Académique Documents

Professionnel Documents

Culture Documents

UREZ6 X

Transféré par

hai dangDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

UREZ6 X

Transféré par

hai dangDroits d'auteur :

Formats disponibles

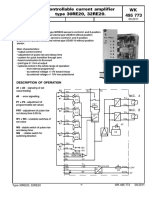

Electrically controlled directional WK

control poppet valve type UREZ6 423 770

NS6 up to 35 MPa up to 30 dm3/min 10.2015

DATA SHEET - OPERATION MANUAL

APPLICATION version 4UREZ6

Electrically controlled directional control poppet valve

type UREZ6… is intended for changing the direction of

hydraulic fluid flow in a system, which allows for change

of the direction of the receiver

motion - usually a piston rod of a cylinder or a hydraulic

motor, as well as performance of modes start, stop. It is version 3UREZ6

suitable for subplate mounting in any position in

hydraulic systems.

The product is complied with the regulations of

directive 2006/95/WE for the following voltages:

•50 – 250 V for AC

•75 – 250 V for DC

DESCRIPTION OF OPERATION

3UREZ6 D1 - 12/B15 G24 N Z4

T P

A B

P P

A

6 2 T 4 3 1 5 7 8

Main elements of the UREZ6… type valve include: body (1) the flow from A to T is open. Override of the valve is

with valve seats (2) and (3), spool with a closing poppet (4), performed by moving the spool (4) by the solenoid (5) to the

solenoid (5), spring (6) and manual override switch (7). Both opposite end position, where the poppet of the spool (4) is

chambers from the side of the spring (6) and solenoid (5) are pressed to the port (3) allowing to open the flow from

by the design of the body (1) and the spool (4) connected to P to A and shutting off port T. Return to the initial (neutral)

port P and shut off from port T in order to balance the forces position is forced by the spring (6), In case of power outage,

affecting the spool (4). This allows the flow in specific it is possible to perform manual override of the valve by the

directions (in accordance to the diagrams on page 4) at the button (7). In the 3-way version, port B of the valve is

max. working pressure in each of the ports. The 3-way manufactured as a blind hole, after shutting of the T

version of the valve 3UREZ6… can be manufactured as connection, the valve can act as a 2-way valve. When

closed in neutral (current-free) position - version 3UREZ6D1 connected to an additional sandwich type subplate (9), the

(shown on the drawing) or open - version 3UREZ6D2, 3-way directional valve can be used as a 4-way - version

depending on the body (1) side where the solenoid (5) and 4UREZ6… (description of operation on page 2). Optionally,

spring (6) are installed. In the version shown on the drawing, the valve can be equipped with a reducer (8), installed in

in neutral position the poppet of the spool (4) is pressed by port P.

the spring (6) to the valve seat (2). Port P remains shut-off,

Type UREZ6 -1- WK 423 770 10.2015

DESCRIPTION OF OPERATION

4UREZ6 D3 - 12/B15 G24 N Z4

6 2 3 5 7

C-C

1 4

C T P

A B

T A P

12

11

10

13

B

T A B P

14

C P

A P B

9 8

T

A 4-way version of the valve 4UREZ6… (analogically to control spool (10) through port A (connected to T).

the 3-way version) can be manufactured as closed in Pressure in port P presses the ball (11) to the valve

neutral (current-free) position - version 4UREZ6D3 (shown seat (12). This results in opening the flow from P to B and

on the drawing) or open - version 4UREZ6D4, depending from A to T (position shown on the drawing). After

on the body (1) side where the solenoid (5) and spring (6) overriding the valve ports P and A are connected.

are installed. In the version shown on the drawing, in Pressure supplied from port A through the canal (14) to

neutral position, the poppet of the spool (4) is pressed by the larger surface of the control spool (10) results in the

the spring (6) to the port (2). Port P is shut off, flow from ball (11) being pressed to the seat(13). This results in

the A to T direction is open. This allows for a relief of the opening the flow from the B to T and from P to A

check valve space from the side of larger surface of the directions.

WK 423 770 10.2015 -2- Type UREZ6

TECHNICAL DATA

Hydraulic fluid mineral oil

Required fluid cleanliness class ISO 4406 class 20/18/15

o

Nominal fluid viscosity 37 mm 2/s at temperature 55 C

Viscosity range 2,8 up to 380 mm 2/s

recommended 40 oC up to 55 o C

Fluid temperature range (in a tank)

max -20 o C up to +70 oC

Ambient temperature range - 20 oC up to +50 oC

Maximum operating pressure ports P, A, B, T - 35 MPa

versions 3UREZ6... - 1,9 kg

Weight

versions 4UREZ6... - 2,9 kg

DC AC

Nominal supply voltage for solenoids (plug-in connector with rectifier)

12V 24V 110V 110V - 50Hz 220V- 50Hz

Supply voltage tolerance ±10%

Power consumption (DC) 30 W

Degree of pr otection IP 65

Solenoid coil temperature max 150 oC

INSTALLATION AND OPERATION REQUIREMENTS

1. Only fully functional and operational valve, properly 5. In order to ensure failure free and safe operation the

connected to electrical installation must be used. following must be checked:

Connecting or disconnecting the valve to an electrical • condition of the electrical connection

installation must only be carried out by qualified • proper working of the valve

personnel. • cleanliness of the hydraulic fluid

2. Ground connection ( ) must be connected with 6. Due to heating of electromagnet solenoid coils to

protective earth wire (PE ) in supply system high temp., the valve shall be placed in such way to

according to appropriate instructions. eliminate the risk of accidental contact with solenoid

3. Solenoid plug shall precisely adhere to socket and shall during operation or to apply suitable covers acc. to

be secured with thread bolt screwed in securely in a PN - EN ISO 13732 - 1 and PN - EN 982

place. It is forbidden to operate the valve if the 7. In order to ensure tightness of the directional valve

tightness and suitable clamp of cable in the plug gland block, one should take care of dimension of sealing

are not ensured. rings and valve operation parameters given in this

4. During the period of operation must be kept fluid Data Sheet - Operation Manual

viscosity acc. to requirements defined in this Data 8. A person that operates the valve must be thoroughly

Sheet - Operation Manual familiar with this Data Sheet - Operation Manual.

Type UREZ6 -3- WK 423 770 10.2015

DIAGRAMS

schematic diagrams for 3-way * valves - versions 3UREZ6...

valve working positions working and

version indirect positions

A A

a b a b

3UREZ6 D1... a b

a b

P T P T

A A

a b a b

3UREZ6 D2... a b a b

P T P T

hydraulic diagrams for 4-way valves - versions 4UREZ6...

valve simplified detailed

version working positions working and

indirect positions

A

a b

A B A B a b

a b a b P T

4UREZ6 D3... a b a b

P T P T

P B T A

A

a b

A B A B a b

a b a b P T

4UREZ6 D4... a b a b

P T P T

P B T A

NOTE:

(*) - when using a 3-way valve as a 2-way valve on must cut off the T port.

WK 423 770 10.2015 -4- Type UREZ6

OVERALL AND CONNECTION DIMENSIONS

3-way version 3UREZ6...

5 3 1 4 2 6 10

O 9,4 4 deepenings

15

5,3 4 holes

H (acc. to tab.)

a b

55

48

42

23,5

7 45

8 155

70

T**

A

32,5

B*

31

P

40,5 15

70 70

155 9

electrical connection power supply voltage dimension H 1 - Solenoid on side a

plug-in-connector type DC 2 - Solenoid on side b

83,5

ISO 4400 - item 3, 4 12V 24V 110V 3 - Plug-in-connector on side a - type ISO 4400

plug-in-connector type AC (DIN 43650 - A)

ISO 4400 - item 5, 6 90,5 4 - Plug-in-connector on side b - type ISO 4400

with rectifier 110V -50Hz 220V -50Hz (DIN 43650 - A)

5 - Plug-in-connector on side a - type ISO 4400

(DIN 43650 - A) with rectifier

6 - Plug-in-connector on side b - type ISO 4400

(DIN 43650 - A) with rectifier

7 - Sealing o-ring 9,25 x 1,78 - 4 pcs/set (P, T**, A, B*)

11

O

M5 depth 10 - 4 holes

7,6 (max) - 4 holes (P,T, A, B)

8 - Overall dimension of the 3-way valve with solenoid

on side a - version 3UREZ6D2...

9 - Overall dimension of the 3-way valve with solenoid

T**

on side b - version 3UREZ6D1...

45 (min)

A B*

31,75

10 - Additional distance for dismantling the plugs (item 3 to 6)

32,5

26,55

P 11 - Porting pattern for directional spool valve -

configuration of connection holes in accordance with

the standard ISO 4401

16,25

0,75

5,95

10,3 designation ISO 4401-03-02-0-94

19 (nominal size CETOP 03)

27,8 fixing screws M5 x 50 - 10.9 in accordance with

40,5 15 (min) PN - EN ISO 4762 - 4 pcs/set - must be ordered

separately; tightening torque Md = 9 Nm

70 (min) 12 - Subplate surface required

r 0,01/100 mm

0,63

NOTES:

(*) - port B in the 3-way valves (versions 3UREZ6...) is

manufactured as a deepening with a sealing ring (blind hole)

(**) - when using the above version of the valve as a 2-way

12 valve, additionally the T port should be cut off

Type UREZ6 -5- WK 423 770 10.2015

OVERALL AND CONNECTION DIMENSIONS

4-way version 4UREZ6...

5 3 1

O 9,4 4 deepenings

4 2 6 10

15

5,3 4 holes

a b

H (acc. to tab.)

55

48

23,5

86,5

44,5

7

4 screws M5 45

8,5

8 155

70

32,5

A B

31

P

40,5 15

70 70

155 9

electrical connection power supply voltage dimension H 1 - Solenoid on side a

plug-in-connector type DC 2 - Solenoid on side b

128

ISO 4400 - item 3, 4 12V 24V 110V 3 - Plug-in-connector on side a - type ISO 4400

plug-in-connector type AC (DIN 43650 - A)

ISO 4400 - item 5, 6 135 4 - Plug-in-connector on side b - type ISO 4400

with rectifier 110V -50Hz 220V -50Hz (DIN 43650 - A)

5 - Plug-in-connector on side a - type ISO 4400

11

O

M5 depth 10 - 4 holes

7,6 (max) - 4 holes (P,T ,A, B)

(DIN 43650 - A) with rectifier

6 - Plug-in-connector on side b - type ISO 4400

(DIN 43650 - A) with rectifier

T 7 - Sealing o-ring 9,25 x 1,78 - 4 pcs/set (P, T**, A, B*)

45 (min)

8 - Overall dimension of the 4-way valve with solenoid

A B

31,75

32,5

26,55

on side a - version 3UREZ6D4...

P 9 - Overall dimension of the 4-way valve with solenoid

on side b - version 3UREZ6D3...

16,25

0,75

5,95

10 - Additional distance for dismantling the plugs (item 3 to 6)

10,3

11 - Porting pattern for directional spool valve -

19

configuration of connection holes in accordance with

27,8 the standard ISO 4401

40,5 15 (min) designation ISO 4401-03-02-0-94

70 (min) (nominal size CETOP 03)

r 0,01/100 mm

0,63

fixing screws M5 x 95 - 10.9 in accordance with

PN - EN ISO 4762 - 4 pcs/set - included in the scope

of delivery; tightening torque Md = 9 Nm

12 - Subplate surface required

12

WK 423 770 10.2015 -6- Type UREZ6

PERFORMANCE CURVES

o

measured at viscosity ν = 41 mm 2/s and temperature t = 50 C

Flow resistance curves

characterisic curves ∆p (Q) of the 3-way directional poppet

valve - version 3UREZ6... for various flow directions

2,5

performance flow

1

diagram no. direction

2,0

2 1 P→A

2 A →T

∆ p [MPa]

1,5

1,0

0,5

0 5 10 15 20 25 30

3

Q [dm /min]

characterisic curves ∆p (Q) of the 4-way directional poppet

valve - version 4UREZ6... for various flow directions

4,0 performance

3 flow

3,5 diagram no. direction

1

3,0 1 P →A

4 2 P→B

2,5

∆ p [MPa]

2 3 A →T

2,0

4 B →T

1,5

1,0

0,5

0 5 10 15 20 25 30

3

Q [dm /min]

Operating limits curves

characterisic curves p - Q of the directional poppet valve

type UREZ6...; 3 and 4-way versions for various flow

directions

40

performance valve version flow

35 diagram no. direction

1 2 3 1 ...UREZ6D2...; ...D4... P → A

30

2 ...UREZ6D1...; ...D3... P → A

25 A →T

3 ...UREZ6...

p [MPa]

20 (B→T)*

15 NOTE:

(*) - flow direction B → T refers only to 4-way

10 versions 4UREZ6...

5

0 5 10 15 20 25 30

3

Q [dm /min]

Type UREZ6 -7- WK 423 770 10.2015

SPOSÓB ZAMAWIANIA

UREZ 6

Number of service ports

*

3-way =3

4-way =4

Nominal size (NS)

NS6 =6

Hydraulic diagram (acc. to page 4)

diagram D1 (for 3-way version 3UREZ6...) = D1

diagram D2 (for 3-way version 3UREZ6...) = D2

diagram D3 (for 4-way version 4UREZ6...) = D3

diagram D4 (for 4-way version 4UREZ6...) = D4

Series number

(12-19) - connection and installation dimensions unchanged = 1X

series 12 = 12

Throttle orifice (in port P)

without orifice = no designation

orifice φ 0,8 = B 08

orifice φ 1,0 = B 10

orifice φ 1,2 = B 12

orifice φ 1,2 = B 12

Supply voltage for solenoid

12V DC = G12

24V DC = G24

110V DC = G110

110V AC 50Hz (plug-in-connector with rectifier) = W110R

220V AC 50Hz (plug-in-connector with rectifier) = W220R

Manual override

solenoid with manual override =N

Electrical connection

plug-in-connector type ISO 4400 (DIN 43650 - A) without LED = Z4

plug-in-connector type ISO 4400 with LED = Z4L

Sealing

NBR (for fluids on mineral oil base) = no designation

FKM (for fluids on phosphate ester base) =V

Further requirements in clear text

(to be agreed with the manufacturer)

NOTES:

The directional poppet valve should be ordered according to the above coding.

The symbols in bold are preferred versions in short delivery time.

Coding example: 3UREZ6 D1 - 12/G24 N Z4

WK 423 770 10.2015 -8- Type UREZ6

SUBPLATES AND FIXING SCREWS

Subplates must be ordered according to Data Sheet Fxing screws for the valve versions:

WK 496 480. Subplate symbols: • version 3UREZ6... - M5 x 50 - 10,9 acc. to PN - EN ISO 4762

G 341/01 - threaded connections G 1/4 pcs 4/set must be ordered separately.

G 342/01 - threaded connections G 3/8 • version 4UREZ6... - M5 x 95 - 10,9 acc. to PN - EN ISO 4762

G 502/01 - threaded connections G 1/2 pcs 4/set are delivered with the valve.

G 341/02 - threaded connections M14 x 1,5

G 342/02 - threaded connections M16 x 1,5 Tightening torque Md = 9 Nm

Subplates must be ordered separately. .

NOTE:

The subplate symbol in bold is the preferred

version available in short delivery time.

Type UREZ6 -9- WK 423 770 10.2015

PONAR Wadowice S.A.

ul. Wojska Polskiego 29

34-100 Wadowice

tel. +48 33 488 21 00

fax.+48 33 488 21 03

www.ponar-wadowice.pl

WK 423 770 10.2015 - 10 - Type UREZ6

Vous aimerez peut-être aussi

- Farval Dr45 & Dr460a Reversing ValvesDocument8 pagesFarval Dr45 & Dr460a Reversing ValvesanwarmughalPas encore d'évaluation

- Service Training 2005Document76 pagesService Training 2005Heidi Cuevas Venegas100% (1)

- Sample Maintenance Sheet: TrailerDocument2 pagesSample Maintenance Sheet: TrailerTrisPas encore d'évaluation

- Canon MP520 Service ManualDocument35 pagesCanon MP520 Service ManualJacek Piasecki0% (1)

- Ra 22058 PDFDocument12 pagesRa 22058 PDFmanjappahPas encore d'évaluation

- 4-Port, Spool Type, Directional Control Valves With Hand Lever Actuation and Wide Variety of Spool Types With Spring-Centered, Spring-Offset and De-Tent ArrangementsDocument4 pages4-Port, Spool Type, Directional Control Valves With Hand Lever Actuation and Wide Variety of Spool Types With Spring-Centered, Spring-Offset and De-Tent ArrangementsSiddharth GajjarPas encore d'évaluation

- Group 6 RCV Pedal: 1. StructureDocument6 pagesGroup 6 RCV Pedal: 1. StructureالمهندسوليدالطويلPas encore d'évaluation

- 3drep6 2x SeriesDocument14 pages3drep6 2x SeriesKings JamesPas encore d'évaluation

- Pressure Relief Valve Pilot Operated Remote Pressure Adjusting ValveDocument10 pagesPressure Relief Valve Pilot Operated Remote Pressure Adjusting ValveDaniel Sandoval FernándezPas encore d'évaluation

- Re 64551 PDFDocument8 pagesRe 64551 PDFAlvaro FloresPas encore d'évaluation

- Pilot Control Device in Pedal Design For The Remote Control of Directional Valves, Pumps and Motors Type 2 TH6 R, Series 1XDocument8 pagesPilot Control Device in Pedal Design For The Remote Control of Directional Valves, Pumps and Motors Type 2 TH6 R, Series 1XAlvaro FloresPas encore d'évaluation

- 2 FRM 5 (Series 3X) - RA28138 - 5.94Document4 pages2 FRM 5 (Series 3X) - RA28138 - 5.94pjsc.online.workPas encore d'évaluation

- Re64354 2003-06Document20 pagesRe64354 2003-06thierrylindoPas encore d'évaluation

- Chapter 3: Valves and CircuitsDocument13 pagesChapter 3: Valves and CircuitsSayanSanyalPas encore d'évaluation

- Vaso Piscina PRDocument40 pagesVaso Piscina PRemmanuelgovernor433Pas encore d'évaluation

- AX152886480987en 000202Document44 pagesAX152886480987en 000202HIDRAULICA MANSE SERVICIO TECNICOPas encore d'évaluation

- Rexroth A10VODocument8 pagesRexroth A10VOAdam100% (1)

- P-80 Hand Pump Parts PDFDocument8 pagesP-80 Hand Pump Parts PDFJustinPas encore d'évaluation

- WE10 S 15 XDocument12 pagesWE10 S 15 Xargo_arjieantoPas encore d'évaluation

- 2/2-, 3/2-And 4/2-Way Directional Poppet Valves, Solenoid OperatedDocument16 pages2/2-, 3/2-And 4/2-Way Directional Poppet Valves, Solenoid OperatedOgulcan CafPas encore d'évaluation

- 140h-Cont Val9Document2 pages140h-Cont Val9thiherPas encore d'évaluation

- Group 6 RCV Pedal: 1. StructureDocument6 pagesGroup 6 RCV Pedal: 1. Structuredeniden2013Pas encore d'évaluation

- WK 499 482 Directional Spool Valve Type WEH16 Electro-Hydraulically OperatedDocument24 pagesWK 499 482 Directional Spool Valve Type WEH16 Electro-Hydraulically OperatedРома БлошенкоPas encore d'évaluation

- Pressure Relief Valve Direct Operated: Type DBD... 10Document8 pagesPressure Relief Valve Direct Operated: Type DBD... 10Daniel Sandoval FernándezPas encore d'évaluation

- Eight Position Cylinders Service Information: Warnings-Installation and MountingDocument10 pagesEight Position Cylinders Service Information: Warnings-Installation and MountingyelmustafaaliPas encore d'évaluation

- BrandDocument66 pagesBrandCentral HydraulicsPas encore d'évaluation

- Figure 1. Hydraulic Schematic SymbolsDocument20 pagesFigure 1. Hydraulic Schematic Symbolsamin chaabenPas encore d'évaluation

- WK 496 480 Subplates Type G Nominal Size 6: Ns6 32 MpaDocument4 pagesWK 496 480 Subplates Type G Nominal Size 6: Ns6 32 MpaРома БлошенкоPas encore d'évaluation

- MEC-E5003 Fluid Power Basics Calculation Exercises 3 Spring 2017Document2 pagesMEC-E5003 Fluid Power Basics Calculation Exercises 3 Spring 2017أبو أسامة حمديPas encore d'évaluation

- 140h-Cont Val10Document2 pages140h-Cont Val10thiherPas encore d'évaluation

- Group 6 RCV Pedal: 1. StructureDocument6 pagesGroup 6 RCV Pedal: 1. StructureАлексейPas encore d'évaluation

- 2/2, 3/2 and 4/2 Directional Seat Valve With Solenoid ActuationDocument16 pages2/2, 3/2 and 4/2 Directional Seat Valve With Solenoid Actuationmanuel polancoPas encore d'évaluation

- Polti Vaporetto 1030-ENGDocument12 pagesPolti Vaporetto 1030-ENGChristian AlbertiniPas encore d'évaluation

- 4/3, 4/2 and 3/2 Directional Valve With Wet-Pin AC or DC SolenoidDocument10 pages4/3, 4/2 and 3/2 Directional Valve With Wet-Pin AC or DC SolenoidMahmoued LotfyPas encore d'évaluation

- Illustrated Parts Catalogue: Ed. 4 Rev. 3 - November, 2018Document2 pagesIllustrated Parts Catalogue: Ed. 4 Rev. 3 - November, 2018Andrii KlishchevskyiPas encore d'évaluation

- WK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32Document22 pagesWK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32Рома БлошенкоPas encore d'évaluation

- Manual Cargador Hyundai6Document6 pagesManual Cargador Hyundai6hernando ramosPas encore d'évaluation

- Group 3 Self Level Valve: 1. StructureDocument6 pagesGroup 3 Self Level Valve: 1. StructureTaha RdmanPas encore d'évaluation

- Farval Dr45 & Dr460a Reversing ValvesDocument8 pagesFarval Dr45 & Dr460a Reversing ValvesRobinson MarinPas encore d'évaluation

- Válvula Direcional RexRothDocument22 pagesVálvula Direcional RexRothrfcardPas encore d'évaluation

- Instructions RPE4-10 RPEW4-10 Ha0061 ENDocument1 pageInstructions RPE4-10 RPEW4-10 Ha0061 ENVito LaudicinaPas encore d'évaluation

- 4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XDocument8 pages4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XlizbethdiosesPas encore d'évaluation

- SECTION 07 Hydraulics2 9020-9030Document16 pagesSECTION 07 Hydraulics2 9020-9030Vjz10997100% (2)

- Esquema Hidraulico MT1740Document2 pagesEsquema Hidraulico MT1740el mendaPas encore d'évaluation

- Group 6 RCV PedalDocument6 pagesGroup 6 RCV Pedaldeniden2013Pas encore d'évaluation

- Belimo Control ValveDocument106 pagesBelimo Control ValveAnderson SiqueiraPas encore d'évaluation

- Section 6 Work EquipmentDocument33 pagesSection 6 Work EquipmentАлексейPas encore d'évaluation

- Re10460 PDFDocument20 pagesRe10460 PDFINVESTIGACION Y DESARROLLOPas encore d'évaluation

- 4we6 Series 6xDocument12 pages4we6 Series 6xJas SumPas encore d'évaluation

- L2082 Rev. G 01/20 P-80, 1006 Models With Date Code Beginning With The Letter "D". P-84 Models With Date Code Beginning With The Letter "A". IndexDocument8 pagesL2082 Rev. G 01/20 P-80, 1006 Models With Date Code Beginning With The Letter "D". P-84 Models With Date Code Beginning With The Letter "A". Indexbayo96Pas encore d'évaluation

- REXROTH 4wrz 16 5x-6x Series PDFDocument20 pagesREXROTH 4wrz 16 5x-6x Series PDFمحمدلمينابراهيمالموريتاني100% (1)

- Presure Limiting Load Sensing Compensator Pvb5 Thru Pvb29Document2 pagesPresure Limiting Load Sensing Compensator Pvb5 Thru Pvb29loloeasPas encore d'évaluation

- SODODocument1 pageSODOMinh NguyễnPas encore d'évaluation

- SodoDocument1 pageSodoMinh NguyễnPas encore d'évaluation

- SodoDocument1 pageSodoMinh NguyễnPas encore d'évaluation

- LUDV Control Block in Mono Block/sandwich Plate Design M7-20Document16 pagesLUDV Control Block in Mono Block/sandwich Plate Design M7-20rodrigomessiasPas encore d'évaluation

- MO-40 Re64370 2015-01Document12 pagesMO-40 Re64370 2015-01omar farukPas encore d'évaluation

- Lab Sesseion #1Document14 pagesLab Sesseion #1m.sheraz malikPas encore d'évaluation

- 4wrte Mannesmann RexrothDocument16 pages4wrte Mannesmann RexrothRuben Torres100% (1)

- GROUP 5 EPPR (Electro Proportional Pressure Reducing) VALVEDocument3 pagesGROUP 5 EPPR (Electro Proportional Pressure Reducing) VALVERiahi RezegPas encore d'évaluation

- Section 6 Work EquipmentDocument33 pagesSection 6 Work Equipmentjuanchis650Pas encore d'évaluation

- MFB Training PDFDocument19 pagesMFB Training PDFhai dangPas encore d'évaluation

- Regenerative Braking Strategy For Motor Hoist by UltracapacitorDocument9 pagesRegenerative Braking Strategy For Motor Hoist by Ultracapacitorhai dangPas encore d'évaluation

- Hydraulic Regenerative Braking System PDFDocument12 pagesHydraulic Regenerative Braking System PDFhai dangPas encore d'évaluation

- KoreisováG Identification-Of-Viscous SP-DFJP 2006 PDFDocument10 pagesKoreisováG Identification-Of-Viscous SP-DFJP 2006 PDFhai dangPas encore d'évaluation

- 30 Re 20Document4 pages30 Re 20hai dangPas encore d'évaluation

- " " Series Variable Displacement Piston PumpsDocument42 pages" " Series Variable Displacement Piston Pumpshai dangPas encore d'évaluation

- Week 5 ABS ESP TCS SystemsDocument72 pagesWeek 5 ABS ESP TCS SystemsahmedaboshadyPas encore d'évaluation

- Scooter IndiaDocument16 pagesScooter IndiaPankaj GauravPas encore d'évaluation

- Network Termination Unit STU2: Always Up-To-DateDocument2 pagesNetwork Termination Unit STU2: Always Up-To-DateНатальяPas encore d'évaluation

- TrainingDocument31 pagesTrainingAyush Goyal100% (2)

- BVM-Seminar PPT NEWDocument29 pagesBVM-Seminar PPT NEWSandeep JonathanPas encore d'évaluation

- Manual de Servicio WF Xxseriespdf PDFDocument89 pagesManual de Servicio WF Xxseriespdf PDFromero_reveronPas encore d'évaluation

- Kubota Tractor B21 Parts CatalogDocument200 pagesKubota Tractor B21 Parts CatalogSAGAR GUPTAPas encore d'évaluation

- CEPU TOA Price ListDocument5 pagesCEPU TOA Price ListJoglo SoloPas encore d'évaluation

- Company Details ReepDocument9 pagesCompany Details ReepDharshini NagalingamPas encore d'évaluation

- Synchronization of MSEB With GeneratorDocument2 pagesSynchronization of MSEB With GeneratorSarah FrazierPas encore d'évaluation

- Janome 1422 Sewing Machine Instruction ManualDocument42 pagesJanome 1422 Sewing Machine Instruction ManualiliiexpugnansPas encore d'évaluation

- Chennai Forge Products PVT LTD ProfileDocument33 pagesChennai Forge Products PVT LTD ProfilepmlmkpPas encore d'évaluation

- Air Dryer - FushengDocument44 pagesAir Dryer - Fushengrema irma100% (1)

- List Capel SPK2 1075Document5 pagesList Capel SPK2 1075singki bernando junitra singki bernando junitraPas encore d'évaluation

- M12 Series DC 3-Wire SN 8/10mm: Inductive Sensors FeaturesDocument1 pageM12 Series DC 3-Wire SN 8/10mm: Inductive Sensors Featuresany3000Pas encore d'évaluation

- Arduino SHT15 HumidityDocument6 pagesArduino SHT15 Humiditypeterson_msc5Pas encore d'évaluation

- Catalogo Comercial Troidon 44 (Ing)Document3 pagesCatalogo Comercial Troidon 44 (Ing)EDWIN ESPEJOPas encore d'évaluation

- SAIDEEPA Top Hammer Catalogue - CompressedDocument36 pagesSAIDEEPA Top Hammer Catalogue - Compressedantonio rodriguesvieiraPas encore d'évaluation

- Savback Helicopter Airbus Helicopters h130 2024Document5 pagesSavback Helicopter Airbus Helicopters h130 2024Ene Alexandru-MihaiPas encore d'évaluation

- VMC Maintenance Manual (Alarm) : (Mynx 6500/)Document156 pagesVMC Maintenance Manual (Alarm) : (Mynx 6500/)Sagar HankarePas encore d'évaluation

- Catalogo Productos Merten Schneider KNX ISC02052EN - 2010Document95 pagesCatalogo Productos Merten Schneider KNX ISC02052EN - 2010jjjjPas encore d'évaluation

- Technical Education and Skills Development AuthorityDocument5 pagesTechnical Education and Skills Development AuthorityRenniel DingcongPas encore d'évaluation

- DeviceNet BrochureDocument251 pagesDeviceNet BrochureabufaruqiPas encore d'évaluation

- Nte 128-129 PDFDocument3 pagesNte 128-129 PDFrrebollarPas encore d'évaluation

- Electromagnetic Clutch System Full Seminar Report 4537Document30 pagesElectromagnetic Clutch System Full Seminar Report 4537Lalit Tanan100% (1)

- Questions On DC Circuit - Electrical4uDocument16 pagesQuestions On DC Circuit - Electrical4udhineshp0% (2)

- MAX31865PMB1Document7 pagesMAX31865PMB1ghodghod123Pas encore d'évaluation

- Manual M3PRO 80Document2 pagesManual M3PRO 80Aziz el materziPas encore d'évaluation