Académique Documents

Professionnel Documents

Culture Documents

New

Transféré par

Suman Nakarmi0 évaluation0% ont trouvé ce document utile (0 vote)

13 vues1 pagerapture

Copyright

© © All Rights Reserved

Formats disponibles

TXT, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentrapture

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme TXT, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

13 vues1 pageNew

Transféré par

Suman Nakarmirapture

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme TXT, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

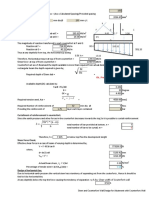

1.

1 Introduction and Problem Statement

Before 2007, the Minnesota Department of Transportation (MnDOT) found that many

precast, prestressed concrete bridge girders were arriving at the construction site

with cambers much lower than predicted. It was thought that the method for

estimating the camber at the time of erection was the problem. The method being

used at the time was the �PCI multiplier method,� which specified that the upward

deflection due to initial prestress and downward deflection due to self-weight be

multiplied by 1.80 and 1.85, respectively. In 2007, MnDOT began using a single

multiplier of 1.5, but observed erection cambers were still lower than predicted.

In a study conducted by O�Neill et al. (2012), it was found that, for 1067 girders

produced between 2006 and 2010, the average camber at release on average was only

74% of the predicted design camber. The main factor contributing to the lower than

predicted cambers was the underestimation of the concrete elastic modulus at

release. The underestimation of the elastic modulus resulted from two factors.

First, the relation used to predict the modulus was the ACI 363 equation associated

with high strength concrete (i.e., f�c = 6,000 psi) rather than the Pauw (1960)

equation. Second, the concrete compressive strength at release used in the equation

was underestimated by approximately 15% on average. These factors accounted for the

majority of the difference in the measured to predicted cambers. The remainder of

the difference was attributed to possible prestress losses due to thermal effects

during fabrication. Because the girders are cast on a fixed bed, changes in

temperature during fabrication cause associated changes in stress in the strands.

In this study, it was assumed that the temperature changes that occur prior to

steel/concrete bond result in unrecoverable changes in prestress force that become

locked in the girders. This report summarizes an

Vous aimerez peut-être aussi

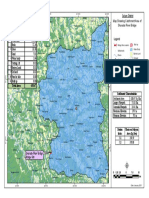

- Summary of Land Use Type in Catchment AreaDocument1 pageSummary of Land Use Type in Catchment AreaSuman NakarmiPas encore d'évaluation

- 15 CV 741Document48 pages15 CV 741Suman NakarmiPas encore d'évaluation

- At Support: IRC 70R Wheel Vechicle Main Girder Response (ILD)Document2 pagesAt Support: IRC 70R Wheel Vechicle Main Girder Response (ILD)Suman NakarmiPas encore d'évaluation

- Deflection and Rotation Due To Dead Load: Mid Span SupportDocument3 pagesDeflection and Rotation Due To Dead Load: Mid Span SupportSuman NakarmiPas encore d'évaluation

- Compression Member LSMDocument1 pageCompression Member LSMSuman NakarmiPas encore d'évaluation

- Connection Design:: SB NB Ub Yb Mo MB MFDocument1 pageConnection Design:: SB NB Ub Yb Mo MB MFSuman NakarmiPas encore d'évaluation

- Assessment of A Railway Concrete Arch Bridge by Numerical Modelling and MeasurementsDocument10 pagesAssessment of A Railway Concrete Arch Bridge by Numerical Modelling and MeasurementsSuman NakarmiPas encore d'évaluation

- IRC 112: Limit State Design of RCC Bridges Course InformationDocument1 pageIRC 112: Limit State Design of RCC Bridges Course InformationSuman NakarmiPas encore d'évaluation

- PileDocument5 pagesPileSuman NakarmiPas encore d'évaluation

- Design of Rear Counterfort:: Ok, Provided Depth Is GreaterDocument2 pagesDesign of Rear Counterfort:: Ok, Provided Depth Is GreaterSuman NakarmiPas encore d'évaluation

- Tringe Khola - CatchmentDocument1 pageTringe Khola - CatchmentSuman NakarmiPas encore d'évaluation

- Methodology:: Structural Element of Open Spandrel Arch BridgeDocument1 pageMethodology:: Structural Element of Open Spandrel Arch BridgeSuman NakarmiPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)