedule - R0-10-08-2023Document8 pagesMMTC - Chiller Equipment Schedule - R0-10-08-2023rkpatel40Pas encore d'évaluation

- Major Equipment List Cilacap LNG TerminalDocument2 pagesMajor Equipment List Cilacap LNG Terminalwong_949618676Pas encore d'évaluation

- Specification For Hyundai Synchronous GeneratorDocument27 pagesSpecification For Hyundai Synchronous Generatorwin htikePas encore d'évaluation

- Pipe SizingDocument2 pagesPipe SizingAnish Mangalathu MohananPas encore d'évaluation

- Site Engineer Data PDFDocument28 pagesSite Engineer Data PDFNani Cherry50% (2)

- Demonstration 3Document1 pageDemonstration 3Anish Mangalathu MohananPas encore d'évaluation

- Ebook Ptuts 10 MUST HAVE Primavera P6 LayoutsDocument41 pagesEbook Ptuts 10 MUST HAVE Primavera P6 Layoutstijo kurian100% (2)

- Management KeywordsDocument2 pagesManagement KeywordsAnish Mangalathu MohananPas encore d'évaluation

- Views On The Actual Critical Path Vs As-Built Critical Path - LinkedInDocument3 pagesViews On The Actual Critical Path Vs As-Built Critical Path - LinkedInAnish Mangalathu MohananPas encore d'évaluation

- Demonstration 4Document1 pageDemonstration 4Anish Mangalathu MohananPas encore d'évaluation

- Demonstration 2Document1 pageDemonstration 2Anish Mangalathu MohananPas encore d'évaluation

- 7 Hide Days Hide Comments: SL No Description Ref: No R0 Days R1 Days Type ofDocument4 pages7 Hide Days Hide Comments: SL No Description Ref: No R0 Days R1 Days Type ofAnish Mangalathu MohananPas encore d'évaluation

- High Rise Structures:Plumbing Design Guidelines.Document6 pagesHigh Rise Structures:Plumbing Design Guidelines.shrikant85% (27)

- Demonstration 1Document1 pageDemonstration 1Anish Mangalathu MohananPas encore d'évaluation

- BL P6 Excel FormatDocument15 pagesBL P6 Excel FormatAnish Mangalathu MohananPas encore d'évaluation

- Design of Water Based Fire Protection SystemsDocument43 pagesDesign of Water Based Fire Protection SystemsKumararaja Konikki94% (33)

- Aalco Metals LTD Aluminium Alloy 5251 H22 Sheet and Plate 150Document2 pagesAalco Metals LTD Aluminium Alloy 5251 H22 Sheet and Plate 150Anish Mangalathu MohananPas encore d'évaluation

- 2009 National Standard Plumbing CodeDocument332 pages2009 National Standard Plumbing Codemelvin_parilla7774100% (1)

- Summary Plumbing Code DONEDocument3 pagesSummary Plumbing Code DONERap PinedaPas encore d'évaluation

- 006 e Thermal Load Calculation (Cust. Service Building)Document1 page006 e Thermal Load Calculation (Cust. Service Building)Anish Mangalathu MohananPas encore d'évaluation

- Robert Andrew Associates, Inc: Suretrak BasicsDocument39 pagesRobert Andrew Associates, Inc: Suretrak Basicsbrad3kPas encore d'évaluation

- @water & Drainage Equipement DesignDocument46 pages@water & Drainage Equipement DesignDesigner ForeverPas encore d'évaluation

- Design - HVAC DuctDocument5 pagesDesign - HVAC DuctHumaid ShaikhPas encore d'évaluation

- Sap2000 TutorialDocument24 pagesSap2000 Tutorialhasib100% (1)

- Sissor LiftDocument1 pageSissor LiftAnish Mangalathu MohananPas encore d'évaluation

- Welding Electrode Classifications 123Document2 pagesWelding Electrode Classifications 123Unnikrishnan RajanPas encore d'évaluation

- Xsteel - Lesson1 BasicModelingDocument39 pagesXsteel - Lesson1 BasicModelingsaisssms9116100% (5)

- Is 5950-1984Document10 pagesIs 5950-1984Anish Mangalathu MohananPas encore d'évaluation

- Color ChartDocument0 pageColor ChartMashudi FikriPas encore d'évaluation

- Primavera P6 V3,1 - Ch5!10!19Document54 pagesPrimavera P6 V3,1 - Ch5!10!19gsolenoPas encore d'évaluation

- 5356 SpecDocument2 pages5356 SpecAnish Mangalathu MohananPas encore d'évaluation

- LG Cassette Brochure Feb 2021Document7 pagesLG Cassette Brochure Feb 2021Junior EngineerPas encore d'évaluation

- Heat Pumps Refrigeration Troubleshooting ManualDocument24 pagesHeat Pumps Refrigeration Troubleshooting Manualfstaday66240% (1)

- Tut Sheet 5-2nd LawDocument2 pagesTut Sheet 5-2nd LawVIJAYRAJ SINGHPas encore d'évaluation

- Kitchen Ventilation Design GuideDocument15 pagesKitchen Ventilation Design GuideCuong Vu100% (2)

- Energy Recovery Ventilation (Erv) Engineering Manual: ERV Indoor Units 470 To 1,180 CFMDocument34 pagesEnergy Recovery Ventilation (Erv) Engineering Manual: ERV Indoor Units 470 To 1,180 CFMElvis FariasPas encore d'évaluation

- VRV Reference: GuideDocument72 pagesVRV Reference: Guidekhamsone pengmanivongPas encore d'évaluation

- Duct Works ChecklistDocument1 pageDuct Works Checklistmd azmathPas encore d'évaluation

- RAC Experimental Water Cooler Storage TypeDocument7 pagesRAC Experimental Water Cooler Storage TypeShashi Bhushan PatelPas encore d'évaluation

- DPA120B3WDB-Product SpecificationsDocument2 pagesDPA120B3WDB-Product SpecificationsCédric TsochiPas encore d'évaluation

- Experiment 8 Cooling and De-Humidification of Air: 1. ObjectiveDocument6 pagesExperiment 8 Cooling and De-Humidification of Air: 1. ObjectiveShakyamuni Gautam Kumar100% (1)

- Detailed Performance Summary: Input DataDocument5 pagesDetailed Performance Summary: Input DataMalik rehmabPas encore d'évaluation

- HC-702WE - Service Manual (20-Mar-2013) PDFDocument16 pagesHC-702WE - Service Manual (20-Mar-2013) PDFPaulAbiNasrPas encore d'évaluation

- Rakesh ReportDocument81 pagesRakesh ReportRakesh SharmaPas encore d'évaluation

- PH Floor StandingDocument2 pagesPH Floor StandingRC Bahoy, Anfernee John E.Pas encore d'évaluation

- MEP MCQ - 22nd Jul 20 - Answer KeysDocument19 pagesMEP MCQ - 22nd Jul 20 - Answer KeyspremPas encore d'évaluation

- Geothermal Central SystemDocument7 pagesGeothermal Central SystemPaul KwongPas encore d'évaluation

- امثلةAHU examples - sheet PDFDocument2 pagesامثلةAHU examples - sheet PDFMacroec.pip. BIBPas encore d'évaluation

- VRF Systems PresentationDocument194 pagesVRF Systems Presentationdonchakde75% (4)

- Liebert PDX Liebert PCW System Design Manual - 2017Document140 pagesLiebert PDX Liebert PCW System Design Manual - 2017JeffPas encore d'évaluation

- EDID341414Document676 pagesEDID341414Yudhi YudadmokoPas encore d'évaluation

- ASHRAE Cooling Load Check FiguresDocument7 pagesASHRAE Cooling Load Check Figuresvinci10167% (6)

- Technical Guide YORK Latitude SeriesDocument40 pagesTechnical Guide YORK Latitude Seriesdesto20% (1)

- Heat Sink CalculationDocument1 pageHeat Sink CalculationkkbusPas encore d'évaluation

- Basics of Fire and Smoke Damper Installations - NFPADocument9 pagesBasics of Fire and Smoke Damper Installations - NFPAumerPas encore d'évaluation

- Materi Refrigerant OilDocument10 pagesMateri Refrigerant OilSubastianPas encore d'évaluation

- Odyssey PBDocument40 pagesOdyssey PBanon_568723957Pas encore d'évaluation

- Catalogue V-C Hisense 4-PipesDocument7 pagesCatalogue V-C Hisense 4-PipesOULDITTOU MohamedPas encore d'évaluation

- A Liquid Desiccant System For Solar Cooling and DehumidificationDocument7 pagesA Liquid Desiccant System For Solar Cooling and Dehumidificationvinay muleyPas encore d'évaluation

- Generator Sizing CalculatorDocument4 pagesGenerator Sizing CalculatorNedunuri.Madhav Murthy100% (1)