Académique Documents

Professionnel Documents

Culture Documents

Quality Assurance Inspection Checklist (By Asp)

Transféré par

Sushil SinghTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Quality Assurance Inspection Checklist (By Asp)

Transféré par

Sushil SinghDroits d'auteur :

Formats disponibles

Public

CHECK LIST 1 (8)

Prepared (Subject resp) No.

EIL/PBD/AA Santanu Swami Nath EIL-14:004131 Uen

Approved (Document resp) Checked Date Rev Reference

EIL/PBD/A [Ajay Pandit] 2019-07-13 A

QUALITY ASSURANCE INSPECTION CHECKLIST (BY ASP)

Instruction: Project shall keep this filled check list for Record & Verification (Not to be sent to Engineering

dept.)

ASP Team Leader / ASP QA person is responsible to fill up this check list & submit back to Project.

Site Details Site No. LWDWL01.Site Name. WADWALI . Circle .MH&G . Customer.

…AURANGABAD……… ASP Details ASP Name. Aerial .Team Leader / Supervisor Name. Sushil

Kumar . Equpt. Details RBS Type. ..Site Type –GBT Other Status - New Site / Expansion / Swap/ Other

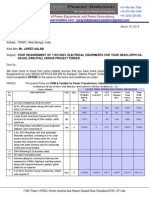

IE Doc OCI Tools Safety Installation VSWR Red Surplus

Installation Process Available Done Available Belts checked measurem marking Material list

compliance ✔ Used ent. Done done to project

(Pl tick mark activity done / checked) ✔ ✔ ✔ ✔ ✔ ✔ ✔

S. Check Point Fault Status Remarks

No. Ratings OK

1 EARTHING

1.1 Incoming Earthing and lightning system

Critical OK

1.1.1 Indoor & Outdoor ECB installation & connection to G.I. Strip / main

earth terminal, continuity checked till earth pits

OK

1.1.2 Major

Earth cable size 16 mm² Cu Min / 50 mm² G.I. for ECB to main earth /

MET.

1.1.3 OK

Connection at all ECB & G.I. strip properly tightened. All ECBs are Major

interconnected.

1.2 Earthing principles

Major OK

1.2.1 Earth distribution cable size 16 mm² Cu Min.

1.2.2 Cable ladder (indoor & outdoor) is earthed OK

Critical

1.2.3 IE Module earthing scheme is followed correctly

Major OK

Earthing connection in AC supply box (MDB, BTS PDU, SMPS, ACDB OK

1.3 etc) Critical

Check BTS AC power supply PE (Protective Earth) continuity to Critical

earth. OK

1.4 Cable Lugs and C-clamps

1.4.1 C clamp Crimped at both end properly (Outdoor & Indoor).Plastic

cover / insulation tape provided on Indoor c-clamp only. Critical OK

1.4.2 Conductor passed through C clamp and insulation cap at other end. Major OK

C-clamp is not loose.

1.4.3 Cable lugs of earthing cables are crimped, connected properly (indoor Critical OK

& outdoor). Right size lugs used with no insulation tape.

ASP Quality Checklist-updated

Public

CHECK LIST 2 (8)

Prepared (Subject resp) No.

EIL/PBD/AA Santanu Swami Nath EIL-14:004131 Uen

Approved (Document resp) Checked Date Rev Reference

EIL/PBD/A [Ajay Pandit] 2019-07-13 A

1.5 Earth connection of Equipment cabinet (BTS, TX rack, DF, SMPS,

Battery / BBU etc)

1.5.1 Earth connections done & tightened. Shake proof washer is used.

Major OK

1.5.2 Earthing cable size 16 mm² Minimum (Tx magazines, DF with

OK

supplied cables along with equipment) Major

1.5.3 Equipment earth connections are parallel connected to earthing

Major OK

system / Cable.

1.5.4 Outdoor RBS–Separate earthing connected to Base frame & RBS NA

Major

Other Point

1.6

Any Other Point

2 CABINET INSTALLATION

Assembly and alignment of cabinet, levelling is done correctly. No NA

2.1 scratches / dirt on cabinet Major

2.2 Fastening Of Cabinet

2.2.1 Base frame grouted to floor. Cabinet fastened to base frame (Front &

Back) & clamped to wall / ladder correctly. Bolts tightened. Major NA

2.2.2

Minimum gap between indoor cabinet and wall >5 cm

Major NA

2.2.3

Outdoor RBS – Installation frame, Mounting base / base frame is

levelled & fixed to foundation. Grouting done. Distance washer Major NA

used at foundation & installation frame.

2.3 Radio cabinet jumper connection and Labels

2.3.1 Tightness of connectors / No Damage on Jumpers Major OK

2.3.2 Jumper bending is > Min. radius / Bend not close to connector. Major OK

2.3.3 Labelling is done. Laid neatly & fastened with plastic ties (indoor). Minor OK

Jumper length is sufficient for future expansion cabinet (If reqd)

2.4 PCM cabling connection and Labels

No sharp bend / No Insulation damage on cables. Labelling done at OK

2.4.1 both ends. Major

2.4.2 OK

Connectors – mounting / tightness Done correctly Major

2.5 Alarm cables

OK

2.5.1 Proper connection / No insulation damage & Labelling Done. Major

2.5.2 Laid neatly & extra length kept in cable chute. Minor NA

2.6 DC power cabling and connection

2.6.1 No cable Insulation Damage. Cable laying is proper. Major OK

2.6.2 Outdoor RBS DC cables are armoured / laid through GI conduit. Major

OK

2.6.3 Connector / termination tightened correctly Major OK

OK

2.6.4 Cable size is correct as per IE document Major

2.6.5 Cable labelling done correctly Minor OK

2.6.6 In case of Looping of PSU, cable size & looping sequence is as per IE Major

OK

doc. / specification & connections are tight. No Cu strands visible

outside termination point.

2.6.7 RBS power is taken through correct rating MCB in DCDB/ SMPS Major OK

ASP Quality Checklist-updated

Public

CHECK LIST 3 (8)

Prepared (Subject resp) No.

EIL/PBD/AA Santanu Swami Nath EIL-14:004131 Uen

Approved (Document resp) Checked Date Rev Reference

EIL/PBD/A [Ajay Pandit] 2019-07-13 A

2.7 AC power cabling and connection

OK

2.7.1 No cable Insulation Damage. Cable laying is proper. Major

2.7.2 Outdoor RBS AC cable are armoured / laid through GI conduit. Major OK

OK

2.7.3 Connector / termination tightness & labels ensured Major

OK

2.7.4 RBS power is taken through correct rating MCB in ACDB Major

2.8 Opto fibre cabling

2.8.1 No damage , Neat & proper laying, routing through conduit & proper Major OK

labelling, No Sharp bend on cables

2.9 GPS Cabling & Connection – For CDMA / WCDMA

OK

2.9.1 GPS cable connection is correct. Cable laid neatly & no damages Major

2.10 Other Defects

3 EQUIPMENT IN CABINETS

3.1 Door filter (indoor Cabinet) - Available, installed correctly & Clean Major OK

3.2 Magazine / Modules / PCB installation

OK

3.2.1 Magazines / Modules / PCBs are installed correctly with all screws Major

OK

3.2.2 No dummy plate / front at empty or open slot is fixed / provided Major

3.3 Internal cabling OK

3.3.1 Cabling is proper, connectors are tight. No mechanical stress. Major

NA

3.3.2 Cables are fastened & Laid properly & cable ties cut properly Major

3.4 Power & Fuse connection

OK

3.4.1 Connections are correct & Tightened Major

3.4.2 Correct fuses rating & cable size used. Major OK

OK

3.5 Fan units are operational Major

3.6 AC Mains Connection & Setting ( Outdoor Cabinet)

3.6.1 AC mains connections are correct & tight Major OK

3.6.2 Correct setting / strapping done for 1- phase / 3- phase connection OK

Major

3.7 Other Defects

4 TRANSMISSION & ALARM

PCM & Alarm Cables connected correctly at terminal block / Krone OK

4.1 Major

No damage to cables & Cable labelling done for all

OK

4.2 PCM cable shield earthed with suitable lug to Krone frame / earthing Critical

point

OK

4.3 Extra length of cables stored in cable chute kept at ladder Minor

4.4 Signal & Power/ earth cable separation at DF Cable chute / Tx cabinet Major OK

OK

4.5 Alarm cable shield connected to clamp in DF Major

ASP Quality Checklist-updated

Public

CHECK LIST 4 (8)

Prepared (Subject resp) No.

EIL/PBD/AA Santanu Swami Nath EIL-14:004131 Uen

Approved (Document resp) Checked Date Rev Reference

EIL/PBD/A [Ajay Pandit] 2019-07-13 A

5 CABLING

OK

5.1 Separation between power(AC, DC & Earthing Cables) and signal Major

cables(PCM,ALARM etc.) maintained on ladder, cable tray, & cabinet

5.2 Cables laying & routing

Cable laying & routing is neat & no stress on cables OK

5.2.1 Major

No cable Insulation damage/Not resting on sharp edges. OK

5.2.2 Major

Cable ties are proper & tails cut properly. No sharp edge on cable tie OK

5.2.3 Major

5.3 Cable ladders

NA

5.3.1 Fixing, alignment and level of cable ladders (Indoor & Outdoor is Major

correct & as per IE document.

OK

5.3.2 Outdoor Ladder pendulums are grouted correctly Major

OK

5.3.3 Earthing jumper cables connected for each part of indoor ladder for Major

earthing. Paint scratched at earthing point for proper connectivity.

5.4 Assembly of cable ladder and trays –no sharp edges, proper joints, Major OK

wall support and pendulums at correct place.

5.5 Other Defects

6 BACKUP BATTERY / Power supply system - If Applicable

NA

6.1 Protection cover provided at battery poles & cable connection Major

NA

No risk of Short circuiting at battery poles / terminal connection

6.2 Critical

NA

6.3 No Acid leakage from batteries Critical

NA

6.4 No Corrosion on battery poles, Petroleum jelly applied on poles Major

NA

6.5 All cables and connectors correctly labelled / Standard Marking Minor

done

NA

6.6 Protection cover available on DC power collection bar at BBS / Major

SMPS.

NA

Insulation boards used at BBU (Outdoor RBS) as per instructions

6.7 Major

NA

DC Cable connections tightened at BBS/ SMPS , Battery & Labelled

6.8 correctly Major

NA

6.9 DC cables connected to correct fuses / MCBs in SMPS / BBS Major

6.10 Temperature sensor installed correctly as per manufacturer Major

instructions

ASP Quality Checklist-updated

Public

CHECK LIST 5 (8)

Prepared (Subject resp) No.

EIL/PBD/AA Santanu Swami Nath EIL-14:004131 Uen

Approved (Document resp) Checked Date Rev Reference

EIL/PBD/A [Ajay Pandit] 2019-07-13 A

7 MINI LINK INDOOR NA

7.1 Module Installation – TX rack, AMM, Fan unit, DDU, DF, IF cable Major

adopter installed at correct position with proper screws / fasteners.

7.2 Fan unit installed with Air-plates at AMM correctly & earthing Major

terminated. Temp at MMU is < 45 °C

7.3 Earthing of Modules done correctly & all modules earthing cable Critical

connected to ECB individually & termination is tight.

Major

Neat cable routing, labelling is correct and connectors tightened

7.4 Cabling – All cables in Tx are laid & routed correctly. Excess length is Minor

kept in proper roll / winded up. All cables & AMM modules labelled.

7.5 Other Defect

8 ANTENNA FEEDERS

8.1 Feeder bending radius

OK

8.1.1 No damage on feeder Critical

8.1.2 Bending radius > min. radius (200mm for 7/8” feeder) / No bend near Major

clamps

8.2 Feeders running and laying on cable ladder is ( straight & correct Major

OK

No stress on feeders & neatly laid

Major

8.3 Feeders fixing and clamping

8.3.1 Clamp of correct size / specification used & installed correctly & NA

tightened. No plastic ties used outdoor for cable / feeder fastening. Major

NA

8.4 Space between feeder clamps in tower 0.9 mtr max. for 7/8 feeder. Major

8.5 Feeder and antenna / TMA jumper markings done correctly near Major NA

connectors at both ends

8.6 Feeder – jumper connectors & Sealing

8.6.1 Connectors are made as per instructions & tightened. Major

8.6.2 Sealing of connectors done correctly with self-fusing tape & PVC tape Major NA

8.6.3 Self-fusing tape is not protruding from the PVC tape sealing Major

8.7 Earthing kit on feeders outdoor

8.7.1 Correct earthing kit used & Installed correctly before the bend (600

Major NA

mm from feeder bend) at tower & before cable inlet

8.7.2 Earthing kits are earthed at tower & roxtec ECB & connection

Major NA

tightened. No more than 2 earthing terminated at single point

8.7.3 Additional earthing kit installed at every 30 mtr, if antenna height is 40

Major NA

mtr / all the earthing kits installed at specified location as per IE doc.

NA

8.7.4 Earthing kits are sealed & no chances of water entry

Critical

ASP Quality Checklist-updated

Public

CHECK LIST 6 (8)

Prepared (Subject resp) No.

EIL/PBD/AA Santanu Swami Nath EIL-14:004131 Uen

Approved (Document resp) Checked Date Rev Reference

EIL/PBD/A [Ajay Pandit] 2019-07-13 A

8.8 Antenna jumpers fixing and clamping

Distance between jumper clamps less than 0 .9 mt. Jumpers not Major OK

8.8.1 hanging. No plastic ties used for jumper fastening at outdoor.

Major OK

8.8.2 Jumper bending > Min.radius & Jumpers are laid straight, without

loop.

NA

8.9 Protection of feeders on horizontal cable ladder provided (If reqd) Major

8.10 Feeder Inlet/Roxtec

OK

8.10.1 Installation and sealing of feeder inlet (light not visible through it Major

from indoor), roxtec installed correctly with all screws and tightened OK

8.10.2 Roxtec rubber blocks placed correctly & only required layers removed. Major

8.11 Drip loop on feeders entry is correct & no chances of water entering Major

along the feeders.

8.12 VSWR Reading (ASP to fill the measured data & provide Cell A: Cell B: Cell C:

printout)

1.29 1.09 1.09

8.13 Other Defect

9 ANTENNAS

OK

9.1 Antenna mounts / support are fitted correctly & tightened. Major

NA

Antenna clamps / fittings are fixed correctly. Lock nuts of antenna

9.2 clamps are tightened. Major

9.3 Antenna Earthing

Tower legs (2 legs min.) are earthed and antenna & Antenna support NA

earthed thru tower. Critical

9.4 Antenna Height as per IE / RF data document – ASP to provide data & to be verified

in L2 Audit

RTT Site : Buiding height = G + N (No of floor) = 4 + 3XN Mtr

Tower Foundation Ht. = As per measurement OK No of Floor : ………….. Buid.

Ant. Ht = 1-Tower section height X No of section, where ant. Height:………………….mtr

Installed – Height of Section top to Ant. Center point

Tower Foundatio Height

GBT : Tower Foundation Ht. = As per measurement :………………….. mtr

Ant. Ht = 1-Tower section height X No of section, where ant.

Installed – Height of Section top to Ant. Center point

No. of Tower Section (where Ant.

Installed) :……………..

Calculated Height of Antenna from

AGL : ………………….. mtr

9.5 Antenna direction and tilt angles as per IE Document. Antenna Major NA

mounts are exactly vertical.

GPS antenna (WCDMA) installed at correct place & no obstruction in OK

9.6 front. GPS antenna not exposed to direct lightening. Major

9.7 TMA, ASC / RET are installed correctly & clamped to tower. Earthing Critical OK

is done & Jumper laid & connected correctly with connector sealing.

ASP Quality Checklist-updated

Public

CHECK LIST 7 (8)

Prepared (Subject resp) No.

EIL/PBD/AA Santanu Swami Nath EIL-14:004131 Uen

Approved (Document resp) Checked Date Rev Reference

EIL/PBD/A [Ajay Pandit] 2019-07-13 A

9.6 RRU installation

OK

9.6.1 RRU Installed correctly & on vertical leg / member. Major

9.6.2 RRU support fastening nuts are tight & lock nuts provided. Major OK

OK

9.6.3 RRU earthing is connected & terminated to tower / earthing point. Critical

Earthing cable laid straight down. Separate earthing done for each

RRU.

9.7 RRU DC cable

OK

9.7.1 DC cable of RRU laid correctly & gland placed at entry & tightened. Major

No damage to DC cable & cable is protected through armouring / OK

9.7.2 conduit. Major

OK

9.7.3 No sharp bend on cables & clamped correctly on tower & top Major

9.8 RRU fibre optical cable (OIL)

OK

9.8.1 OFC laid correctly & gland used at entry. Major

9.8.2 No damage to cable & protection provided like conduit. Major OK

OK

9.8.3 No sharp bend on cables & clamped correctly on tower & top. Major

9.9 Other Defects

10 MINI LINK OUTDOOR

10.1 Antenna & support

NA

10.1.1 Microwave antenna & mounts installed at correct position & tightened

Major

fully.

Critical NA

10.1.2 Antenna support is as per specification & size.

10.1.3 1.2 Mtr & bigger antenna support rod & fixtures are provided & Major NA

10.1.4 installed correctly & fastened to tower structure. Major NA

Support Rod (side strut) is at 90º angle ± 25º & fixed opposite side of

antenna mounting frame.

10.2 Antenna Earthing

10.2.1 Microwave Antenna is earthed thru tower. Critical

_

10.2.2 Radio earthing is connected & tightened. Earthing cable is running Critical

straight down & terminated to tower / earthing point correctly.

10.3 All connectors tightened and sealed correctly. AGC screw caped Major _

10.4 Radio Cables labelled correctly at both ends. Label is weatherproof. Major _

10.5 Radio link cable running and laying on cable ladder – straight Major _

10.6 Radio link cable fixing and clamping using proper clamp. No plastic Major

ties used. _

10.7 Earthing kits on radio link cable

10.7.1 Installed before the bend & at roxtec & terminated correctly. Major

NA

10.7.2 Earthing kit weather proofing done. Major

10.8 Flexible wave guide is clamped/ fixed correctly Major NA

ASP Quality Checklist-updated

Public

CHECK LIST 8 (8)

Prepared (Subject resp) No.

EIL/PBD/AA Santanu Swami Nath EIL-14:004131 Uen

Approved (Document resp) Checked Date Rev Reference

EIL/PBD/A [Ajay Pandit] 2019-07-13 A

11 SITE SAFETY AND GENERAL

OK

11.1 Hazardous/exposed voltage – Risk of electric shock / Short Circuiting Critical

11.2 Ericsson PDU installation – workmanship / Connection tight, Earthing Major OK

done

NA

11.3 Escape routes – Door opening from inside without key Major

OK

11.4 Site appearance - Clean / No surplus material lying Major

NA

11.5 Climbing safety equipment – Available / mounted Major

OK

11.6 Safety rails – available / catwalk provided Major

OK

11.7 Roof top illumination – Lights outside shelter provided Major

OK

11.8 Down conductor connections at tower and earth pit Critical

OK

11.9 Lightening rod at tower and its connection to earth Critical

12 INSTALLATION ENGINEERING

OK

12.1 Installation documentation (IE-module available) Major

NA

12.2 Location, Floor, Antenna, Ladder, cabling, Earthing drawing available Major

NA

12.3 Future expansion is feasible ( No. of RBS cabinets can be added)

12.4 As built documentation (Red marking done) Major

Remarks :

ASP Supervisor’s Signature: Checked By (Ericsson) :

Name: Name: SUSHIL KUMAR

Date: 13/07/2019 Date: 13/07/2019

ASP Quality Checklist-updated

Vous aimerez peut-être aussi

- Token Ring Technology ReportD'EverandToken Ring Technology ReportPas encore d'évaluation

- PURICASABLANCADocument100 pagesPURICASABLANCAWasisPas encore d'évaluation

- GRP-08-TS003-ILF-ELE-DWG-DD-000XX CRS Rev00Document10 pagesGRP-08-TS003-ILF-ELE-DWG-DD-000XX CRS Rev00MhijaziPas encore d'évaluation

- Utility PDB PanelDocument20 pagesUtility PDB PanelTILAK RAJ KambojPas encore d'évaluation

- Inspection Report - Electrical WorkDocument9 pagesInspection Report - Electrical Workpremkumarance_999016Pas encore d'évaluation

- Minutes of Departmental Safety Meeting on 21st January 2018Document2 pagesMinutes of Departmental Safety Meeting on 21st January 2018NabarunSarmaPas encore d'évaluation

- 3.1 System CabinetDocument1 page3.1 System CabinetBoualem AisPas encore d'évaluation

- MAX-C670 SamsungDocument65 pagesMAX-C670 SamsungJuan Carlos Huaman HuertaPas encore d'évaluation

- MPS-10M-1-A 1500-0452-201 March 18-2002Document20 pagesMPS-10M-1-A 1500-0452-201 March 18-2002Marco PoloPas encore d'évaluation

- Electrical Installation Certificate GuideDocument6 pagesElectrical Installation Certificate GuideKuljinder VirdiPas encore d'évaluation

- Ypu 2Document47 pagesYpu 2deividPas encore d'évaluation

- ATP Document Ufone To PTCL Consolidation Project: Region: Site Name Site ID Address City Site Type GF RTDocument6 pagesATP Document Ufone To PTCL Consolidation Project: Region: Site Name Site ID Address City Site Type GF RTAbdul WahidPas encore d'évaluation

- PM Checklist: Visit Date: Time In: Time Out: Responsible PM Staff Name Responsible NOC Staff NameDocument35 pagesPM Checklist: Visit Date: Time In: Time Out: Responsible PM Staff Name Responsible NOC Staff NamekltowerPas encore d'évaluation

- Service: ManualDocument37 pagesService: ManualirvinatorvPas encore d'évaluation

- Sr. No. Comment/ Observation Resolution/ Action: GeneralDocument9 pagesSr. No. Comment/ Observation Resolution/ Action: GeneralmahipalPas encore d'évaluation

- Parker KVP-2126CDocument25 pagesParker KVP-2126Cgabriel6276100% (1)

- Monitoring Sheet For CommissioningDocument4 pagesMonitoring Sheet For CommissioningRatul PalodhiPas encore d'évaluation

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - ADocument2 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - AAmyPas encore d'évaluation

- NHB Site 3.1Document71 pagesNHB Site 3.1Robert TiinPas encore d'évaluation

- 1 Service InformationDocument11 pages1 Service InformationSaad ElhemediPas encore d'évaluation

- Equipo PanasonicDocument42 pagesEquipo PanasonicCarlos JaramilloPas encore d'évaluation

- ALL VESSELS Elect - System ListDocument2 pagesALL VESSELS Elect - System ListLevy AlfianPas encore d'évaluation

- Product Specification For Battery Connection Distribution 1 GeneralDocument2 pagesProduct Specification For Battery Connection Distribution 1 Generalsebax123Pas encore d'évaluation

- Ei GSM Nortel BSC atDocument20 pagesEi GSM Nortel BSC atarvind-kumarPas encore d'évaluation

- Inspection Checklist: Earthing SystemDocument1 pageInspection Checklist: Earthing SystemMohd A IshakPas encore d'évaluation

- Classroom Media Systems Responsibility Matrix: NotesDocument11 pagesClassroom Media Systems Responsibility Matrix: NotesnormoPas encore d'évaluation

- Eil Job No.: A545: Owner:-Dangote Oil Refining CompanyDocument5 pagesEil Job No.: A545: Owner:-Dangote Oil Refining CompanySandip SurPas encore d'évaluation

- Right Factorz Projects PVT LTD Checklist For Cable InstallationDocument9 pagesRight Factorz Projects PVT LTD Checklist For Cable InstallationRajesh RaghunathanPas encore d'évaluation

- FA-PA BOQ Non CommercialDocument2 pagesFA-PA BOQ Non CommercialJoshuaPas encore d'évaluation

- Technical Data Sheets for Electrical WorksDocument36 pagesTechnical Data Sheets for Electrical WorksVikas Dwivedi0% (1)

- Mechanical Test: Plans and Procedures: GLAST Large Area TelescopeDocument22 pagesMechanical Test: Plans and Procedures: GLAST Large Area TelescopeTokkummaa CimsaaPas encore d'évaluation

- CA-0603076-Agc-A02-A12-Equipment Checklist - 1. Process Housing Assembly & Internal Label.Document8 pagesCA-0603076-Agc-A02-A12-Equipment Checklist - 1. Process Housing Assembly & Internal Label.Enano000Pas encore d'évaluation

- Commissioning Checks for LV Load Panel at King Abdul-Aziz AirportDocument3 pagesCommissioning Checks for LV Load Panel at King Abdul-Aziz Airporteswaran005Pas encore d'évaluation

- METHOD FOR GROUNDING RESISTANCE TESTDocument8 pagesMETHOD FOR GROUNDING RESISTANCE TESTHân TiênPas encore d'évaluation

- Service Card IPMDocument3 pagesService Card IPMIng. Gilberto Macias ReyesPas encore d'évaluation

- Samsung ht-x20 kx20 tx22 tx25 thx22 thx25 tkx22 tkx25 PDFDocument65 pagesSamsung ht-x20 kx20 tx22 tx25 thx22 thx25 tkx22 tkx25 PDFNicu TerciuPas encore d'évaluation

- Samsung ht-x20 kx20 tx22 tx25 thx22 thx25 tkx22 tkx25 PDFDocument65 pagesSamsung ht-x20 kx20 tx22 tx25 thx22 thx25 tkx22 tkx25 PDFJander LuisPas encore d'évaluation

- SCC PIW SD PE Taman Salmon SG BulohDocument4 pagesSCC PIW SD PE Taman Salmon SG BulohJohan RamliPas encore d'évaluation

- CREW: U.S. Department of Homeland Security: U.S. Customs and Border Protection: Regarding Border Fence: 6/29/10 - Updated Spreadsheet Showing The 14 Buffer Miles Redacted) 13Document13 pagesCREW: U.S. Department of Homeland Security: U.S. Customs and Border Protection: Regarding Border Fence: 6/29/10 - Updated Spreadsheet Showing The 14 Buffer Miles Redacted) 13CREWPas encore d'évaluation

- China+Gltm 320bDocument12 pagesChina+Gltm 320bMarius FilonPas encore d'évaluation

- QA/QC Templates Electrical ConstructionDocument11 pagesQA/QC Templates Electrical Constructioncaleb isukuruPas encore d'évaluation

- Khazzan Project Earthing System CalculationDocument21 pagesKhazzan Project Earthing System CalculationbhavikPas encore d'évaluation

- Nautel S Ground RecomendationsDocument62 pagesNautel S Ground RecomendationsfernandoalejandroPas encore d'évaluation

- Generic EICRDocument6 pagesGeneric EICRKuljinder VirdiPas encore d'évaluation

- Solid Block WorkDocument8 pagesSolid Block WorkGabriel GabePas encore d'évaluation

- Docs 3Document21 pagesDocs 3MD. Mazidul Islam MahfujPas encore d'évaluation

- Foundation Calculation Sheet: Title DescriptionDocument30 pagesFoundation Calculation Sheet: Title DescriptionResti OktavianiPas encore d'évaluation

- Field Audit Team Format - Elect v.1 2Document40 pagesField Audit Team Format - Elect v.1 2Mohammed SajjadPas encore d'évaluation

- CRS-VD-0301-ZML-MAR-0005-001B ResDocument3 pagesCRS-VD-0301-ZML-MAR-0005-001B Resshrikanth5singhPas encore d'évaluation

- Indra: Cabinet NameDocument1 pageIndra: Cabinet NameBoualem AisPas encore d'évaluation

- General Deck Maintenance - Needle Gunning - Power Brushing - Cleaning - Priming & PaintingDocument2 pagesGeneral Deck Maintenance - Needle Gunning - Power Brushing - Cleaning - Priming & PaintingMelPas encore d'évaluation

- CL-NG-6460-002-064 Checklist For OC & Earth Fault Prot Relay Rev01Document2 pagesCL-NG-6460-002-064 Checklist For OC & Earth Fault Prot Relay Rev01Ahmed SabryPas encore d'évaluation

- Checklist Ver3 - For Engg. DeputationDocument6 pagesChecklist Ver3 - For Engg. Deputationveera chaitanyaPas encore d'évaluation

- Micom p142 CBFDocument2 pagesMicom p142 CBFm khPas encore d'évaluation

- Hayat Snags Analysis For AugustDocument31 pagesHayat Snags Analysis For AugustMoahmed IBrahim YOUSSEF ALiPas encore d'évaluation

- Observation Report - Abu Rdis - P.T Failure - Rev.00Document25 pagesObservation Report - Abu Rdis - P.T Failure - Rev.00TossonPas encore d'évaluation

- Yuyangtelecom L Lgp32atn Et-Sb-Si 1334642042 PDFDocument139 pagesYuyangtelecom L Lgp32atn Et-Sb-Si 1334642042 PDFjuampere2Pas encore d'évaluation

- IKBN Kemasik Project Status UpdateDocument13 pagesIKBN Kemasik Project Status UpdateMohamad Salehan AnPas encore d'évaluation

- Disouq Well Hand-Over Certificate: (Y/N) (Rigless "Gravel Pack")Document6 pagesDisouq Well Hand-Over Certificate: (Y/N) (Rigless "Gravel Pack")eng20072007Pas encore d'évaluation

- Murphy pv101C Users GuideDocument47 pagesMurphy pv101C Users GuideRafael StriederPas encore d'évaluation

- 1024ulxpd16 PDFDocument188 pages1024ulxpd16 PDFingelerrrPas encore d'évaluation

- K7VM2-R30 UmDocument29 pagesK7VM2-R30 UmSyed Irfan BashaPas encore d'évaluation

- Astm A307-14Document6 pagesAstm A307-14Xamir Suarez Alejandro100% (2)

- Sokkia Cx-50 Brochure Sok 1034 Reva SMDocument2 pagesSokkia Cx-50 Brochure Sok 1034 Reva SMHerdi Ade PrasetyoPas encore d'évaluation

- Module C Exercise ModC - QB09 - EngDocument8 pagesModule C Exercise ModC - QB09 - Engapi-3812894Pas encore d'évaluation

- HP Pavilion Dv6500, Dv6600, and Dv6700 Entertainment PCS: Maintenance and Service GuideDocument160 pagesHP Pavilion Dv6500, Dv6600, and Dv6700 Entertainment PCS: Maintenance and Service GuideAntonio MonteiroPas encore d'évaluation

- Configure home media gateway network settingsDocument3 pagesConfigure home media gateway network settingsJonny RnlPas encore d'évaluation

- Crucial m2 SSD Install Guide enDocument5 pagesCrucial m2 SSD Install Guide enShumbla MolinaPas encore d'évaluation

- 50hz Sine PWM Using Tms320f2812 DSPDocument10 pages50hz Sine PWM Using Tms320f2812 DSPsivananda11Pas encore d'évaluation

- Technology Livelihood Education-Computer System Servicing: Quarter 2 - Module 1.3: Microsoft Windows 10 InstallationDocument19 pagesTechnology Livelihood Education-Computer System Servicing: Quarter 2 - Module 1.3: Microsoft Windows 10 InstallationXhyel Mart75% (4)

- Android App For Student Intimation SynopsisDocument35 pagesAndroid App For Student Intimation SynopsisNatheem SafinPas encore d'évaluation

- Wmic Command ListDocument31 pagesWmic Command ListjoseanPas encore d'évaluation

- ZOS 1.12 JES2 New FunctionsDocument53 pagesZOS 1.12 JES2 New FunctionsPatrícia RosaPas encore d'évaluation

- Windows Ginune ErrorDocument6 pagesWindows Ginune ErrorMandis ShahPas encore d'évaluation

- BOM Registraton ManagementDocument11 pagesBOM Registraton ManagementNguyễn Hoàng SơnPas encore d'évaluation

- PFAD-900CS Manual de Instalacion PDFDocument12 pagesPFAD-900CS Manual de Instalacion PDFMauro Barragan SanchezPas encore d'évaluation

- Unit 3 Cloud Virtualization TechnologyDocument18 pagesUnit 3 Cloud Virtualization TechnologyYonesH gurUngPas encore d'évaluation

- AWS LambdaDocument6 pagesAWS LambdaVishakha SinghPas encore d'évaluation

- EDA Companies and Tools GuideDocument9 pagesEDA Companies and Tools GuideLaxmanaa GajendiranPas encore d'évaluation

- NetworkingDocument20 pagesNetworkingAnitha JebarajPas encore d'évaluation

- Roland SR-G01Document8 pagesRoland SR-G01anonyouPas encore d'évaluation

- Load Cell ManualDocument32 pagesLoad Cell Manualrahuldevpatel5100% (1)

- NSi AutoStore InstallGuide enDocument49 pagesNSi AutoStore InstallGuide enTheriuss Allan Zaragoza SPas encore d'évaluation

- Computer essentials explainedDocument8 pagesComputer essentials explainedShaima AbdulazimPas encore d'évaluation

- RobotStudio 2023-1 Release NotesDocument34 pagesRobotStudio 2023-1 Release Notesduy.nguyen.2501Pas encore d'évaluation

- Power Equipment Suppliers for NTPC ProjectDocument17 pagesPower Equipment Suppliers for NTPC ProjectSharafat AliPas encore d'évaluation

- MainDocument33 pagesMainabdulgani11Pas encore d'évaluation

- Astral Column Pipe PricelistDocument4 pagesAstral Column Pipe PricelistVaishamPas encore d'évaluation

- Ecodial Advance Calculation: Live Update (Minor) Example: 4.8. 4.8Document8 pagesEcodial Advance Calculation: Live Update (Minor) Example: 4.8. 4.8benkhelilPas encore d'évaluation