Académique Documents

Professionnel Documents

Culture Documents

Steel Painting

Transféré par

mosdnsCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Steel Painting

Transféré par

mosdnsDroits d'auteur :

Formats disponibles

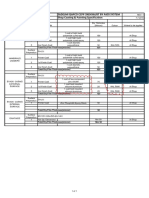

Section 15 Structural Steel Work

TABLE 15.7

Surface Protection to Structural Steel

Surface Painting

Details of Painting System

Preparation system

Primer : Drying oil based zinc phosphate primer, applied in 1 coat

As Clause Type A Dry film thickness = 40 µm

15.61 (i) Finishing coat : Drying oil based finishing coat, applied in 2 coats

Dry film thickness = 80 µm

Minimum overall dry film thickness = 120 µm

Primer : 2-pack surface tolerant epoxy based aluminium paint

As Clause Type B Dry film thickness = 80 µm

15. 61 (ii) Finishing coat : 2-pack recoatable polyurethane finishing paint, applied in 2 coats

Dry film thickness = 80 µm

Minimum overall dry film thickness = 160 µm

Primer : 2-pack epoxy based zinc rich primer, applied in 1 coat, to BS 4652

As Clause Type C (except that the content of zinc metal in the dry film shall not be

15.61 (iii) less than 80% (by weight) of the cured paint film)

Dry film thickness = 60 µm

Undercoat : 2-pack epoxy based micaceous iron oxide paint

Dry film thickness = 100 µm

Finishing coat : 2-pack recoatable polyurethane coats finishing coat, applied in 2

coats

Dry film thickness = 100 µm

Minimum overall dry film thickness = 260 µm

Primer : 2-pack epoxy based zinc rich primer, applied in 1 coat, to BS 4652

As Clause Type D (except that the content of zinc metal in the dry film shall not be

15.61 (iii) less than 80% (by weight) of the cured paint film)

Dry film thickness = 60 µm

Undercoat : 2-pack epoxy based micaceous iron oxide paint

Dry film thickness = 100 µm

Finishing coat : 2-pack epoxy based finishing coat

Dry film thickness =100 µm

Minimum overall dry film thickness = 260 µm

Type E NOT USED

Primer : Nil

Hot dip Type F Pretreatment : Degrease and rinse.

galvanized to Apply British Rail T-Wash or equivalent. Excess etchant to be

Clause 15.63 thoroughly rinsed.

Undercoat : Nil

Finishing coat : 2-packed recoatable polyurethane finishing paint applied in 2

coats recommended as suitable by paint manufacturer for direct

application to etched surface. Etched surface shall be overcoated

within 24 hours or the time limit by the manufacturer

Dry film thickness = 80 µm

Primer : Nil

Hot dip Type G Pretreatment : Degrease and rinse.

galvanized to Apply British Rail T-Wash or equivalent. Excess etchant to be

Clause 15.63 thoroughly rinsed.

Undercoat : 2-pack epoxy based micaceous iron oxide paint recommended as

suitable by paint manufacturer for direct application to etched

surface. Etched surface shall be overcoated within 24 hours or the

time limit by the manufacturer

Dry film thickness = 80 µm

Finishing coat : 2-packed recoatable polyurethane finishing paint applied in 2

coats

Dry film thickness = 80 µm

Minimum overall dry film thickness = 160 µm

Note : Drying oils dry (or cure) in the presence of atmospheric oxygen; they include linseed oil, urethane oil,

alkyd, modified alkyd, phenolic varnish or epoxy ester.

15-18

Vous aimerez peut-être aussi

- Pages From Painting Spec TenderDocument2 pagesPages From Painting Spec TenderkareemPas encore d'évaluation

- Technical Specification For Paints, Thinner and PrimerDocument3 pagesTechnical Specification For Paints, Thinner and PrimerRadhakrishnan SreerekhaPas encore d'évaluation

- Painting ScheduleDocument3 pagesPainting SchedulewaqasPas encore d'évaluation

- Nanocrete FC Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureDocument5 pagesNanocrete FC Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureVelmurugan BalasubramanianPas encore d'évaluation

- Bituseal Liquid: Heavy Duty Bituminous CoatingDocument2 pagesBituseal Liquid: Heavy Duty Bituminous Coatingengramir07Pas encore d'évaluation

- System S3.21 - Epoxy Zinc Rich Primer, 160 MicronsDocument2 pagesSystem S3.21 - Epoxy Zinc Rich Primer, 160 MicronsemilyspanouPas encore d'évaluation

- Technical Data Sheet for Acrylic Clear Sunscreen TopcoatDocument1 pageTechnical Data Sheet for Acrylic Clear Sunscreen TopcoatShaijan JosephPas encore d'évaluation

- MicrofinoBI enDocument3 pagesMicrofinoBI enEdin Krdžalić EdoPas encore d'évaluation

- Zinc Rich Epoxy For Damaged Steel Coatings: ZincfixDocument2 pagesZinc Rich Epoxy For Damaged Steel Coatings: Zincfix200365530Pas encore d'évaluation

- System S3.18 - Epoxy Zinc Phosphate Primer, 200 MicronsDocument3 pagesSystem S3.18 - Epoxy Zinc Phosphate Primer, 200 MicronsemilyspanouPas encore d'évaluation

- Nippon ArocoatDocument3 pagesNippon ArocoatHANIF IZANI ISHAKPas encore d'évaluation

- Fast drying epoxy coating for steel and other surfacesDocument1 pageFast drying epoxy coating for steel and other surfacesGunjan GaganPas encore d'évaluation

- Rust O Cap PDFDocument1 pageRust O Cap PDFTitus PraveenPas encore d'évaluation

- 15ifiziegftenioneers Standard Specification For Surface Preparation and Protective Coating 6-79-0020 Rev. 0Document3 pages15ifiziegftenioneers Standard Specification For Surface Preparation and Protective Coating 6-79-0020 Rev. 0Chinmay DavePas encore d'évaluation

- Flame Inhibiting Paint Provides Fire ProtectionDocument1 pageFlame Inhibiting Paint Provides Fire ProtectionRafa JalPas encore d'évaluation

- NORD-Painting CodeDocument3 pagesNORD-Painting CodeubabPas encore d'évaluation

- Paint Schedule HELIDECKDocument24 pagesPaint Schedule HELIDECKAsongwe HansPas encore d'évaluation

- Mipa P 85 Technical Data SheetDocument2 pagesMipa P 85 Technical Data SheetGeorgianaPas encore d'évaluation

- TL_226_EN_2013-08-01 Paintworks on Materials Used in the Vehicle Interior Trim; RequirementsDocument12 pagesTL_226_EN_2013-08-01 Paintworks on Materials Used in the Vehicle Interior Trim; Requirementsjacek.sadlonPas encore d'évaluation

- Summary Specification Painting For Project P3Fh - Antam (System 2 & System 3)Document4 pagesSummary Specification Painting For Project P3Fh - Antam (System 2 & System 3)argaPas encore d'évaluation

- Quotation-Tirupati GardenDocument12 pagesQuotation-Tirupati GardenAnonymous fLgaidVBhzPas encore d'évaluation

- PAINTING STRUCTURE Rev.3Document2 pagesPAINTING STRUCTURE Rev.3Reza PramataPas encore d'évaluation

- HJF24R R4 ES - eDocument3 pagesHJF24R R4 ES - evincatesPas encore d'évaluation

- HMG Epozinc1000Document2 pagesHMG Epozinc1000ben.ledwidgePas encore d'évaluation

- HGF10R R4 ES - eDocument3 pagesHGF10R R4 ES - eNico RoisnerPas encore d'évaluation

- MicrostoneBI ENDocument3 pagesMicrostoneBI ENEdin Krdžalić EdoPas encore d'évaluation

- High Temperature CoatingsDocument12 pagesHigh Temperature CoatingsWagiyanto MulyaPas encore d'évaluation

- Silvakote: Bitumen-Based Aluminium PaintDocument2 pagesSilvakote: Bitumen-Based Aluminium PaintBangos Bratislava MakhafolaPas encore d'évaluation

- (NON Insulated) Structure Steel, Piping (Up To 120 Q) : Galbon S-HB 100Document11 pages(NON Insulated) Structure Steel, Piping (Up To 120 Q) : Galbon S-HB 100katfy1Pas encore d'évaluation

- Investigation of The Effects of Dry Film Thickness and Peak Metal Temperature On Surface Effect On Polyester Wrinkle Coil CoatingsDocument7 pagesInvestigation of The Effects of Dry Film Thickness and Peak Metal Temperature On Surface Effect On Polyester Wrinkle Coil Coatingsmdab2529Pas encore d'évaluation

- TDS PUFFIN COOKWARE STOVING DoneDocument3 pagesTDS PUFFIN COOKWARE STOVING DoneYoga RahadianPas encore d'évaluation

- NP ArocoatDocument4 pagesNP ArocoatJohn HaPas encore d'évaluation

- PU White Primer Tech SheetDocument1 pagePU White Primer Tech SheetSalemPas encore d'évaluation

- Technical Specifications - Painting of SteelDocument1 pageTechnical Specifications - Painting of SteeldineshPas encore d'évaluation

- DataSheet 06042022051050Document2 pagesDataSheet 06042022051050dassourjya2.0Pas encore d'évaluation

- Paint Specification 1phDocument5 pagesPaint Specification 1phNhien ManPas encore d'évaluation

- PaintingDocument1 pagePaintingDefrimaulana BaihaqiPas encore d'évaluation

- TDS - Solvent Free Epoxy STDDocument2 pagesTDS - Solvent Free Epoxy STDRameshp PalanisamyPas encore d'évaluation

- MX-99-2K MP SB: Multipurpose Epoxy CoatinglDocument2 pagesMX-99-2K MP SB: Multipurpose Epoxy CoatinglGo Joko AriefPas encore d'évaluation

- Level Concrete Floors with FS80 ScreedDocument2 pagesLevel Concrete Floors with FS80 ScreedEngineer Gul ZamanPas encore d'évaluation

- 4910 NastroDocument3 pages4910 NastrowillyPas encore d'évaluation

- Carbozinc 858Document2 pagesCarbozinc 858Muhammad RizwanPas encore d'évaluation

- PU Recoatable Finish NipponDocument4 pagesPU Recoatable Finish Nipponyarth880% (1)

- Nippon Arocoat Protective Coating for Aggressive EnvironmentsDocument3 pagesNippon Arocoat Protective Coating for Aggressive EnvironmentsHamza GhaniPas encore d'évaluation

- Brushbond Cool Coat PDFDocument2 pagesBrushbond Cool Coat PDFtrading materialPas encore d'évaluation

- Sadelmi Qapco CCPP 3Xhaust By Pass System Shop Coating & Painting SpecificationDocument1 pageSadelmi Qapco CCPP 3Xhaust By Pass System Shop Coating & Painting SpecificationAmer Y KPas encore d'évaluation

- BSEZ - (PCCL-GKB) - MAR-094. Touch Up Paint For Galvanized PartDocument9 pagesBSEZ - (PCCL-GKB) - MAR-094. Touch Up Paint For Galvanized PartHồng Trung DươngPas encore d'évaluation

- EPICON ZINC RICH PRIMER B-2 Technical Data SheetDocument3 pagesEPICON ZINC RICH PRIMER B-2 Technical Data SheetBhayu Senoaji Dwi PrimasanjoyoPas encore d'évaluation

- Thermoplastic Road Marking Paint: Product Code: TTP 1 & TTP 2Document3 pagesThermoplastic Road Marking Paint: Product Code: TTP 1 & TTP 2Veera PandiPas encore d'évaluation

- MicatexDocument3 pagesMicatexsarcozy922Pas encore d'évaluation

- Nitomortar TC2000 PDFDocument3 pagesNitomortar TC2000 PDFtalatzahoor100% (2)

- Silva Spar No.500Document1 pageSilva Spar No.500Anonymous cossY9FPas encore d'évaluation

- Sigmazinc 158 New PDFDocument7 pagesSigmazinc 158 New PDFgst ajahPas encore d'évaluation

- Evoprotect 240: Technical Data SheetDocument3 pagesEvoprotect 240: Technical Data SheetJayadiPas encore d'évaluation

- Luxol PU EnamelDocument2 pagesLuxol PU EnamelPramod ShriwastavaPas encore d'évaluation

- FM-906 Product SpecDocument1 pageFM-906 Product Specnkpong849005Pas encore d'évaluation

- Fosroc Nitocote EN901 High Chemical Resistant Protective LiningDocument4 pagesFosroc Nitocote EN901 High Chemical Resistant Protective LiningVincent JavatePas encore d'évaluation

- 2-pack Epoxy primer technical data sheetDocument3 pages2-pack Epoxy primer technical data sheetKL LeePas encore d'évaluation

- Zinky-14 Inorganic Zinc Primer Technical Data SheetDocument5 pagesZinky-14 Inorganic Zinc Primer Technical Data SheetppglPas encore d'évaluation

- Water-Based Paint Formulations, Vol. 3D'EverandWater-Based Paint Formulations, Vol. 3Évaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Degree of Purity ExplainedDocument3 pagesDegree of Purity ExplainedmosdnsPas encore d'évaluation

- Bolt and Nut Hardness TesterDocument15 pagesBolt and Nut Hardness TestermosdnsPas encore d'évaluation

- How To Install - CrackDocument12 pagesHow To Install - CrackAlfian Nur LuthfiPas encore d'évaluation

- Gs 2017Document540 pagesGs 2017CHANPas encore d'évaluation

- Code of Practice On Wind Effects in Hong Kong 2019Document74 pagesCode of Practice On Wind Effects in Hong Kong 2019Francisco Javier Torres AlvaradoPas encore d'évaluation

- Fatigue Assessment of Bridge Structures According To EurocodesDocument21 pagesFatigue Assessment of Bridge Structures According To Eurocodesmosdns100% (1)

- Temperature TestDocument19 pagesTemperature TestmosdnsPas encore d'évaluation

- Explanation For BC Joint: LHS Ms LHS MWDocument16 pagesExplanation For BC Joint: LHS Ms LHS MWmosdnsPas encore d'évaluation

- Keyboard Shortcuts Guide for RevitDocument9 pagesKeyboard Shortcuts Guide for RevitMohit KohliPas encore d'évaluation

- Arcelor Mittal - En-6106 - Design Guide For Floor VibrationDocument56 pagesArcelor Mittal - En-6106 - Design Guide For Floor VibrationBoris DikovPas encore d'évaluation

- Corrosion (Piles)Document8 pagesCorrosion (Piles)JavierPas encore d'évaluation

- ASD General Specification For Building 2012 PDFDocument526 pagesASD General Specification For Building 2012 PDFmosdns100% (1)

- ASD General Specification For Building 2012 PDFDocument526 pagesASD General Specification For Building 2012 PDFmosdns100% (1)

- ASD General Specification For Building 2012 PDFDocument526 pagesASD General Specification For Building 2012 PDFmosdns100% (1)

- Asme B18.2.6 2003Document11 pagesAsme B18.2.6 2003Jesse ChenPas encore d'évaluation

- 17.weldability - McqsDocument5 pages17.weldability - McqsJawed AkhterPas encore d'évaluation

- Materials Today: Proceedings: Gowram Iswarya, Beulah MDocument8 pagesMaterials Today: Proceedings: Gowram Iswarya, Beulah Mshivanand hippargaPas encore d'évaluation

- H05V-K PVC Single Core Cable SpecsDocument2 pagesH05V-K PVC Single Core Cable SpecsAlicia AltamiranoPas encore d'évaluation

- 18 LockoutDocument5 pages18 LockoutheniPas encore d'évaluation

- (Estimate) View Tower - v3.2Document54 pages(Estimate) View Tower - v3.2Prayush RajbhandariPas encore d'évaluation

- Mivan TechnologyDocument6 pagesMivan TechnologyIJIERT-International Journal of Innovations in Engineering Research and TechnologyPas encore d'évaluation

- Joint Coating Application & Pipe Coating ProcedureDocument7 pagesJoint Coating Application & Pipe Coating Proceduregst ajahPas encore d'évaluation

- Ductile Iron (DI) Pipes - Quality StandardsDocument3 pagesDuctile Iron (DI) Pipes - Quality StandardsKalpana KrishnaPas encore d'évaluation

- Port Said University Concrete Mixing ProjectDocument38 pagesPort Said University Concrete Mixing Projectstefax2010Pas encore d'évaluation

- Hyd-Stc-Phe - Boq - 13.10.2023Document2 pagesHyd-Stc-Phe - Boq - 13.10.2023AMOLPas encore d'évaluation

- API 653 Recertification PDF FreeDocument5 pagesAPI 653 Recertification PDF Freekevin RichPas encore d'évaluation

- Piping Support Design ManualDocument4 pagesPiping Support Design ManualxkokarcaxPas encore d'évaluation

- Acknowledging Support for Inplant TrainingDocument36 pagesAcknowledging Support for Inplant Trainingyogesh vPas encore d'évaluation

- Field Inspection ReportDocument14 pagesField Inspection ReportRanjit SinghPas encore d'évaluation

- How To Repair Dripping TapDocument6 pagesHow To Repair Dripping TapBob KowalskiPas encore d'évaluation

- Single bolt capacity and fillet weld strengthDocument17 pagesSingle bolt capacity and fillet weld strengthabhijitPas encore d'évaluation

- Corrosion Testing Report Zinc Rich Primer Vs Stainless SteelDocument2 pagesCorrosion Testing Report Zinc Rich Primer Vs Stainless SteelOscar JiménezPas encore d'évaluation

- NDT of Precipitation Hardened SteelsDocument12 pagesNDT of Precipitation Hardened SteelsMahade Hasan DipuPas encore d'évaluation

- Slotted Drain Specification for Polymer Concrete Channel and Stainless Steel BrickslotDocument2 pagesSlotted Drain Specification for Polymer Concrete Channel and Stainless Steel BrickslotmeenhonPas encore d'évaluation

- Diaphragm DesignDocument32 pagesDiaphragm Designwestqueen100% (6)

- ASTM - Aceptables Por ASME - 2019Document10 pagesASTM - Aceptables Por ASME - 2019Javier CeladaPas encore d'évaluation

- Comparaison en 10253-4 Et DinDocument32 pagesComparaison en 10253-4 Et Dinodaue100% (2)

- Aipi - 03 02 018Document57 pagesAipi - 03 02 018Kenan Sofu100% (3)

- Jaquar PVD Catalogue 2022Document52 pagesJaquar PVD Catalogue 2022anujbhatnagar009Pas encore d'évaluation

- 07 - Ajie Manggala Putra (TML) - 26in BOC - BOD Pipeline ReplacementDocument8 pages07 - Ajie Manggala Putra (TML) - 26in BOC - BOD Pipeline ReplacementSamuel JohnPas encore d'évaluation

- Design of RC StructuresDocument1 pageDesign of RC Structureskamalnitrr0% (3)

- Selection of Welding Electrodes PDFDocument1 pageSelection of Welding Electrodes PDFAnonymous VohpMtUSNPas encore d'évaluation

- MBIE - Grade 500E Reinforcing Steel - Good PracticeDocument8 pagesMBIE - Grade 500E Reinforcing Steel - Good PracticeNelson ChinPas encore d'évaluation

- Life Safety Systems in Buildings PDFDocument25 pagesLife Safety Systems in Buildings PDFAlthea PeralesPas encore d'évaluation