Académique Documents

Professionnel Documents

Culture Documents

Piping

Transféré par

Nurcahyo Djati WTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Piping

Transféré par

Nurcahyo Djati WDroits d'auteur :

Formats disponibles

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

2 of 267

RECORD OF REVISIONS

Rev Implemented

Section Page Company Comment Explanation

No (Y/N)

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

3 of 267

TABLE OF CONTENTS

1. INTRODUCTION ......................................................................................................................5

1.1 General ...........................................................................................................................5

1.2 Scope..............................................................................................................................6

2. DEFINITION AND ABBREVIATIONS ......................................................................................7

2.1 Definition ........................................................................................................................7

2.2 Abbreviations ................................................................................................................7

3. REFERENCE, CODE AND STANDARDS ...............................................................................8

3.1 Project Specifications ...................................................................................................9

3.2 Santos Engineering Standard ......................................................................................9

3.3 Codes, Standards & Regulations .................................................................................9

3.3.1 American Society of Mechanical Engineers ......................................................9

3.3.2 ASME Boiler & Pressure Vessel Code .............................................................10

3.3.3 American Petroleum Institute ...........................................................................10

3.3.4 NACE International ............................................................................................10

3.3.5 Australian Standards .........................................................................................10

3.3.6 American Society for Testing and Material .....................................................11

3.3.7 British Standard .................................................................................................11

3.3.8 Det Norske Veritas .............................................................................................11

4. DESIGN PRINCIPLES ...........................................................................................................12

4.1 Design Values ..............................................................................................................12

4.2 Valves ...........................................................................................................................12

4.2.1 Valve Operator....................................................................................................14

4.2.2 Valve Materials ...................................................................................................14

4.3 Flanges & Fittings .......................................................................................................15

4.4 Studs, Nuts & Gaskets ................................................................................................16

4.5 Threaded & Socket Welded Piping ............................................................................16

4.6 Branch Connections ...................................................................................................17

4.7 Supports, Anchors & Guides .....................................................................................17

4.8 Materials .......................................................................................................................17

4.9 Tube Fittings ................................................................................................................17

4.10 Tubing ..........................................................................................................................17

4.11 Process Vents and Drains ..........................................................................................18

4.12 Pressure Instrument Connections .............................................................................18

4.13 Thermowells ................................................................................................................18

5. PIPING AND VALVE SPECIFICATION CODE......................................................................18

5.1 Pipe Specification Code Format ................................................................................18

5.1.1 Identifier 1 – Pressure Rating ...........................................................................19

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

4 of 267

5.1.2 Identifier 2 – Material Type ................................................................................19

5.1.3 Identifier 3 – Corrosion Allowance ...................................................................19

5.1.4 Identifier 4 – Supplementary Code ...................................................................19

5.2 Valve Specification Code Format ..............................................................................24

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

5 of 267

1. INTRODUCTION

1.1 General

The Ande Ande Lumut (AAL) oil field is in the North-West Natuna Production Sharing

Contract (PSC) as shown in Figure 1-1. The block is in Indonesian waters in the South

China Sea and the location is in the West Natuna area in a water depth of approximately

73m. The block covers some 4,400 sq. km. There is presently no other infrastructure in the

PSC.

Figure 1-1: Location of Ande Ande Lumut Field

The Ande Ande Lumut (AAL) field development consists of a fixed structure production

wellhead platform (WHP) and an attendant spread-moored Suezmax FPSO for processing,

storing and offloading the crude.

The unique feature of the facilities has the WHP located 45m (riser porch to riser porch) on

the port side of the FPSO. The FPSO is to be close-moored and bridge-linked to the WHP.

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

6 of 267

Figure 1-2 General Arrangement of AAL Complex

Liquids production from the numerous wells located on the WHP are delivered to the FPSO

via flexible flow-lines suspended (catenary) between the WHP and FPSO. Similar catenaries

are used to deliver service water, diesel fuel, utility air and various chemicals from the FPSO

to the WHP. Facilities on the riser porches have been allocated for future fuel gas, fire water

and water injection flexible pipes. Electrical power (12 MW) for the production operations on

the WHP is supplied by the power generation equipment on the FPSO by suspended cables

to the WHP.

A nominal Aframax shuttle upload from the FPSO will be conducted once per month. The

proposed method for an upload is that of tandem mooring the shuttle with the FPSO and

using floating hoses for the crude oil transfer. Given due regard to the nature of the crude

being transferred then facilities planned for the FPSO include hook-ups for the floating

hoses (fore and aft) to flush-out any remaining crude from the floating hose.

1.2 Scope

This specification defines piping material requirements for the design, selection of materials

of construction, manufacture and supply of piping components for the use in Piping Work in

Wellhead Platform and FPSO, AAL Development Project.

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

7 of 267

2. DEFINITION AND ABBREVIATIONS

2.1 Definition

PROJECT Ande Ande Lumut Development Project

COMPANY Santos Northwest Natuna B.V

CONTRACTOR EPCI Contractor

VENDOR/SUPPLIER A company selected and awarded by COMPANY to supply a

Project goods

2.2 Abbreviations

BE Bevel End

BW Butt Weld

CL Class

CNAF Compressed Non-Asbestos Fibre

CON Concentric

CS Carbon Steel

ECC Eccentric

ER External Ring

ENP Electro Nickel Plated

FB Full Bore

FF Flat Face

FL Flange

Gr Grade

HDPE High Density Polyethylene

IR Internal Ring

M/F Male / Female

MDT Minimum Design Temperature

N Newton

NB Nominal Bore – (Metric)

NPS Nominal Pipe Size – (Imperial)

NPTF National Pipe Thread Female

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

8 of 267

OD Outside Diameter

OS&Y Outside Screw & Yoke

PBE Plain Both End

PE Plain End

POE Plain one End

PTFE Polytetrafluoroethylene

PVC Polyvinyl Chloride

RB Reduced Bore

RF Raised Face

RTJ Ring Type Joint

SCRD Screwed

SCH Schedule

SMLS Seamless

SO Slip On

SS Stainless Steel

SW Socket Weld

TBE Thread Both Ends

THK Thickness

TOE Thread one End

UNO Unless Otherwise Noted

UPVC Unplasticized Polyvinyl Chloride

WN Weld Neck

WD Wound

3. REFERENCE, CODE AND STANDARDS

The latest version of the codes, standards and specifications listed (including revisions,

addenda, and other documents incorporated by reference) shall be part of this specification.

Any conflicts between specifications related to work and these references shall be presented

in writing to the COMPANY or designated representative for resolution.

The VENDOR shall obtain copies of the latest versions of the Industry and Government

Standards referenced herein or incorporated by reference and these shall be used in

performance of the work.

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

9 of 267

3.1 Project Specifications

9602-050-SPC-0001 “Piping Standard Details”

9600-050-SPC-0003 “Painting and Protective Coating Specification”

3.2 Santos Engineering Standard

1515-50-G001 Design Practice for Piping

1515-50-G002 Design Practice for Valves

1515-50-G006 Design Practice for Hot Tapping

1515-50-G007 Design Practice for Gas and Oil Gathering Systems

1515-50-G008 Design Practice for Tie-in (or Golden) Welds

1515-50-SPC-0001 Specification for Piping and Valves

1515-50-S002 Specification for Plant Pressure Pipe

1515-50-S003 Specification for Hot Bends

1515-50-S004 Specification for High Pressure Steel Line pipe

3.3 Codes, Standards & Regulations

All piping components, systems design and material shall meet the requirements of this

specification, other referenced Project Specifications and the latest editions of the following

codes, Standards and Statutory Regulations (where applicable).

3.3.1 American Society of Mechanical Engineers

ASME B31.3 Process Piping

ASME B1.20.1 Pipe Threads General Purpose

ASME B16.5 Pipe Flanges and Flanged Fittings

ASME B16.9 Wrought Steel Butt Weld Fittings

ASME B16.10 Face to Face and End to End Dimensions of Valves

ASME B16.11 Forged Steel Fittings, Socket Weld and Threaded

ASME B16.20 Ring Joint Gaskets and Grooves, for Steel Pipe Flanges

ASME B16.21 Nonmetallic Flat Gaskets for Pipe Flanges

ASME B16.25 Butt Welding Ends

ASME B16.34 Valves, Flanged and BW Ends

ASME B16.47 Large Diameter Steel Flanges

ASME B31.8 Gas Transmission and Distribution Piping System

ASME B36.10 Welded and Seamless Wrought Steel Pipe

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

10 of 267

ASME B36.19 Stainless Steel Pipe

ASME B16.36 Steel Orifice Flange 300, 600, 900, 1500, 2500

ASME B46.1 Flange Surface Finish

3.3.2 ASME Boiler & Pressure Vessel Code

Section VIII Unfired Pressure Vessels

Section IX Welding Qualifications

3.3.3 American Petroleum Institute

API 5L Specification for Line Pipe

API 6D Specification for Pipeline Valves

API 6A Specification for Wellhead and Christmas Tree Equipment

API 6FA Specification for Fire Test Valves

API 594 Wafer Check Valves

API 598 Valve Inspections and Test

API 600 Steel Gate Valves, Flanged and BW Ends

API 602 Compact Carbon Steel Gate Valves

API 607 Fire Test for Soft-Seated Ball Valves

API 608 Metal Ball Valves-Flanged and Butt Welding Ends

API 609 Lugs and Wafer Type Butterfly Valves

API RP14E Design and Installation of Offshore Platform Piping Systems

API 15LR Specification for Low Pressure Fiberglass Line Pipe

API 15HR Specification For High Pressure Fiberglass Line Pipe

API 15S Qualification Of Spoolable Reinforced Plastic Line Pipe

3.3.4 NACE International

MR 0175 Sulphide Stress Cracking Resistant Metallic Materials for Oilfield

Equipment

3.3.5 Australian Standards

AS 2129 Flanges for Pipes and Fittings

AS 1345 Identification of Piping Conduits and Ducts

AS 1897 Electroplated coating on threaded components

AS 1790 Electroplated coatings – cadmium on iron or steel

AS 1791 Chromate conversion coatings – zinc and cadmium

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

11 of 267

3.3.6 American Society for Testing and Material

ASTM A53 Standard Specification for Pipe, Steel, Black & Hot Dipped, Zinc-

Coated Welded and Seamless.

ASTM A105 Carbon Steel Forging for Piping Components

ASTM A106 Standard Specification for Seamless Carbon Steel Pipe for High-

Temperature Service

ASTM A182 Forged or Rolled Alloy Steel Pipe Flanges, Forged Fittings, and

Valves and Parts for High Temp. Service

ASTM A193 Alloy Steel and Stainless Bolting Materials for High Temperature

Service

ASTM A194 Carbon and Alloy Steel Nuts for Bolts for High Pressure &High

Temperature Service

ASTM A216 Carbon Steel Casting Suitable for Fusion Welding for High

Temperature Service

ASTM A234 Pipe Fittings of Wrought Carbon Steel for Moderate and Elevated

Temperatures

ASTM A269 Seamless Stainless Tubing

ASTM A312 Seamless and Welded Austenitic Stainless Steel Pipes

ASTM A358 Austenitic Cr-Ni Pipe for High Temperature service

ASTM A403 Wrought Austenitic Stainless Steel Piping Fittings

ASTM A733 Standard Specification for Welded and Seamless Carbon Steel and

Austenitic Stainless Steel Pipe Nipples

ASTM A790 Standard Specification for Seamless and Welded Ferritic/Austenitic

Stainless Steel Pipe

ASTM A815 Standard Specification for Wrought Ferritic, Ferritic/Austenitic, and

Martensitic Stainless Steel Piping Fittings

ASTM B61 Standard Specification for Steam or Valve Bronze Castings

ASTM D2310 Standard Classification for Machine Made Fiberglass (Glass-Fiber

Reinforcement Thermosetting - Resin) Pipe

ASTM D5421 Standard Specification for Contact Molded "Fiberglass" (Glass-Fiber-

Reinforced Thermosetting Resin) Flanges

ASTM D5685 Standard Specification for "Fiberglass" (Glass-Fiber-Reinforced

Thermosetting-Resin) Pressure Pipe Fittings

3.3.7 British Standard

BS EN-10204 Metallic Products - Types of Inspection Documents

3.3.8 Det Norske Veritas

DNV-OSS-102 Rules for Classification of Floating Production and Storage Units

DNV-OS-E201 Hydrocarbon Production Plant

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

12 of 267

4. DESIGN PRINCIPLES

4.1 Design Values

Diameter nominal of pipe size 2½”, 3½”, 5” and 7” are prohibited except as necessary to

connect to equipment. Any prohibited size necessary shall be changed to conventional size

immediately adjacent to equipment.

Corrosion allowances for piping shall be as stated in the relevant material classifications.

The carbon content of ASTM A106 Grade B material shall not exceed 0.23 %. the carbon

content of ASTM A105 material shall not exceed 0.25 %. Maximum carbon equivalent shall

be 0.3 % by analysis or 0.45 % by check analysis according the formula:

Mn Cr Mo V Ni Cu

CE C

6 5 15

All materials specified and installed shall be new, clean and free from rust, mill scale, pits

and defects.

No cast iron, ductile iron, malleable iron, aluminum, plastic or copper bearing alloy shall be

used in hydrocarbon services.

Material substitutions may only be made with the prior approval in writing to COMPANY.

Pulled bends shall not be used unless individually specified as a Special Piping (SP) items.

All piping material shall be identified with batch or heat number. Unidentified material is not

acceptable. All piping materials shall be inspected and be complete with all necessary

documentation.

All materials such as valves, traps, etc shall have a stainless steel tag permanently attached

to identify its particular service.

4.2 Valves

The face-to-face dimensions of flanged valves shall conform with ASME Standard B16.10

and the flanges on steel flanged valves shall conform to ASME B16.5 for ½” to 24” and

ASME B16.47 on 26” and larger.

Globe valve shall be used only where throttling is required. Valve operated in wide open and

block-in service shall be ball valves as required for product and service.

Valve shall not be installed with their stems below the horizontal position except gate valves

in flare headers.

Control valves, block valves and by pass valves shall be individually sized and the sizes

noted on flow sheets or P&ID drawings.

Any block valve installed in a relief line shall be locked open or sealed open, using an

approved proprietary system.

Reduced ports in ball valves shall be limited to one line size smaller than body size.

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

13 of 267

No bushings shall be used.

Where product contamination must be prevented in lines designed for more than on stream,

double block valves with a bleed valve between shall be installed (Refer to Design Guide for

Valves, doc. no. 1515-50-G002 sec.3.1.1).

Block valves shall generally be line size valves in accordance with the appropriate piping

material class.

Where indicate on the valve data sheets that fire testing is required, valves shall be to a

certified fire tested design in accordance with API RP 6FA or API 607. Fire test certification

shall be provided and shall demonstrate that the valves and operating mechanism supplied

are capable of meeting the specified fire test requirements.

The fire tests shall have been witnessed and certification issued by an independent

authority.

Bonnet gaskets shall comply with the following requirements:

CL 150 & CL 300 Spiral wound gaskets complete with external guide ring as

per ASME B16.20

CL 600 Spiral wound gaskets complete with internal and external

guide rings as per ASME B16.20

CL 900 & CL1500 Ring per API 6A octagonal type R soft iron Cadmium Coated

The materials for the gaskets shall be as follows:

Winding – 316L SS

Filler – Graphite

Internal and External guide rings – 316L SS

Valve operation shall generally be as indicated on the Valve Data Sheets, providing the

force to operate the valve does not exceed 250N with the valve in the open or closed

position under maximum differential pressure. Operator dimensions shall be stated.

Unidirectional valves shall have a directional arrow integrally cast / forged with the body.

Valves shall have a position indicator, which cannot be wrongly oriented, either on initial

assembly or during subsequent dismantling and reassembly.

For quarter turn valves, provision for mounting a “lever lock” type wrench shall be

incorporated in the valve design. This wrench shall be interchangeable with the standard

non-locking wrench. All valves shall be capable of being locked in fully open or closed

position (except non return valves).

Wrenches / hand wheels shall have a fixing bolt and / or nut.

Gear operators shall be sized such that its output torque is at least 1.5 times the maximum

required operating torque of the valve proper.

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

14 of 267

The gear ratio shall be maximum 1:60 for valves 8” and smaller or maximum 1:120 for

valves 10” or larger.

Gear operators shall have self-locking gears, and be provided with a position indicator.

All carbon steel valves shall be blasted and primed in accordance with 9600-050-SPC-0003

“Painting and Protective Coating Specification”.

Each valve ID-tag shall be hard stamped with the valve tag number and size in characters at

least 10mm high and attached securely to the valve with SS-wire.

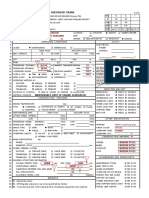

4.2.1 Valve Operator

Valve operator design shall be as per below table.

Gate, Globe valves

Size 150# 300# 600# 900# 1500# 2500#

≤ 100 Handwheel Handwheel Handwheel Handwheel Handwheel Handwheel

150 Handwheel Handwheel Handwheel Handwheel Handwheel Gear

200 Handwheel Handwheel Gear Gear Gear ‐

250 Handwheel Gear Gear Gear Gear ‐

300 Gear Gear Gear Gear Gear ‐

≥ 350 Gear Gear Gear Gear ‐ ‐

Ball, Plug valves

Size 150# 300# 600# 900# 1500# 2500#

≤ 80 Lever Lever Lever Lever Lever Lever

100 Lever Lever Lever Lever Lever Gear

150 Lever Lever Lever Lever Gear Gear

200 Lever Lever Lever Lever Gear ‐

250 Gear Gear Gear Gear Gear ‐

300 Gear Gear Gear Gear Gear ‐

≥ 350 Gear Gear Gear Gear ‐ ‐

Butterfly valves

Size 150# 300# 600# 900#

≤ 200 Lever Lever Lever Lever

≥ 250 Gear Gear Gear Gear

4.2.2 Valve Materials

The carbon steel used for manufacturing cast or forged valve bodies and components

shall be produced in an electrical furnace, or by the basic oxygen process.

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

15 of 267

Stainless steel valves shall be type 316 alloys.

Material certification requirements shall be in accordance with EN 10204. Metallic

products – types of inspection documents shall be as defined below.

Table 1-1 INSPECTION DOCUMENT REQUIREMENTS

PRESSURE

OTHER ‘WETTED’

CONTAINING PARTS OR

BASIC VALVE PARTS

LOAD BEARING

MATERIAL

Standard Designation to Standard Designation to

EN 10204 EN 10204

Carbon Steel 3.1 3.1

Austenitic

3.1 3.1

Stainless Steel

Bronze 3.1 3.1

Ductile Iron 3.1 3.1

Certification for bolting shall be standard designation 2.2 unless stated otherwise. Where

supplementary requirements or impact testing in excess of the product specification are

specified, the Vendor shall provide certification proving that bolting meets the specified

requirements.

Pressure containing parts for valves are as follows:

Ball valve Body, bonnet and stem

Globe valve Body and bonnet

Gate valve Body and bonnet

Check valve Body and cover

4.3 Flanges & Fittings

All flanges 24” and smaller shall be furnished in strict accordance with ASME B16.5.

Details of flanges which mate to a higher rated specification e.g. specification breaks at

valves, control valves etc. shall be as per the line specification except that the rating and

facing shall be specified to match the higher rated specification.

Weld neck flanges shall be bored to the inside diameter of the pipe to which they are to be

welded.

Orifice flanges shall be in accordance with ASME B16.36.

Flanges shall be installed with both holes straddling normal horizontal and vertical

centerlines.

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

16 of 267

Flat face flanges shall be used when mating to cast bronze, iron or aluminum flanges. Lap

joint and RF flanges shall not be used for mating flat face flanges, unless otherwise noted.

Long radius butt weld elbows shall be used wherever possible. Short radius elbows may be

used only where space requirements so dictate.

Welded miter bends shall not be used.

Reduction in line size shall be made only by reducing fittings or swages. No bushing shall be

used.

Butt weld caps shall normally be used to close the ends of welded lines. Where required for

future extension, blind flanges shall be used.

Special fittings shall only be permitted where no standard fittings can be employed.

Flange gasket surface finished shall be in accordance with ASME B46.1 and the following:

a. CL 150 Serrated spiral finish (stock finish) roughness between RA 6.3 and

12.5 micron

b. CL 300 & 600 Smooth finish – roughness between RA 3.2 and 6.3 micron

c. CL 900 Smooth finish – roughness between RA 1.6 micron (groove wall)

d. CL 1500 Smooth finish – roughness between RA 1.6 micron (groove wall)

4.4 Studs, Nuts & Gaskets

Stud bolts, nuts and gaskets shall be the type specified on the relevant materials

classification.

Except for stainless steel materials, the bolting must undergo surface treatment of the

Fluorocarbon type.

Material stamping required by the material specification shall be legible after coating.

Ring type gaskets, unless stated otherwise on material requisitions shall be style “R”

Octagonal in accordance with ASME B16.20.

Soft Iron ring joints shall be supplied with a maximum hardness of 90 HB

Austenitic stainless steel ring type joints AISI 316 shall be supplied in a fully solution

annealed condition and minimum hardness of 160 HB.

Super Austenitic stainless steel ring type joints shall be alloy 904L or 254 SMO, shall

be fully solution annealed and have a maximum hardness of 180 HB.

All ring type joint gaskets except soft iron shall comply with NACE MR 0175.

4.5 Threaded & Socket Welded Piping

For thread form refer relevant pipe specification.

Use of half couplings is prohibited.

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

17 of 267

Threaded plugs shall be solid steel round or hexagonal bar stock.

Threaded full length pipe nipples, street ells, or street tees shall not be used.

4.6 Branch Connections

Branch connections shall comply with the relevant piping material class. Lateral olets may

be used in lieu of 45o fittings where necessary.

4.7 Supports, Anchors & Guides

All piping shall be adequately supported by means of hangers or, preferably, support of

proper structural design. Provisions shall be made by the use of suitable anchors and guides

and piping flexibility to prevent undue movement caused either by expansion, contraction,

vibration or distortion of connected structural members under load.

Rod hangers, where used shall be designed to take the load and be constructed of rod not

less than 10mm diameter for any size line.

Piping supports shall be designed for weight of piping, contents (full), attached unsupported

equipment, wind and seismic loading and where it becomes necessary to dismantle piping

components for maintenance.

Supports shall be correctly located to ensure excessive loads are not transferred to the

equipment, nozzles when the operating temperature is reached. Consideration shall be

given to the use of spring-type supports. Pipe supports welded directly to piping shall be of

compatible material.

4.8 Materials

Copper, copper based alloys, galvanized materials, cadmium plated materials, etc. shall not

be exposed to hydrogen sulphide, amine, caustic or similar materials.

All forgings shall be normalized.

4.9 Tube Fittings

Tube fitting shall be “Swagelok” or equal. For break connections such as for skid

maintenance the Cajon Co or equal, O-Ring Face Seal Fittings shall be used.

4.10 Tubing

Tubing shall use forged stainless steel ASTM A182 Gr F316, flareless compression type

connection. Swagelok or equal, size range 8 – 15.

General use is 0.9 mm wall thickness. Size range is 8 - 15 OD, except 2500# systems

where size range is restricted to 6.5 - 9.5 OD.

For tubing requirement and installation detail refer to 1515-50-G001 “Design Practice for

Piping” Sec 9.8 and 1515-70-S011 “Specification for Instrument Installation” Sec 6.5

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

18 of 267

4.11 Process Vents and Drains

Process vents and drains shall consist of a 3/4” Sockolet and a 1” PBE Nipple UNO.

Valve requirements are as follows:

For valves in Class 600 or below, the following shall be used:

Hydrocarbon Gas Service 3/4” SW x SCRD Ball Valve

Air Service 3/4” SCRD Ball Valve

Other Service 3/4” SW x SCRD Ball Valve

For valves greater than Class 600, the following shall be used:

Hydrocarbon Gas Service ¾“ Ball Valve with downstream 20NB ball bleed

High vibration equipment ¾” integral flange – Weldolet arrangement and 1” DBB

monoblock manifold valve (1” Sockolet and PBE

Nipple not required).

Other service ¾” Ball Valve with downstream ¾” ball bleed.

A 1” POE/TOE Nipple is required with a 1” threaded cap UNO (Air service will use 1” TBE

Nipple with threaded cap).

4.12 Pressure Instrument Connections

Unless otherwise specified, all pressure instruments shall be mounted directly to a

integrated monoflange valve type of 3 ways, double block and bleed arrangement, flanged

directly to pipe or vessels.

Detail connection refers to P&ID typical details (9602-010-PID-0003-2) and also refers to

piping standard details (9600-050-SPC-0001)

4.13 Thermowells

All thermowells to be 2” flange unless otherwise noted.

5. PIPING AND VALVE SPECIFICATION CODE

5.1 Pipe Specification Code Format

1 2 3 4

1 C 1 R

Supplementary Code

Corrosion Allowance

Material Type

Pressure Rating

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

19 of 267

5.1.1 Identifier 1 – Pressure Rating

ASME

1 CL150 9 CL 900

3 CL 300 15 CL 1500

6 CL 600

5.1.2 Identifier 2 – Material Type

C Carbon Steel G Carbon Steel Galvanized

L Low Temperature Carbon Steel H Copper Nickel

S Stainless Steel 316L J Glass Reinforced Epoxy

D Duplex SAF2205 K HDPE

E Super Duplex SAF 2507 P PVC (UPVC)

T Glass Reinforced Epoxy – Q Polypropylene

Conductive

5.1.3 Identifier 3 – Corrosion Allowance

0 Nil 2 6.0 mm

1 3.0 mm

5.1.4 Identifier 4 – Supplementary Code

An alphabetical supplementary code is used as required to nominate any special features

such as material grade or service, etc. this supplementary code is assigned and used on

a project by project basis.

R Supplementary Code for ASME B31.3

S Supplementary Code for ASME B31.8

L Supplementary Code for ASME B31.4

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

20 of 267

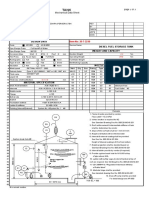

PIPE SPECIFICATION AND SERVICE SUMMARY

SERVICE SYSTEM DESIGN CONDITION

FLANG

PIPE ASME E

C.A. MATERIAL O PRESSURE

SPEC. RATING FACIN TEMP C

CODE DESCRIPTION G kPag

(MIN/MAX)

(MAX/MIN)

DF DIESEL FUEL

DC CLOSED DRAIN

DO OPEN DRAIN

FG FUEL GAS

HYDROCARBON

HC

CONDENSATE

N NITROGEN

RV RELIEF GAS

3 A53 GR. B or

1C1R VENT TO 150# RF -29 / 350 1,770 / 840

VA MM A106 GR. B, CS

ATMOSPHERE

RG RAW GAS

PF PROCESS FLUID

OW OILY WATER

ST STEAM

PW PRODUCED WATER

HO HOT OIL

HF HELI FUEL

PF PROCESS FLUID

RV RELIEF GAS

OW OILY WATER

RG RAW GAS

6 A53 GR. B or

1C2R RW RAW WATER 150# RF -29 / 350 1,770 / 840

MM A106 GR. B, CS

ST STEAM

SW SERVICE WATER

PW PRODUCED WATER

DC CLOSED DRAIN

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

21 of 267

SERVICE SYSTEM DESIGN CONDITION

FLANG

PIPE ASME E

C.A. MATERIAL O PRESSURE

SPEC. RATING FACIN TEMP C

CODE DESCRIPTION G kPag

(MIN/MAX)

(MAX/MIN)

A53 GR. B or

3

1G1R IA INSTRUMENT AIR A106 GR. B, CS 150# RF -29 / 350 1,770 / 840

MM

(GALV)

A790 UNS

METHANOL /

1D0R M / CD NIL S31803, 150# RF -29 / 150 1,770 / 1,586

CHECMICAL DOSING

DUPLEX

FIRE WATER ASTM B466

C70600

FW NIL Seamless or 150# FF 150 1,390

1H0R

SEA WATER B467 C70600

Welded Anealed

METHANOL /

M / CD

CHECMICAL DOSING

DO OPEN DRAIN

A312 Gr

IA INSTRUMENT AIR 304/316 or

1S0R NIL 150# RF -100 / 150 1,570 / 1,390

A358

SA SERVICE AIR Gr.304/316

UW UTILITY WATER

UA UTILITY AIR

RW RAW WATER

FW FIRE WATER

20FR16-C, FRP

1T0R NIL 150# FF AMB / 85 1600

CONDUCTIVE

CW COOLING WATER

SW SEA WATER

Type IV, Gr 1,

1X0R CL CLORINE INJECTION NIL CPVC 4120, 150# FF AMB/60 760

ASTM D1784

DC CLOSED DRAIN

PF PROCESS FLUID 3 A53 Gr. B or

3C1R 300# RF -29 / 343 5,102 / 3792

MM A106 Gr. B, CS

HO HOT OIL

RG RAW GAS

PF PROCESS FLUID

6 A53 Gr. B or

3C2R N NITROGEN PURGING 300# RF -29 / 350 4,640 / 3700

MM A106 Gr. B, CS

RG RAW GAS

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

22 of 267

SERVICE SYSTEM DESIGN CONDITION

FLANG

PIPE ASME E

C.A. MATERIAL O PRESSURE

SPEC. RATING FACIN TEMP C

CODE DESCRIPTION G kPag

(MIN/MAX)

(MAX/MIN)

PF PROCESS FLUID

API Spec 5L-

6

3C2L X56, API Spec 300# RF 0 /120 4,640 / 4,590

HYDROCARBON MM

HC 5CT-J55

CONDENSATE

FIRE WATER ASTM B466

C70600

Seamless or

3H0R FW NIL 300# FF 93.3 3630

B467 C70600

Welded

SEA WATER Annealed

A312 Gr

METHANOL / 304/316 or

3S0R M / CD NIL 300# RF -100 / 150 4,090 / 3,630

CHECMICAL DOSING A358

Gr.304/316

RW RAW WATER

FW FIRE WATER

20FR16-C, FRP

3T0R NIL 300# FF AMB / 93 4640

CONDUCTIVE

CW COOLING WATER

SW SEA WATER

RG RAW GAS

3 A53 Gr. B or

6C1R 600# RF -29 / 350 9,280 / 7,390

MM A106 Gr. B, CS

FL FLARE GAS

PF PROCESS FLUID

6 A53 Gr. B or 600# 9,280 / 7,390

6C2R RF -29 / 350

MM A106 Gr. B, CS

RG RAW GAS

A312 Gr

METHANOL / 304/316 or

6S0R M / CD NIL 600# RF -100 / 150 8,180 / 7,270

CHECMICAL DOSING A358

Gr.304/316

API Spec 5L-

3

6C1S RG RAW GAS X56, API Spec 600# RF 0 / 120 9,280 / 9,190

MM

5CT-J55

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

23 of 267

SERVICE SYSTEM DESIGN CONDITION

FLANG

PIPE ASME E

C.A. MATERIAL O PRESSURE

SPEC. RATING FACIN TEMP C

CODE DESCRIPTION G kPag

(MIN/MAX)

(MAX/MIN)

HYDROCARBON

HC

CONDENSATE

PF PROCESS FLUID 3 A53 Gr, B or

9C1R 900# RTJ -29 / 350 13,910 / 11,090

MM A106 Gr. B, CS

RG RAW GAS

WI WATER INJECTION

PF PROCESS FLUID

HYDROCARBON 6 A53 Gr, B or

HC 900# RTJ -29 / 350 13,910 / 11,090

9C2R CONDENSATE MM A106 Gr. B, CS

RG RAW GAS (NOTE1)

PF PROCESS FLUID

API Spec 5L-

HYDROCARBON 3

9C1L HC X56, API Spec 900# RTJ 0 / 120 13,910 / 13,770

CONDENSATE MM

5CT-J55

OW OILY WATER

A312 Gr

METHANOL / 304/316 or

9S0R M / CD NIL 900# RTJ -100 / 150 12,280 / 11,580

CHECMICAL DOSING A358

Gr.304/316

Note: 1. Raw gas from other production gas line. WHP itself not produce raw gas for distribution. All gas

shall be flared

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

24 of 267

5.2 Valve Specification Code Format

1 2 3

4 C 01

Specific Valve and Trim

Pressure Rating

Type of Valve

The first digit The second digit, a The last two digits define the specific valve and

defines letter, defines the the trim

the type of valve ASME flange

classification or

pressure rating

3 Gate A 150 01 DN 15 - 40 Carbon steel valves for

4 Globe B 300 General Service

5 Check C 600 02 DN 50 - 600 Carbon steel valves for

6 Ball D 900 General Service

7 Plug E 1500 03 DN 15 - 40 Carbon steel valves for Raw

8 Butterfly F 2500 Gas Service

9 Needle G 800 04 DN 50 - 600 Carbon steel valves for Raw

H 6000 Gas Service

I 3000 05 to 19 Other Carbon steel valves

21 to 39 Low Temperature steel valves

41 to 59 Stainless steel valves

61 to 79 Aluminum Bronze valve

91 to 99 Plastic valve

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

25 of 267

ATTACHMENT – 1

PIPING MATERIAL SPECIFICATION

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

26 of 267

PIPE SPEC 1C1R ASME 150# CARBON STEEL PIPING

CODE ASME B31.3, ASME B16.5

SIZES ½”, ¾”, 1½, 2”, 3”, 4”, 6”, 8”, 10”, 12”, 14”, 16”, 18”, 20”, 24”

PROCESS FLUIDS

Hydrocarbon Condensate, Fuel Gas, Nitrogen, Relief Gas, Diesel Fuel, Closed

Drain, Open Drain, Raw Gas, Vent to Atmosphere, Diesel Fuel, Process Fluid, Oily

water, Steam, Produced Water, Heli Fuel, Hot Oil

DESIGN Pressure @ Maximum Temperature 840 kPag @ 350 oC

o

Pressure @ 100 C 1,770 kPag @ 100 oC

Pressure @ Minimum Temperature 1,770 kPag @ -29 oC

MAOP or WT calculation is required for flange limit conditions.

CORROSSION ALLOWANCE

3 mm corrosion allowance or 12.5 % manufacture tolerance

ENDS Raised face and socket weld

MATERIAL SUMMARY

Pipe ASTM A106 Gr B (or A53 Gr B)

Flanges ASTM A105

Fittings ASTM A234 Gr WPB

Studs ASTM A193 Gr B7

Nuts ASTM A194 Gr 2H

Tubing ASTM A269 Gr 316

Valves Carbon steel - see valve specifications

PIPING AND FITTINGS

(Size range) (Minimum wall schedule, material, end preparation)

PIPE Dimensions to ASME B36.10

½” Sch 80 1” Sch 80

¾” Sch 80 1-½ ” Sch 80

Seamless carbon steel ASTM A106 Gr B (or A53 Gr B), plain ends

2” Sch 80 12” Sch 30

3” Sch 40 14” Sch 30

4” Sch 40 16” Sch 20

6” Sch 40 18” Sch 20

8” Sch 40 20” Sch 20

10” Sch 40 24” Sch 20

Seamless carbon steel ASTM A106 Gr B (or A53 Gr B), beveled ends

FLANGES Dimensions to ASME B16.5

½” – 1½ ” Match pipe bore, forged carbon steel ASTM A105, 150# RF socket weld

2” - 24” Match pipe bore, forged carbon steel ASTM A105, 150# RFWN

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

27 of 267

PIPE SPEC 1C1R (Continued)

FITTINGS AND BRANCH CONNECTIONS

Refer Piping Branch Connections table

½” – 1½” Match pipe bore, forged carbon steel ASTM A105, 3000# socket weld as per ASME

B16.11

2” - 24” Match pipe bore for branch connection size limits, seamless carbon steel ASTM

A234 Gr WPB, butt-weld, per ASME B16.9

JOINTS

½” – 1½” Match pipe bore, carbon steel ASTM A105, 150# RF socket weld or 3000# socket

weld coupling

2” - 24” Match pipe bore, carbon steel ASTM A105, 150# RFWN flanged or welded

SMALL FITTINGS

(Size range) (Minimum wall schedule, material, end preparation)

SWAGE NIPPLES

½” – 1½” Sch 80/XS, seamless carbon steel ASTM A105, plain both ends, fabrication to

ASTM A733

2” - 6” Beveled end to be same schedule as pipe of same size, carbon steel ASTM A105,

plain end / beveled end

PIPE NIPPLES

½” – 1½” Sch 80/XS, seamless carbon steel ASTM A106 Gr B (or A53 Gr B), plain both ends,

fabrication to ASTM A733

PLUGS

½” – 1½” Forged carbon steel ASTM A105, solid hex head bull plug, NPT threaded to ASME

B16.11

BOLTS

All sizes Stud bolts alloy steel ASTM A193 Gr B7, each with two hex nuts alloy steel ASTM

A194 Gr 2H, all threaded. Sizes 1¼” and over to be one diameter longer than

standard. Stud Bolts & Nuts shall be Fluorocarbon Coated

GASKETS

All sizes Category D fluid (non flammable, non toxic) may use 1.5 mm thick CF self centering

flat ring to ASME B16.5 Group 1A and ASME B16.21.

All other services use 4.5 mm thick Gr 304 (or 316) s/s spiral wound with graphite

filler and carbon steel outer guide ring per ASME B16.5 Group 1B and ASME

B16.20. Colour code to ASME B16.20. Colour code to ASME B16.20. For raw gas,

corrosive or erosive service - add s/s inner rings to match pipe bore. Engineer to

specify on P&ID.

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

28 of 267

PIPE SPEC 1C1R (Continued)

INSTRUMENT CONNECTION FITTINGS

½” – 1½” 3000#, forged carbon steel A105, thermowell, sockolet, thredolet or threaded

elbolet. Dimensions per ASME B16.11.

Fabricated connections use fully welded or flanged fittings up to the first isolation

valve. Otherwise, use isolation valves with integral welding attachment to pipe.

Addition of gusseting or bracing is required near vibrating machinery. Use of 3/4”

needle valve directly connected to thredolet is permitted only in locations remote

from collision and vibration and corrosion hazards. Refer 1515-50-G001 “Design

Practice for Piping” for further detail.

ORIFICE FLANGES Dimensions to ASME B16.34

1” - 24” Match pipe bore, forged carbon steel ASTM A105, 300# RFWN, furnished with jack

screws and drilled for ½” socket weld or drilled and tapped ½” NPT per AGA -

Engineer to specify

PROCESS TUBING

¼” – ½” OD 0.9 mm min wall thickness, seamless stainless steel ASTM A269 Gr 304

(or 316)

PROCESS TUBING FITTINGS

¼” – ½” OD Forged stainless steel ASTM A182 Gr F304 (or F316), flareless compression

type connection: Swagelok or equal

TESTING AND CERTIFICATION

(Size range) (Type, frequency)

MATERIAL CERTIFICATES - With material supply

All sizes Mill chemical analysis, mill material properties, 100%

WELD PROCEDURE

All sizes Weld procedure qualified, welder qualified, 100%

NON DESTRUCTIVE TESTING

All sizes Radiography 5%

HYDROSTATIC TEST

All sizes 2,660 kPag for 1 hour.

Leak check only required on atmospheric vents and drains

FIELD INSTALLATION CHECKLIST

All sizes Weld procedure, NDT, hydrostatic test

VALVES

(Valve spec Size, service, ends)

GATE 3A01 ½” – 1½”, Gen service, 150# RF flanged

3A02 2” – 24”, Gen service, 150# RF flanged

3G01 ½” – 1½”, Gen service, 800# socket weld

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

29 of 267

PIPE SPEC 1C1R (Continued)

3G02 ½” – 1½”, Gen service, 800# socket weld x threaded

3G03 ½” – 1½”, Gen service, 800# threaded F x F

GLOBE 4A01 ½” – 1½”, Gen service, 150# RF flanged

4A02 2” – 24”, Gen service, 150# RF flanged

4G01 ½” – 1½”, Gen service, 800# socket weld

4G02 ½” – 1½”, Gen service, 800# socket weld x threaded

4G03 ½” – 1½”, Gen service, 800# threaded F x F

CHECK 5A01 ½” – 1½”, Gen service, 150# RF flanged, Swing type

5A02 2” – 24”, Gen service, 150# RF flanged, Swing type

5A05 2” – 24”, Gen service, 150# RF flangeless, Wafer type

5A06 6” – 24”, Gen service, 150# RF flangeless, Wafer type

5G01 ½” – 1½”, Gen service, 800# socket weld, Lift type

5G02 ½” – 1½”, Gen service, 800# socket weld x threaded F, Lift type

5G03 ½” – 1½”, Gen service, 800# threaded F x F, Lift type

BALL 6A01 ½” – 1½”, Gen service, 150# RF flanged

6A02 2” - 24”, Gen service, 150# RF flanged

6A05 2” - 24”, Produced Water service, 150# RF flanged

6A06 30”, Produced Water service, 150# RF flanged

6A07 2” - 24”, Hot Oil service, 150# RF flanged

6G01 ½” - 1-½”, Gen service, 800# socket weld

6G02 ½” - 1-½”, Gen service, 800# socket weld x threaded

6G03 ½” - 1-½”, Gen service, 800# threaded F x F

6G05 ½” - 1-½”, Gen service, 800# socket weld C/w Nipple

6G06 ½” - 1-½”, Gen service, 800# socket weld C/w Nipple NPT

BUTTERFLY 8A02 2” – 24”, Gen service, 150# RF flangeless

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

30 of 267

PIPE SPEC 1C2R ASME 150# CARBON STEEL PIPING

CODE ASME B31.3, ASME B16.5

SIZES ½”, ¾”, 1½, 2”, 3”, 4”, 6”, 8”, 10”, 12”, 14”, 16”, 18”, 20”, 24”, 30”

PROCESS FLUIDS

Process Fluid, Relief Gas, Oily Water, Raw Gas, Raw Water, Steam, Service Water,

Produced Water, Closed Drain.

DESIGN Pressure @ Maximum Temperature 840 kPag @ 350 oC

o

Pressure @ 100 C 1,770 kPag @ 100 oC

Pressure @ Minimum Temperature 1,770 kPag @ -29 oC

MAOP or WT calculation is required for flange limit conditions.

WT ALLOWANCE

6 mm Corrosion or 12.5 % manufacture tolerance

ENDS Raised face and socket weld

MATERIAL SUMMARY

Pipe ASTM A106 Gr B (or A53 Gr B)

Flanges ASTM A105

Fittings ASTM A234 Gr WPB

Studs ASTM A193 Gr B7

Nuts ASTM A194 Gr 2H

Tubing ASTM A269 Gr 316

Valves Carbon steel - see valve specifications

PIPING AND FITTINGS

(Size range) (Minimum wall schedule, material, end preparation)

PIPE Dimensions to ASME B36.10

½” Sch XXS 1” XXS

¾” Sch XXS 1-½ ” XXS

Seamless carbon steel ASTM A106 Gr B (or A53 Gr B), plain ends

2” Sch 160 12” Sch 40

3” Sch 160 14” Sch 40

4” Sch 80 16” Sch 40

6” Sch 80 18” Sch 30

8” Sch 60 20” Sch 30

10” Sch 40 24” Sch XS

30” Sch XS

Seamless carbon steel ASTM A106 Gr B (or A53 Gr B), beveled ends

FLANGES Dimensions to ASME B16.5

½” – 1½ ” Match pipe bore, forged carbon steel ASTM A105, 150# RF socket weld

2” - 24” Match pipe bore, forged carbon steel ASTM A105, 150# RFWN

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

31 of 267

PIPE SPEC 1C2R (Continued)

FLANGES Dimensions to MSS SP-44 or ASME B16.47 Series A

30” Match pipe bore, forged carbon steel ASTM A105 or A216 WCB, 150# RFWN

FITTINGS AND BRANCH CONNECTIONS

Refer Piping Branch Connections table

½” – 1½” Match pipe bore, forged carbon steel ASTM A105, 3000# socket weld as per ASME

B16.11

2” - 24” Match pipe bore for branch connection size limits, seamless carbon steel ASTM

A234 Gr WPB, butt-weld, per ASME B16.9

30” Match pipe bore for branch connection size limits, seamless carbon steel ASTM

A234 Gr WPB, butt-weld, per ASME B16.9

JOINTS

½” – 1½” Match pipe bore, carbon steel ASTM A105, 150# RF socket weld or 3000# socket

weld coupling

2” - 24” Match pipe bore, carbon steel ASTM A105, 150# RFWN flanged or welded

30” Match pipe bore, carbon steel ASTM A105, 150# RFWN flanged or welded

SMALL FITTINGS

(Size range) (Minimum wall schedule, material, end preparation)

SWAGE NIPPLES

½” – 1½” Sch XXS, seamless carbon steel ASTM A105, plain both ends, fabrication to ASTM

A733

2” - 6” Beveled end to be same schedule as pipe of same size, carbon steel ASTM A105,

plain end / beveled end

PIPE NIPPLES

½” – 1½” Sch XXS, seamless carbon steel ASTM A106 Gr B (or A53 Gr B), plain both ends,

fabrication to ASTM A733

PLUGS

½” – 1½” Forged carbon steel ASTM A105, solid hex head bull plug, NPT threaded to ASME

B16.11

BOLTS

All sizes Stud bolts alloy steel ASTM A193 Gr B7, each with two hex nuts alloy steel ASTM

A194 Gr 2H, all threaded. Sizes 1¼” and over to be one diameter longer than

standard. Stud Bolts & Nuts shall be Fluorocarbon Coated

GASKETS

All sizes Category D fluid (non flammable, non toxic) may use 1.5 mm thick CF self centering

flat ring to ASME B16.5 Group 1A and ASME B16.21.

All other services use 4.5 mm thick Gr 304 (or 316) s/s spiral wound with graphite

filler and carbon steel outer guide ring per ASME B16.5 Group 1B and ASME

B16.20. Colour code to ASME B16.20. Colour code to ASME B16.20. For raw gas,

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

32 of 267

PIPE SPEC 1C2R (Continued)

corrosive or erosive service - add s/s inner rings to match pipe bore. Engineer to

specify on P&ID.

INSTRUMENT CONNECTION FITTINGS

½” – 1½” 3000#, forged carbon steel A105, thermowell, sockolet, thredolet or threaded

elbolet. Dimensions per ASME B16.11.

Fabricated connections use fully welded or flanged fittings up to the first isolation

valve. Otherwise, use isolation valves with integral welding attachment to pipe.

Addition of gusseting or bracing is required near vibrating machinery. Use of 3/4”

needle valve directly connected to thredolet is permitted only in locations remote

from collision and vibration and corrosion hazards. Refer 1515-50-G001 Design

Practice for Piping for further detail.

ORIFICE FLANGES Dimensions to ASME B16.34

1” - 24” Match pipe bore, forged carbon steel ASTM A105, 300# RFWN, furnished with jack

screws and drilled for ½” socket weld or drilled and tapped ½” NPT per AGA -

Engineer to specify

PROCESS TUBING

¼” – ½” OD 0.9 mm min wall thickness, seamless stainless steel ASTM A269 Gr 304 (or 316)

PROCESS TUBING FITTINGS

¼” – ½” OD Forged stainless steel ASTM A182 Gr F304 (or F316), flareless compression type

connection: Swagelok or equal

TESTING AND CERTIFICATION

(Size range) (Type, frequency)

MATERIAL CERTIFICATES - With material supply

All sizes Mill chemical analysis, mill material properties, 100%

WELD PROCEDURE

All sizes Weld procedure qualified, welder qualified, 100%

NON DESTRUCTIVE TESTING

All sizes Radiography 5%

HYDROSTATIC TEST

All sizes 2,660 kPag for 1 hour.

Leak check only required on atmospheric vents and drains

FIELD INSTALLATION CHECKLIST

All sizes Weld procedure, NDT, hydrostatic test

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

33 of 267

PIPE SPEC 1C2R (Continued)

VALVES (Valve spec Size, service, ends)

GATE 3A01 ½” – 1½”, Gen service, 150# RF flanged

3A02 2” – 24”, Gen service, 150# RF flanged

3G01 ½” – 1½”, Gen service, 800# socket weld

3G02 ½” – 1½”, Gen service, 800# socket weld x threaded

3G03 ½” – 1½”, Gen service, 800# threaded F x F

GLOBE 4A01 ½” – 1½”, Gen service, 150# RF flanged

4A02 2” – 24”, Gen service, 150# RF flanged

4G01 ½” – 1½”, Gen service, 800# socket weld

4G02 ½” – 1½”, Gen service, 800# socket weld x threaded

4G03 ½” – 1½”, Gen service, 800# threaded F x F

CHECK 5A01 ½” – 1½”, Gen service, 150# RF flanged, Swing type

5A02 2” – 24”, Gen service, 150# RF flanged, Swing type

5A05 2” – 24”, Gen service, 150# RF flangeless, Wafer type

5G01 ½” – 1½”, Gen service, 800# socket weld, Lift type

5G02 ½” – 1½”, Gen service, 800# socket weld x threaded F, Lift type

5G03 ½” – 1½”, Gen service, 800# threaded F x F, Lift type

BALL 6A01 ½” - 1-½”, Gen service, 150# RF flanged

6A02 2” - 24”, Gen service, 150# RF flanged

6A05 2” - 24”, Produced Water service, 150# RF flanged

6A06 30”, Produced Water service, 150# RF flanged

6G01 ½” - 1-½”, Gen service, 800# socket weld

6G02 ½” - 1-½”, Gen service, 800# socket weld x threaded

6G03 ½” - 1-½”, Gen service, 800# threaded F x F

6G05 ½” - 1-½”, Gen service, 800# socket weld C/w Nipple

6G06 ½” - 1-½”, Gen service, 800# socket weld C/w Nipple NPT

BUTTERFLY 8A02 2” – 24”, Gen service, 150# RF flangeless

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

34 of 267

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

35 of 267

PIPE SPEC 1G1R ASME 150# CARBON STEEL GALVANIZED PIPING

CODE ASME B31.3, ASME B16.5

SIZES ½”, ¾”, 1½, 2”

PROCESS FLUIDS

Instrument Air

DESIGN Pressure @ Maximum Temperature 840 kPag @ 350 oC

Pressure @ 100 oC 1,770 kPag @ 100 oC

Pressure @ Minimum Temperature 1,770 kPag @ -29 oC

MAOP or WT calculation is required for flange limit conditions.

CORROSION ALLOWANCE

3 mm or 12.5 % manufacture tolerance

ENDS Raised face, threaded up to 2”

MATERIAL SUMMARY

Pipe ASTM A53 Gr B or ASTM A106 Gr. B, Hot Dip Galvanized

Flanges ASTM A105, Hot Dip Galvanized

Fittings ASTM A234 Gr WPB, Hot Dip Galvanized

Studs ASTM A193 Gr B7, Hot Dip Galvanized

Nuts ASTM A194 Gr 2H, Hot Dip Galvanized

Gasket 4.4 mm thick 316 SS spiral wound

Tubing ASTM A269 Gr TP316

Valves Carbon steel – see valve specifications

PIPING AND FITTINGS

(Size range) (wall thickness, material, end preparation)

PIPE Dimension to ASME B36.10

½” Sch 80 1 ½” Sch 80

¾” Sch 80 2” Sch 80

1” Sch 80

Galvanized seamless carbon steel ASTM A53 Gr B or ASTM A106 Gr. B, Threaded

End ASME B1.20.1

FLANGES Dimensions to ASME B16.5

½” – 2” Match pipe bore, forged carbon steel ASTM A105, 150# threaded, Galvanized

FITTINGS AND BRANCH CONNECTIONS

Refer Piping Branch Connections table

½” – 2” Match pipe bore, forged galvanized carbon steel ASTM A105, 3000# threaded as

per ASME B16.11, Galvanized

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

36 of 267

PIPE SPEC 1G1R (Continued)

JOINTS

½” – 2” Match pipe bore, carbon steel ASTM A105, 3000# threaded, Galvanized.

SMALL FITTINGS

(Size range) (wall thickness, material, end preparation)

SWAGE NIPPLES

½” – 1 ½” Sch 80, seamless carbon steel ASTM A105, threaded both ends, fabrication to

ASTM A733, Galvanized.

2” – 2” Threaded, to be same schedule as pipe of same size, carbon steel ASTM A105,

Galvanized.

PIPE NIPPLES

½” – 1 ½” Sch 80, seamless carbon steel ASTM A53 Gr B or ASTM A106 Gr. B, threaded

both ends, fabrication to ASTM A733, Galvanized.

PLUGS

½” – 1” Forged carbon steel ASTM A105, solid hex head bull plug, NPT threaded to

ASME B16.11, Galvanized.

BOLTS

All sizes Stud bolts alloy steel ASTM A193 Gr B7, each with two hex nuts alloy steel ASTM

A194 Gr 2H, all threaded. Sizes 1 ¼” and over to be one diameter longer than

standard. Stud bolt & nuts shall be fluorocarbon coated or galvanized.

GASKETS

All sizes 4.4 mm thick 316 SS spiral wound with graphite filler and carbon steel guide ring

per ASME B16.5 Group 1B and ASME B16.20.

INSTRUMENT CONNECTION FITTINGS

½” – 1 ½” 3000#, forged carbon steel ASTM A105, threaded, Galvanized. Dimensions per

ASME B16.11, Galvanized.

Use isolation valves with integral welding attachment to pipe. Addition of

gusseting or bracing is required near vibrating machinery. Use of ¾” needle valve

directly connected to thredolet is permitted only in locations remote from collision

and vibration and corrosion hazards. Refer 1515-50-G001 Design Practice for

Piping for further detail.

ORIFICE FLANGES Dimensions to ASME B16.36

2” – 2” Match pipe bore, forged galvanized carbon steel ASTM A105, 150# RF screwed,

furnished with jack screws and drilled for ½” drilled and tapped 15 NPT per AGA.

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

37 of 267

PIPE SPEC 1G1R (Continued)

PROCESS TUBING

¼” – ½” OD 0.9 mm wall thickness, seamless stainless steel ASTM A269 GR TP316.

¾” OD 1.25 mm wall thickness, seamless stainless steel ASTM A269 GR TP316.

PROCESS TUBING FITTINGS

¼” – ½” Forged stainless steel ASTM A182 Gr F316, flareless compression type

connection: Swagelok or equal

TESTING AND CERTIFICATION

(Size range) (type, frequency)

MATERIAL CERTIFICATES – With material supply

All sizes Mill chemical analysis, mill material properties, 100%

WELD PROCEDURE

All sizes Weld procedure qualified, welder qualified, 100%.

> 19 mm wt Post weld heat treatment required

NON DESTRUCTIVE TESTING

All sizes Radiography, 20%

> 19 mm wt Ultrasonic 100%, Magnetic particle 5%

HYDROSTATIC TEST

For Header (NPS ≥ 2”) 2,655 kPag for 1 hour

Small Bore (NPS ≤ 1 ½”) Pneumatic Leak Test shall be performed

FIELD INSTALLATION CHECK LIST

All sizes Weld procedure, NDT, Hydrostatic test

VALVES (Valve spec size, service, ends)

GATE 3A01 ½” – 1½”, General service, 150# RF flanged

3A02 2” – 2”, General sevice, 150# RF flanged

3G03 ½” – 1½”, General service, 800# threaded F x F

GLOBE 4A01 ½” – 1½”, General service, 150# RF flanged

4A02 2” – 2”, General service, 150# RF flanged

4G03 ½” – 1 ½”, General service, 800# threaded F x F

CHECK 5A01 ½” – 1 ½”, General service, 150# RF flanged, Swing type

5A02 2” – 2”, General service, 150# RF flanged, Swing type

5A05 2” – 2”, Gen service, 150# RF flangeless, Wafer type

5G03 ½” – 1 ½”, General service, 800# threaded F x F, Lift check

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

38 of 267

PIPE SPEC 1G1R (Continued)

BALL 6A01 ½” – 1 ½”, General service, 150# RF flanged

6A02 2” – 2”, General service, 150# RF flanged

6G03 ½” – 1 ½”, General service, 800# threaded F x F

NEEDLE 9H01 ½” – 1”, General service, 6000# threaded 20 F x 20 F

9H02 ½” – 1”, General service, 6000# threaded 20 M x 15F

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

39 of 267

PIPE SPEC 1D0R ASME 150# DUPLEX STAINLESS STEEL PIPING

CODE ASME B31.3, ASME B16.5

SIZES ½”, ¾”, 1½, 2”, 3”, 4”, 6”, 8”, 10”, 12”, 14”, 16”, 18”, 20”, 24”

PROCESS FLUIDS

Methanol, Chemical Dosing

DESIGN Pressure @ Maximum Temperature 1,586 kPag @ 150 0C

0

Pressure @ 100 C 1,770 kPag @ 100 0C

Pressure @ Minimum Temperature 1,770 kPag @ -29 0C

MAOP or WT calculation is required for flange limit conditions.

WT ALLOWANCE

Nil corrosion allowance, 12.5% manufacture tolerance

ENDS Raised face and socket weld

MATERIAL SUMMARY

Pipe ASTM A790 UNS S31803 [Duplex SAF 2205]

Flanges ASTM A182 Gr F51

Fittings ASTM A815 UNS S31803

Studs ASTM A193 Gr. B8M

Nuts ASTM A194 Gr 8M

Tubing ASTM A269 Gr 316

Valves ASTM A182 Gr F51 or A890 Gr 4A

PIPING AND FITTINGS

(Size range) (Minimum wall schedule, material, end preparation)

PIPE Dimensions to ASME B36.19

½” Sch 40s 1” Sch 40s

¾” Sch 40s ½ Sch 40s

Seamless stainless steel ASTM A790 UNS S31803 (smls), plain ends

2” Sch 5s 12” Sch 5s

3” Sch 5s 14” Sch 5s

4” Sch 5s 16” Sch 5s

6” Sch 5s 18” Sch 5s

8” Sch 5s 20” Sch 5s

10” Sch 5s 24” Sch 10s

Seamless stainless steel ASTM A790 UNS S31803 beveled ends

FLANGES Dimensions to ASME B16.5

½” – 1½” Match pipe bore, forged stainless steel ASTM A182 Gr F51, 150# RF socket weld

2” – 24” Match pipe bore, forged stainless steel ASTM A182 Gr F51, 150# RFWN

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

40 of 267

PIPE SPEC 1D0R (Continued)

FITTINGS AND BRANCH CONNECTIONS

Refer Piping Branch Connections table

½” – 1½” Match pipe bore, forged stainless steel ASTM A815 UNS S31803, 3000# socket

weld as per ASME B16.11

2” – 24” Match pipe bore for branch connection size limits, seamless stainless steel ASTM

A815 UNS S31803, butt-weld, per ASME B16.9

JOINTS

½” – 1½” Match pipe bore, stainless steel ASTM A182 Gr F51, 150# RF socket weld or

3000# socket weld coupling

2” – 24” Match pipe bore, stainless steel ASTM A182 Gr F51, 600# RFWN flanged or

welded

SMALL FITTINGS

(Size range) (Minimum wall schedule, material, end preparation)

SWAGE NIPPLES

½” – 1½” Sch 80s, seamless stainless steel ASTM A182 Gr F51 (smls), plain both ends,

fabrication to ASTM A733

2” – 6” Beveled end to be same schedule as pipe of same size, stainless steel ASTM

A182 Gr F51 (smls), plain end / beveled end

PIPE NIPPLES

½” – 1½” Sch 80s, seamless stainless steel ASTM A790 UNS S31803 (smls), plain both

ends, fabrication to ASTM A733

PLUGS

½” – 1” Forged stainless steel ASTM A182 Gr F51, solid hex head bull plug, NPT threaded

to ASME B16.11

BOLTS

All sizes Stud bolts alloy steel ASTM A193 Gr B8M, each with two hex nuts alloy steel

ASTM A194 Gr 8M, all threaded. Sizes 1¼” and over to be one diameter longer

than standard.

GASKETS

All sizes 4.5 mm thick Gr 304 (or 316) s/s spiral wound with graphite filler and stainless

steel guide ring per ASME B16.5 Group 1B and ASME B16.20. Colour code to

ASME B16.20. For corrosive or erosive service s/s inner rings to match pipe bore

may be required - Engineer to specify on P&ID.

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

41 of 267

PIPE SPEC 1D0R (Continued)

INSTRUMENT CONNECTION FITTINGS

½” – 1½” 3000#, forged stainless steel ASTM A182 Gr F51, thermowell, sockolet, thredolet

or threaded elbolet. Dimensions per ASME B16.11. Fabricated connections use

fully welded or flanged fittings up to the first isolation valve. Otherwise, use

isolation valves with integral welding attachment to pipe. Addition of gusseting or

bracing is required near vibrating machinery. Use of 20 mm needle valve directly

connected to thredolet is permitted only in locations remote from collision and

vibration and corrosion hazards. Refer 1515-50-G001 Design Practice for Piping

for further detail.

PROCESS TUBING

¼” – ½” OD 0.9 mm min wall thickness, seamless stainless steel

PROCESS TUBING FITTINGS

¼” – ½” OD Forged stainless steel ASTM A182 Gr F316, flareless compression type

connection:

Parker Hannifin CPI preferred for Moomba and SA stellites, or equal

Swagelok for Pt Bonython, Qld, NT, Vic and other sites, or equal

TESTING AND CERTIFICATION

(Size range) (Type, frequency)

MATERIAL CERTIFICATES - With material supply

All sizes Mill chemical analysis, mill material properties, 100%

WELD PROCEDURE

All sizes Weld procedure qualified, welder qualified, 100%

NON DESTRUCTIVE TESTING

All sizes Radiography 100%

HYDROSTATIC TEST

All sizes 2,655 kPag for 1 hour

FIELD INSTALLATION CHECKLIST

All sizes Weld procedure, NDT, hydrostatic test

VALVES

(Valve spec Size, service, ends)

GATE 3A51 ½” – 1½”, Duplex Stainless Steel, 150# RF flanged

3A52 2” – 24”, Duplex Stainless Steel, 150# RF flanged

3G51 ½” – 1½”, Duplex Stainless Steel, 800# socket weld

GLOBE 4A51 ½” – 1½”, Duplex Stainless Steel, 150# RF flanged

4A52 2” – 24”, Duplex Stainless Steel, 150# RF flanged

4G51 ½” – 1½”, Duplex Stainless Steel, 800# socket weld

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

42 of 267

PIPE SPEC 1D0R (Continued)

CHECK 5A51 ½” – 1½”, Duplex Stainless Steel, 150# RF flanged, Swing type

5A52 2” – 24”, Duplex Stainless Steel, 150# RF flanged, Swing type

5A55 2” – 24”, Duplex Stainless Steel, 150# RF flangeless, Wafer type

5G51 ½” – 1½”, Duplex Stainless Steel, 800# socket weld, Lift type

BALL 6A52 2” – 24”, Duplex Stainless Steel, 150# RF flanged

6G51 ½” – 1½”, Duplex Stainless Steel, 800# socket weld

6G55 ½” – 1½”, Duplex Stainless Steel, 800# socket weld C/W Nipple NPT

6G56 ½” – 1½”, Duplex Stainless Steel, 800# socket weld C/W Nipple

BUTTERFLY 8A52 2” – 24”, Duplex Stainless Steel, 150# RF flangeless

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

43 of 267

PIPE SPEC 1H0R ASME 150# COPPER NICKEL PIPING

CODE ASME B31.3, ASME B16.5

SIZES DN ½”, ¾”, 1½, 2”, 3”, 4”, 6”, 8”, 10”, 12”

PROCESS FLUIDS

Fire Water, Sea Water

DESIGN Pressure @ Maximum Temperature 1,379 kPag @ 93.3 oC

MAOP or WT calculation is required for flange limit conditions.

WT ALLOWANCE

Nil corrosion allowance, 12.5 % manufacture tolerance

ENDS Raised face and socket weld

MATERIAL SUMMARY

Pipe ASTM B466 C70600 Seamless or B467 C70600 Welded Annealed.

Flanges Composite CS Cu-Ni

Fittings Cu-Ni Seamless To Grade C70600

Studs ASTM A193 Gr B7, Hot Dip Galvanized

Nuts ASTM A194 Gr 2H, Hot Dip Galvanized

1

Gasket /8” thick soft neoprene rubber, flat face, Garlock 8314 or approved

equal

Tubing Cu-Ni Seamless To Grade C70600

Valves Aluminum Bronze – see valve specifications

PIPING AND FITTINGS

(Size range) (Minimum wall schedule, material, end preparation)

PIPE Dimensions to ASME B36.10

½” Sch 40 1” Sch 40

¾” Sch 40 ½ Sch 40

ASTM B466 C70600 Seamless or B467 C70600 Welded Annealed, plain ends

2” Sch 5 8” Sch 10

3” Sch 5 10” Sch 10

4” Sch 5 12” Sch 10

6” Sch 5

ASTM B466 C70600 Seamless or B467 C70600 Welded Annealed, beveled end

FLANGES Dimensions to ASME B16.5

½” – 1½” Match pipe bore, 90-10 Forge Fe Cu-Ni, 150# FF socket weld

2” – 12” Match pipe bore, 90-10 Forge Fe Cu-Ni, 150# FF Lap Joint

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

44 of 267

PIPE SPEC 1H0R (Continued)

FITTINGS AND BRANCH CONNECTIONS

Refer Piping Branch Connections table

½” – 1½” Match pipe bore, Seamless Cu-Ni Grade C70600, 3000# socket weld as per

ASME B16.11

2” – 24” Match pipe bore for branch connection size limits, Seamless Cu-Ni Grade C70600,

butt-weld, per ASME B16.9

JOINTS

½” – 1½” Match pipe bore, Cu-Ni Grade C70600, 150# FF socket weld flanged or 3000#

socket weld coupling

2” – 24” Match pipe bore, Cu-Ni Grade C70600, 150# FF WN flanged or welded

SMALL FITTINGS

(Size range) (Minimum wall schedule, material, end preparation)

SWAGE NIPPLES

½” – 1½” Sch 80, Seamless Cu-Ni Grade C70600, plain both ends, fabrication to ASTM

A733

2” – 6” Beveled end to be same schedule as pipe of same size, Cu-Ni Grade C70600

plain end / beveled end

PIPE NIPPLES

½” – 1½” Sch 80, Cu-Ni Grade C70600, plain both ends, fabrication to ASTM A733

PLUGS

½” – 1” Cu-Ni Grade C70600, solid hex head bull plug, NPT threaded to ASME B16.11

BOLTS

All sizes ASTM A193 Gr B7, Hot Dip Galvanized, each with two hex nuts alloy steel ASTM

A194 Gr 2H, Hot Dip Galvanized, all threaded. Sizes 1¼” and over to be one

diameter longer than standard.

GASKETS

1

All sizes /8” thick soft neoprene rubber, flat face, Garlock 8314 or approved equal per

ASME B16.5.

INSTRUMENT CONNECTION FITTINGS

½” – 1½” 3000#, Cu-Ni Grade C70600, thermowell, sockolet, thredolet or threaded elbolet.

Dimensions per ASME B16.11. Fabricated connections use fully welded or flanged

fittings up to the first isolation valve. Otherwise, use isolation valves with integral

welding attachment to pipe. Addition of gusseting or bracing is required near

vibrating machinery. Use of 20 mm needle valve directly connected to thredolet is

permitted only in locations remote from collision and vibration and corrosion

hazards. Refer 1515-50-G001 Design Practice for Piping for further detail.

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

45 of 267

PIPE SPEC 1H0R (Continued)

PROCESS TUBING

¼” – ½” OD 0.9 mm min wall thickness, Cu-Ni Grade C70600, SMLS

PROCESS TUBING FITTINGS

¼” – ½” OD Cu-Ni Grade C70600, SMLS, flareless compression type connection:

Swagelok or equal

TESTING AND CERTIFICATION

(Size range) (Type, frequency)

MATERIAL CERTIFICATES - With material supply

All sizes Mill chemical analysis, mill material properties, 100%

WELD PROCEDURE

All sizes Weld procedure qualified, welder qualified, 100%

NON DESTRUCTIVE TESTING

All sizes Radiography 100%

HYDROSTATIC TEST

All sizes 2,068.5 kPag for 1 hour

FIELD INSTALLATION CHECKLIST

All sizes Weld procedure, NDT, hydrostatic test

VALVES

(Valve spec Size, service, ends)

GATE 3A61 ½” – 24”, Aluminum Bronze, 150# FF flanged

GLOBE 4A61 ½” – 24”, Aluminum Bronze, 150# FF flanged

CHECK 5A61 ½” – 24”, Aluminum Bronze, 150# FF flanged

5A62 ½” – 24”, Aluminum Bronze, 150# FF flangeless

BALL 6A61 ½” – 24”, Aluminum Bronze, 150# FF flanged

BUTTERFLY 8A61 ½” – 24”, Aluminum Bronze, 150# FF flangeless

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

46 of 267

PIPE SPEC 1S0R ASME 150# STAINLESS STEEL PIPING

CODE ASME B31.3, ASME B16.5

SIZES ½”, ¾”, 1½, 2”, 3”, 4”, 6”, 8”, 10”, 12”, 14”, 16”, 18”, 20”, 24”

PROCESS FLUIDS

Methanol, Chemical Dosing, Open Drain, Instrument Air, Service Air, Service Water,

Utility Air

DESIGN Pressure @ Maximum Temperature 1390 kPag @ 150 oC

Pressure @ 100 oC 1570 kPag @ 100 oC

Pressure @ Minimum Temperature 1570 kPag @ -100 oC

MAOP or WT calculation is required for flange limit conditions.

MDT of -120 0C is possible by application of design to B31.3 Cl 323.2.2.

WT ALLOWANCE

Nil corrosion allowance, 12.5 % manufacture tolerance on seamless only

ENDS Raised face and socket weld

MATERIAL SUMMARY

Pipe ASTM A312 or ASTM A358, Gr 304 (or 316)

Flanges ASTM A182 Gr F 304 (or F 316)

Fittings ASTM A403 Gr WP 304 (or WP 316)

Studs ASTM A193 Gr. B8M

Nuts ASTM A194 Gr. 8M

Tubing ASTM A269 Gr 304 (or 316)

Valves Stainless steel - see valve specifications

PIPING AND FITTINGS

(Size range) (Minimum wall thickness, material, end preparation)

PIPE Dimensions to ASME B36.19

½” Sch 40s 1” Sch 40s

¾” Sch 40s 1½” Sch 40s

Seamless stainless steel ASTM A312 Gr. 304 (or 316) or Welded stainless steel

ASTM A358 Gr 304 CL1 (or 316 CL1), plain ends

2” Sch 10s 14” Sch 10s*

3” Sch 10s 16” Sch 10s*

4” Sch 10s 18” Sch 10s*

6” Sch 10s 20” Sch 10s*

8” Sch 10s* 22” Sch 10s*

10” Sch 10s* 24” Sch 10s *

Seamless stainless steel ASTM A312 Gr 304 (or 316) or Welded stainless steel

ASTM A358 Gr 304 CL1 (or 316 CL1), beveled ends

* In low pressure systems over 8” diameter, thinner wall pipes of welded

construction may be used. Select pipe thickness and material for economy

AAL DEVELOPMENT PROJECT – FPSO FEED

PIPING SPECIFICATION AND MATERIAL

CLASSES

SANTOS NORTHWEST NATUNA B.V DOCUMENT NO. 9600-050-SPC-0002 REV. D4

47 of 267

PIPE SPEC 1S0R (Continued)

FLANGES Dimensions to ASME B16.5

½” – 1½” Match pipe bore, forged stainless steel ASTM A182 Gr F304 (or F316), 150# RF

socket weld

2” – 24” Match pipe bore, forged stainless steel ASTM A182 Gr F304 (or F316), 150# RFWN

FITTINGS AND BRANCH CONNECTIONS

Refer Piping Branch Connections table

½” – 1½” Match pipe bore, forged stainless steel ASTM A182 Gr F304 (or F316), 3000#

socket weld as per ASME B16.11

2” – 24” Match pipe bore for branch connection size limits, seamless stainless steel ASTM

A403 Gr WP304 (or WP316), butt-weld, per ASME B16.9

JOINTS

½” – 1½” Match pipe bore, stainless steel ASTM A182 Gr F304 (or F316), 150# RF socket

weld or 3000# socket weld coupling

2” – 24” Match pipe bore, stainless steel ASTM A182 Gr F304 (or F316), 150# RFWN

flanged or welded

SMALL FITTINGS

(Size range) (Minimum wall thickness, material, end preparation)

SWAGE NIPPLES

½” – 1½” Sch 80s, seamless stainless steel ASTM A182 Gr 304 (or 316), plain both ends,

fabrication to ASTM A733

2” – 6” Beveled end to be same schedule as pipe of same size, stainless steel ASTM A182

Gr 304 (or 316) (smls), plain end / beveled end

PIPE NIPPLES

½” – 1½” Sch 80s, seamless stainless steel ASTM A312 Gr 304 (or 316), plain both ends,

fabrication to ASTM A733

PLUGS