Académique Documents

Professionnel Documents

Culture Documents

Concrete Grade

Transféré par

Aniket InarkarCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Concrete Grade

Transféré par

Aniket InarkarDroits d'auteur :

Formats disponibles

Revision 01 FS 01 SCW- 3.

5 KPa

4 3 2 1

ISO A1 594mm x 841mm

1.0 GENERAL 4. NON-LOAD BEARING FEATURE COLUMNS

5. ALL SECONDARY STEELWORK THE CONCRETE SHOULD BE COMPACTED WELL TO ACHIEVE THE REQUIRED DENSITY WITHOUT ANY

1.1 THIS SHEET SHALL BE READ AS PART OF THE STRUCTURAL DRAWINGS AND IS DEEMED TO BE PART OF THE 6. STRUCTURAL STEELWORK CONNECTIONS HONEYCOMBS AND VOIDS. THE CONTRACTOR TO DECIDE THE REQUIREMENT OF SELF-COMPACTING

CONTRACT DOCUMENTS. 7. STRUCTURAL SUPPORT FOR MEP SERVICES CONCRETE FOR THE PROJECT. ADMIXTURES ARE TO BE ADDED TO ACHIEVE THE FULL COMPACTION OF THE

1.2 STRUCTURAL DRAWINGS SHALL BE READ AND VERIFIED IN CONJUNCTION WITH RELEVANT ARCHITECTURAL, 8. SHADE STRUCTURES AND CANOPIES CONCRETE ON SITE.

D ELECTRICAL, MECHANICAL, PLUMBING AND OTHER STRUCTURAL DRAWINGS. FOR MAIN SETTING OUT AND LEVELS 9. METAL ROOFING SYSTEM

REFER TO THE ARCHITECTURAL DRAWINGS. ANY DISCREPANCIES OR CONFLICT IN THE SETTING OUT LINES, 10. BALUSTRADE AND CRASH BARRIER

LEVELS, DETAILS, LOCATIONS, SIZES, REINFORCEMENT ETC. OF THE STRUCTURAL MEMBER SHALL BE BROUGHT TO 11. STRUCTURAL GLASS 4.80 OPENINGS, SLEEVES

THE ATTENTION OF THE ENGINEER PRIOR TO COMMENCEMENT OF THE WORK. 12. INTERIOR SIGNAGE

1. NO HOLES, SLEEVES OR PENETRATIONS SHALL BE PLACED VERTICALLY OR HORIZONTALLY THROUGH BEAMS UNLESS

13. PRODUCTION OF SHOP DRAWINGS

1.3 DO NOT SCALE THE DRAWINGS. ALL DIMENSIONS SHALL BE READ FROM THE DRAWING OR COMPUTED. APPROVED BY THE ENGINEERS.

14. EXPANSION JOINT DETAILS

ELEVATIONS ARE IN METERS, DISTANCES AND REINFORCEMENT BAR SIZES ARE IN MILLIMETERS. 15. STRUCTURAL DETAILS AT TRANSFORMER AND LV ROOMS AS PER DEWA DRAWINGS 2. NO HOLES TO BE MADE IN SLABS UNLESS APPROVED BY THE ENGINEERS. PROJECT

16. STRUCTURAL DETAILS FOR ROAD BLOCKER

1.4 ALL LEVELS ARE ARE ASSUMED TO BE RELATIVE TO DUBAI MUNICIPALITY DATUM U.N.O 4.9 CONSTRUCTION JOINTS

THE DESIGN OF THE PRIMARY STRUCTURE CONSIDERS THE INTERFACE WITH THESE STRUCTURES (LOADING REACTIONS,

1.5 SLEEVES SHALL BE PROVIDED AT LOCATIONS INDICATED ON DRAWINGS OR AS DIRECTED BY THE ENGINEER.

ADDITIONAL REINFORCEMENT SHALL BE PROVIDED AROUND OPENINGS AS REQUIRED BY THE ENGINEER.

OPENINGS. ETC.) AND WERE DETAILED TO ACCOMMODATE THESE ELEMENTS INTO THE DESIGN. 1. THE CONTRACTOR SHALL SUBMIT TO THE ENGINEER FOR APPROVAL A PLAN SHOWING THE LOCATION OF ALL DOWNTOWN DUBAI

3.0 LOADING CONSTRUCTION JOINTS.

1.6 ALL CONCRETE WORK SHALL CONFORM TO THE RECOMMENDATIONS OF C.I.R.I.A. `GUIDE TO CONCRETE

CONSTRUCTION IN THE GULF REGION.

3.1 SUPERIMPOSED (DEAD LOADS AND LIVE LOADS) 2. HORIZONTAL CONSTRUCTION JOINTS SHALL NOT BE MADE IN BEAMS, UNLESS APPROVED BY THE CONSULTANT OR DEVELOPMENT

ENGINEER.

1.7 THE CONTRACTOR SHALL PRODUCE SHOP DRAWINGS AND SCHEDULES AS REQUIRED FOR COMPLETION OF THE DEAD LOADS AND LIVE LOADS ARE SHOWN ON THE LOAD MAP DRAWINGS. FORTE

3. VERTICAL CONSTRUCTION JOINTS MAY BE LOCATED BETWEEN MIDSPAN AND THIRD POINT OF SLABS OR BEAMS AFTER

WORKS AND RECORD DRAWINGS OF THE AS-BUILT AND BUILDER WORKS FOR THE CONSULTANT'S APPROVAL. 3.2 WIND LOADS REVIEWED AND APPROVED BY THE ENGINEERS. Dubai, UAE

1.8 THE CONTRACTOR IS RESPONSIBLE FOR PRODUCING FULLY DETAILED G.A. AND REINFORCEMENT DRAWINGS. THESE WIND LOADING ARE AS PER WIND-INDUCED STRUCTURAL RESPONSES REPORT NO. RWDI # 1501691

DATED MAY 30, 2016. 4. CONTRACTOR SHALL SUBMIT SHEAR FRICTION AND THE ADDITIONAL REQUIRED REINFORCEMENT CALCULATION AT

ARE TO BE SUBMITTED TO THE ENGINEER FOR HIS REVIEW WELL IN ADVANCE OF CASTING STRUCTURAL ELEMENTS, CONSTRUCTION JOINTS (AT ANY LOCATION) FOR ENGINEER REVIEW AND APPROVAL.

SHOWING ALL SLEEVING REQUIREMENTS INCLUDING SIZE AND LOCATION OF ALL MECHANICAL AND ELECTRICAL

OPENINGS AND DEPRESSIONS IN THE SLAB. SOME OF THESE MAY BE DEPENDENT UPON CHOICE OF MECHANICAL 3.3 SEISMIC LOAD - UNIFORM BUILDING CODE 1997 5. WATER STOPS SHALL BE PROVIDED FOR ALL CONSTRUCTION JOINTS BELOW GROUND WATER TABLE LEVEL AS PER

1. OCCUPANCY CATEGORY = II CLIENT

FITS. PERMIT TIME FOR NECESSARY REVISIONS OR ADJUSTMENT TO ENSURE THE STRUCTURAL INTEGRITY OF THE SOIL INVESTIGATION REPORT. REINJECTABLE INJECTION HOSES TO BE USED AT ALL CONSTRUCTION JOINTS IN

AFFECTED ELEMENTS. ADJUST SHOP DRAWINGS PRIOR TO CONSTRUCTION TO CONFORM NECESSARY CHANGES. 2. SEISMIC IMPORTANCE = I = 1.0 CONTACT WITH THE GROUND.

HERE GROUPS OF SLEEVES ARE LOCATED THEY MUST NOT BE SUCH AS TO AFFECT THE INTEGRITY OF STRUCTURAL 3. SITE CLASS SC (AS PER GEOTECHNICAL REPORT)

MEMBERS. 4. CA = 0.24G

5. CV = 0.32G

5.0 REINFORCEMENT Emaar Properties PJSC

1.9 OPENINGS SMALLER THAN OR EQUAL TO 200MM WIDTH ARE NOT SHOWN ON THE STRUCTURAL DRAWINGS. 6. SEISMIC DESIGN CATEGORY = 2B 5.1 THE REINFORCEMENT USED IN THE R.C WORKS SHALL BE ROUND, DEFORMED TYPE 2 BARS MARKED AS (T)

Building 3, Level 1

7. BASIC SEISMIC FORCE RESISTING SYSTEM BEARING WALL SYSTEM = ORDINARY REINFORCED

1.10 TECHNICAL SPECIFICATIONS AND WRITTEN INSTRUCTIONS OR DECISIONS OF THE CONSULTANT SHALL TAKE CONCRETE SHEAR WALL NOT BE EXCEED 0.51 FOR GRADE 460 P.O.Box 9440, Dubai, UAE

PRECEDENCE OVER THESE NOTES. 8. RESPONSE MODIFICATION FACTOR , R = 4.5 5.2 REINFORCEMENT DETAILS SHOWN ARE INDICATIVE. THE CONTRACTOR SHALL PREPARE DETAILED SHOP T +97143673333 tel

1.11 ALL DISCREPANCIES SHALL BE BROUGHT TO THE ATTENTION OF THE CONSULTANT ENGINEER BEFORE DRAWINGS & FULL BAR BENDING SCHEDULES IN ACCORDANCE WITH THE DESIGN DRAWINGS AND SHALL BE www.emaar.com

PROCEEDING WITH THE WORK ON SITE. 10.EQUIVALENT STATIC FORCE PROCEDURE AND MODAL RESPONSE SPECTRUM ANALYSIS USED CUT AND BENT IN ACCORDANCE WITH ACI 315-09 FOR THE ENGINEER'S APPROVAL AT LEAST FOUR WEEKS

AS PER ASCE 7-05 SEC. 12.9. PRIOR TO COMMENCEMENT OF R.C. WORK AND AFTER COORDINATING WITH ALL CONCERNED PARTIES.

1.12 ALL MATERIALS USED SHALL COMPLY WITH THE REQUIREMENTS OF THE SPECIFIED

CODES, STANDARDS AND ORDINANCE OF RELEVANT BUILDING AUTHORITIES UNLESS NOTED OTHERWISE IN THE 3.4 TEMPERATURE LOAD CONSULTANT

5.3 LAP LENGTHS AND ANCHORAGE LENGTHS OF REINFORCEMENT SHALL BE AS PER ACI 318M-08. ADDITIONAL

PROJECT SPECIFICATION AND / OR DRAWINGS. LAPPING IF REQUIRED TO BE PROVIDED WITH ENGINEER'S APPROVAL. THE MINIMUM LAP LENGTH OF

VARIATION.

1.13 ALL DIMENSIONS AND LEVELS SHOWN ON THE DRAWINGS SHALL BE VERIFIED BY THE CONTRACTOR. ANY DISCREPANCIES

SHALL BE BROUGHT TO CONSULTANT'S ATTENTION PRIOR TO CONSTRUCTION. 3.5 LATERAL PRESSURE OF SOIL (PRESUMED)

REINFORCEMENT SHALL BE THE MAXIMUM OF 45 BAR DIA IN GENERAL AND 50 DIA FOR TENSION OR THE

VALUES OF THE BELOW TABLE REINFORCEMENT. AECOM

1.14 THE CONTRACTOR SHALL ENSURE THAT DURING CONSTRUCTION, NO PART OF THE STRUCTURE IS OVERSTRESSED BY TENSION SPLICE LENGTH SCHEDULE LTS (mm)

AECOM MIDDLE EAST LIMITED

C 1. UNIT WEIGHT OF (ABOVE WATER TABLE) SOIL

EXCESSIVE CONSTRUCTION LOADS UNTIL THEIR COMPLETION. TEMPORARY BRACING AND PROPPING TO BE PROVIDED 2. UNIT WEIGHT OF (BELOW WATER TABLE) SOIL U-Bora Tower, Level 43, Business Bay,

WHERE REQUIRED. HORIZONTAL BAR WITH LESS HORIZONTAL BAR WITH MORE

3. BUOYANT WEIGHT OF SOIL

THAN 300mm CONCRETE THAN 300mm CONCRETE BELOW COMPRESSION SPLICE LENGTH PO Box 51028, Dubai, UAE

1.15 THE CONTRACTOR SHALL IMPLEMENT SITE SAFETY POLICIES IN ACCORDANCE WITH THE PROJECT REQUIREMENTS AND 3.6 MATERIAL UNIT WEIGHT (mm) +971-4-439-1000 tel +971-4-439-1001 fax

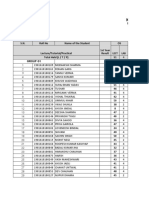

SHALL BE RESPONSIBLE FOR THE SAFETY OF THE WORKERS AT ALL TIMES. THE CONTRACTOR SHALL ENSURE BAR SIZE BELOW BAR OR VERTICAL BAR BAR BAR SIZE (APPLICABLE TO ALL CONCRETE

CLEANLINESS AND THAT THERE ARE NO LEFT OVER TIMBERS OR BURIED FORMWORKS WHICH CAN CAUSE TERMITE 1. CONCRETE www.aecom.com

INFESTATION. 2. WATER GRADES AND BAR TYPES)

3. STEEL 36 MPa >40

1.16 THE CONTRACTOR SHALL SUBMIT A METHOD STATEMENT FOR ALL ELEMENTS OF WORK AND SHALL NOT PROCEED

4. SOLID BLOCK - MPa 36 MPa >40

- MPa T10 375

UNTIL CONSULTANT'S WRITTEN APPROVAL IS GIVEN. THE METHOD STATEMENT SHALL PROVIDE THE CONTRACTOR'S

PREFERABLE OPTIONS WHERE SUCH OPTIONS ARE AVAILABLE.

5. HOLLOW BLOCK T10 475 450 620 585 T12 450 CONSULTANT

6. AAC BLOCK T12 570 540 740 700

1.17 THE CONTRACTOR SHALL COMPLY WITH ALL REQUIREMENTS OF THE LOCAL REGULATIONS AND REQUIREMENTS OF ALL T14 525

CONCERNED AUTHORITIES. 4.0 CONCRETE

T14 665 630 865 820 T16 575

4.1 ALL CONCRETE WORKS SHALL CONFORM TO THE ACI 318M-08. A GRADE OF C62/50 INDICATES THAT CONCRETE

1.18 TRIAL PITS MUST BE TAKEN BY CAREFUL HAND EXCAVATION TO LOCATE EXISTING SERVICES. IN THE EVENT OF EXISTING T16 760 720 985 935 T20 725

PAVED AREAS AROUND THE PLOT LINE REQUIRING EXCAVATION FOR LOCATING SERVICES, A SEPARATE ROAD CUTTING

N.O.C WILL HAVE TO BE OBTAINED FROM THE ROAD DEPARTMENT BEFORE CUTTING IS TO BE MADE. T20 950 900 1235 1170 T22 800

CONCRETE MIX DESIGN SHALL COMPLY WITH ACI 301-05 AS FOLLOWS:

1.19 ALL EXISTING SERVICES AND ROAD STRUCTURES WILL HAVE TO BE PROTECTED AT ALL TIMES. MUNICIPALITY BEARS NO T22 1290 1220 1680 1590 T25 900

RESPONSIBILITY TOWARDS ANY COLLAPSE OF SIDE WALLS OR ANY OTHER MISHAPS OCCURRING TO ANY PART MIX NUMBER 1 2 3 4 T25 1460 1390 1905 1810 T28 1000

WHATSOEVER. GRADE 20/20 62/50 62/50 85/68

T28 1640 1560 2135 2030 T32 1150

MIN. CEMENTITIOUS CONTENT kg/m 200 380 380 380

Filename: \\AEAUH1NTAP1\PROJECT\003 PROJECT RECORDS\60345201.00_D1-D2TOWERS\8 PRODUCTION\8.5 ST\CAD\GENERAL\SHEET\60345201-G-ACM-DG-ST-0003-00.DWG

1.20 CONCRETE SHALL BE CURED BY AN APPROVED MEANS IN ACCORDANCE WITH THE SPECIFICATIONS. T32 1875 1780 2440 2315 CONSULTANT

CEMENT TYPE OPC OPC OPC OPC

1.21 UNLESS CAMBERS ARE SHOWN ON THE DRAWINGS OR THE ENGINEER DIRECTS OTHERWISE PROVIDE THE FOLLOWING

STANDARD CAMBER: MAX. FREE w/c RATIO 0.55 0.40 0.40 0.40

CAMBER IN SLABS AND BEAMS SLUMP (mm) 100 75 75 75

BAR SIZE BAR SIZE

GGBS - 65% 40% 40% 36 MPa >40 MPa 36 MPa >40 MPa

CAMBER 'C' (mm) - -

SPAN MAX. AGGREGATE SIZE (mm) 20 20 20 20

T10 365 345 T10 200 200

SLABS BEAMS

L *. 65% GGBS MAY BE REPLACED BY 50% GGBS + 5% SILICA FUME. THE CONTRACTOR HAS TO TEST EACH MIX T12 440 415 T12 240 240

(mm) ONE END BOTH END ONE END BOTH END AND SELECT THE ONE THAT SATISFIES THE SPECIFIED STRENGTH AND DURABILITY REQUIREMENT OR OTHERWISE

CONTINUOUS CONTINUOUS CONTINUOUS CONTINUOUS PROPOSE AN ALTERNATIVE MIX. FOR THE ENGINEERS REVIEW AND APPROVAL. T14 510 485 T14 280 280

3000 6 - - - **. T16 585 555 T16 320 320 REGISTRATION

4000 10 6 - - T20 730 690 T20 400 400

MIX 1 : USED FOR PLAIN CONCRETE BLINDING, SCREEDS AND MASS FILL.

5000 13 8 12 8 T22 990 940 T22 435 435

6000 17 10 17 10 MIX 2 : USED IN ALL REINFORCED CONCRETE WORKS FOR GROUND & BASEMENTS (EXCEPT TOWERS WALLS

AND COLUMNS). TRIPLE BLEND MIX EQUIVALENT TO BE USED FOR BASEMENT AND ALL CONCRETE IN

T25 1130 1070 T25 495 495 Issued For Construction

B T28 1260 1200 T28 555 555 CONSTRUCTION SHALL NOT COMMENCE PRIOR TO OBTAINING

7000 20 12 20 12 CONTACT WITH SOIL. BUILDING PERMIT AND NECESSARY AUTHORITY APPROVALS

8000 22 13 22 13 MIX 3 : USED IN ALL REINFORCED CONCRETE STRUCTURES (SLAB AND BEAMS) AT THE PODIUM LEVELS, AND T32 1440 1370 T32 635 635

9000 25 15 25 15 TOWER LEVELS ALSO USED FOR ALL VERTICAL ELEMENTS (WALLS AND COLUMNS) AT THE PODIUM T40 1800 1710 T40 795 795

LEVELS OTHER THAN THE TOWER WALLS AND COLUMNS.

10000 1. THESE TENSION DEVELOPMENT LENGTHS APPLY TO BEAMS, SLABS,COLUMNS AND WALLS U.N.O.

11000 MIX 4 : USED FOR TOWERS WALLS, COLUMNS, AND COUPLING BEAMS FROM FOUNDATION LEVEL TO UPPER

2. VALUES FOR SLABS AND WALLS APPLY ONLY FOR BAR CLEAR SPACING OF 100mm OR GREATER. VALUES FOR BEAMS

12000

ROOF.

AND COLUMNS APPLY ONLY FOR BAR CLEAR SPACINGS OF 80mm OR GREATER. FOR SPACING LESS THANTHIS

ISSUE

REFER TO PLANS REFER TO BEAMS SCHEDULE 4.2 CONTRACTOR SHALL IMPLEMENT A TRIAL MIX IN ACCORDANCE WITH THE PROJECT SPECIFICATIONS. & TRIAL MIX VALUES REFER TO THE DRAWINGS.

13000 RESULTS SHALL BE SUBMITTED FOR ENGINEER'S REVIEW & APPROVAL PRIOR TO COMMENCING CONCRETING.

14000 3. VALUES FOR T40 BARS ARE DEVELOPMENT LENGTHS ONLY. THESE BAR SIZES ARE NOT TO BE LAP SPLICED.

4.3 CONCRETE NOTED EITHER MASS OR LIGHTWEIGHT CONCRETE WITHIN DRAWINGS TO HAVE A MIX STRENGTH OF

16000 4. TABULATEDVALUES ARE FOR NORMAL WEIGHT CONCRETE. THE VALUES ON THIS SHEET DO NOT APPLY TO

PERMITTED SUBJECT TO THE PRIOR APPROVAL OF ENGINEER. LIGHT-WEIGHT CONCRETE.

NOTE: 4.4 CONTRACTOR SHALL SUBMIT DETAILS OF ALL ADDITIVES, PLASTICIZERS, MICRO SILICA, CURING COMPOUNDS

WATERPROOFING AGENTS ETC. APPLICATION SHOULD FOLLOW STRICTLY THE MANUFACTURER RECOMMENDATION. 5. WHERE ACTUAL CONDITIONS DIFFER FROM THE CLEAR COVER SHOWN ON THE TYPICAL DETAILS OR DIFFER FROM

1. MAINTAIN MINIMUM UNIFORM SLAB THICKNESS AS CALLED FOR ON THE DRAWINGS WHEN APPLYING IT IS CONTRACTORS RESPONSIBILITY TO ENSURE THAT ALL CONSTITUENTS OF CONCRETE ARE COMPATIBLE WITH PROVIDED SCHEDULED BAR SIZE, MINIMUM SPACING AND/OR fc, LENGTHS SHALL BE ADJUSTED ONLY WITH THE

CAMBER. 0 07/09/2017 ISSUED FOR CONSTRUCTION

EACH OTHER APPROVAL OF THE STRUCTURAL ENGINEER OF RECORD.

2. PROVIDE 3/4 'C' AT 1/4 POINTS OF THE SPAN I/R DATE DESCRIPTION

4.5 MAXIMUM PERCENTAGE (BY WEIGHT) OF SALT CONTENTS PERMISSIBLE IN AGGREGATES USED FOR CONCRETE, 6. TABULATED VALUES ARE FOR NON-EPOXY COATED REINFORCEMENT. FOR EPOXY COATED REINFORCEMENT

3. FOR CANTILEVER BEAM AND CANTILEVER SLAB, UNLESS OTHERWISE SHOWN ON THE DRAWING, A HOLLOW BLOCKS, & HOURDI BLOCKS, ETC, SHALL BE AS FOLLOWS: MULTIPLY VALUES BY 1.3 FOR 'TOP BARS' AND 1.5 FOR ALL OTHER REINFORCEMENT.

CAMBER OF 10mm SHOULD BE CONSIDERED. a) ACID SOLUBLE CHLORIDES IN AGGREGATE - (FINE 0.03%, COURSE 0.02%)

b) ACID SOLUBLE SULPHATE IN AGGREGATE - (FINE 0.3%, COURSE 0.2%) 7. WHERE BARS OF DIFFERENT SIZES ARE LAP SPLICED IN TENSION. THE LAP LENGTH SHALL BE THE LARGER OF THE KEY PLAN

1.22 QUALITY OF CONCRETE FINISH FOR ALL UNCLAD NON-PLASTERED COLUMNS AND WALLS IS TO BE IN

ACCORDANCE WITH - FAIR FACED CONCRETE AS REFLECTED ON THE ARCHITECTURAL DRAWINGS AND TENSION LAP SPLICE LENGTH (LTS) OF THE SMALLER BAR AND THE TENSION DEVELOPMENT LENGTH (Ldt) OF THE

4.6 AGGREGATES SHALL BE FROM APPROVED SOURCE AND IN ACCORDANCE WITH THE SPECIFICATIONS.

SPECIFICATIONS. LARGER BAR.

1.23 ANY STRUCTURAL REQUIREMENTS SPECIFIED BY RELEVANT AUTHORITIES, WHICH ARE NOT COVERED IN NOTES AND 4.7 THE FLOOR FRAMING PLANS PROVIDE A POUR STRIP REQUIREMENT FOR PARTICULAR CASES. 8. WHERE BARS OF DIFFERENT SIZES ARE LAP SPLICED IN COMPRESSION, THE COMPRESSION LAP LENGTH (LCS) SHALL N

SPECIFICATIONS ARE ASSUMED TO BE DULY CONSIDERED BY THE CONTRACTOR. OVERALL DETAILED POUR STRIP LAYOUT TO BE PROVIDED BY THE CONTRACTOR TO MITIGATE EARLY BE THE LARGER OF THE COMPRESSION DEVELOPMENT LENGTH (Lds) OF THE LARGER BAR OR THE COMPRESSION LAP

THERMAL EFFECT AND TO SUBMIT FOR THE ENGINEER REVIEW AND APPROVAL. SPLICE LENGTH OF THE SMALLER BAR.

1.24 ALL TYPICAL DETAILS AND NOTES SHOWN ON DRAWINGS SHALL APPLY UNLESS NOTED OTHERWISE. TYPICAL DETAILS

MAY NOT NECESSARY BE INDICATED ON THE PLANS BUT SHALL STILL APPLY AS SHOWN OR DESCRIBED IN THE 9. SPACER BARS IN BEAMS SHALL BE MINIMUM T25 OR THE SIZE OF BAR IF GREATER AT 1000mm C/C; CHAIRS IN SLABS

DETAILS. WHERE PARTICULAR DETAILS ARE NOTED ON THE DRAWINGS THE SPECIFIED DETAIL SHALL BE USED. SHALL BE A MINIMUM T12@1000mm C/C, AND MINIMUM TIES IN WALLS SHALL BE T8@1000mm C/C.

1.25 ALL COLUMNS ARE CENTERED ON GRID UNO. CONCRETE EXPOSED TO SOIL OR WATER SHALL BE PROTECTED AGAINST AGGRESSIVE SOIL AND CLIMATIC NOTE:

1.26 DESIGN LIFE OF THE STRUCTURE OF THIS PROJECT SHALL MAINTAIN A MINIMUM OF 50 YEARS LIFE PERIOD. THE CONDITIONS BY ISOLATION USING MEMBRANES AS DETAILED IN THE STRUCTURAL DRAWINGS. REFER

PRIMARY STRUCTURAL COMPONENTS ARE TO BE DESIGNED AND DETAILED TO SATISFY THIS REQUIREMENT. CONCRETE 1. THE LENGTHS ARE BASED ON THE FOLLOWING MIN. COVER TO THE BAR:

DWG.NO. 60345201-G-ACM-DG-ST-0011-00, ST-0012-00 AND ST-0013-00. SLABS, WALLS -GREATER OF 25 MM OR BAR DIA. BEAMS AND COLUMNS - 40 MM.

MIX SUPPLIER SHALL SUBMIT A LIFE CYCLE ANALYSIS WHICH REFLECT A 50 YEARS DESIGN LIFE WITHOUT MAINTENANCE,

INSPECTION AND REPAIR REQUIREMENT DURING THIS PERIOD. AS PER GEOTECHNICAL REPORT BLENDED CONCRETE MIX TO BE USED FOR CONCRETE IN CONTINUOUS 2. FOR LAP SPLICE LENGTH THE TENSION DEVELOPMENT LENGTH (Ld) IS TO BE MULTIFIED BY 1.3.

PROJECT NUMBER

CONTACT WITH SOIL/WATER WITH HIGH CHLORIDE CONTENT.

1.27 THE CONTRACTOR HAS TO CONSIDER THE EXPANSION JOINT WIDTH AS PROVIDED IN THE ENGINEERING DRAWINGS AS 5.4 T36 & T40 BARS SHALL BE SPLICED WITH APPROVED MECHANICAL COUPLERS. LAPS ARE NOT PERMITTED. 60345201

A

Approved:

FINAL REQUIREMENT. CONCRETE MOVEMENT DUE TO SHRINKAGE EFFECT NEED TO BE CALCULATED AND DETECTED

FROM THE PROVIDED JOINT WIDTH TO CONCLUDE A NET JOINT WIDTH AT THE FINAL STAGE (EXPANSION JOINT FIXING 5.5 CLEAR COVER TO REINFORCEMENT INCLUDING LINKS, STIRRUPS, AND TIES SHALL BE AS FOLLOWS:-

600 COULOMBS PASSING AT 28 DAYS IN RCP (RAPID CHLORIDE PERMEABILITY TESTING) WITH 50% OR 65 % SHEET TITLE

TIME) EQUAL TO WHAT PROVIDED ON THE DRAWINGS. a) STRUCTURE IN CONTACT WITH GROUND (BASEMENT)

PILE CAPS/RAFT UNDER TOWERS = 100mm Bottom, 75mm Sides & 50mm Top

Project Managment Initials (As Required)

2.0 DESIGN MEASURES FOR CONTROL OF TEMPERATURE OF CONCRETE ARE TO BE CARRIED OUT. BASEMENT RAFT SLAB = 75mm Bottom & 50mm Top GENERAL NOTES - (SHEET 1 of 2)

CORROSION INHIBITOR TO BE ADDED TO CONCRETE MIX IN THE BASEMENT. WALL AND COLUMN = 50mm

2.1 CONSULTANT DESIGN GROUND BEAM = 50mm

CONCRETE TO SUIT CLASS 2 SULPHATE CONDITION CATEGORIZED BY BS 5628 PART 1 1997 TABLE 7A,B AND C SLAB AT GRADE LEVEL = 50mm

DESIGN AND CONSTRUCTION OF REINFORCED CONCRETE STRUCTURAL MEMBERS, SHALL BE IN ACCORDANCE

Last Plotted date: 2017-09-03

Last Modified by: DELARAH

(REFER TO GEOTECHNICAL REPORT).

checked:

WITH ACI318M-08 AND THE STRUCTURAL STEEL MEMBERS TO BS 5950 b) SUPER STRUCTURE

ADEQUATE COVER SHALL BE PROVIDED AS INDICATED IN THE DRAWINGS (SEE NOTE 5.5) COLUMNS (INTERNAL) = 40mm

2.2 CONTRACTOR DESIGN CONCRETE CRACK WIDTH TO BE LIMITED AS INDICATED IN THE DRAWINGS (SEE NOTE 7.0) COLUMNS (EXTERNAL) = 40mm

BEAMS (INTERNAL) = 40mm SHEET NUMBER

THE CONTRACTOR IS RESPONSIBLE FOR THE DESIGN OF ALL TEMPORARY WORKS (SHORING FOR EXCAVATION, OTHER REQUIREMENTS TO ENSURE A DURABLE CONCRETE INCLUDE THE FOLLOWING (GENERALLY): BEAMS (EXTERNAL) = 40mm

DEWATERING, SIGNAGE... ETC) AND THE FOLLOWING ITEMS OF PERMANENT SLABS (INTERNAL) = 30mm

SECONDARY WORKS: (SUBJECT TO ENGINEER'S REVIEW AND APPROVAL) MAXIMUM CHLORIDE ION PERMEABILITY - 1300 COULOMBS AT 28 DAYS. 60345201-G-ACM-DG-ST-0003-00

SLABS (EXTERNAL) = 30mm

1. SWIMMING POOL DETAILS MAXIMUM WATER ABSORPTION - AS PER BS 1881 SHALL BE 1.5% WALLS (INTERNAL) = 40mm

Designer:

2. PRECAST CONCRETE ELEMENTS WALLS (EXTERNAL) = 40mm

3. ARCHITECTURAL FACADE AND SUPPORT STEELWORK WATER PERMEABILITY - 8MM IN 28 DAYS (DIN 1048)

ALL CONCRETE ELEMENTS IN CONTACT WITH WATER 50mm

4 3 2 1 c 2014 AECOM TECHNICAL SERVICES, INC.

D1 D2 Forte Tower, Dubai, UAE Zebian Aluminium & Glass Industries LLC Page 221 of 221

Vous aimerez peut-être aussi

- Structural Specifications and Standard DetailsDocument1 pageStructural Specifications and Standard Detailsdomin domPas encore d'évaluation

- (S01-S12) CDocument12 pages(S01-S12) CMa'arif Nuzul AddibPas encore d'évaluation

- GCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 1Document1 pageGCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 1TOM YEEPas encore d'évaluation

- M Bar 000DS0 CB00 Edr 990701Document1 pageM Bar 000DS0 CB00 Edr 990701ayman ammarPas encore d'évaluation

- General Notes For Structure: SymbolsDocument14 pagesGeneral Notes For Structure: SymbolsKarl Anne DomingoPas encore d'évaluation

- Weight by Drawing Sheet: RevisionDocument1 pageWeight by Drawing Sheet: RevisionOseni MomoduPas encore d'évaluation

- Page 16Document1 pagePage 16barcoma.mylene.nPas encore d'évaluation

- Pineda, Khian, M. - Comed PlumbingDocument6 pagesPineda, Khian, M. - Comed PlumbingKhian PinedaPas encore d'évaluation

- E. Formworks: (Structural)Document1 pageE. Formworks: (Structural)Nonoy Justiniane-Giray JrPas encore d'évaluation

- Architectural key plan and general notesDocument1 pageArchitectural key plan and general notesAbid AyubPas encore d'évaluation

- Cps STRC Ifc Sept 25 2018Document57 pagesCps STRC Ifc Sept 25 2018Manimaran PPas encore d'évaluation

- MCS 01302023 MechDocument2 pagesMCS 01302023 MechBENEDICK TEOXONPas encore d'évaluation

- For Construction Drawing - FCD: General Structural Notes & SpecificationsDocument1 pageFor Construction Drawing - FCD: General Structural Notes & SpecificationsJossell De AlaPas encore d'évaluation

- Seakeeper 35 26 Installation Fixture Kit Bolt in 24apr2019Document2 pagesSeakeeper 35 26 Installation Fixture Kit Bolt in 24apr2019Abrham B. GMPas encore d'évaluation

- 9 Plumbing DetailsDocument1 page9 Plumbing DetailsMilan RedosPas encore d'évaluation

- General Notes TunnelDocument3 pagesGeneral Notes TunnelEnglish for KidsPas encore d'évaluation

- General Notes FBDocument3 pagesGeneral Notes FBEnglish for KidsPas encore d'évaluation

- General Notes and Specification: 3-LegendDocument1 pageGeneral Notes and Specification: 3-LegendReadian FedelinPas encore d'évaluation

- 2 Structural DrawingsDocument7 pages2 Structural DrawingsRA LapitanPas encore d'évaluation

- General Construction NotesDocument1 pageGeneral Construction NotesjanellePas encore d'évaluation

- Documents - Pub Ss9208 Rev 48 Production Acceptance CriteriaDocument64 pagesDocuments - Pub Ss9208 Rev 48 Production Acceptance CriteriaflyinzeskyPas encore d'évaluation

- Girls Hostle StructuralDocument9 pagesGirls Hostle StructuralNoor MuhammadPas encore d'évaluation

- I - General NotesDocument1 pageI - General NotesReadian FedelinPas encore d'évaluation

- 5219132-ATK-GLW-XX-DR-EW-000004Document1 page5219132-ATK-GLW-XX-DR-EW-000004BEN BENPas encore d'évaluation

- SHTL, XP 2.5000, YP 2.2500, G3: Notes: Unless Otherwise SpecifiedDocument2 pagesSHTL, XP 2.5000, YP 2.2500, G3: Notes: Unless Otherwise SpecifiedEricson. TatlongmariaPas encore d'évaluation

- Annex 02Document12 pagesAnnex 02rukshan jayasinghePas encore d'évaluation

- ELEVATIONDocument1 pageELEVATIONradhapunnaPas encore d'évaluation

- De02 Struc 2024-03-13 - Wip 1Document59 pagesDe02 Struc 2024-03-13 - Wip 1AnandPrabuPas encore d'évaluation

- Site DrawingDocument1 pageSite DrawingRoemaric AguasPas encore d'évaluation

- Quiruben M. Mera Engr. Landrito R. Pilao: S-1 Highline Builders CompanyDocument1 pageQuiruben M. Mera Engr. Landrito R. Pilao: S-1 Highline Builders CompanyHighline BuildersPas encore d'évaluation

- Department of Transportation and Communications: Joint Venture WithDocument4 pagesDepartment of Transportation and Communications: Joint Venture WithDordas SingPas encore d'évaluation

- Rack and Bridge Assembly DrawingDocument14 pagesRack and Bridge Assembly DrawingFahad NaveedPas encore d'évaluation

- S 001Document1 pageS 001Rashed SiddiqiPas encore d'évaluation

- TLX-AM-IHS-VSI03 Illuminated Starlets Skylight 2Document3 pagesTLX-AM-IHS-VSI03 Illuminated Starlets Skylight 2Shannon TurnerPas encore d'évaluation

- S-001-General Notes-1Document1 pageS-001-General Notes-1JohnIsaacPas encore d'évaluation

- LS-101 - Rev. 01Document1 pageLS-101 - Rev. 01david901221Pas encore d'évaluation

- Arch Plans v2 (Approved)Document12 pagesArch Plans v2 (Approved)rabbetmrPas encore d'évaluation

- Steel Design Project PublishDocument48 pagesSteel Design Project PublishCzelsi Carlos NavarroPas encore d'évaluation

- General Notes:-: Tirupati Smart City Corporation LimitedDocument1 pageGeneral Notes:-: Tirupati Smart City Corporation LimitedAecom IndiaPas encore d'évaluation

- General notes and legend for architectural drawingDocument1 pageGeneral notes and legend for architectural drawingradhapunnaPas encore d'évaluation

- Design Notes:: Commonwealth of PennsylvaniaDocument1 pageDesign Notes:: Commonwealth of PennsylvaniaHDPas encore d'évaluation

- CW - 03 General Notes (Sheet 01 of 02)Document1 pageCW - 03 General Notes (Sheet 01 of 02)Hurriyat AliPas encore d'évaluation

- Rev 05-ModelDocument1 pageRev 05-ModelKHALID NAZKIPas encore d'évaluation

- General construction notes and requirementsDocument4 pagesGeneral construction notes and requirementsGrachelle Tan100% (1)

- SpecificationDocument1 pageSpecificationdanielsu87Pas encore d'évaluation

- Ncca-16-0166 Peace River Walkway Struct TenderDocument3 pagesNcca-16-0166 Peace River Walkway Struct TenderKevin L KermodePas encore d'évaluation

- Niagara Frontier Transportation Authority Serving The Niagara RegionDocument1 pageNiagara Frontier Transportation Authority Serving The Niagara RegionHamid EhsanPas encore d'évaluation

- Section H - Fireprotection & Loss ControlDocument49 pagesSection H - Fireprotection & Loss ControlNevlinPas encore d'évaluation

- Proposed Three-Storey Building: General Structural / Construction Notes and SpecificationsDocument1 pageProposed Three-Storey Building: General Structural / Construction Notes and SpecificationsAngelo AmarPas encore d'évaluation

- Scale: C9 C5 C9 C1 NC NCDocument1 pageScale: C9 C5 C9 C1 NC NCmahmoudragan11Pas encore d'évaluation

- El 10d27 Ev 201b Podium Floor Plan (Part 02)Document1 pageEl 10d27 Ev 201b Podium Floor Plan (Part 02)shajbabyPas encore d'évaluation

- NEW OMER-ModelDocument1 pageNEW OMER-ModelomermustaafaaPas encore d'évaluation

- General Structural Notes Structural Steel Framing Notes:: Site Prep For CT ScannerDocument14 pagesGeneral Structural Notes Structural Steel Framing Notes:: Site Prep For CT ScannerMark JangadPas encore d'évaluation

- E:/1. Hai Phat/Nh19/1. Detail Design/99. Xuat Ho So/General Notes/General Notes - DWG - Date: Thu, 22 Oct 2020 - 1:58Pm Pc:LamntDocument2 pagesE:/1. Hai Phat/Nh19/1. Detail Design/99. Xuat Ho So/General Notes/General Notes - DWG - Date: Thu, 22 Oct 2020 - 1:58Pm Pc:LamntHoang Nguyen HuyPas encore d'évaluation

- 5 X 47 U'sDocument1 page5 X 47 U'sshahul hameedPas encore d'évaluation

- Philippines building permit plansDocument8 pagesPhilippines building permit plansJizzusPas encore d'évaluation

- Rev 04-ModelDocument1 pageRev 04-ModelKHALID NAZKIPas encore d'évaluation

- Da 950065 001Document1 pageDa 950065 001BIPIN BALANPas encore d'évaluation

- 1473a-Ir-A0-0001 - General Notes and Legends Irrigation LayoutDocument1 page1473a-Ir-A0-0001 - General Notes and Legends Irrigation LayoutMohsin ShaikhPas encore d'évaluation

- Real Analysis and Probability: Probability and Mathematical Statistics: A Series of Monographs and TextbooksD'EverandReal Analysis and Probability: Probability and Mathematical Statistics: A Series of Monographs and TextbooksÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- ANCHOR CHANNEL CHECKLISTDocument3 pagesANCHOR CHANNEL CHECKLISTAniket InarkarPas encore d'évaluation

- MS Framing WeightageDocument14 pagesMS Framing WeightageAniket InarkarPas encore d'évaluation

- WT12 SectionDocument1 pageWT12 SectionAniket InarkarPas encore d'évaluation

- SJ MEPLA Calculation Protocol:: Basic Form: QuadrangleDocument3 pagesSJ MEPLA Calculation Protocol:: Basic Form: QuadrangleAniket InarkarPas encore d'évaluation

- Drafts - Ecopark - Cracked Conc CaseDocument8 pagesDrafts - Ecopark - Cracked Conc CaseAniket InarkarPas encore d'évaluation

- Steel Required WT 13a & 11Document11 pagesSteel Required WT 13a & 11Aniket InarkarPas encore d'évaluation

- Louver Profiles Failed ReportDocument12 pagesLouver Profiles Failed ReportAniket InarkarPas encore d'évaluation

- Consultancy Calculation Review StatusDocument2 pagesConsultancy Calculation Review StatusAniket InarkarPas encore d'évaluation

- Drafts - WT 07 - Bottom BracketDocument10 pagesDrafts - WT 07 - Bottom BracketAniket InarkarPas encore d'évaluation

- Drafts - 1.5kpa Ecopark New Slab Mounted Bracket - Cracked Conc CaseDocument8 pagesDrafts - 1.5kpa Ecopark New Slab Mounted Bracket - Cracked Conc CaseAniket InarkarPas encore d'évaluation

- Steel Support RequiredDocument1 pageSteel Support RequiredAniket InarkarPas encore d'évaluation

- WT 13Document1 pageWT 13Aniket InarkarPas encore d'évaluation

- Add Stiffneres As Shown AboveDocument1 pageAdd Stiffneres As Shown AboveAniket InarkarPas encore d'évaluation

- Project Details Glazing Information: WT 03-Spandrel Glass Failure Report - 8Mm HsDocument3 pagesProject Details Glazing Information: WT 03-Spandrel Glass Failure Report - 8Mm HsAniket InarkarPas encore d'évaluation

- Analysis of Double Height Spider GlazingDocument43 pagesAnalysis of Double Height Spider GlazingAniket InarkarPas encore d'évaluation

- Analysis Report of Spider Glazing: ProjectDocument41 pagesAnalysis Report of Spider Glazing: ProjectAniket InarkarPas encore d'évaluation

- Glass Check 550mm X 1550mmDocument7 pagesGlass Check 550mm X 1550mmAniket InarkarPas encore d'évaluation

- Drafts - WT 07 - TOP BracketDocument13 pagesDrafts - WT 07 - TOP BracketAniket InarkarPas encore d'évaluation

- Glass Check 550mm X 1550mmDocument7 pagesGlass Check 550mm X 1550mmAniket InarkarPas encore d'évaluation

- SPIGOT GLASS RAILING @1.5KPaDocument18 pagesSPIGOT GLASS RAILING @1.5KPaAniket InarkarPas encore d'évaluation

- BALUSTRADE at 2.25kPa-R01Document57 pagesBALUSTRADE at 2.25kPa-R01Aniket InarkarPas encore d'évaluation

- Hilti anchor calculation for cracked concreteDocument6 pagesHilti anchor calculation for cracked concreteAniket InarkarPas encore d'évaluation

- Mx_DL ≔ -0.00 kN‐m Mx_WL ≔ -0.00 kN‐m V_DL ≔ 0.00 kN V_WL ≔ 0.00 kNDocument111 pagesMx_DL ≔ -0.00 kN‐m Mx_WL ≔ -0.00 kN‐m V_DL ≔ 0.00 kN V_WL ≔ 0.00 kNAniket InarkarPas encore d'évaluation

- Hilti anchor calculation for M12 anchor in C25/30 concreteDocument8 pagesHilti anchor calculation for M12 anchor in C25/30 concreteAniket InarkarPas encore d'évaluation

- Type 4 AnsysDocument12 pagesType 4 AnsysAniket InarkarPas encore d'évaluation

- Web 5198Document63 pagesWeb 5198skorabnPas encore d'évaluation

- Complain CeDocument5 pagesComplain CeAniket InarkarPas encore d'évaluation

- Sliding Window Glass Report FullDocument3 pagesSliding Window Glass Report FullAniket InarkarPas encore d'évaluation

- SIDE LOCATION MULLION THROUGH BOLT-Bottom Bracket-Normal ConditionDocument3 pagesSIDE LOCATION MULLION THROUGH BOLT-Bottom Bracket-Normal ConditionAniket InarkarPas encore d'évaluation

- Kuraray 4 1 Physical Properties of SentryglasDocument9 pagesKuraray 4 1 Physical Properties of SentryglaskurtainPas encore d'évaluation

- Engineered Over 10,000 km Transmission LinesDocument2 pagesEngineered Over 10,000 km Transmission Linesmhergonzales100% (1)

- Master of Professional EngineeringDocument1 pageMaster of Professional EngineeringEduardo Jose Tovar CamachoPas encore d'évaluation

- TOPIC (All Caps, Font 22, Bold, No Underline and No Italics, Centered)Document4 pagesTOPIC (All Caps, Font 22, Bold, No Underline and No Italics, Centered)Pawan GuptaPas encore d'évaluation

- CE 123 Construction and Management NotesDocument3 pagesCE 123 Construction and Management NotesCherie Lynne GomintongPas encore d'évaluation

- Concrete Production ProcessDocument34 pagesConcrete Production ProcessHan Kyung SoonPas encore d'évaluation

- Gujarat Technological University: Aeronautical EngineeringDocument16 pagesGujarat Technological University: Aeronautical EngineeringNiik StarPas encore d'évaluation

- Speakers Moderator: Rid9Yg5AicxggDocument2 pagesSpeakers Moderator: Rid9Yg5AicxggAnonymous wosn1lyPas encore d'évaluation

- International Journal of Science and Business ISSN 2520-4750Document2 pagesInternational Journal of Science and Business ISSN 2520-4750ijsab.comPas encore d'évaluation

- LarruDocument118 pagesLarruRafael VerdeliPas encore d'évaluation

- Jntua r13 Eee SyllabusDocument116 pagesJntua r13 Eee SyllabusRayapati Devi PrasadPas encore d'évaluation

- LRFD Section 3.76 Concrete Pile Cap DesignDocument21 pagesLRFD Section 3.76 Concrete Pile Cap DesignNurali MamenPas encore d'évaluation

- (PPR) Lbycvg1 Field TestsDocument4 pages(PPR) Lbycvg1 Field TestsJan Marielle LandichoPas encore d'évaluation

- Steel Pipe PilesDocument12 pagesSteel Pipe PilesSteven LiyantoPas encore d'évaluation

- CIVI 6051-Winter 2022-OutlineDocument3 pagesCIVI 6051-Winter 2022-OutlineMartialPas encore d'évaluation

- Section - 11356 - Dewatered Sludge Storage SilosDocument24 pagesSection - 11356 - Dewatered Sludge Storage SilosjufrejjPas encore d'évaluation

- Top RCC Questions Asked in SSC JEDocument41 pagesTop RCC Questions Asked in SSC JEaman67% (9)

- Software 4 Model Answer Papers From 2019 To 2022Document27 pagesSoftware 4 Model Answer Papers From 2019 To 2022tapstaps902Pas encore d'évaluation

- Aakash (1) 2Document4 pagesAakash (1) 2Mandar OzaPas encore d'évaluation

- Capstone - Design, Installations and Testing of Electrical Systems in BuildingDocument10 pagesCapstone - Design, Installations and Testing of Electrical Systems in BuildingHaziq10101Pas encore d'évaluation

- PVC Pipes & Fittings: Sanitary Fittings CatalogDocument3 pagesPVC Pipes & Fittings: Sanitary Fittings CatalogDesiree jayne NoriegaPas encore d'évaluation

- Accomplishment Report Arc V1Document24 pagesAccomplishment Report Arc V1ANO BYNOUUSPas encore d'évaluation

- Ms Project Report PDFDocument7 pagesMs Project Report PDFKhaja MohiddinPas encore d'évaluation

- 2nd Year Weekly Attendance Even Sem 2020-2021Document608 pages2nd Year Weekly Attendance Even Sem 2020-2021Jos BatlarPas encore d'évaluation

- Construction Workers Fall Accidents from ScaffoldingDocument5 pagesConstruction Workers Fall Accidents from ScaffoldingNikola LopacaninPas encore d'évaluation

- PLC Automation ProjectsDocument3 pagesPLC Automation Projectswhanumant100% (1)

- Resource Planning of A Colony Project Using PrimaveraDocument6 pagesResource Planning of A Colony Project Using PrimaveraSheikh Ubaid100% (1)

- 01-Lessons LearnedDocument6 pages01-Lessons LearnedengrfarhanAAAPas encore d'évaluation

- END-SEMESTER AND MID-SEMESTER EXAM SCHEDULE July 2021Document32 pagesEND-SEMESTER AND MID-SEMESTER EXAM SCHEDULE July 2021sunny soniPas encore d'évaluation

- Department of Electronics and Communication Engineering: Siruganur, Tiruchirappalli - 621 105Document3 pagesDepartment of Electronics and Communication Engineering: Siruganur, Tiruchirappalli - 621 105susan williamPas encore d'évaluation