Académique Documents

Professionnel Documents

Culture Documents

ADMA Standard STD-143

Transféré par

gk80823Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ADMA Standard STD-143

Transféré par

gk80823Droits d'auteur :

Formats disponibles

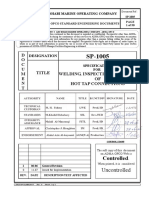

Document Ref.

:

ABU DHABI MARINE OPERATING COMPANY STD-143

Control Sheet

PAGE

ADMA-OPCO STANDARD ENGINEERING DOCUMENTS

1 of 47

COPYRIGHT © ABU DHABI MARINE OPERATING COMPANY - ADMA-OPCO

All rights reserved. The information contained in this document is regarded as confidential. Recipient(s) other than ADMA-

OPCO's employees undertake both during the continuance of their services to ADMA-OPCO and after termination to maintain

in safe custody and not to use any such information for any purpose other than a purpose falling within the scope of the

Agreement or Contract under which this document was supplied. Recipient(s) further agree not to dispose of, make copies, in

whole or in part of such information or permit the use or access of the same by any Third Party unless the prior written

permission of ADMA-OPCO Manager Facilities Engineering is obtained.

D

O

DESIGNATION STD-143

C

U STANDARD

M

TITLE FOR

E LOW VOLTAGE SWITCHGEAR

N AND

T CONTROL GEAR

AUTHORITY NAME TITLE B.UNIT/DIV SIGNATURE DATE

TECHNICAL

Thenarasu S. Muthu SEE Dev./FED

CUSTODIAN

STANDARDS M.Khalid Elshobary SSL Dev./FED

DISCIPLINE

Hisham Z. Awda DETL(A) Dev./FED

ENGINEERING

APPROVAL Daniel M.Lemarchand MFE Dev./FED

ENDORSEMENT Ahmad S. Al-Suwaidi AGM(D) Development

CONTROL STAMP

The soft copy of this

document on

ADMA-OPCO Web is

Controlled.

When printed, it is considered

0 06-06 Issued For Implementation

REV. DATE DESCRIPTION/TEXT AFFECTED Uncontrolled

ADMA-OPCO/SEF/007 Rev. 0 Sheet 1 of 1

Liability for utilization by personnel/organizations outside ADMA-OPCO

Whilst every effort has been made to ensure the accuracy of this document,

neither ADMA-OPCO nor its employees will assume liability for any application

or use outside ADMA-OPCO premises/assets.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

2

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

TABLE OF CONTENTS

1. INTRODUCTION......................................................................................................................................5

1.1 SCOPE........................................................................................................................................5

1.2 COVERAGE..............................................................................................................................5

1.3 EXCLUSION .............................................................................................................................5

1.4 REFERENCE STANDARDS...................................................................................................5

1.5 ABBREVIATIONS ...................................................................................................................6

1.6 DEFINITIONS ..........................................................................................................................6

1.7 USE OF LANGUAGE ..............................................................................................................6

1.8 LOW VOLTAGE (LV) SWITCHGEAR AND CONTROL GEAR DATA SHEET ..........6

2. QUALITY ASSURANCE .........................................................................................................................7

2.1 QUALITY ASSURANCE SYSTEM .......................................................................................7

2.2 QUALITY PLAN ......................................................................................................................7

2.3 INSPECTION AND CERTIFICATION REQUIREMENTS ...............................................8

3. ENVIRONMENTAL CONDITIONS......................................................................................................8

4. ELECTRICAL HAZARDOUS AREA CERTIFICATIONS...............................................................9

5. SPECIFIC DESIGN REQUIREMENTS FOR LV SWITCHGEAR AND CONTROL GEAR .....9

5.1 GENERAL .................................................................................................................................9

5.2 ENCLOSURES, CONSTRUCTION AND RATING...........................................................10

5.3 BUSBARS ................................................................................................................................13

5.4 PROVISIONS FOR EXTERNAL CABLE...........................................................................14

5.5 EARTHING .............................................................................................................................14

5.6 INTERLOCKS ........................................................................................................................15

5.7 LOCKING ARRANGEMENT ..............................................................................................16

5.8 CIRCUIT BREAKERS...........................................................................................................17

5.9 MOTOR STARTERS AND CONTACTOR FEEDERS .....................................................20

5.10 FUSES, FUSE HOLDERS AND LINKS...............................................................................22

5.11 INDICATING INSTRUMENTS............................................................................................23

5.12 PROTECTIVE RELAYS .......................................................................................................24

5.13 CURRENT TRANSFORMERS.............................................................................................25

5.14 VOLTAGE TRANSFORMERS ............................................................................................26

5.15 ISOLATING DEVICES .........................................................................................................27

5.16 INDICATING LAMPS ...........................................................................................................27

5.17 TERMINALS AND TERMINATIONS ................................................................................28

5.18 CONTROL DEVICES ............................................................................................................29

5.19 CONTROL...............................................................................................................................29

5.20 INTERNAL WIRING AND MARKING ..............................................................................30

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

3

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.21 ANTI-CONDENSATION HEATERS...................................................................................32

5.22 NAME PLATES AND LABELS............................................................................................32

5.23 INTERFACE WITH ELECTRICAL CONTROL SYSTEM (ECS) AND PROCESS

CONTROL SYSTEM .............................................................................................................33

5.24 PAINTING...............................................................................................................................34

5.25 INSPECTION AND TESTING..............................................................................................34

5.26 DOCUMENTATION ..............................................................................................................37

5.27 HANDLING, PACKING AND SHIPMENT ........................................................................38

APPENDIX-A: DATA SHEET FOR LV SWITCHGEAR AND CONTROL GEAR ..............................39

APPENDIX-B: ABBREVIATIONS .................................................................................................................43

APPENDIX-C: DEFINITIONS ........................................................................................................................45

APPENDIX-D: REFERENCED DOCUMENTS ...........................................................................................46

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

4

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

1. INTRODUCTION

1.1 Scope

1.1.1 This Standard specifies ADMA-OPCO minimum requirements for Low Voltage

Switchgear and Control Gear for offshore and onshore applications.

1.1.2 This Standard provides the design, materials, fabrication, inspection, testing,

documentation and preparation requirements for shipment of low-voltage

switchgear and control gear based on IEC 60947.

1.2 Coverage

1.2.1 This Standard covers the design, manufacture, testing and supply of LV

switchgear and control gear to be installed for various ADMA-OPCO projects.

1.2.2 This Standard relates to equipment suitable for operation on alternating current

supplies at voltages up to 1000V for LV switchgear and control gear.

1.2.3 This Standard should be applied to switchgear and control gear generally found in

industry and includes equipment, which is to be installed in areas classified as

hazardous and/or non-hazardous.

1.2.4 This Standard also covers the modifications/extensions of existing switchgears.

1.2.5 Both indoor and outdoor applications are covered herein, however indoor locations

are considered the norm. For outdoor applications particular respect for

environmental conditions and references herein shall be applied.

All outdoor applications will require the specific approval of ADMA-OPCO.

1.3 Exclusion

Any HV Switchgear and Control gear operating above 1000V AC.

1.4 Reference Standards

1.4.1 General

The latest edition (at the time of the contract award) of the documents listed in

Appendix-D shall, to the extent specified herein, represent part of this Standard.

The latest edition/revision of ADMA-OPCO Standard Engineering Documents

shall be utilized as indicated in the Status List SL-001.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

5

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

1.4.2 Equivalent Standards

Standard Documents equivalent to those referred to herein shall not be substituted

without written approval from ADMA-OPCO. Approval of equivalent Standard

Documents will not, in any way, remove responsibility from the Manufacturer to

meet the best practices and/or requirements of the Standard Engineering Documents

referred to herein, in the event of conflict.

Where differences and/or conflicting issues occur between the referenced

documents themselves or the requirements of this Standard, the requirements of this

Standard shall overrule unless otherwise advised by the ADMA-OPCO. However

major conflicts shall be reported in writing to ADMA-OPCO for

arbitration/resolution.

Where this Standard states no overriding requirements over the Standard

Engineering Documents requirements, the later shall apply in full.

The Manufacturer shall equip himself with copies of all the referenced Standard

Engineering Documents referred in Appendix-D of this Standard and shall make

them readily available to all ADMA-OPCO, or nominated representative, personnel

involved in the work.

1.5 Abbreviations

The abbreviations used in this Standard are listed in Appendix-B.

1.6 Definitions

The definitions used in this Standard are listed in Appendix-C.

1.7 Use of Language

Throughout this document, the words ‘will’, ‘may’, ‘should’ and ‘shall’, when used

in the context of actions by ADMA-OPCO or others, have specific meanings as

follows:

a. ‘Will’ is used normally in connection with an action by ADMA-OPCO and/or

nominated representative, rather than by a Contractor or Vendor.

b. ‘May’ is used where alternatives are equally acceptable.

c. ‘Should’ is used where provision is preferred.

d. ‘Shall / Must’ is used where a provision is mandatory/vital.

1.8 Low Voltage (LV) Switchgear and Control Gear Data Sheet

ADMA-OPCO Job Officer shall complete the information of the required LV

Switchgear and Control Gear utilizing the Data Sheet in Appendix-A of this

Standard.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

6

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

2. QUALITY ASSURANCE

2.1 Quality Assurance System

2.1.1 All switchgear and control gear shall be procured from Manufacturers approved

by ADMA-OPCO.

2.1.2 The Manufacturer shall operate Quality Management Systems (QMS) within their

organizations, which ensure that the requirements of this document are fully

achieved.

2.1.3 The Manufacturer’s quality management system shall be based on the latest issue

of ISO 9001 and accredited by an international certifying agency.

The Manufacturer’s quality manual shall provide details for the preparation of a

quality plan, which shall include provisions for the QA/QC of design, materials,

fabrication, testing and final inspection.

Where an approved Manufacturer revises their Quality Management System that

will affect the ADMA-OPCO approved Quality Plan/Inspection & Test Plan, and

then the revised Quality Plan/Inspection & Test Plan shall be submitted for

ADMA-OPCO approval before initiating any manufacturing process.

2.1.4 The effectiveness of the Manufacturer’s QMS may be subject to monitoring by

ADMA-OPCO or its representative and may be audited following an agreed

period of notice.

2.1.5 The Manufacturer shall make regular QA audits on all their Sub-

Contractors/Suppliers. Details of these audits shall be made available to ADMA-

OPCO when requested.

2.1.6 The Manufacturer shall maintain sufficient Inspection and Quality Assurance

staff, independent of the service provider management, to ensure that the QMS is

correctly implemented and that all related documentation is available.

2.2 Quality Plan

2.2.1 The activities associated with LV switchgear and control gear manufacture shall

be performed in accordance with an approved Quality Plan (QP).

2.2.2 The level of detail required in the Quality Plan shall ensure the quality of the

switchgear and control gear and shall be subject to ADMA-OPCO approval.

2.2.3 During manufacture, quality assurance/quality control issues are the responsibility

of the Manufacturer and shall be subject to inspection by ADMA-OPCO or TPA

Representative.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

7

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

2.3 Inspection and Certification Requirements

Inspection and certification requirements shall be as per ADMA–OPCO Code of

Practice CP-102.

3. ENVIRONMENTAL CONDITIONS

Parameter Description

Temperature Existing conditions:

Minimum ambient temperature: 8.9 deg.

Maximum ambient temperature: 43.3 deg. C

Design ambient temperatures:

a) For Indoor Installations: 40 deg. C

b) For Outdoor Installations: 50 deg. C

(Note: All components shall be capable of withstanding storage and

transport in temperatures up to 85 deg. C.)

Humidity The relative humidity is high throughout the year, averaging about

70% and reaching 95% or more in the early morning hours, although

in winter the humidity may fall below 50% temporarily during a

‘Shamal’.

Design relative humidity: 95%

Altitude Sea level

Atmosphere Saliferous and corrosive, often containing fine dust and pollutant, in

particular carbon dioxide and hydrogen sulphide.

Dust storms Dust storms are commonly associated with ‘Shamals’ and may reduce

the visibility to less than 1.5 km.

This fine dust has extremely high mobility and can penetrate

normally dustproof enclosures. All measures shall be taken to protect

such ingress of dust and prevent subsequent accumulation within

equipment and cause malfunction.

Rainfall Relatively rare and amounts are small.

Measurable rainfall usually occurs on an average of about 10 days per

year.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

8

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

4. ELECTRICAL HAZARDOUS AREA CERTIFICATIONS

Switchgear shall be certified by an internationally recognized standards organization such

as CENELEC or ATEX for operation within the designated classification of hazardous

area in which they operate. However, certification from other recognized authorities such

as BASEEFA, SIRA, KEMA, FM, PTB etc shall be considered subject to ADMA-OPCO’s

approval.

5. SPECIFIC DESIGN REQUIREMENTS FOR LV SWITCHGEAR AND CONTROL

GEAR

5.1 General

5.1.1 All LV switchgear and control gear shall be designed for a service life of at least 30

years in the environment conditions and duty specified on the data sheets.

5.1.2 The switchgear shall be suitable for a minimum of 3 years of continuous operation

from the time it is installed and commissioned, without any major maintenance at

the duty specified on the data sheets.

5.1.3 All equipment shall be of standard design, and the type and ratings shall be in

accordance with the latest international standards specified under Appendix-D and

other related standards unless they are intended for special applications.

5.1.4 The switchgear and control gear shall be designed to ensure maximum safety

during all operating conditions, regular inspection, testing, maintenance and

installation.

5.1.5 The manufacturer shall consider necessary equipment de-ratings for the maximum

ambient temperature specified in the data sheet. Full details shall be advised to

ADMA-OPCO.

5.1.6 The electrical arrangement of the switchgear/control gear, protection, metering,

control, inter-tripping etc., shall be as shown on the switchgear single line

diagram(s) and/or in the protection diagrams referenced in the material requisition.

5.1.7 The Manufacturer shall confirm full compliance with project specification (with

deviations, if any, listed under a separate Deviation/Exceptions List in the

proposal). Any deviation that is not included under that list will not be considered.

5.1.8 The equipment shall be designed and constructed to fully meet the ambient

conditions especially the saline, tropical, environment conditions, high

temperatures and humidity etc. and the application requirements specified in the

data sheets.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

9

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.1.9 Switchgear and control gear to be used in hazardous areas shall be designed as per

the requirements specified in the data sheet and shall be type tested and certified by

an approved international authority.

5.1.10 Assemblies shall be multi-cubicle type for indoor installation in accordance with

IEC 60439-1 and relevant parts of IEC 60947.

5.1.11 Switchgear assembly shall be complete with the lifting facilities.

5.1.12 The complete factory built assembly shall be of adequate fault rating and self-

ventilating.

5.1.13 Assemblies for offshore installations shall comply with IEC 61892, Parts 1 and 2.

5.1.14 Supply System Variations

The switchgear and control gear shall be capable of continuous operation at their

ratings and within their limits of temperature rise under continuous deviation of

the nominal values of the system voltage and frequency:

a. Voltage: ± 10%

b. Frequency: ± 5%

5.1.15 Modification/Extension of existing switchgears

Unless obsolete, same make and type of cubicles shall be supplied. How ever, due

to technological evaluations, components /devices (VTs, CTs, relays, switches

etc.) of the extension and/or modification works shall comply with this standard.

Specific approval from ADMA shall be obtained for the new makes and types of

components/devices proposed for the obsolete items. Any requirement of

adaptation cubicles, change in dimensions of the cubicles etc., in complete, shall

be brought to the attention of ADMA-OPCO in bid stage itself.

5.2 Enclosures, Construction and Rating

5.2.1 Enclosures of assemblies shall provide following overall degree of protection as

per IEC 60529.

a. Indoor installations: IP 42

b. Onshore outdoor installations: IP 54

c. Offshore outdoor installations: IP 55

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

10

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.2.2 Where openings for ventilating circuit breakers or starters are necessary, the

assembly enclosure protection may be relaxed to IP 32 but then baffle plates shall

be provided to prevent access to live or moving parts.

5.2.3 Partitions, shutters and inspection windows forming part of an enclosure shall

provide the required degree of ingress protection of not less than IP 30.

5.2.4 When a functional unit is open or withdrawn, the degree of protection from inside

of the open or withdrawn functional unit to all other compartments of the

assembly shall be at least IP 40.

a. When a functional unit is isolated and open or withdrawn, the degree of

protection to any remaining live part shall be at least IP 20 and any covers,

shrouds etc. preventing access to live parts shall be fitted with labels stating

the voltage as follows:

‘Danger…volts’

b. If the IP 20 degree of protection cannot be fully complied with, it shall only

be possible to open or withdraw the functional unit with the use of specialized

tools. Labels shall be fitted to the outside and inside of the functional unit

stating the voltage as follows:

‘Danger.... volts, isolate elsewhere before removing covers’.

5.2.5 The form of separation shall be Form 4b. Type classification (Type 5, 6 or 7) shall

be verified with ADMA during bid proposal stage.

5.2.6 Withdrawable parts shall have the following positions (module or switch):

a. Connected (power and auxiliary contacts)

b. Test: auxiliary circuits connected but power contacts disconnected in order to

test the whole control and automation circuits

c. Disconnected (isolated)

d. Removed.

Each unit shall be withdrawable without using tools except for breaker above

630A.

Withdrawable parts shall be effectively earthed until they are completely

withdrawn with all power and control connections disconnected.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

11

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.2.7 Busbars Ducting

Busbar ducting may be provided for connecting the power transformers to the

SWGR or for connecting two sections if required. SWGR manufacturer shall be

responsible for coordinating the design and suitability of flange connections of the

busbar ducting at the SWGR side.

The degree of ingress protection for indoor bus bar ducting shall be IP 42 or better,

and for outdoor bus bar ducting shall be IP 55 or better.

5.2.8 The incoming cubicles shall be located in the centre of the switchgear.

5.2.9 Back-to-back layout of switchgear is not permitted unless expressly requested and

approved by ADMA-OPCO.

5.2.10 Doors and covers to high power compartments, which may be opened without the

use of specialized tools, shall be equipped with mechanical interlocking and

padlocking facilities.

5.2.11 All components that will require periodic maintenance shall be easily accessible.

5.2.12 The switchgear assembly and their components shall be of standard type and

similar parts and components shall normally be interchangeable.

5.2.13 The number of module type shall be limited.

5.2.14 SWGR assemblies shall be of sheet steel construction at least 2 mm thick and shall

be extensible at both ends without cutting, drilling or welding any part of their

equipment. It shall be possible to erect extension units without isolating the SWGR

until it is required to connect the bus bars.

5.2.16 The maximum height shall be 2.0 meters. No meter panel or relay panel shall

extend above a height of 1.6 meters, nor be located below 200 mm.

5.2.17 Withdrawable equipment shall be equipped with a mechanical ‘stop’ to limit the

withdrawal distance.

5.2.18 Equipment shall be rated for the full load current specified, assuming 24 hour

average maximum ambient temperature with all functional units including circuit

breakers operating at their rated full load current, with no diversity.

5.2.19 LV switchgear and control gear assembly shall comply with IEC 61641 to assess

the ability to limit the risk of personal injury resulting from an internal arcing fault.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

12

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.3 Busbars

5.3.1 Bus bars and bus bar trunking systems (bus ways) shall be electrically refined

hard-drawn high conductivity copper, fully rated along their entire length, braced

and supported to withstand all dynamic and thermal forces and dielectric stresses.

Aluminum shall not be used for any current carrying components. Bus bars and

bus bar trunking systems (bus ways) shall comply with IEC 60439-2.

5.3.2 Bus bars shall be located in a separate compartment or chamber, or as required by

the Form 4b design.

5.3.3 All power connections shall be tin plated.

5.3.4 Unless otherwise specified in the requisition, the assembly shall be laid out for a

TN-S power system, i.e. with separate neutral and phase bus bars throughout the

system, including the droppers (also called risers). The main bus bars shall not be

rated lower than the incoming and sectionalizing circuit breakers. The main bus

bars shall be easily extensible at both ends. Current rating of neutral bus bars shall

be no less than 50% of the corresponding phase bus bars.

5.3.5 All LV bus bars and connections shall be fully insulated with flame retardant

materials, which comply with IEC 60332. Insulating caps shall be provided for

all connections, which can be removed for inspection and maintenance. Insulation

materials shall withstand, without damage, the effects of rated short time fault

withstand current of the SWGR.

5.3.6 All vertical bus bars and branches shall have a minimum rating not less than the

sum of the maximum full load ratings of all the possible outgoing units that can be

connected.

5.3.7 Bus bar joints and connections shall be corrosion-protected, secured to prevent

loosening and discharge-free.

5.3.8 Means shall be provided to prevent arc propagation across bus-section switching

units.

5.3.9 Bus bar insulations shall be marked red, yellow and blue according to the phase

and black for neutral.

5.3.10 Where bus duct is used to connect two or more sections of switchgear or motor

control center, the continuous ampere rating, momentary rating and bus bracing

shall equal or exceed rating of the main bus.

5.3.11 Momentary duty rating and bus bracing for motor control centers shall exceed the

maximum available fault current specified on drawings and/or data sheets.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

13

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.3.12 All covers providing access to bus bars shall carry a “caution, risk of electric

shock” symbol.

5.3.13 Barriers shall be provided, where applicable, to prevent arcs occurring in

incoming bus ducts or from cable terminations flashing to the main bus bars.

5.3.14 Where bus section breakers are specified, they shall be so arranged that one

complete section of bus bar and associated connections can be isolated and made

safe to work on while an adjoining section of bus bar is still energized.

5.4 Provisions for External Cable

5.4.1 Separate terminal boxes shall be provided for main and auxiliary circuit cables.

5.4.2 Provision shall be made to support external cables at intervals not to exceed 450

mm between cable entry and top or bottom of switchgear.

5.4.3 Main circuit cable terminals shall have means of locking connections.

5.4.4 Main and auxiliary circuits within an enclosure shall be segregated.

5.4.5 Undrilled gland plates shall be provided. Gland plates shall be non-ferrous where

single core cables are used.

5.4.6 Connections, to and from units incorporating circuit breakers, shall be covered

with solid insulation and have a short circuit current and time rating compatible

with cable ratings.

5.4.7 Connections and circuit wiring to load circuit fuses shall have a continuous

current rating compatible with largest fuse-link.

5.5 Earthing

5.5.1 An earth bar (hard drawn, high conductivity copper) suitably marked and sized,

shall extend to the length of the assembly.

5.5.2 Vertical earth bars shall be provided, to which each gland plate shall be bonded by

connections complying with IEC 60439-1.

5.5.3 All metallic non-current carrying parts of the switchgear assembly including

hinged doors shall be bonded together and connected to the earth bus bar. Care

shall be taken to prevent any damage to the bonding between doors and frames

during door movement.

5.5.4 It shall be possible to install cabling without dismantling any earthbar.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

14

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.5.5 Provision shall be made for joints between transport units. Joints in main earthing

conductors shall be corrosion protected, provide good electrical contact and be

secure.

5.5.6 Provisions shall be made, adjacent to the cable terminations, for earthing cable

armour and screen to the earth bar.

5.5.7 Each wiring circuit shall be identified by green/yellow strips.

5.5.8 Within each cable box, a brass stud shall be provided to connect any earth core in

the external cable.

5.5.5 Control and instrument transformer secondary shall be earthed via a link.

5.5.6 The method by which the neutral circuit of the incoming transformer is earthed

shall be defined in the data sheet.

5.5.7 Earthing switches shall have a rated short circuit making capacity not less than

the rated asymmetrical (peak) making current specified on the project data sheets.

5.6 Interlocks

5.6.1 Mandatory interlocks shall be mechanical and shall comply with IEC 60947-5-1.

5.6.2 Mechanical interlocks shall be provided to prevent:

a. Door of functional unit being opened unless the functional unit is isolated and

locked-off.

b. A functional unit being energised unless the door is closed.

c. Simultaneous closure of devices that may cause a fault by simultaneous

closure, for example ‘forward’ and ‘reverse’ contactors.

d. A withdrawable unit being withdrawn unless unit is isolated. It shall not be

possible to close isolating device unless the unit is in either a service or test

position.

e. A withdrawable unit being placed in its service position unless the isolating

device is open.

f. Closure of those isolators associated with mechanically latched contactors

when the contactor is in the closed position.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

15

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.6.3 Interlocks shall comply with the following: -

(Means to achieve these interlocks to be furnished by the vendor)

a. Any interlock capable of being defeated without the use of special tools for a

particular safe purpose shall be provided with a padlocking facility.

b. The test facility within starters and contactor outgoing feeders shall prevent

door closure or replacement of a withdrawn unit whilst the test supply is

connected.

c. Disconnectors and isolators shall be interlocked to prevent their operation

unless the associated circuit-switching device is ‘open’.

5.6.4 Electrical interlocks shall be “fail safe.”

5.7 Locking Arrangement

Locking/Padlocking facilities shall, at least, be the following:

5.7.1 All shutters in their ‘closed’ position.

5.7.2 All ‘local and remote’ selector switches in either position.

5.7.3 All racking devices in the ‘disconnected’, ‘service’, or ‘earth’ position.

5.7.4 Compartment doors shall be lockable with an integral lock.

5.7.5 All isolating devices in the ‘off’ position.

5.7.6 All circuit breakers and contactors in their ‘off’ and ‘disconnected’ (or

‘withdrawn’) positions.

5.7.7 It shall not be possible to padlock any switching device in its closed position,

except the switches used for earthing.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

16

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.8 Circuit Breakers

5.8.1 General

a. Circuit breakers shall comply with IEC 60947, Parts 1 and 2, utilization

category B suitable for uninterrupted duty.

b. The performance of circuit breakers specified in IEC 60947, Parts 1 and 2

shall be verified when they are installed within the assembly for the exact

configuration supplied.

c. Circuit breakers shall be withdrawable.

d. Circuit breakers for incomers and the bus ties of a same switchgear assembly

shall be identical.

e. Circuit breakers shall be of the type, duty and rating as specified in the project

single line diagram(s)/enquiry documents.

f. The short circuit breaking capacity of all circuit breakers shall be appropriate

to the specified system short circuit rating.

g. Circuit breakers shall be used for motor starters where the kW rating of the

motor is too high for a fused-contactor or MCCB-contactor combination.

h. The following provisions are mandatory for main circuit breakers : -

h.1 The withdrawal or engagement of a circuit breaker shall not be possible

unless it is in the ‘open’ position.

h.2 The operation of a circuit breaker shall not be possible unless it is in the

‘service’, ‘disconnected’, ‘removed’, ‘test’ or ‘earthing’ position.

h.3 It shall not be possible to close the circuit breaker, switch or contactor in the

‘service’ position unless it is connected to the auxiliary circuit.

5.8.2 Operating Mechanism

a. Operating mechanisms shall:

a.1 Include an anti-pumping device.

a.2 Incorporate a local manual trip facility fitted with a guard to preclude

inadvertent operation.

a.3 Give positive indication of switch position.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

17

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

b. All CBs with automatic close operations shall have the manual close facility

on the cubicle pad-lockable in the non-operative position. The mechanical trip

mechanism shall not be inhibited when the close facility is locked OFF.

c. If the standard equipment has a local manual close facility, then this shall be

disabled on all CBs having synchronizing check relays and on any other CBs,

which are interchangeable.

d. The type of closing mechanism shall be stored energy by motor charged

spring and manual charging, with manual and electric closing release.

e. Directly driven mechanical indication of the CB position visible from the

front of the cubicle.

f. For incomers, bus-section and switchboard inter-connectors, which have their

operating mechanisms fitted with d.c. shunt-trip circuits (i.e. energize to trip),

they shall also be fitted with trip circuit supervision. This supervision shall

not alarm when the CB is isolated.

g. Operating mechanisms fitted with electric closing circuits shall have

interlocks so that closing cannot be initiated when a trip condition exists e.g.

lockout relay operated and not reset.

h. An early closing contact shall be provided in the trip circuit of circuit

breakers. It shall be arranged such that if it is attempted to close while a trip

condition exists, the breaker will trip before the main contacts close.

i. Close and trip circuits shall be protected by fuses or MCBs and arranged so

that it is not possible for the closing mechanism to operate if the protective

device is either blown, tripped or in open position. The protection shall be

coordinated such that under all conditions, the fuse or MCB nearest to the

fault operates first without damaging or reducing the life or performance of

other fuses or MCBs.

j. It shall be possible to operate each circuit breaker in the isolated position,

with all auxiliary circuits operational.

k. Unless otherwise specified, When the switchboard has two or more sections

of busbars, then the incoming and bus section circuit breakers shall be

provided, as a minimum, with a momentary paralleling interlocking scheme

and check synchronizing facility. This is necessary to ensure that a no-break

transfer can be achieved.

l. Incoming circuit breaker protection and tripping circuits shall be provided

with facilities for 2-way intertrip with sending end circuit breaker via

appropriate master trip/intertrip relays wired to outgoing terminals.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

18

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.8.3 Safety Shutters

a. Automatic safety shutters shall cover fixed isolating contacts.

b. Shutters shall be individually operated by withdrawable part.

c. Shutters shall be opened and closed by a positive mechanical drive.

d. Facilities shall be provided to padlock shutters in closed position.

e. Means shall be provided to facilitate testing of shutters.

f. Shutters shall be colored and labeled in accordance with Table 1 below.

Table 1

Equip Shutter Letter

Label

ment Colour Colour

Busbars

Busbars Red Danger Black

Volts

Circuit

Circuit Yellow Danger Black

Volts

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

19

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.9 Motor Starters and Contactor Feeders

5.9.1 General

a. Motor starters and contactor feeder units shall comprise fuse or Moulded

Case Circuit Breaker (MCCB) protected contactors.

b. All motor starters and contactor feeders shall be withdrawable type.

c. Starters (DOL/Star delta/ Rheostatic rotor) shall comply with IEC 60947-4-1.

d. Autotransformer starters shall be suitable for Class 12 intermittent operating

duty (12 starts per hour). They shall have taps at 50%, 65% and 80% voltage.

Transformers shall be selected assuring that motors have a starting

characteristic in accordance with IEC 60034.

e. All motor starters shall be provided with phase failure or single phasing

protection and over load protection.

f. All motor starters shall have operation counters.

g. Contactors shall comply with IEC 60947-4-1.

h. Mechanical endurance of contactors shall not be less than 10,000,000

operations. Category for use shall correspond to conditions stipulated in IEC

60947-4-1 and shall be AC 3.

i. Thermal overload protection shall be performed as follows:

i.1 Motors < 63A : Direct thermal protection.

i.2 Motors > 63A: Three-pole thermal protection against single phase and

overload operation supplied by three current transformers (1A) installed in

the removable part to ensure interchangeability of racks equipped with

contactor of the same rating.

i.3 Motors > 110 kW: Digital protection relay may be used when required for

following protections: 27-37-46-49-50-51-51LR-66.

j. All contactors shall trip in the event of loss of electricity at the main bus bars.

k. All motor contactors shall close upon restoration of the electricity at the main

bus bars if a ‘close’ signal exists.

l. Co-ordination between starters or contactor feeders and associated short

circuit protective devices shall be in accordance with IEC 60947-4-1, Type

‘2’. The manufacturer shall provide test evidence to verify that the specified

co-ordination has been achieved.

Where type ‘2’ co-ordination is achieved by use of a fuse link less than the

maximum capacity of the fuse holder, then a label shall be provided with the

following legend:

‘Maximum fuse rating ______ A to maintain IEC 60947-4-1 type ‘2’

coordination’.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

20

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

m. Motor starters with full load current exceeding 30A shall be provided with

instantaneous earth fault protection arranged to trip at 15% of full load

current or 30A, whichever is smaller.

n. Contactor feeders with main fuses or MCCBs exceeding 200 A shall be

provided with earth fault protection.

o. Earth fault protection shall be either a direct connected hand reset earth

leakage circuit breaker or an instantaneous hand reset earth fault relay.

p. Motor management relays: If specified in project single line diagrams, motor

management relays with complete protection and monitoring functions shall

be provided. The protection functions shall be as stated in the Protection

single line diagrams.

q. VFD/Soft starters for the motor feeders shall be as per the requirements

stipulated elsewhere or otherwise, ADMA’s advice on the same shall be

sought.

5.9.2 Control Circuit

a. Unless otherwise specified, lockable local/remote switches shall be provided.

Local control shall only be possible in test position.

Individual control supplies shall be provided for each motor starter and

contactor feeder. AC control supplies shall be derived from the circuit side of

the main circuit isolating device.

b. Primary windings of control transformers shall be connected via a fuse for

phase connections and a link for neutral connections. One pole of the

secondary winding shall be earthed via a link and the other pole fused.

c. The control circuit auxiliary transformer shall be suitably over-rated above

the consumption of the LV contactor coil and other devices in the control

circuit.

d. Where a 110V AC control supply is provided, it shall be derived from two

phases of the main circuit via a transformer in accordance with IEC 61558. A

metallic inter-winding screen shall be provided, earthed to frame of

transformer.

e. Phase-to-neutral control supplies shall be connected via a fuse and a link.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

21

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.9.3 Auxiliary Contacts for Power CBs and Contactors

Circuit breakers and contactors shall be provided with auxiliary switch contacts

with the following features:

a. The bank of auxiliary contacts shall be driven positively into both the open

and closed positions by the main device operating mechanism. Auxiliary

contacts shall be wired to outgoing terminal blocks and identified as shown

on the manufacturer’s drawings. These contacts shall be in addition to those

required for the control circuits within the cubicle.

b. All auxiliary switches and their circuits shall be capable of carrying a current

of at least 10 amps continuously.

c. Unless stated on the data sheets, the auxiliary switches shall be capable of

breaking at least a 5 ampere inductive load at 110V DC, with a time constant

of 20 milli-seconds.

d. The manufacturer shall advise the current ratings of all auxiliary switches.

e. The manufacturer shall advise in his tender documentation, the maximum

number of normally open, normally closed, changeover and convertible

switches that can be attached to and be operated from each type of CB.

f. Auxiliary switches for motor anti-condensation heaters shall be double-pole

type.

g. When specified on the project data sheets, the auxiliary switch contacts for

each motor heater supply shall be provided so that the heaters are energised

when the main switching device is ‘open’. When the main switching device is

isolated, the heater supply shall also be isolated.

5.10 Fuses, Fuse Holders and Links

5.10.1 Fuses shall comply with IEC 60269, Parts 1 and 2. It is preferable that fuse

holders are self colored black and link holders are self colored white.

5.10.2 Unearthed poles of supplies shall be fused. Earthed poles shall be connected via a

link holder.

5.10.3 Links used solely for earthing of control supplies and current transformers shall be

of a type readily removable for test purposes, with the use of tools if necessary.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

22

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.11 Indicating Instruments

5.11.1 Analogue instruments (Ammeters are must with suitable scale) shall be flush

mounted, complying with the relevant parts of IEC 60051, class index 2.5.

External zero adjustment shall be provided.

5.11.2 Incoming units shall be equipped with a digital and analogue means for measuring

voltage and current in all phases. Analogue voltmeters and ammeters shall comply

with IEC 60051-2 and shall be supplied with selector switches arranged to

measure each line-to-line voltage and current in each phase.

5.11.3 If specified in the enquiry documentation, incoming units shall be equipped with a

3 phase, 4 wire, unbalanced load kilowatt-hour meter of digital or analogue type

and shall comply with IEC 60051-3.

5.11.5 Remote ammeters shall be fed from current transformers. The use of current

transducers should be considered for certain applications.

5.11.6 If specified in the enquiry documentation, outgoing units shall be equipped with

an ammeter and/or kilowatt-hour measurement device.

5.11.7 Analogue ammeters connected in motor starter main circuits shall have

suppressed upper scale readings to match with the motor starting currents. If no

other information is available then a suppressed scale to at least 6 times the range

of the ammeter should be selected.

5.11.8 Analogue ammeter scales shall be selected such that full load current appears

between 50% and 80% of the normal scale angular deflection.

5.11.9 Ammeters for motors shall have suppressed scales at the high levels of currents,

so that at least 8 times full load current can be seen on the ammeter without it

being damaged.

5.11.10 Ammeters shall be fed from CT’s for full load currents exceeding 40 A.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

23

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.12 Protective Relays

5.12.1 Protection shall be as specified in the Single line diagrams and/or other relevant

documents.

5.12.2 Electrical protective relays shall comply with IEC 60255.

5.12.3 The relays shall be flush-mounted and fitted on the front of the cubicle within

easy reach for the operator to reset them. They shall not be mounted near the

floor. Hand resetting shall be from outside the relay case.

5.12.4 Protective relays shall be designed to withstand the output current of CTs for at

least the specified withstand time of the SWGR.

5.12.5 Protective relays shall have adequate input and output (alarm and trip) contacts

wired to terminals. Contact multiplication is not acceptable. Manufacturer shall

provide comprehensive manuals/softwares of the relays.

5.12.6 Tripping circuits and contacts shall be volt-free and separate from other circuits

within the relay.

5.12.7 For the purposes of testing, test blocks shall be provided to facilitate secondary

current or voltage injection testing. If test blocks are not available as standard

items then the manufacturer shall describe in the tender documentation, an

alternative method of testing for each type of relay.

5.12.8 Unless otherwise stated, all relays shall be electronic type capable of

communicating with SCADA and DCS systems. The manufacturer shall verify

the existing facilities and describe in detail at the tender stage all the relays he

proposes to use and the network communication details e.g. digital software

language, protocol, hardwire or optical medium, speed of transmission, hierarchy

and management of information exchange. The software for such protective relays

shall be very ‘user friendly’ and menu driven.

5.12.9 Motor overload protection shall be by 3-pole thermal overload relays

incorporating single phasing protection and ambient temperature compensation

and shall comply with IEC 60947-4-1.

5.12.10 Where trip circuit supervision is required, the trip circuit wiring including the

lockout relay shall be arranged so that the supervising relay operates if any of the

circuit wiring becomes discontinuous. Supervision relays shall monitor the trip

circuit when the CB is open or closed, by a normally energized ‘HEALTHY

TRIP’ indicating lamp.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

24

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.12.11 Thermistor control units shall comply with IEC 60034-11.

5.12.12 Lock out relays shall be provided with local manual reset.

5.12.13 The manufacturer shall clearly state whether any external resistances or

impedances are required in the protection circuits. Details shall include ohmic

values, rated power dissipation and calculations for knee-points voltages, CT and

VT burdens, wiring route impedance etc.

5.12.14 Where microprocessor based protection relays are used, protection setting shall be

retained within relay without external power supply available.

5.13 Current Transformers

5.13.1 Current transformers shall comply with IEC 60044-1.

Standard ratios shall only be used. Separate CTs shall be used for metering &

protection. All protection CTs shall be 5P20 and metering CTs shall be class 1.0.

Class X and Class 0.5 CTs shall also be supplied, if required, as per the protection

scheme.

The CT volt-ampere (VA) shall be chosen with at least a plus 20% margin to

allow for future additional load. The VA ratings should also consider the scheme

in full including external wiring. In any case, VA shall NOT be less than 10.

5.13.2 Where current transformers are not readily accessible with the equipment

energized, duplicate rating plates shall be fitted in an accessible location.

5.13.3 Current transformers shall be of dry insulation type (complete coating of

thermosetting synthetic resin).

5.13.4 Current transformers shall have a short time current rating at least equal to that of

switchgear or let-through current of main circuit fuse. Unless specified otherwise,

the primary winding shall match with the current rating of the CB or contactor.

5.13.5 The manufacturer shall submit detailed calculations to confirm that the VA

ratings of the CTs are adequate to operate the relays under worst-case fault

conditions, and also, suitable for any third party supplied relays/meters (REF,

Differential protection etc).

5.13.6 Current transformers shall have 1 ampere secondary windings, unless specified

otherwise on the data sheets.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

25

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.13.7 All remote ammeter circuits shall be fed from 1 amp secondary windings. Their

accuracy shall be, as a minimum, Class 1 to IEC 60044, unless otherwise

specified on the data sheets. Their saturation characteristics shall be such that

meters and instruments are not damaged due to the flow of fault currents.

5.13.8 Location of CTs for all circuits shall be on the cable side and shall be accessible

safely without having to de-energize the bus bars.

5.13.9 Secondary windings shall be connected to terminals integral within current

transformer.

5.13.10 Current transformer circuit wiring connected to external circuits shall be provided

with captive-type shorting links at outgoing terminals.

5.13.11 Test Certificates and magnetization curves of each CT shall be submitted by the

manufacturer.

5.13.12 The minimum cross section for wiring of current transformer secondary circuits

and other secondary wiring shall be 600/1000V grade, PVC insulated conductors

of 2.5 mm2 size. For wiring to other cubicle circuits (i.e external circuits), a

minimum cross section of 4.0 mm2 shall be used for the CT connections.

5.14 Voltage Transformers

5.14.1 Voltage transformers shall comply with IEC 60044-2.

5.14.2 Voltage transformers shall be of dry insulation type (complete coating of

thermosetting synthetic resin).

5.14.3 The accuracy shall be Class 1 for measurement functions and Class 3P for

protective relay functions, unless otherwise specified on the data sheets. VTs

offered shall also meet the requirements of generator AVR vendor, if applicable.

5.14.4 The secondary winding nominal voltage shall be 110V AC between phases unless

otherwise stated on the data sheets or on the single line diagrams.

5.14.5 The minimum cross section for wiring of voltage transformer secondary circuits

shall be 600/1000V grade, PVC insulated conductors of 1.5 mm2 size.

5.14.6 Voltage transformer primaries shall be protected by removable HRC fuses and

secondaries shall be suitably protected.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

26

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.15 Isolating Devices

5.15.1 Isolating devices shall consist of a MCCB, disconnector-fuse or a fuse-

disconnector.

5.15.2 Disconnector-fuse and fuse disconnectors shall be to IEC 60947-3 for

uninterrupted duty, AC-23B utilization category.

5.15.3 Rated fused short-circuit current of a disconnector-fuse or fuse-disconnector shall

be equal to the value specified in the Data Sheets.

5.15.4 The mechanism shall be of the independent manual type.

5.15.5 External circuits not deriving their supply from the unit shall be connected via

auxiliary contacts of the isolator.

5.15.6 Isolating devices shall be self-aligning.

5.16 Indicating Lamps

5.16.1 All power circuit breakers, motor starters and contactor feeder shall be fitted with

panel mounted lamps to indicate their status and the state of their tripping circuits.

5.16.2 Colours for indicating lamps shall comply with IEC 60073. Indicating lamps for

motor feeders shall be red for running, green for stop and amber for trip.

5.16.3 Lamps shall be of non-filament type, e.g. multi-segment LED or neon.

5.16.4 Indicating lamps shall be flush mounted with a fitment to ensure they cannot

rotate even if retaining nut is not fully tightened.

5.16.5 Lamp holders and lenses shall be designed to dissipate heat produced by largest

lamp that can be fitted, without deterioration or discolouration.

5.16.6 All lamps operating at the same voltage to be interchangeable.

5.16.7 Lamp voltages shall be at least 110% of nominal supply voltage.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

27

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.17 Terminals and Terminations

5.17.1 A minimum of 20% spare terminal blocks shall be provided.

5.17.2 Terminals of either screw clamp or stud type shall be provided for connection of

all wiring. Pressure plates shall be incorporated such that no screws or nuts shall

bear directly on wiring. Securing arrangements shall incorporate a locking feature.

5.17.3 Screw clamp type terminals shall be arranged so only one conductor is secured by

one screw clamp.

5.17.4 When screw clamps are used, multiple connections at one point shall be effected

by means of cross connecting links.

5.17.5 Wiring terminated on stud type terminals shall be fitted with straight-shanked

compression type cable lugs.

5.17.6 Terminals shall be provided for termination of external cabling.

5.17.7 All wiring for external connections and for analogue circuits shall be brought out

to individual terminals on a readily accessible terminal block.

5.17.8 Terminals provided for external connections exceeding 6 mm2 shall be suitable

for straight-shank compression type cable lugs.

5.17.9 Terminals for different a.c. voltages shall be separated from each other by a

barrier and completely segregated from d.c circuits.

5.17.10 Terminals shall be identified by means of an engraved, embossed or similar type of

permanent marker.

5.17.11 Terminals in circuits operating at voltages of 110V and above shall be shrouded

unless interlocking precludes live access.

5.17.12 Terminal blocks with shrouds shall be grouped by operating voltage and each

group shall be labelled ‘Danger ... Volts’.

5.17.13 Terminal blocks for tripping supplies shall be labelled ‘tripping supply’.

5.17.14 Terminal blocks shall have separate terminals for internal and external

connections.

5.17.15 Main circuit terminals shall be marked with phase colours, red, yellow and blue.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

28

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.18 Control Devices

5.18.1 Control relays, push buttons and related control switches shall comply with IEC

60947-5-1.

a. Control relays shall operate between 85% and 110% of supply voltage

measured at busbars.

b. Control relays should remain energized without chatter at 75% of supply

voltage measured at busbars.

c. Plug-in control relays are not acceptable.

5.18.2 Push-button switches, except stop switches, shall have a full shroud to prevent

inadvertent operation.

5.18.3 Stop push buttons shall be stay-put type, manually reset and coloured red.

5.18.4 Start push buttons shall be coloured green.

5.18.5 Stop devices in stop position shall prevent closing of switching device.

5.19 Control

5.19.1 Circuit breakers and contactors shall have a manual trip facility local to panel with

a padlocking facility to prevent unauthorized use.

5.19.2 Circuit breakers with electrical closing and contactors that are remote controlled,

will have closing device local to panel and shall be inoperable when circuit

breaker or contactor is in normal operating position.

5.19.3 Circuit breakers with electrical closing, and withdrawable type contactors shall be

provided with a means of operational testing when in test, or withdrawn isolated

position.

5.19.4 Tripping and closing device local to panel shall be operable in the test position. In

test position, all other remote and automatic control circuits shall be inoperable.

5.19.5 Emergency ‘stop’ control for motor starters shall form part of primary stop control

circuit and interposing relays should be avoided.

5.19.6 Release of any emergency ‘stop’ control shall not cause re-energisation of

equipment concerned.

5.19.7 Manufacturer shall advise maximum control distance recommended for:

a. Interposing relays.

b. 48/110V DC Control.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

29

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.20 Internal Wiring and Marking

5.20.1 Internal wiring conductors shall be 7-strand, 1.5 mm2 minimum.

5.20.2 No more than two wires shall be connected to any one terminal.

5.20.3 Wiring shall be fitted with interlocking numbered identification ferrules.

a. Ferrules shall be fitted at both ends of wire.

b. Ferrules shall be indelibly marked with cross-references.

c. Ferrules shall not be removable without disconnecting the termination.

d. Paper ferrules are not acceptable.

e. Wiring numbering shall be done in such a way that they are read from the

terminals end towards the cable.

5.20.4 Preferred bus wiring methodology:

a. Wiring for interlocking, alarms etc. shall be routed between compartments in

conduit.

b. Tripping power shall be routed between compartments in conduit separate

from all other wiring.

c. Wiring for a specific functional unit shall not be routed through another

functional unit.

5.20.5 Fuses shall protect wiring for circuits connected to bus wired power supplies.

5.20.6 Fuse arrangements shall ensure that an electrical circuit fault within one unit will

not cause loss of supplies to other units.

5.20.7 Control and internal wiring shall be easily identifiable and traceable throughout

circuit schematic and/or wiring diagrams.

5.20.8 Switchgear unit inter-wiring shall be in duct and/or as per manufacturer’s

standards, but properly supported.

5.20.9 Solder connections are not acceptable.

5.20.10 Conductor ends shall be fitted with an insulating shank crimped terminating

device.

5.20.11 Conductor insulation shall be PVC or approved equal.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

30

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.20.12 Colour coding shall be as specified in Table 1 below:

Table 1

Type of Wiring Insulation colour Identification Ferrule

colour

AC Black Phases: Red, Yellow and

Blue

Neutral: None

DC Grey None

Earth Green/Yellow None

Circuits energized Orange # None

from outside the

switchgear unit

# Coloring the insulation orange is the preferred method of identifying circuits

that are energized from outside the switchgear unit. If this cannot be achieved,

then the minimum requirement is that terminals associated with externally

energized wires carry warning labels.

5.20.13 Switchgear unit inter-wiring ducts shall be accessible without de-energizing any

circuits. Sufficient space shall be left in ducts and trunks for an additional 10% of

wires to be installed.

5.20.14 Control, secondary and logic-level wires shall have marker attached at each wire

termination. Markers shall be:

a. Heat shrinkable.

b. Permanent sleeve-type.

c. Made with typewritten characters.

d. Located 20 mm minimum, to 50 mm maximum, from lug.

f. Visible from termination.

5.20.15 Care shall be taken to avoid any damage to the internal wiring throughout the

switchgear.

5.20.16 Wiring terminals shall be identified in accordance with IEC 60445 and IEC

60947-1, Annexure L.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

31

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.21 Anti-Condensation Heaters

5.21.1 Anti-condensation heaters shall be provided in each tier and each cubicle. One or

more suitably rated anti-condensation heaters shall be required in each enclosed

compartment of each vertical tier, e.g. metering, instrument, distribution

compartments. The heaters shall be thermostatically controlled.

5.21.2 Heaters shall be suitable for operation at the voltage specified in the data sheet.

5.21.3 Heaters shall have minimum degree of protection IP 50 to IEC 60529.

5.21.4 Heaters shall be wired to a common terminal block in each transportable assembly

for connection to an external supply. These terminals shall be easily accessible

when the assembly is packed for shipping. The heater wiring shall be arranged so

that one common circuit can be provided when the switchgear is installed.

5.22 Name plates and Labels

5.22.1 Danger and warning labels shall comply with IEC 60417 and ISO 3864.

5.22.2 Other labels and terminal labels shall comply with IEC 60445.

5.22.3 Labels shall be in English.

5.22.4 Circuit label designations (at front and rear of panel, on the fixed and removal

parts, at the main and auxiliary cable terminations) shall be in accordance with the

switchgear assembly single line diagram and associated data sheets.

5.22.5 Nameplates/labels shall be secured with stainless steel screws.

5.22.6 Switchgear shall be identified with a label at front and rear and marked with

circuit designation, rated current, design temperature, description of and

connected equipment number.

5.22.7 Assembly nameplate shall comply with section 5.1 of IEC 60439-1 and shall also

include the following:

a. Vendor project ref no.

b. Month & year of manufacture.

5.22.8 Where appropriate, a label containing the name, type and manufacturer of the

dielectric medium used shall be attached to the current and voltage transformers to

ensure ultimate safe disposal at the end of the working life.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

32

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.22.9 Labels shall be provided to identify all equipments/components/devices as per the

drawings.

5.22.10 Where two or more components of a particular type are incorporated, each

individual component of that type shall be provided with a unique identification

label.

5.22.11 Main circuit fuse-links shall have a label with:

a. Manufacturer’s designation.

b. Type reference.

c. Number of fuse-links per phase.

d. Maximum current rating per phase.

5.23 Interface with Electrical Control System (ECS) and Process Control System

5.23.1 Interface with Electrical Control System (ECS)

When specified, switchgear assembly shall be connected to an Electrical control

system dedicated to control the general electrical system. A Programmable Logic

Controller (PLC) or dedicated Remote Control Unit (RCU) for the Electrical

Control System (ECS) shall be installed within each switchgear assembly by the

Manufacturer.

The Manufacturer shall be responsible for the co-ordination with ECS supplier to

ensure the proper data transmission between the switchgear assembly and the

ECS.

It shall be possible to isolate all incoming ECS controls for maintenance and

manual operation.

5.23.2 Interface with Process Control System

The required indications and alarm signals shall be as per the project

requirements.

Status signals shall be originated from volt free contacts.

Process information can be sent through a communication network if specified in

the single line diagrams/requisition.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

33

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

5.24 Painting

5.24.1 The carbon steel frames shall be painted in accordance with PSN 620 of ADMA-

OPCO Painting Manual MNL-01.

5.24.2 Manufacturer is allowed to propose his standard painting procedure, which shall

be subject to ADMA-OPCO approval.

5.24.3 Finishing coat shall be the standard color of the Manufacturer unless specified

otherwise in the data sheet.

5.25 Inspection and Testing

5.25.1 General

a. Requirements for witnessing type and routine tests should be agreed with the

manufacturer at the enquiry stage.

b. Tests shall be carried out in accordance with this Specification and referenced

external standards, unless otherwise agreed.

c. Manufacturer shall state in his quotation if normal test arrangements are not

adequate, or if he is not capable of carrying out specified tests. Performing

alternative tests shall be approved by ADMA-OPCO before order is awarded.

d. Some or all tests may be witnessed by ADMA-OPCO or the inspector

representing them. The witnessed tests shall be indicated on the data sheets or

accompanying documents.

e. The Manufacturer shall agree with ADMA-OPCO two weeks in advance of

the test dates.

5.25.2 Type Tests

a. For each type and rating of switchgear offered, the manufacturer shall provide

certificates to prove that the design of switchgear has been successfully fully

type-tested in accordance with IEC 60947.

b. Type-test verification of dielectric properties for each individual unit as

detailed in IEC 60439-1 shall be made.

c. Type-tests shall have been undertaken by a recognized testing authority.

Testing authorities should preferably be subject to independent approval and

audit e.g. KEMA and ASTA. However, where manufacturer’s test facilities

are administered as independent organizations and are considered reputable

for the tests being undertaken, then these may also be considered to be

acceptable.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

34

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

d. Copies of type-test certificates shall be provided with quotation. When

appropriate type test certificates do not exist, tests shall be made at the time of

manufacture of the equipment to which this specification refers, subjected to

ADMA-OPCO approval.

e. Any specific project related type test may be required which shall be

indicated in the data sheet.

f. Motor starters and contactor-fuse-isolator combinations shall be type tested in

accordance with IEC 60947 and shall include special tests to verify that the

Type 2 co-ordination has been achieved.

g. A switch of each type and rating shall have been Type Tested in accordance

with IEC 60947, and certificates shall be made available.

5.25.3 Routine Tests

a. Before the SWGR leaves the factory, the manufacturer shall carry out the

witnessed routine tests (FAT) in accordance with IEC 60439-1 on the total

assembly or parts thereof if the SWGR is to be delivered at different time

intervals, and the results shall be recorded in a test report.

b. Witnessed tests shall be carried out on every cubicle and every tier of the

assembled SWGR.

c. Contactors, Disconnectors, isolators and switches shall be tested in

accordance with IEC 60947.

d. VTs shall be subject to the Routine Tests in accordance with IEC 60044-2

and tested for correctness of ratio and polarity.

e. CTs shall be subject to the Routine Tests in accordance with IEC 60044-1 and

tested for correctness of ratio and polarity.

f. The SWGR shall be visually inspected for technical execution and conformity

with the latest issue of the approved drawings and documents of the

requisition. Spot checks shall be made to verify the following:

f.1. Completeness of the data on the general equipment nameplate.

f.2 Degree of protection of the enclosure.

f.3. Degree of protection within the compartments.

f.4. Effectiveness of safety shutters, partitions and shrouds.

f.5. Effectiveness of operating mechanisms, locks and interlocking systems.

f.6. Insulation of the bus bar system.

f.7. Creepage distances and clearances.

f.8. Proper mounting of components.

f.9. Internal wiring, trunking and cabling systems.

f.10. Correct wiring of main and auxiliary circuits.

f.11. Suitability of clamping, earthing and terminating arrangements.

f.12. Correct labeling of functional units and auxiliary devices.

f.13. Availability of the earthing system throughout the SWGR.

f.14. Inter-changeability of electrically identical components.

f.15. Non-inter-changeability of mechanically identical but electrically different

components.

0 06-06 Issued For Implementation

Rev. Date Description / Text Affected

STANDARD FOR LOW VOLTAGE SWITCHGEAR AND CONTROL GEAR

ADMA-OPCO STD-143 PAGE

35

ADMA-OPCO/SEF/008 Rev. 0 Sheet 1 of 1

g. The following tests shall be witnessed:

g.1. The insulation resistance test shall be carried out separately between each

phase and the neutral against the earth, with the remaining phases and

neutral connected to earth. These tests shall require all the manual and

latched type switching devices in their closed positions and with all the

main fuses installed. The insulation resistance measured shall be at least 10

mega-ohms when a d.c. voltage of 1.1 times the rated a.c. voltage of the

equipment (1000V a.c.) is applied.

g.2. Dielectric tests to IEC 60439-1, but for 1 minute. The test voltage shall be at

least, 2500 V a.c. for the main power circuits, and 2 times the rated voltage

plus 1000 V a.c. with a minimum of 1500 V a.c. for the control and

auxiliary circuits.

g.3. Ratio and polarity of all current and voltage transformers shall be checked

by primary injection.

g.4. Operational tests of protective relays and circuits by primary injection of

current or voltage as required.

g.5. Interchangeability test.

g.6. All contactors and relays shall be checked to ensure that they close without

chatter at 85% supply voltage and remain closed at 75% supply voltage.