Académique Documents

Professionnel Documents

Culture Documents

Purlin PU-1, PU-2 & PU-3 - R02 PDF

Transféré par

Amol GoleTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Purlin PU-1, PU-2 & PU-3 - R02 PDF

Transféré par

Amol GoleDroits d'auteur :

Formats disponibles

6741

6711

6471

6591

3651

40

0

451

°

2

45°

60

75

5

1.

96.6

15

86.4

2994

3048

2038

5014

5068

1984

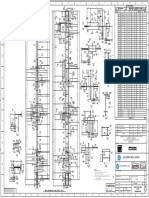

PURLIN PU 1

1028

18

4058

4004

974

13 Nos. 7.5x10Ø SLOT 10 Nos. 11.5x14Ø SLOT

6024

6078

FOR M6 BOLT FOR M10 BOLT PU-60HUx40x1.2X15X5

PURLIN PU-1

6471

6591

6711

6741

3610

410

270

150

30

0

40

°

2

96.6

45°

60

75

5

1.

15

86.4

PURLIN PU 2

6707

6653

647

593

1603

1657

2613

2667

4633

4687

5643

5697

14 Nos. 7.5x10Ø SLOT PU-60HUx40x1.2X15X5

3677

3623

FOR M6 BOLT

PURLIN PU-2 16Nos. 11.5x14Ø

SLOT FOR M10 BOLT

6769

7300

270

150

30

369

0

3569

40

96.6

°

2

45°

60

75

5

1.

15

86.4

7282

1222

1276

3242

3296

6272

PURLIN PU 3

2232

4252

5262

2286

4306

5316

6326

212

266

15 Nos. 7.5x10Ø SLOT

FOR M6 BOLT 12Nos. 11.5x14Ø PU-60HUx40x1.2X15X5

PURLIN PU-3 SLOT FOR M10 BOLT

BOLT DESCRIPTION

S.NO SIZE LOCATION TOTAL PART NAME

1 7.5X10Ø SLOT TOP FLANGE 13 PURLIN PU-1

2 11.5X14Ø SLOT BOTTOM FLANGE 10 PURLIN PU-1

SPECIAL NOTES: 3 7.5X10Ø SLOT TOP FLANGE 14 PURLIN PU-2

RENOVATION OF UNCOATED OR DAMAGED AREAS FOR PREGALVANIZED MATERIALS: AREA OF SURFACE THAT ARE UNCOATED/DRILLED/CUTTED EDGES WHEN GALVANIZED SHALL BE RENOVATED BY ZINC SPRAYING (AFTER CLEANING & REMOVAL OF MILL SCALE), BY ZINC RICH 4 11.5X14Ø SLOT BOTTOM FLANGE 16 PURLIN PU-2

5 7.5X10Ø SLOT TOP FLANGE 15 PURLIN PU-3

PAINT (NORMALLY MIN. 90 PERCENT M/M METALLIC ZINC CONTENT OF DRY FILM) OR BY LOW MELTING ZINC ALLOY ISSUED FOR MASS PRODUCTION 6 11.5X14Ø SLOT BOTTOM FLANGE 12 PURLIN PU-3

PROJECT TITLE :- 1.5 MW SPV PROJECT AT MALLANGINAR,TN

CLIENT EPC CONTRACTOR CONSULTANT

CLIENT :- STATKRAFT SOLAR SOLUTIONS (SKSS)

NOTES:- TOLERANCE:-

EPC CONTRACTOR :-

1. FABRICATION AND ERECTION SHALL BE CARRIED OUT IN 1. THE STRAIGHTNESS OF ANY LENGTH SHALL BE SUCH THAT

ACCORDANCE WITH LATEST IS 800 AND IS 801. THE OFFSET DOES NOT EXCEED 1 /600 OF THAT LENGTH, CONSULTANT :- ARBUTUS CONSULTANT PVT LTD 02 21.06.2018 REVISED AS PER COMMENTS SS

2. MATERIAL TOLERANCE SHALL BE AS PER IS 1852. WHEN MEASURED ALONG BOTH THE X-X AND Y-Y AXIS.

3. HOT DIP GALVANIZATION SHALL BE CARRIED OUT AS PER IS DRAWING TITLE :- MMS-FABRICATION DETAILS 01 13.06.2018 REVISED AS PER COMMENTS SS

2. THE DEVATION OF THE PROFILE DIMENSIONS SHALL NOT

4759. EXCEED ±0.5 MM. THE DEVIATION FROM THE ANGLE OF 90°

DRAWING NO :- SKSS_TN03_2019-001-C-9 00 03.06.2018 FIRST SUBMISSION SS

4. ALL COLD FORM SECTION SHALL BE AS PER IS 811. SHALL NOT EXCEED ±1.

5. INTERNAL RADIUS "AT CURVES SHALL GENERALLY BE 3. THE SECTION SHALL BE REASONABLY FREE FROM TWIST. DRAWN SS SCALE NTS NO. DATE REMARKS DRAWN

TAKEN AS 1.5t. 4. THE TOLERANCE ON THICKNESS FOR THE STRIP USED DRAWING ISSUED STATUS :

6. STRUCTURAL STEEL FOR PURLIN MEMBERS SHALL BE AS SHALL BE THE SAME AS THAT SPECIFIED IN IS: 1852-1985. CHECKED SM SHEET NO 01 FOR INFORMATION FOR

AS-BUILT

PER IS 15961 WITH MINIMUM YIELD STRENGTH OF 550 MPA. APPROVAL ONLY CONSTRUCTION

APPROVED DP PAPER SIZE A3

DATE 21.06.2019 REV NO. 02

Vous aimerez peut-être aussi

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredD'EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredPas encore d'évaluation

- Campus Layout DetailsDocument1 pageCampus Layout Detailsmrjk0555Pas encore d'évaluation

- Key Plan (9Th-20Th Floor Framing Plan: Scale NTSDocument1 pageKey Plan (9Th-20Th Floor Framing Plan: Scale NTSSimeon James Defeo VillacrusisPas encore d'évaluation

- Weight Boiler: 40.000kg Weight Water: 30.000kg Weight Total: 70.000kgDocument1 pageWeight Boiler: 40.000kg Weight Water: 30.000kg Weight Total: 70.000kgPinak ProjectsPas encore d'évaluation

- Urban Utilities Dial Before You DigDocument1 pageUrban Utilities Dial Before You DigBrett AndreassenPas encore d'évaluation

- 04 Hallelujah - TBN 4 PDFDocument1 page04 Hallelujah - TBN 4 PDFGonzalo ArdilaPas encore d'évaluation

- 6148 Datasheet 6CHLDocument1 page6148 Datasheet 6CHLMohammad Hafidz AsyariPas encore d'évaluation

- SRS 222 23395 06 R5Document3 pagesSRS 222 23395 06 R5Mr. AliPas encore d'évaluation

- Upper BasementDocument11 pagesUpper BasementAnh Khoa LePas encore d'évaluation

- Ascott Office New AreaDocument1 pageAscott Office New AreaMuh IhwanzPas encore d'évaluation

- Left View Wall Frame Detailed Elevation: J HostelDocument1 pageLeft View Wall Frame Detailed Elevation: J HostelHassan AlaskaPas encore d'évaluation

- SRE BNC V 204 0 - BkkNoiDeviator PDFDocument1 pageSRE BNC V 204 0 - BkkNoiDeviator PDFkeaorePas encore d'évaluation

- Eg135 S Single PDFDocument5 pagesEg135 S Single PDFMohammed AbdelsalamPas encore d'évaluation

- TELEPHONE1 Layout ApproedDocument1 pageTELEPHONE1 Layout Approedzafrikhan875Pas encore d'évaluation

- 1025 K.IN Studio & HANAMORI's Office - 210525-E5Document1 page1025 K.IN Studio & HANAMORI's Office - 210525-E5KinoPas encore d'évaluation

- 50A 7 8 9 2 or 7 8 9 1 331 55 56 59 Or56aor60 55 60 59 or 57A or 57Document1 page50A 7 8 9 2 or 7 8 9 1 331 55 56 59 Or56aor60 55 60 59 or 57A or 57ANGEL MURILLOPas encore d'évaluation

- Saxofon Tenor de La Cabeza A Los Pies 2023Document2 pagesSaxofon Tenor de La Cabeza A Los Pies 2023Hernan OrtegaPas encore d'évaluation

- Arch Detales 3Document1 pageArch Detales 3Joseph JayakanthanPas encore d'évaluation

- P Ple Als 220 30001 0Document1 pageP Ple Als 220 30001 0BadiPas encore d'évaluation

- PUJ-ESM-DT-EST-12-03 (Estructural Losa Piso 6 N+24.50 y Piso 7 N+29.05)Document1 pagePUJ-ESM-DT-EST-12-03 (Estructural Losa Piso 6 N+24.50 y Piso 7 N+29.05)Welding Testing Services SASPas encore d'évaluation

- Document Status: If in Doubt AskDocument3 pagesDocument Status: If in Doubt AskNitinPas encore d'évaluation

- Mozart Clarinet Concerto IIIDocument5 pagesMozart Clarinet Concerto IIIlesusiusPas encore d'évaluation

- 90dcd 9. Editio Spetialis.Document4 pages90dcd 9. Editio Spetialis.Guerreiro livre 91 G.L.91Pas encore d'évaluation

- Sheet 1of2Document1 pageSheet 1of2Shivendra KumarPas encore d'évaluation

- Homework 2 Highway Engineering: LegendDocument9 pagesHomework 2 Highway Engineering: LegendWalter SanchezPas encore d'évaluation

- Plan Mansarda PDFDocument1 pagePlan Mansarda PDFsergiuardeleanPas encore d'évaluation

- Tico-Tico No Fubá - Clarinet in BBDocument2 pagesTico-Tico No Fubá - Clarinet in BBLuís M. EspadanaPas encore d'évaluation

- Tico-Tico No Fubá - Clarinet in BBDocument2 pagesTico-Tico No Fubá - Clarinet in BBLuís M. Espadana100% (1)

- Cold EasyDocument3 pagesCold EasymarPas encore d'évaluation

- SRE BNC V 203 0 - BkkNoiAbutDim PDFDocument1 pageSRE BNC V 203 0 - BkkNoiAbutDim PDFkeaorePas encore d'évaluation

- SiteDocument1 pageSitecRi SocietyPas encore d'évaluation

- HẦM B2Document1 pageHẦM B2An Nguyen TruongPas encore d'évaluation

- Eep 000097 0102148005 3 ST Det 0684 R02Document1 pageEep 000097 0102148005 3 ST Det 0684 R02Vikram DalalPas encore d'évaluation

- XSS138-228-258/24L / / / /: StatusDocument1 pageXSS138-228-258/24L / / / /: StatusJosePas encore d'évaluation

- BSC Drive Thru ElevDocument1 pageBSC Drive Thru ElevJake Ariel Partosa ElmidoPas encore d'évaluation

- 3 - Ga Drawing 3 of 3Document1 page3 - Ga Drawing 3 of 3nimish.aquamarinePas encore d'évaluation

- Bones Imagine DragonsDocument3 pagesBones Imagine DragonsTomás GutierrezPas encore d'évaluation

- Peta Topografi Gunung Welirang / PacetDocument1 pagePeta Topografi Gunung Welirang / PacetIhwal Praja Putra PratamaPas encore d'évaluation

- Oberon SusaphoneDocument1 pageOberon Susaphoneendys castellanos BeltranPas encore d'évaluation

- Alma Trombon 3Document3 pagesAlma Trombon 3Orquesta Son ColónPas encore d'évaluation

- Prilog 2. Geoloska Karta-ModelDocument1 pagePrilog 2. Geoloska Karta-ModelbecanovicvladanPas encore d'évaluation

- Je Te Laisserai Des Mots Patrick WatsonDocument2 pagesJe Te Laisserai Des Mots Patrick WatsonMohamed HusseinPas encore d'évaluation

- Je Te Laisserai Des Mots Patrick WatsonDocument2 pagesJe Te Laisserai Des Mots Patrick WatsonannaPas encore d'évaluation

- Je Te Laisserai Des Mots Patrick WatsonDocument2 pagesJe Te Laisserai Des Mots Patrick WatsonJuanvi Lladosa ArnauPas encore d'évaluation

- Je Te Laisserai Des Mots Patrick WatsonDocument2 pagesJe Te Laisserai Des Mots Patrick WatsonCristina Almeida100% (1)

- Je Te Laisserai Des Mots: Patrick WatsonDocument2 pagesJe Te Laisserai Des Mots: Patrick WatsonAngelina Herrera75% (4)

- Je Te Laisserai Des Mots Patrick WatsonDocument2 pagesJe Te Laisserai Des Mots Patrick Watson7kxccccrt5Pas encore d'évaluation

- Je Te Laisserai Des Mots Patrick WatsonDocument2 pagesJe Te Laisserai Des Mots Patrick WatsonMelyssawoituskiPas encore d'évaluation

- Accidentally in Love-ViolaDocument2 pagesAccidentally in Love-ViolaCarlos NunoPas encore d'évaluation

- COLLASUYO-Corno en FaDocument2 pagesCOLLASUYO-Corno en FaAntonio Llontop PachecoPas encore d'évaluation

- Carol of The Bells Christmas MedleyDocument7 pagesCarol of The Bells Christmas Medleyeng.thalhannafreitasPas encore d'évaluation

- 2 Estudios Diarios ViolinDocument1 page2 Estudios Diarios Violinruben beckPas encore d'évaluation

- In The MoodAlto Sax SoloDocument2 pagesIn The MoodAlto Sax SolomikyPas encore d'évaluation

- PO178 - 20 10t X 20m Span + 5.2m Cantilever Gantry Crane - Part16Document1 pagePO178 - 20 10t X 20m Span + 5.2m Cantilever Gantry Crane - Part16ahmed saadPas encore d'évaluation

- NCRTC DM009 Aye Duhd Adm M2 ST 11205Document1 pageNCRTC DM009 Aye Duhd Adm M2 ST 11205Zaid HussainPas encore d'évaluation

- PO178 - 20 10t X 20m Span + 5.2m Cantilever Gantry Crane - Part16Document1 pagePO178 - 20 10t X 20m Span + 5.2m Cantilever Gantry Crane - Part16ahmed saadPas encore d'évaluation

- QTX Qa1000Document1 pageQTX Qa1000Joao Raffagnato CaldasPas encore d'évaluation

- Blue Swing ShuffleDocument2 pagesBlue Swing Shufflemdionne001Pas encore d'évaluation

- Kilim Clutch 1 - Stitch FiddleDocument2 pagesKilim Clutch 1 - Stitch FiddlelkolonauskiPas encore d'évaluation

- Extended Abstract Ana FernandesDocument10 pagesExtended Abstract Ana FernandesVukasin LisaninPas encore d'évaluation

- Swichgear Base Channel DesignDocument3 pagesSwichgear Base Channel DesignAmol GolePas encore d'évaluation

- 1percentinfiltration PDFDocument2 pages1percentinfiltration PDFAmol GolePas encore d'évaluation

- Permissible Stress Level of Brick Masonry Under Compressive Cyclic LoadingDocument7 pagesPermissible Stress Level of Brick Masonry Under Compressive Cyclic LoadingAmol GolePas encore d'évaluation

- Amol Gole - Resume - 20181112Document3 pagesAmol Gole - Resume - 20181112Amol GolePas encore d'évaluation

- ConnectionDocument3 pagesConnectionAmol GolePas encore d'évaluation

- STAAD - PRO - Single PoleDocument2 pagesSTAAD - PRO - Single PoleAmol GolePas encore d'évaluation

- Annexture 1-MG - STAAD.Document5 pagesAnnexture 1-MG - STAAD.Amol GolePas encore d'évaluation

- The 20 Ultimate 20 Pullout 20 Capacity 20 of 20 Anchors 20 in 20 Frictional 20 SoilsDocument18 pagesThe 20 Ultimate 20 Pullout 20 Capacity 20 of 20 Anchors 20 in 20 Frictional 20 SoilsAmol GolePas encore d'évaluation

- Material Safety Data SheetDocument4 pagesMaterial Safety Data SheetAmol Gole50% (4)

- Table of Material Properties For Structural Steel S235, S275, S355, S420Document6 pagesTable of Material Properties For Structural Steel S235, S275, S355, S420Amol GolePas encore d'évaluation

- Col DesignDocument3 pagesCol DesignAmol GolePas encore d'évaluation

- Land Conservation and Restoration Report - Yachini Project (Eng Version)Document28 pagesLand Conservation and Restoration Report - Yachini Project (Eng Version)Amol GolePas encore d'évaluation

- CV761 04 Traffic Loading and VolumeDocument52 pagesCV761 04 Traffic Loading and VolumeBhaskerBanu100% (1)

- 1 s2.0 S2452321617303232 MainDocument8 pages1 s2.0 S2452321617303232 MainAmol GolePas encore d'évaluation

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFAmol GolePas encore d'évaluation

- 14 330SoilClassification PDFDocument40 pages14 330SoilClassification PDFMartin Andrade100% (2)

- Land Conservation and Restoration Report - Yachini Project (Eng Version)Document28 pagesLand Conservation and Restoration Report - Yachini Project (Eng Version)Amol GolePas encore d'évaluation

- SHALLOW FOUNDATIONS March 19Document61 pagesSHALLOW FOUNDATIONS March 19Amol GolePas encore d'évaluation

- UnoffDocument31 pagesUnoffHeang BorinPas encore d'évaluation

- SHALLOW FOUNDATIONS March 19Document61 pagesSHALLOW FOUNDATIONS March 19Amol GolePas encore d'évaluation

- Mechanical and Physcial Properties of Fibre Cement Board PDFDocument5 pagesMechanical and Physcial Properties of Fibre Cement Board PDFanhnguyenhaiPas encore d'évaluation

- Screed ConcreteDocument3 pagesScreed ConcreteAmol GolePas encore d'évaluation

- Receipt PDFDocument1 pageReceipt PDFAmol GolePas encore d'évaluation

- Screed ConcreteDocument3 pagesScreed ConcreteAmol GolePas encore d'évaluation

- Bending Strength of Deep Corrugated Steel Panels PDFDocument34 pagesBending Strength of Deep Corrugated Steel Panels PDFAmol GolePas encore d'évaluation

- 390x90x190 Hollow Block 7.5 N MM2Document1 page390x90x190 Hollow Block 7.5 N MM2Amol GolePas encore d'évaluation

- MCR GA Commented PDFDocument1 pageMCR GA Commented PDFAmol GolePas encore d'évaluation

- Annexture 2 - Grade Slab Design (Egyptian Code)Document4 pagesAnnexture 2 - Grade Slab Design (Egyptian Code)Amol GolePas encore d'évaluation

- AI Hempadur AvantGuardDocument5 pagesAI Hempadur AvantGuardAmol GolePas encore d'évaluation

- CarbonCure Technical Note - Types of Concrete CarbonationDocument4 pagesCarbonCure Technical Note - Types of Concrete CarbonationSakinePas encore d'évaluation

- Urban Transformers Safety and Environmental ChallengesDocument8 pagesUrban Transformers Safety and Environmental ChallengesNicodemus Ervino MandalaPas encore d'évaluation

- Slump of Hydraulic Cement Concrete Fop For Aashto T 119Document2 pagesSlump of Hydraulic Cement Concrete Fop For Aashto T 119anbertjonathanPas encore d'évaluation

- Experiments 3,4,5Document13 pagesExperiments 3,4,5Athirah JamalludinPas encore d'évaluation

- A. Reading Assignment: Analysis of Members With Axial Loads and MomentsDocument19 pagesA. Reading Assignment: Analysis of Members With Axial Loads and MomentsIhab El AghouryPas encore d'évaluation

- Cast Designer 2018 E Brochure GravityDocument14 pagesCast Designer 2018 E Brochure GravityVivek ShrivastavaPas encore d'évaluation

- Program Outcomes (Pos) Addressed by The Activity: Activity No. 3: Building Envelope Systems and Assemblies 1.1Document13 pagesProgram Outcomes (Pos) Addressed by The Activity: Activity No. 3: Building Envelope Systems and Assemblies 1.1Jazcel GalsimPas encore d'évaluation

- Reverse OsmosisDocument4 pagesReverse OsmosisKiran ShresthaPas encore d'évaluation

- Ebook Membranes 2013Document577 pagesEbook Membranes 2013sergiogonzalez371375% (4)

- Report On Treatment of Waste WaterDocument7 pagesReport On Treatment of Waste WaterSaptarshi GiriPas encore d'évaluation

- TestDocument19 pagesTestCikgu AnitaPas encore d'évaluation

- Sa 4820M00450 00001 01 - 00Document1 pageSa 4820M00450 00001 01 - 00mohdfaridabubakarPas encore d'évaluation

- Burnt Clay Building Bricks - Methods of Tests: Indian StandardDocument8 pagesBurnt Clay Building Bricks - Methods of Tests: Indian Standardmohd waseemPas encore d'évaluation

- Livro - Molybdenum in Agriculture - Umesh C. Gupta PDFDocument286 pagesLivro - Molybdenum in Agriculture - Umesh C. Gupta PDFchagasidiarnPas encore d'évaluation

- A493 00 PDFDocument3 pagesA493 00 PDFJohano AraújoPas encore d'évaluation

- Cuzn38Pb1.5: Comparable Standards: Aurubis Designations: Pna259 en Cw608N Uns C35300 Bs Cz128Document2 pagesCuzn38Pb1.5: Comparable Standards: Aurubis Designations: Pna259 en Cw608N Uns C35300 Bs Cz128Paulo Henrique NascimentoPas encore d'évaluation

- ADxC-51-001 AMM Edition 6.0 Oratex Application ManualDocument138 pagesADxC-51-001 AMM Edition 6.0 Oratex Application ManualJuan Manuel Valcarcel RosadoPas encore d'évaluation

- SYNOCURE886S70Document2 pagesSYNOCURE886S70Samuel AgusPas encore d'évaluation

- Industrial Waste Management: Che 3101 G1 1/N 00 1/1Document2 pagesIndustrial Waste Management: Che 3101 G1 1/N 00 1/1JAN JERICHO MENTOYPas encore d'évaluation

- Solid State Physics - 04 GrapheneDocument45 pagesSolid State Physics - 04 GrapheneMassimo GiordanoPas encore d'évaluation

- Novel Hybrid Structural Core Sandwich Materials For Aircraft ApplicationsDocument4 pagesNovel Hybrid Structural Core Sandwich Materials For Aircraft Applicationsphd.meethaqPas encore d'évaluation

- Distillation Procedures Manual - Ed5 PDFDocument46 pagesDistillation Procedures Manual - Ed5 PDFLuz Elizabet Mejía RojasPas encore d'évaluation

- Regenerative Cooling of Liquid Rocket Engine Thrust ChambersDocument100 pagesRegenerative Cooling of Liquid Rocket Engine Thrust ChambersRaol Martínez SantiagoPas encore d'évaluation

- MECHANICAL PROPERTIES of TitaniumDocument6 pagesMECHANICAL PROPERTIES of TitaniumAmr FawzyPas encore d'évaluation

- ASCE Dox Plank Design InfoDocument17 pagesASCE Dox Plank Design Infomarmusman100% (1)

- Iso 178 2019Document12 pagesIso 178 2019Ana LópezPas encore d'évaluation

- Heat ExchangersDocument49 pagesHeat Exchangersbluelion_19100% (1)

- RA Bill AbstractDocument1 pageRA Bill AbstractpraveenPas encore d'évaluation

- Experiment 11 - Types of Chemical ReactionsDocument7 pagesExperiment 11 - Types of Chemical ReactionsUpekkha Phm100% (1)

- Assignment-7question and SolutionDocument3 pagesAssignment-7question and SolutionTusharPas encore d'évaluation