Académique Documents

Professionnel Documents

Culture Documents

Indoor Air Quality

Transféré par

Darius DsouzaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Indoor Air Quality

Transféré par

Darius DsouzaDroits d'auteur :

Formats disponibles

FACTS

™ Indoor Air Quality

Document Number: 230

SAFETY INFO BY FAX Page: 1 of 3

Background to a single identifiable contaminant found to be

Indoor Air Quality (IAQ) refers to the quality of air prevalent in the indoor environment. An example of

in non-industrial environments, such as offices. Since Building Related Illness is Legionnaires Disease.

the energy crisis of the mid 1970s, IAQ has become Building managers need to treat IAQ complaints seri-

an increasingly important issue for building owners, ously and deal with them promptly. These situations

managers and occupants. The recent increase in are often difficult to diagnose and solve. Quick action

IAQ complaints can be attributed to a decrease in will help prevent other occupants throughout the

building ventilation and a higher level of indoor- building from thinking they might have SBS when

generated pollutants. they’re really experiencing some other form of stress,

Poor building ventilation is a result of more energy- such as being over-tired.

efficient construction and the use of mechanical

ventilation instead of natural ventilation (windows). Mechanical Ventilation Systems

The indoor pollutant level has increased from the use The purpose of mechanical ventilation systems is to

of synthetics in building materials and office furniture, bring in outside air and mix it with a percentage of

the use of chemical cleaning products and the return inside air, condition the air (heat, cool, humid-

increased use of office equipment—all of which ify), and then distribute it to various areas of the

contribute to chemical and particulate contamination building. The National Institute for Occupational

of the indoor air. Safety and Health (NIOSH) found that up to 52 per-

Mechanical ventilation equipment can also contribute cent of IAQ problems are a result of insufficient or

to indoor air contamination. In fact, it can be a source ineffective ventilation.

of dust, mold, bacteria and viruses. Improperly locat- Outside air is brought into buildings to dilute

ed air intake ducts will bring outside pollutants into contaminants originating within the building.

the indoor environment. Insufficient outside air intake, either from improper

Building occupants are yet another source of pollu- system design or mechanical malfunction, can lead to

tants. Our metabolic processes are a source of many contaminant buildup inside the space. Contaminated

different volatile organic compounds—not to mention outside air brought into the building from poorly

perfume, deodorant, hair spray and other grooming located intakes will also contribute to contaminant

products that add contaminants to the indoor air. load in the building.

Tobacco smoke is a very controversial contaminant. Very few problems would exist if only outside air

OSHA’s proposed IAQ standard requires that a desig- was used to replenish exhaust air. The drawback to

nated area with separate ventilation be provided in this solution is cost. Because of the expense, newer

workplaces where smoking is allowed. ventilation equipment is computer controlled to provide

the most cost-effective mix of inside and outside

Results of Poor Indoor Air Quality air. Proper maintenance of mechanical ventilation

Two types of illness can result from contaminated equipment keeps the system cost-effective and

indoor air. Sick Building Syndrome (SBS) is a physical functioning as designed. It also prevents the system

reaction to multiple low-level contaminants. These from becoming a source of contaminants.

contaminants could be chemical (formaldehyde), bio- The American Society of Heating, Refrigeration and

logical (mold) or physical (heat, humidity, lighting). Air Conditioning Engineers (ASHRAE) has specified

Symptoms for SBS include headache, nausea, fatigue, limits on the amount of outside air that must be

eye irritation and respiratory irritation. These symp- brought in and distributed to various parts of build-

toms normally disappear when the afflicted individu- ings. For example, office space requires 20 cubic feet

als leave the building for a period of time—such as a of outside air per minute per occupant; a designated

weekend—but return when they reenter it. smoking area requires 60 cubic feet per minute per

Building Related Illness is the second health problem occupant.

caused by contaminated indoor air. This differs from Carbon dioxide, a gas which we all exhale, is a

Sick Building Syndrome in that it is a physical reaction useful indicator of insufficient outside air intake and

FACTS SAFETY INFO BY FAX 1-800-393-2287

™

Visit our web site at http://www.labsafety.com SAFETY INFO BY FAX

©1998 Lab Safety Supply Inc.

Indoor Air Quality

FACTS

™

Document Number: 230

SAFETY INFO BY FAX Page: 2 of 3

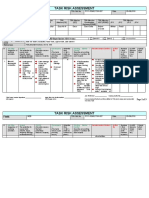

ventilation problems. OSHA’s proposed IAQ standard Standards and Regulations

requires that CO2 levels be maintained below 800 ASHRAE 62-1989—Ventilation for Acceptable Indoor

ppm and monitored on a quarterly basis. ASHRAE and Air Quality. Specifies minimum ventilation rates and

NIOSH both specify 1000 ppm as an indicator of insuf- indoor air quality needed to avoid adverse health

ficient ventilation. The ambient outside CO2 concen- effects to human occupants.

tration is approximately 300 ppm. Note: 800 ppm or

1000 ppm of carbon dioxide is NOT a hazardous con- ASHRAE 55-1981—Thermal Environmental Conditions for

centration, but rather an indicator of potential venti- Human Occupancy. Specifies minimal indoor thermal

lation problems. OSHA’s permissible exposure limit parameters (air temperature, humidity, movement) need-

for CO2 is 5000 ppm. ed to avoid adverse health effects to human occupants.

Occupational Safety & Health Standards 1910.19—

Air Monitoring Special Provisions for Air Contaminants—Indoor Air

IAQ problems are difficult to diagnose and solve Quality. (Proposed Rule)

because of the large number and many types of

contaminants or building stressors that can cause Commonly Asked Questions

problems. The cumulative effect of many stressors

(chemical, biological and physical) is often the most Q. When is the final IAQ standard expected?

difficult to identify. A. Indoor air quality is not a priority for the current

An IAQ investigation begins with thorough research republican-dominated congress. This topic is

and investigation at the problem site to identify extremely controversial and they have received

potential contaminants or stressors. No monitoring numerous comments on the initial proposed stan-

should be done until these items have been identified. dard. It does not appear that a final rule can be

The flowchart on the next page shows just one completed in the near future.

possible approach to an IAQ investigation. Q. Does OSHA have specific limits set for

If air monitoring is necessary, comparative samples contaminants in non-industrial environments?

from non-problem areas of the building are a useful tool A. The current permissible exposure limits are used for

in determining what the possible contaminants are. both industrial and non-industrial environments.

Following is a brief list of building stressors and conta-

minants and the type of equipment used to identify each Sources for More Information

one:

American Society of Heating, Refrigeration and

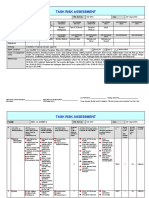

Contaminant/Stressor Monitoring Equipment Air Condition Engineers, Inc. (ASHRAE)

1791 Tullie Circle NE

Air Speed Anemometer Atlanta, GA 30329

Lighting Light meter

Heat Thermometer EPA Indoor Air Quality Information

Noise Sound level meter Clearinghouse

P.O. Box 37133

Humidity Hygrometer

Washington DC 20013-7113

Bacteria, virus, mold Andersen Air Sampler Phone: 800-438-4318

Volatile organic Photo Ionization Detector

compounds (PID), sampling pump NIOSH Guidance for Indoor Air Quality Investigations

and collection media, National Institute for Occupational Safety & Health

dosimeter badges and Hazard Evaluation & Technical Assistance Branch

colorimetric tubes, specific

colorimetric tubes 4676 Columbia Parkway

Cincinnati, OH 45226

Dust and other Collection media and sam- Phone: 513-841-4374

particulates pling pumps

Carbon dioxide Colorimetric detector NIOSH Information Line

tubes,electronic monitor Phone: 800-356-4674

Note: This is not intended to be a complete list of contam-

inants. ASHRAE 62-1989 lists common contaminant levels

for these and other specific chemicals.

FACTS SAFETY INFO BY FAX 1-800-393-2287

™

Visit our web site at http://www.labsafety.com SAFETY INFO BY FAX

©1998 Lab Safety Supply Inc.

Indoor Air Quality

FACTS

™

Document Number: 230

SAFETY INFO BY FAX Page: 3 of 3

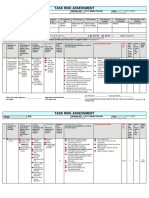

Start (reason for concern)

Initial walkthrough

• preparation

• visual inspection

• talk with occupants and staff

Do you have

Yes

an explanation for

the complaint?

No

Collect additional information about

• building occupants

• the HVAC system

• pollutant pathways

• pollutant sources

(sample contaminants if needed)

Develop one or more hypotheses to

explain the problem. Test by manipulating

building conditions or exposure, or by per-

forming appropriate tests.

Do results Attempt a

No Yes Follow-up

support your control

validation

hypothesis? strategy

No Is the

problem

solved?

Yes

Make necessary changes so that the

problem will not recur.

Finish

FREE Technical Support FREE Catalog

When you have a question, you can rely on For products to meet all your workplace safety and

our team of technical experts. They’ll answer industrial needs, turn to Lab Safety Supply’s General

your questions about product specifications, Catalog. In it you’ll find thousands of safety and

chemical compatibility, regulatory issues, and industrial products, plus a complete service package

general worker safety and health. and our 100% guarantee to stand behind them.

Call our Safety TechLine™ Technical Support toll-free: Call today to reserve your free copy:

1-800-356-2501 1-800-356-0783

6 a.m. to 9 p.m. CT, Monday–Friday 6 a.m. to 9 p.m. CT, Monday–Friday

Please note: The information contained in this publication is intended for general information purposes only. This publication is not a substitute for review

of the applicable government regulations and standards, and should not be construed as legal advice or opinion. Readers with specific questions should refer

to the cited regulation(s), or consult with an attorney.

FACTS SAFETY INFO BY FAX 1-800-393-2287

™

Visit our web site at http://www.labsafety.com SAFETY INFO BY FAX

©1998 Lab Safety Supply Inc.

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- 8) .Tool Box Talk RecordDocument11 pages8) .Tool Box Talk RecordDarius DsouzaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- ERP For Company Covering All SitesDocument7 pagesERP For Company Covering All SitesDarius DsouzaPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- 1) Land Incident Investigaton ReportDocument4 pages1) Land Incident Investigaton ReportDarius DsouzaPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Concrete Pump Maintenance ChecklistDocument4 pagesConcrete Pump Maintenance ChecklistDarius DsouzaPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Lifting PlanDocument31 pagesLifting PlanDarius DsouzaPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Combustible DustDocument12 pagesCombustible DustDarius DsouzaPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Heat Stress Program - J38Document24 pagesHeat Stress Program - J38Darius DsouzaPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Isometric Jum-Tp02 RevdDocument1 pageIsometric Jum-Tp02 RevdDarius DsouzaPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- 14-Telescopic Forklift Check List Hindi English - Page - 1Document1 page14-Telescopic Forklift Check List Hindi English - Page - 1Darius DsouzaPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Accident Causation ModelDocument16 pagesAccident Causation ModelDarius DsouzaPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- De-Com - For Existing 8 12 Inch - Pipeline - TRA1Document6 pagesDe-Com - For Existing 8 12 Inch - Pipeline - TRA1Darius DsouzaPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Aspire 001 IGC I Element 1-Foundations - IGC IDocument48 pagesAspire 001 IGC I Element 1-Foundations - IGC IDarius DsouzaPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- P111-Rsme-Tra-007 - Tra For Cold Tie inDocument5 pagesP111-Rsme-Tra-007 - Tra For Cold Tie inDarius DsouzaPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- TRA # 102 For Installation of Piping and Pipe SupportsDocument5 pagesTRA # 102 For Installation of Piping and Pipe SupportsDarius DsouzaPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- P111-RSME-TRA-007 - TRA For Cold Tie in PDFDocument4 pagesP111-RSME-TRA-007 - TRA For Cold Tie in PDFDarius DsouzaPas encore d'évaluation

- P111-RSME-TRA-007 - TRA For ExcavationDocument3 pagesP111-RSME-TRA-007 - TRA For ExcavationDarius DsouzaPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Valve Station DrawingDocument1 pageValve Station DrawingDarius DsouzaPas encore d'évaluation

- HSE REMINDER-March 2012-Plant Turnaround SafetyDocument1 pageHSE REMINDER-March 2012-Plant Turnaround SafetyDarius DsouzaPas encore d'évaluation

- HIP-Wastewater Revision 03Document14 pagesHIP-Wastewater Revision 03Darius DsouzaPas encore d'évaluation

- MNGMNT CNTRCTR HSE Procedure Manual 10-4Document258 pagesMNGMNT CNTRCTR HSE Procedure Manual 10-4Darius Dsouza100% (1)

- Code of Practice For Safe Lifting Operations at Workplaces OnlineDocument38 pagesCode of Practice For Safe Lifting Operations at Workplaces OnlineDarius Dsouza100% (1)

- Construction Division: Polycarbonate Plant Project Saudi Kayan Petrochemical Complex CRC-KY8501Document1 pageConstruction Division: Polycarbonate Plant Project Saudi Kayan Petrochemical Complex CRC-KY8501Darius DsouzaPas encore d'évaluation

- HSE REMINDER-April 2012-Unsafe Acts & Unsafe ConditionsDocument1 pageHSE REMINDER-April 2012-Unsafe Acts & Unsafe ConditionsDarius DsouzaPas encore d'évaluation

- SafetyStock OverviewDocument3 pagesSafetyStock OverviewJosue FonsecaPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- TML IML DefinitionDocument2 pagesTML IML DefinitionFicticious UserPas encore d'évaluation

- Adel Lock ManualDocument1 pageAdel Lock Manual24245677843Pas encore d'évaluation

- UVEX - Helmets & Eyewear 2009Document19 pagesUVEX - Helmets & Eyewear 2009Ivica1977Pas encore d'évaluation

- Thermal ComfortDocument50 pagesThermal ComfortSSPas encore d'évaluation

- Finite Element Modeling Analysis of Nano Composite Airfoil StructureDocument11 pagesFinite Element Modeling Analysis of Nano Composite Airfoil StructureSuraj GautamPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Bhagavatam English Chapter 10bDocument22 pagesBhagavatam English Chapter 10bsrimatsimhasaneshwarPas encore d'évaluation

- Federal Public Service CommissionDocument2 pagesFederal Public Service CommissionNasir LatifPas encore d'évaluation

- Dr. N. Kumarappan IE (I) Council Candidate - Electrical DivisionDocument1 pageDr. N. Kumarappan IE (I) Council Candidate - Electrical Divisionshanmugasundaram32Pas encore d'évaluation

- A Technical Report ON Centre of Pressure ONA Plane Surface ExperimentDocument13 pagesA Technical Report ON Centre of Pressure ONA Plane Surface ExperimentVictor OwolekePas encore d'évaluation

- Grand Chapter Mentor ProgramDocument13 pagesGrand Chapter Mentor ProgramJulius Wright100% (1)

- User Manual PocketBookDocument74 pagesUser Manual PocketBookmisu2001Pas encore d'évaluation

- Unit 4 ADocument10 pagesUnit 4 AChetan p ShirahattiPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Proac Studio 100: Monitor Level Performance From An Established Compact DesignDocument2 pagesProac Studio 100: Monitor Level Performance From An Established Compact DesignAnonymous c3vuAsWAPas encore d'évaluation

- Only Great Minds Can Read This Based On Cambridge University StudyDocument7 pagesOnly Great Minds Can Read This Based On Cambridge University StudyabotPas encore d'évaluation

- Cross CultureDocument134 pagesCross CulturePhương AnnhPas encore d'évaluation

- Detailed Lesson Plan (DLP) Format: Learning Competency/iesDocument1 pageDetailed Lesson Plan (DLP) Format: Learning Competency/iesErma JalemPas encore d'évaluation

- My LH Cover LetterDocument3 pagesMy LH Cover LetterAkinde FisayoPas encore d'évaluation

- NBCC 2015 Seismic Design Examples in S-FRAME AnalysisDocument91 pagesNBCC 2015 Seismic Design Examples in S-FRAME AnalysisMike Smith100% (1)

- Ericsson AXE 810: Switch (ROTD)Document4 pagesEricsson AXE 810: Switch (ROTD)Kao Sun HoPas encore d'évaluation

- BraunDocument69 pagesBraunLouise Alyssa SazonPas encore d'évaluation

- 04 DosimetryDocument104 pages04 DosimetryEdmond ChiangPas encore d'évaluation

- BIOL 2300 Homework 2 Summer2019Document2 pagesBIOL 2300 Homework 2 Summer2019Tanner JohnsonPas encore d'évaluation

- Enable Modern Authentication in Exchange OnlineDocument2 pagesEnable Modern Authentication in Exchange Onlinedan.artimon2791Pas encore d'évaluation

- Asian RegionalismDocument15 pagesAsian RegionalismLiezel AalaPas encore d'évaluation

- 30 Risk and InsuranceDocument4 pages30 Risk and InsuranceSiti Nur Ain RamliPas encore d'évaluation

- Test Bank Bank For Advanced Accounting 1 E by Bline 382235889 Test Bank Bank For Advanced Accounting 1 E by BlineDocument31 pagesTest Bank Bank For Advanced Accounting 1 E by Bline 382235889 Test Bank Bank For Advanced Accounting 1 E by BlineDe GuzmanPas encore d'évaluation

- Algorithm Design: Figure 1. Architecture Diagram For Greykite Library's Main Forecasting Algorithm, SilverkiteDocument3 pagesAlgorithm Design: Figure 1. Architecture Diagram For Greykite Library's Main Forecasting Algorithm, Silverkitesiper34606Pas encore d'évaluation

- REM630 Broch 756825 LRENdDocument6 pagesREM630 Broch 756825 LRENdsihamuPas encore d'évaluation

- SBU PlanningDocument13 pagesSBU PlanningMohammad Raihanul HasanPas encore d'évaluation

- Laws of UX: Using Psychology to Design Better Products & ServicesD'EverandLaws of UX: Using Psychology to Design Better Products & ServicesÉvaluation : 5 sur 5 étoiles5/5 (9)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsD'EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsPas encore d'évaluation

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneD'EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Transformed: Moving to the Product Operating ModelD'EverandTransformed: Moving to the Product Operating ModelÉvaluation : 4 sur 5 étoiles4/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionD'EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionÉvaluation : 3 sur 5 étoiles3/5 (1)