Académique Documents

Professionnel Documents

Culture Documents

Available I" Our Area. If You Ustullly Buy Fatter, Larger Bagels, E"Large Lbe Pattern To Fit Ibe"

Transféré par

davidTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Available I" Our Area. If You Ustullly Buy Fatter, Larger Bagels, E"Large Lbe Pattern To Fit Ibe"

Transféré par

davidDroits d'auteur :

Formats disponibles

Build the two

body halves first

1 For each bagel slicer, cut four

Wlx5-l4x8W blanks for parts A and

You can cut yourself-possibly seriously- C, the inner and outer faces (we

hanging onto a bagel bare·handed while slicing it. used maple), and two ~x5-l4x8Vl"

To avoid trouble, stick the bagel into our handy blanks for parts H, the body cores

holder. Its tall handJe puts your hand safely above (we used cherry). Cut two pieces

the knife blade. of ¥i"-thick scrapwood the same

size for clamping pads. You'll also

need four Il)i6" lengths of MI- cher-

Note: We sized our holder jor the 4"*Or-so bagels commonly I)' dowel rod.

available I" our area. If you ustUllly buy fatter, larger 2 Make two pholOcopies of the

bagels, e"large lbe pattern to fit Ibe",. Full-Sized Panem, which you'll find

in the WOOD PATTERNS. insert in

the middle of the magazine.

58 WOOD MAGAZL"lE FEBRUARY 1998

5/S' holes

EXPLODED

VIEW

Drll1 through both body halves al once.

This way, the sides will mate accurately.

3/8' dowel

.,

115/16' long ©

~-. ~

~ ~.

~0··· ~ _'~

'-''''L- ...••••..•..••._.••..._

3/8' hole

II__

"'_'."'_IIr-----,

.--l ~/8' ~1fa")

~k

"--l/ ' SEE THE

S WOOO PATIERNSo

INSERT FOR

FULL-SIZED PATIERN Finish the Inside faces before assembly.

Mask the dowels for good glue joints.

3 Gille lip two lamina- remaining pattern to the stack. 4 It's easier to apply the finish to

tiOns, each consisting Bandsaw or scrollsaw around the the inside faces and edges before

of one thin blank (A) solid pattern line, leaving the line. final assembly. Mask about W' at

and one thick blank 7 Separate the pieces, and glue the end of each dowel, then apply

(8). Square the edges, them to the outside faces of the a clear oil finish as shown above.

and clamp the lamina- taped-together parts. Clamp them On the other half, be careful not to

tions between the scrap-" between scrapwood pads until the get finish in the dowel holes. (You

wood pads until the glue dries. glue dries, then sand to the line. eould stick wads of paper or cot-

4 Unclamp the laminations, and ton balls in the holes to protect

fasten them [Ogether with double- Now, put the them.) After the oil cures, spray on

faced tape, placing the l1l"-thick halves together clear polyurethane for durability.

faces together. Adhere a copy of 1 Chuck a :HI" hit (or the size that 5 Allow the finish to dry, then

the pattern to the srack, using rub- best matches your W' cherry dow- remove the masking. Apply glue to

ber cement or spray adhesive. els) in your drill press, and drill the the dowel ends, and slide the other

S B:mdsaw slightly outside the pat- four holes along the bottom, body half onto them. Slip scraps of

tern line. Follow the dotted line shown top right. Change to a ~" \-8"·thick material between the

inside the throat. Using a drum Forstner bit, and bore the hole at halves to space them evenly.

sander, sand the throal area to the the top of the handle. 6 Sand the dowel ends flush on

dotted line. You can sand slightly 2 Remove the pattern. Separate the both sides. Finish-sand the outside

beyond Ihe ends of the dotted line, parts, and sand the inside face of faces, and apply the oil and

but don't sand Ihe rest of the edge each one smooth. polyurethane as before.•

yet. Remove the pattern, but do 3 Glue the four dowels into the :MJ"

not separate the parts. holes in one laminated body half. Prolecl Dcslgn: urry JohnSlOn

l'hOl<Jgr:l.phs: Wm. Hopkins; Many Ilald"'ln

6 Tape the remaining Ml"-thick Bring the ends flush with the Gr:l.phic Design: "erry McF~rlin

blanks together, and adhere the body's outer face. 1II11slrJlions: Roxanne LeMoine: I.oma]ohnson

WOOO MAGAZINE FEBRUARY 1998 59

Blade is tilted at 11.25°

1

Stave position

11.25o bevel edge

on guide block. Adhere sandpaper

to base in this area.

B

Hold-down #8 x 11/2" F.H. wood screw Hold-down

block block

3/4 x 1 x 6" handle

#8 x 11/4" F.H.

wood screws

3/4 x 3/4 x

61/4" stopblock

(Location shown is for left-

3/4 x 41/2 x 113/16" alignment block

tilting saws; place stopblock

at opposite end of alignment

block for right-tilting saws.)

3/4 x 61/2 x 13" base

Stave Taper Jigs

FULL-SIZED PATTERNS Second cut First cut

See page 70

(additional pattern on other side).

1

Adhere sandpaper

to base in this area.

Cut 2

1 Adhere sandpaper

to base in this area.

Cut 1

Cut with saw fence

to right side of blade.

3/4 x 3/4 x 31/2"

alignment blocks

C

3/4 x 2 x 11"

Hold-down

riser block block

Hold-down

block

3/4 x 1 x 6" handle

5/8" hole

3/4 x 61/2 x 13" base

Table Corner Brace

5/32" holes,

FULL-SIZED

countersunk PATTERN C 3/8" hole

Top edge

See page 47

Bagel Slicer

FULL-SIZED PATTERN

31/2" D

See page 58 R=3/8"

2" 3/8" 13/32" hole

3/8" slot

C

SIDE

43/4" R=11/4" 1/4" hole

F

23/8" CORNER BRACE

(4 needed)

A and B 1/4" holes

BODY

Pendulum R=21/4"

3/8" holes 13/4" 1/2" Clock

1/2"

FULL-SIZED

PATTERN

3/8" See page 42

(additional patterns on other side).

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- 50 Best Jobs For Your Personality PDFDocument497 pages50 Best Jobs For Your Personality PDFdavidPas encore d'évaluation

- BoxBeamBench PDFDocument7 pagesBoxBeamBench PDFgiacummo100% (1)

- BoxBeamBench PDFDocument7 pagesBoxBeamBench PDFgiacummo100% (1)

- What Weld Rod To UseDocument2 pagesWhat Weld Rod To Usesatgk0% (1)

- Chainsaw Milling ManualDocument47 pagesChainsaw Milling ManualAnonymous jbeHFUPas encore d'évaluation

- MDR Report Tank PDFDocument11 pagesMDR Report Tank PDFWahyudi MetrizaPas encore d'évaluation

- Lihir Fs PDFDocument1 pageLihir Fs PDFKaye ReiesPas encore d'évaluation

- Dovetailed Tool BoxDocument13 pagesDovetailed Tool Boxdavid100% (1)

- 20b GT PART2 PDFDocument178 pages20b GT PART2 PDFHANIF AKBARPas encore d'évaluation

- The Underhammer RifleDocument1 pageThe Underhammer Rifledavid0% (1)

- 17601.fundamentals of Organic Chemistry by John E. MC - MurryDocument646 pages17601.fundamentals of Organic Chemistry by John E. MC - Murrydavid100% (2)

- Orion Cooker Manual R2web PDFDocument31 pagesOrion Cooker Manual R2web PDFdavidPas encore d'évaluation

- Furniture and Cabinetmaking - 282 - April 2019Document84 pagesFurniture and Cabinetmaking - 282 - April 2019davidPas encore d'évaluation

- Orion Cooker Manual R2web PDFDocument31 pagesOrion Cooker Manual R2web PDFdavidPas encore d'évaluation

- Prepare Your CV PDFDocument220 pagesPrepare Your CV PDFdavidPas encore d'évaluation

- 2018 David's Territory Sales - FinalDocument24 pages2018 David's Territory Sales - FinaldavidPas encore d'évaluation

- 8489-Green Jobs Guidebook FINAL With CoverDocument59 pages8489-Green Jobs Guidebook FINAL With CoverpmanikPas encore d'évaluation

- Chess SetsDocument6 pagesChess SetsdavidPas encore d'évaluation

- Resignation MBSIDocument1 pageResignation MBSIdavidPas encore d'évaluation

- Selected Solutions App. E Kimmel 4eDocument3 pagesSelected Solutions App. E Kimmel 4edavidPas encore d'évaluation

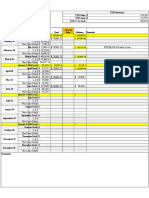

- Loan Amortization ScheduleDocument1 pageLoan Amortization ScheduledavidPas encore d'évaluation

- Depreciation of LandDocument1 pageDepreciation of Landdavidsternleader5768Pas encore d'évaluation

- Product Sheet B25 SwepDocument2 pagesProduct Sheet B25 SwepCristian BontasPas encore d'évaluation

- Cable SwagingDocument3 pagesCable SwagingRajesh Kumar100% (1)

- Latex Paint For Warbirds VaillancourtDocument14 pagesLatex Paint For Warbirds VaillancourtHernan BaigorriaPas encore d'évaluation

- Smurfit Kappa Board 1 Cara BlancaDocument3 pagesSmurfit Kappa Board 1 Cara BlancaJuan JullianPas encore d'évaluation

- Desulphurization of Jet Fuel Using Merox-5Document1 pageDesulphurization of Jet Fuel Using Merox-5Syed FayzanPas encore d'évaluation

- TED (21) - 5121 Revision 2021 Model Question Paper Adhesive TechnologyDocument3 pagesTED (21) - 5121 Revision 2021 Model Question Paper Adhesive TechnologySam JhonsonPas encore d'évaluation

- Export Price List Liquid GroupDocument1 pageExport Price List Liquid GroupAbbas SaqibPas encore d'évaluation

- Piping Works Daily ReportDocument17 pagesPiping Works Daily ReportGomathyselviPas encore d'évaluation

- Synthesis of Acetanilide and Its Purification Through RecrystallizationDocument4 pagesSynthesis of Acetanilide and Its Purification Through RecrystallizationTeresa Saylo100% (1)

- HMTDocument12 pagesHMTsoumyaPas encore d'évaluation

- Cot-00945 Sinnens S.R.L.Document3 pagesCot-00945 Sinnens S.R.L.Carlos Zevallos VeraPas encore d'évaluation

- Gate Notes - Heat TreatmentDocument4 pagesGate Notes - Heat TreatmentStephanie Fleming100% (1)

- Used Water SES 5 Construction of Tunnels Ancillaries 2012Document28 pagesUsed Water SES 5 Construction of Tunnels Ancillaries 2012Mark BenjiePas encore d'évaluation

- Moulding Sand Tesying - 11Document17 pagesMoulding Sand Tesying - 11firdoshansariPas encore d'évaluation

- Hyundaiwia Lineup enDocument18 pagesHyundaiwia Lineup ensunhuynhPas encore d'évaluation

- Askmedata 13thjuneDocument2 pagesAskmedata 13thjuneThakkali KuttuPas encore d'évaluation

- Press Work TerminologyDocument5 pagesPress Work TerminologySenthil Kumar GunasekaranPas encore d'évaluation

- SABA Ecoseal Bio HM PDS ENDocument2 pagesSABA Ecoseal Bio HM PDS ENArda YILDIZEL I Reliant E&CPas encore d'évaluation

- Mse 353 Lecture-1Document7 pagesMse 353 Lecture-1physical metallurgyPas encore d'évaluation

- Gesco ProfileDocument3 pagesGesco Profilefawad2005Pas encore d'évaluation

- Marazzi DesignDocument9 pagesMarazzi DesignQOQO TEAMPas encore d'évaluation

- New Microsoft Office Excel WorksheetDocument2 pagesNew Microsoft Office Excel Worksheetg_sanchetiPas encore d'évaluation

- Kharasanah 1Document36 pagesKharasanah 1Osama TarekPas encore d'évaluation

- Programme For The 16th Chlorine Symposium - Thyssenkrupp Uhde Chlorine Engineers, 15th - 17th June 2016, Dortmund, GermanyDocument2 pagesProgramme For The 16th Chlorine Symposium - Thyssenkrupp Uhde Chlorine Engineers, 15th - 17th June 2016, Dortmund, GermanyChristian Josue Herrera CordobaPas encore d'évaluation

- Siddh UpdatedDocument33 pagesSiddh UpdatedVikrantPas encore d'évaluation

- 500 Mechanical Sy MP-I Smart QuestionsDocument23 pages500 Mechanical Sy MP-I Smart QuestionsGeorge CamachoPas encore d'évaluation