Académique Documents

Professionnel Documents

Culture Documents

Boiler 2 Furnace Tube Thickness and Life

Transféré par

gandungw0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues1 pageFire tube boiler corrosion rate and time to damage the Furnace Tube

Titre original

Boiler 2 Furnace Tube thickness and life

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentFire tube boiler corrosion rate and time to damage the Furnace Tube

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues1 pageBoiler 2 Furnace Tube Thickness and Life

Transféré par

gandungwFire tube boiler corrosion rate and time to damage the Furnace Tube

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

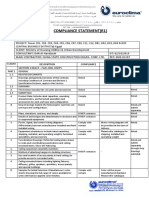

ASME SECTION I - 2015 Rev.

00

PROJECT Fire Tube Boiler 2 TPH PRODUCT : FURNACE SHELL B2 (LORONG API B2)

USER PT CIBADAK

MAXIMUM ALLOWABLE EXTERNAL PRESSURE (PG-28.3.1.2.(a) )

ASME SECTION I - 2015

ASME SECTION II Part D - 2015

1 PART OF THE BOILER : FURNACE SHELL DRG.No. :

2 DESIGN MAXIMUM ALLOWABLE WORKING PRESSURE P psi (G), (kg/cm2(G)) 142.23 (10.000)

3 OUTSIDE DIAMETER OF THE SHELL D Inch, (mm) 26.38 (670.0)

4 OPERATING METAL TEMPERATURE Deg. F, Deg. C 700.07 371.15

5 MATERIAL A-516 Gr.70

Modulus of elasticity of material at design temperature. E psi, (kgf/mm2) 2.45E+07 17,225.2

6 TOTAL LENGTH OF SHELL L Inch, (mm) 78.74 (2000.0)

7 USING THICKNESS OF SHELL t Inch, (mm) 0.46 (11.6)

8 L/D L/D 2.99

9 D/t D/t 57.76

10 Factor A A 0.00100

11 Factor B B 6,700.00

12 MAXIMUM ALLOWABLE EXTERNAL PRESSURE (PG-28.3.1.2.(a).step 6) Pa= 4xB/(3xD/t) psi, (kgf/cm2) 154.67 10.87

13 MAXIMUM ALLOWABLE EXTERNAL PRESSURE (PG-28.3.1.2.(a).step 7) Pa= 2xAxE/(3xD/t) psi, (kgf/cm2) 282.79 19.88

14 MAXIMUM ALLOWABLE EXTERNAL PRESSURE (PG-28.3.1.2.(a).step 8) Lesser : P<Pa.step 6 , P<Pa.step 7 154.67 10.87

15 RESULT : P < Pa OK

Note 1 Laju korosi 0.61 mm/tahun (dari data kerusakan B1), dikarenakan pembersihan dengan chemical yang berlebihan.

2 B1 Rusak pada posisi tebal 11.7 mm dari asalnya 16 mm setelah 17 tahun.

3 Tekanan design 10 kgf/cm2.G.< Pa=10.87 kgf/cm2, tetapi tanpa adanya allowance korosi, sangat beresiko bila ada kerak sehingga

Temperatur metal naik lebih dari 370 C akan beresiko rusak.

Prepared by Checked by Approved by Issued Date

GDW 9-Juli-2019

Vous aimerez peut-être aussi

- Ibr CalculationsDocument12 pagesIbr CalculationsGopal RamalingamPas encore d'évaluation

- VSL CalDocument50 pagesVSL CalEmrahCayboyluPas encore d'évaluation

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument2 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodPas encore d'évaluation

- WT Calculation - Pipelines With CRA CladDocument6 pagesWT Calculation - Pipelines With CRA CladShankar VadivelPas encore d'évaluation

- Data Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFDocument1 pageData Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFSachin KumarPas encore d'évaluation

- Ibr CalculationsDocument9 pagesIbr Calculationsaroonchelikani67% (3)

- Design Notes and AssumptionsDocument19 pagesDesign Notes and AssumptionsDarshan PanchalPas encore d'évaluation

- Api - 650 2008Document27 pagesApi - 650 2008WinsonLimHuiWahPas encore d'évaluation

- Main Product CatalogueDocument4 pagesMain Product CatalogueAshok PaulPas encore d'évaluation

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanPas encore d'évaluation

- SizingDocument4 pagesSizingAlberto ReyesPas encore d'évaluation

- Blind Plate THK - Hydro PDFDocument3 pagesBlind Plate THK - Hydro PDFNaveen JeevaPas encore d'évaluation

- Job No. Item No: Doc. No. Tag No. Client Fine Filter Skid FD-38063A/B Bharat Heavy Electricals LimitedDocument3 pagesJob No. Item No: Doc. No. Tag No. Client Fine Filter Skid FD-38063A/B Bharat Heavy Electricals LimitedgauravPas encore d'évaluation

- Calculation Sheet For Slug CatcherDocument12 pagesCalculation Sheet For Slug CatcherchumaPas encore d'évaluation

- ASME B31.4-Wall Thickness CalDocument2 pagesASME B31.4-Wall Thickness CalBagus Sukoco Koco100% (1)

- Blind Flange Design Calculation As Per Asme Section Vii Division - 1Document4 pagesBlind Flange Design Calculation As Per Asme Section Vii Division - 1mukesh100% (2)

- 15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Document4 pages15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Umair A. KhanPas encore d'évaluation

- Flange Excel NewDocument26 pagesFlange Excel NewvikasPas encore d'évaluation

- ASME B31.4-Wall Thickness Calc For 6 InchDocument2 pagesASME B31.4-Wall Thickness Calc For 6 InchBagus Sukoco KocoPas encore d'évaluation

- 2 PN40 (WCB)Document2 pages2 PN40 (WCB)siddhesh_guessPas encore d'évaluation

- Progen: Pipe Thickness Calculation As Per IBR 350 Eqn.Document4 pagesProgen: Pipe Thickness Calculation As Per IBR 350 Eqn.P s JagatheesanPas encore d'évaluation

- DJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDocument37 pagesDJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDIANTOROPas encore d'évaluation

- Calc' Diesel Fuel (Rev)Document10 pagesCalc' Diesel Fuel (Rev)joko_tm02Pas encore d'évaluation

- Steel Storage Tanks Excel Sheet (API 650-2009) Free-09122209467Document42 pagesSteel Storage Tanks Excel Sheet (API 650-2009) Free-09122209467Hamid Mansouri100% (5)

- Technical Specification For Furnace Pressure Switch High SL - No Description Unit Specification Model No. Range Tag NumberDocument4 pagesTechnical Specification For Furnace Pressure Switch High SL - No Description Unit Specification Model No. Range Tag NumberflowdewicePas encore d'évaluation

- FACADE MODELING Structural AnalysisDocument39 pagesFACADE MODELING Structural AnalysisGodino Christian100% (3)

- Blind Flange Design Calculations - by Abdel Halim GalalaDocument6 pagesBlind Flange Design Calculations - by Abdel Halim GalalaNirmalraj Manoharan67% (3)

- Configuration Data Sheet: Initial I FinalDocument7 pagesConfiguration Data Sheet: Initial I FinalRoberto327Pas encore d'évaluation

- Checking of Pipe Wall Thickness API 5L X52Document1 pageChecking of Pipe Wall Thickness API 5L X52andriPas encore d'évaluation

- Storage Tank Design Calculation - Api 650Document92 pagesStorage Tank Design Calculation - Api 650Abelardo ContrerasPas encore d'évaluation

- Candle Plate ThicknessDocument2 pagesCandle Plate ThicknessAnkur KumarPas encore d'évaluation

- Attachment-2.4A - PSV - Datasheet (Hot Water HPT)Document6 pagesAttachment-2.4A - PSV - Datasheet (Hot Water HPT)mohamed salahPas encore d'évaluation

- Specifications:: Test Analysis Units Limits Test Method MIN MAX Astm EN 1Document1 pageSpecifications:: Test Analysis Units Limits Test Method MIN MAX Astm EN 1BalasubramaniamPas encore d'évaluation

- PT Pim: Vent Steam Silencer Data SheetDocument3 pagesPT Pim: Vent Steam Silencer Data SheetIrwansyah MuchtarPas encore d'évaluation

- Best Tank Calculation SheetDocument88 pagesBest Tank Calculation Sheetchriscivil12Pas encore d'évaluation

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument14 pagesStorage Tank Design Calculation - Api 650: Close Floating Roofhgagselim2012Pas encore d'évaluation

- Process Intensification for Sustainable Energy ConversionD'EverandProcess Intensification for Sustainable Energy ConversionPas encore d'évaluation

- Handbook of Heating, Ventilating and Air ConditioningD'EverandHandbook of Heating, Ventilating and Air ConditioningÉvaluation : 4 sur 5 étoiles4/5 (6)

- Geotechnical Engineering: Testing ManualsD'EverandGeotechnical Engineering: Testing ManualsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Pressuremeter Testing: Methods and InterpretationD'EverandPressuremeter Testing: Methods and InterpretationÉvaluation : 5 sur 5 étoiles5/5 (2)

- Steel and Its Heat Treatment: Bofors HandbookD'EverandSteel and Its Heat Treatment: Bofors HandbookÉvaluation : 2.5 sur 5 étoiles2.5/5 (3)

- Warm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationD'EverandWarm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationPas encore d'évaluation

- Gas Sweetening and Processing Field ManualD'EverandGas Sweetening and Processing Field ManualÉvaluation : 4 sur 5 étoiles4/5 (7)

- Cone Penetration Testing: Methods and InterpretationD'EverandCone Penetration Testing: Methods and InterpretationÉvaluation : 5 sur 5 étoiles5/5 (3)

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysD'EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysPas encore d'évaluation

- Token Ring Technology ReportD'EverandToken Ring Technology ReportPas encore d'évaluation

- Discrete Cosine Transform: Algorithms, Advantages, ApplicationsD'EverandDiscrete Cosine Transform: Algorithms, Advantages, ApplicationsPas encore d'évaluation

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsD'EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsÉvaluation : 5 sur 5 étoiles5/5 (1)

- BUK-306 Pillard Flame ScannersDocument4 pagesBUK-306 Pillard Flame ScannersMoez hannachiPas encore d'évaluation

- 1SCA022620R7200 Ozxt2 Terminal SetDocument2 pages1SCA022620R7200 Ozxt2 Terminal SetJorge Salas CabanaPas encore d'évaluation

- Ashrae D 90405 20100120 PDFDocument233 pagesAshrae D 90405 20100120 PDFrgopikrishna313Pas encore d'évaluation

- Project ReportDocument34 pagesProject ReportSumit Sharma75% (4)

- Pulsar Extreme 3200CDocument28 pagesPulsar Extreme 3200CGuillermoPas encore d'évaluation

- Detroit S60 SpecsDocument2 pagesDetroit S60 Specsgrgramm50% (2)

- Rad Lec 1 Machine OverviewDocument4 pagesRad Lec 1 Machine OverviewTiti DarabanPas encore d'évaluation

- Pig Launcher and ReceiverDocument2 pagesPig Launcher and ReceiverDhanushPas encore d'évaluation

- Procedure Qualification RecordDocument2 pagesProcedure Qualification RecordDan ClarkePas encore d'évaluation

- Current Affairs - Sept 2014Document202 pagesCurrent Affairs - Sept 2014kumar1987Pas encore d'évaluation

- Spe 157798 PDFDocument10 pagesSpe 157798 PDFJhurguen Guzman CorralesPas encore d'évaluation

- SyllabusDocument8 pagesSyllabusSameer SolankiPas encore d'évaluation

- AS5780-Core Requirement Specification For Aircraft Gas Turbine Engine LubricantsDocument9 pagesAS5780-Core Requirement Specification For Aircraft Gas Turbine Engine LubricantsJicheng PiaoPas encore d'évaluation

- compliance sheet of euroclima加承包商Document9 pagescompliance sheet of euroclima加承包商Li Liu100% (1)

- Marine Engine Imo Tier LL and Tier LLL ProgrammeDocument220 pagesMarine Engine Imo Tier LL and Tier LLL ProgrammeMuhammad Farhanuddien AnharPas encore d'évaluation

- Bulletin 836T Pressure ControlsDocument4 pagesBulletin 836T Pressure ControlsWendy CassidyPas encore d'évaluation

- Stok Dan Estimasi Pemakaian Chemical Jan 2024Document43 pagesStok Dan Estimasi Pemakaian Chemical Jan 2024slamet supriyadiPas encore d'évaluation

- JSA TemplateDocument3 pagesJSA TemplateJob MateusPas encore d'évaluation

- Solar TrackerDocument19 pagesSolar TrackerKarthik VanamPas encore d'évaluation

- 435W 450W Astrotwins: Enjoy The Energy of The UniverseDocument2 pages435W 450W Astrotwins: Enjoy The Energy of The UniverseMiro MiroPas encore d'évaluation

- Glaunach Silencer HandbookDocument67 pagesGlaunach Silencer Handbookriff100% (4)

- Lakwagaon - NIT - OILPROJECT - CNP - 62 - LKN - 01Document7 pagesLakwagaon - NIT - OILPROJECT - CNP - 62 - LKN - 01Sunil WadekarPas encore d'évaluation

- Fluid Mechanics Formulas ShortcutsDocument15 pagesFluid Mechanics Formulas Shortcuts9444583008Pas encore d'évaluation

- DatasheetDocument8 pagesDatasheetinalambricPas encore d'évaluation

- Air Conditioner: Parts ListDocument4 pagesAir Conditioner: Parts ListDavid Lemos SanchezPas encore d'évaluation

- Weber Q3000Document44 pagesWeber Q3000Marius MullerPas encore d'évaluation

- Power System ProtectionDocument46 pagesPower System ProtectionRatul MollickPas encore d'évaluation

- B20ME067 SeminarDocument14 pagesB20ME067 SeminarSanjay 69ffPas encore d'évaluation

- CCUS in Steel IndustryDocument52 pagesCCUS in Steel IndustryJonson CaoPas encore d'évaluation