Académique Documents

Professionnel Documents

Culture Documents

Etzc235 Nov24 An

Transféré par

Anirban PalCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Etzc235 Nov24 An

Transféré par

Anirban PalDroits d'auteur :

Formats disponibles

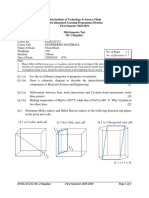

Birla Institute of Technology & Science, Pilani

Work-Integrated Learning Programmes Division

First Semester 2018-2019

Comprehensive Examination

(EC-3 Regular)

Course No. : ET ZC235

Course Title : MANUFACTURING PROCESSES

Nature of Exam : Open Book

Weightage : 40% No. of Pages =2

Duration : 3 Hours No. of Questions = 4

Date of Exam : 24/11/2018 (AN)

Note:

1. Please follow all the Instructions to Candidates given on the cover page of the answer book.

2. All parts of a question should be answered consecutively. Each answer should start from a fresh page.

3. Assumptions made if any, should be stated clearly at the beginning of your answer.

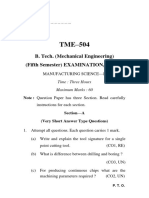

Q.1 (a) Explain the difference in the importance of drafts in green-sand casting vs. permanent

mold casting. [4]

Q.1 (b) In a surface-grinding operation, calculate the chip dimensions for the following

process variables: D = 8 in., d = 0.001 in., v = 30 ft/min, V = 5000 ft/min, C = 500 per

in2, and r = 20. [3]

Q.1 (c) Explain why the cutting force, Fc, increases with increasing depth of cut and

decreasing rake angle. [3]

Q.2 (a) Assume that in orthogonal cutting the rake angle is 150 and the coefficient of friction

is 0.2. Determine the percentage increase in chip thickness when friction is doubled.

[5]

Q.2 (b) (i) Differentiate between Drilling and Reaming. [3]

(ii) Why Drilling, boring, and reaming of large holes is generally more accurate than

just drilling and reaming? [1]

(iii) Why Negative rake angles are generally preferred for ceramic, diamond, and

cubic boron nitride tools? [1]

Q.3 (a) Explain

(a) Why ultrasonic machining is not suitable for soft and ductile metals?

(b) Why the same grinding wheel may act soft or hard?

(c) Why it is generally recommended that a soft-grade wheel be used for grinding

hardened steels?

(d) Why so many different welding processes have been developed?

(e) Similarities and differences between consumable and non-consumable

electrode arc welding processes. [5 x 1 = 5]

Q.3 (b) State the similarities and differences between [5 x 1 = 5]

(a) Casting Of Metals and Fusion Welding

(b) Resistance Seam Welding and Resistance Spot Welding

(c) Bolt and Rivet

(d) Properties of castings made by permanent mold vs. sand-casting methods

(e) Bulk-Deformation Processes and the Sheet-Metal Forming Processes

ET ZC235 (EC-3 Regular) First Semester 2018-2019 Page 1 of 2

ET ZC235 (EC-3 Regular) First Semester 2018-2019 Page 2

Q.4 (a) Which of the advanced machining processes causes thermal damage to workpieces?

List and explain the possible consequences of such damage. [3]

Q.4 (b) A 25-mm-thick copper plate is being machined by wire EDM. The wire moves at a

speed of 1.5 m/min and the kerf width is 1.5 mm. Calculate the power required.

Assume density of copper is = 8970 kg/m3, and it takes 1550 J to melt one gram of

copper. [4]

Q.4 (c) Differentiate between Hard automation, Soft automation and adaptive control

manufacturing processes. [3]

***********

ET ZC235 (EC-3 Regular) First Semester 2018-2019 Page 2 of 2

Vous aimerez peut-être aussi

- ACS Practice ExamDocument18 pagesACS Practice ExamHafsa Khan72% (18)

- Solution Manual of Advanced Engineering Mathematics by Erwin Kreyszig 9th EditionDocument8 pagesSolution Manual of Advanced Engineering Mathematics by Erwin Kreyszig 9th EditionAnirban Pal33% (3)

- Engineering Project Management PDFDocument401 pagesEngineering Project Management PDFLuis Carlos Ayllón Escobar100% (3)

- Engineering Project Management PDFDocument401 pagesEngineering Project Management PDFLuis Carlos Ayllón Escobar100% (3)

- 114 DM 052017Document2 pages114 DM 052017Ravindra JeeviPas encore d'évaluation

- 2022-May ME-322 109Document2 pages2022-May ME-322 109Sidhant SadyalPas encore d'évaluation

- 2k19 5th Sem Papers - Watermark-1Document15 pages2k19 5th Sem Papers - Watermark-1Vishal kumarPas encore d'évaluation

- Interim Semester Take HomeDocument7 pagesInterim Semester Take HomeLhekha RaviendranPas encore d'évaluation

- Unit Test I. 1920Document2 pagesUnit Test I. 1920Balakrushna ParkalePas encore d'évaluation

- r05322003 Metal FormingDocument8 pagesr05322003 Metal FormingSRINIVASA RAO GANTAPas encore d'évaluation

- ME30604 Nontraditional Manufacturing ProcessesDocument3 pagesME30604 Nontraditional Manufacturing Processesshubham jaiswalPas encore d'évaluation

- Final Examination SEMESTER I, SESSION2014/2015Document13 pagesFinal Examination SEMESTER I, SESSION2014/2015Mohamad Yusuf HelmiPas encore d'évaluation

- ME30604 Nontraditional Manufacturing ProcessesDocument3 pagesME30604 Nontraditional Manufacturing Processesshubham jaiswalPas encore d'évaluation

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.Priyadharshan RPas encore d'évaluation

- Question Paper For Minor ExamDocument4 pagesQuestion Paper For Minor ExamVishal kumar SawPas encore d'évaluation

- t1120 Mechanotechnics n4 QP April 2017Document9 pagest1120 Mechanotechnics n4 QP April 2017bistopooe3Pas encore d'évaluation

- S.E (2008 - 2012 Pattern)Document581 pagesS.E (2008 - 2012 Pattern)sagar shindePas encore d'évaluation

- WWW - Manaresults.co - In: (Mechanical Engineering)Document2 pagesWWW - Manaresults.co - In: (Mechanical Engineering)KKPas encore d'évaluation

- Production Technology March 2021Document8 pagesProduction Technology March 2021LuckyPas encore d'évaluation

- 114 DM 112016Document2 pages114 DM 112016Ravindra JeeviPas encore d'évaluation

- 114 DM 112016Document2 pages114 DM 112016Ravindra JeeviPas encore d'évaluation

- July 2004Document6 pagesJuly 2004ffgfgfgffgPas encore d'évaluation

- Mech3002y 3 2007 2 PDFDocument6 pagesMech3002y 3 2007 2 PDFKeshav GopaulPas encore d'évaluation

- Machine Tool Question Paper Jntuh Mt-1-1Document2 pagesMachine Tool Question Paper Jntuh Mt-1-1sudhakarPas encore d'évaluation

- 2018 Ques 5th SemDocument15 pages2018 Ques 5th SemVishal kumarPas encore d'évaluation

- University of MauritiusDocument8 pagesUniversity of MauritiusKeshav GopaulPas encore d'évaluation

- ManPro IJan 2020Document5 pagesManPro IJan 2020Mansingh YadavPas encore d'évaluation

- UTA026Document7 pagesUTA026Panshul SaxenaPas encore d'évaluation

- 2019 CT507 WhitewaresDocument2 pages2019 CT507 WhitewaresSUBHADEEP MANDALPas encore d'évaluation

- Design of Machine Members I Februarymarch 2022Document2 pagesDesign of Machine Members I Februarymarch 2022Junaid AhmedPas encore d'évaluation

- 2022-Dec ME-312 53Document2 pages2022-Dec ME-312 53Aakash TiwariPas encore d'évaluation

- Mody Institute of Technology and Science, Lakshmangarh Faculty of Engineering and TechnologyDocument3 pagesMody Institute of Technology and Science, Lakshmangarh Faculty of Engineering and TechnologyVikrant SharmaPas encore d'évaluation

- Question of Manufacturing ProcessDocument4 pagesQuestion of Manufacturing ProcessRounak AgrawalPas encore d'évaluation

- Mark Scored:: M M M M MDocument5 pagesMark Scored:: M M M M MRamesh ShresthaPas encore d'évaluation

- O-Levels Physics 2020 PDFDocument12 pagesO-Levels Physics 2020 PDFPrethee HlongwanePas encore d'évaluation

- Zimbabwe School Examinations Council Physics 4023/2Document12 pagesZimbabwe School Examinations Council Physics 4023/2Emily NcubePas encore d'évaluation

- MM3304Document2 pagesMM3304xipah14997Pas encore d'évaluation

- Module Code PRDT01C04Document9 pagesModule Code PRDT01C04Sherif El-soudyPas encore d'évaluation

- Enggzc232 Sep29 FNDocument2 pagesEnggzc232 Sep29 FNkasimPas encore d'évaluation

- Final Exam Key AnswerDocument6 pagesFinal Exam Key Answergirma worku100% (1)

- Solution Mid Sem SP2023 PE216Document4 pagesSolution Mid Sem SP2023 PE216Ayush RajPas encore d'évaluation

- Suresh Gyan Vihar University: τ / P = r (1-µr) /1+rDocument3 pagesSuresh Gyan Vihar University: τ / P = r (1-µr) /1+rSonu ChhipaPas encore d'évaluation

- E D1080 Pages: 3: Answer Any Three Questions. Each Question Carries 10 MarksDocument3 pagesE D1080 Pages: 3: Answer Any Three Questions. Each Question Carries 10 MarksDrRoja A RPas encore d'évaluation

- 2nd Year - Sem III - 2015 PAT - Oct 2016Document9 pages2nd Year - Sem III - 2015 PAT - Oct 2016reeyansh lPas encore d'évaluation

- Manufacturing Science-IiDocument5 pagesManufacturing Science-Iiayansiddiqui7700Pas encore d'évaluation

- Ramaiah: Semester End Examinations - January 2020Document2 pagesRamaiah: Semester End Examinations - January 2020hari krishnaPas encore d'évaluation

- FLT-1 Paper-1 Question+SolutionDocument58 pagesFLT-1 Paper-1 Question+SolutionSHIVAM KUMARPas encore d'évaluation

- Manufacturing Processes Kme403Document2 pagesManufacturing Processes Kme403RafelPas encore d'évaluation

- 0910sem1 Me3162 PDFDocument10 pages0910sem1 Me3162 PDFChun Ping OngPas encore d'évaluation

- TCW1202201408 Material Science.Document3 pagesTCW1202201408 Material Science.Tanaka MurekachiroPas encore d'évaluation

- ME204Document2 pagesME204raja93satPas encore d'évaluation

- 1617 Dec SKMM2713Document17 pages1617 Dec SKMM2713Shah MalikPas encore d'évaluation

- Mantech Tie 6122 Assignment Bouquet Oct 2019 PDFDocument4 pagesMantech Tie 6122 Assignment Bouquet Oct 2019 PDFNativity MabasaPas encore d'évaluation

- Tutorial SheetDocument21 pagesTutorial Sheetankita awasthiPas encore d'évaluation

- rr322003 Foundry - WeldingDocument5 pagesrr322003 Foundry - WeldingSRINIVASA RAO GANTAPas encore d'évaluation

- 14 ACAD-R-45 - Unit Test QPDocument9 pages14 ACAD-R-45 - Unit Test QPsomnath swamiPas encore d'évaluation

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityVraj ShahPas encore d'évaluation

- PU Paper Manufacturing Science KME-403 - NewDocument2 pagesPU Paper Manufacturing Science KME-403 - Newdaso khagoPas encore d'évaluation

- PRODUCTIONTECHNOLOGYDocument4 pagesPRODUCTIONTECHNOLOGYSamiullah MohammedPas encore d'évaluation

- r05310303 Production TechnologyDocument4 pagesr05310303 Production TechnologySrinivasa Rao GPas encore d'évaluation

- UofG Civil Engineering 1 202112Document4 pagesUofG Civil Engineering 1 202112dinalamin195Pas encore d'évaluation

- Advances in Ceramic Armor XID'EverandAdvances in Ceramic Armor XIJerry C. LaSalviaPas encore d'évaluation

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIID'EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIITatsuki OhjiPas encore d'évaluation

- Quality Management System at Construction Project: A Questionnaire SurveyDocument5 pagesQuality Management System at Construction Project: A Questionnaire SurveyReynaldo NyotoPas encore d'évaluation

- Maintenance 2 Mark PDFDocument38 pagesMaintenance 2 Mark PDFSaravanan HPas encore d'évaluation

- New Doc 2018-11-15 22.12.46 - 20181115221305 PDFDocument1 pageNew Doc 2018-11-15 22.12.46 - 20181115221305 PDFAnirban PalPas encore d'évaluation

- Et ZC423 Pe ZC423 Powtp ZC423 - L4 1567350214267Document39 pagesEt ZC423 Pe ZC423 Powtp ZC423 - L4 1567350214267Anirban PalPas encore d'évaluation

- IS 456 Amendments - 2013 PDFDocument9 pagesIS 456 Amendments - 2013 PDFAshish JainPas encore d'évaluation

- Et ZC416Document4 pagesEt ZC416Anirban PalPas encore d'évaluation

- 8solar Energy ConversionDocument11 pages8solar Energy ConversionAnirban PalPas encore d'évaluation

- FinalDocument538 pagesFinalAnirban PalPas encore d'évaluation

- Engineering Materials and Metallurgy Notes PDFDocument0 pageEngineering Materials and Metallurgy Notes PDFSenthilkumar Subbiah50% (2)

- Big M 2 PhaseDocument13 pagesBig M 2 PhasekanjaiPas encore d'évaluation

- Company Profile 23566Document25 pagesCompany Profile 23566Anirban PalPas encore d'évaluation

- Etzc235 Sep29 AnDocument2 pagesEtzc235 Sep29 AnAnirban PalPas encore d'évaluation

- Bits Pilani Engg Tech PDFDocument8 pagesBits Pilani Engg Tech PDFAnirban PalPas encore d'évaluation

- Enggzc242 Nov25 AnDocument1 pageEnggzc242 Nov25 AnAnirban PalPas encore d'évaluation

- Q PPCDocument2 pagesQ PPCAnirban PalPas encore d'évaluation

- New Doc 2018-11-15 22.12.46 - 20181115221305 PDFDocument1 pageNew Doc 2018-11-15 22.12.46 - 20181115221305 PDFAnirban PalPas encore d'évaluation

- Sense and SensibilityDocument271 pagesSense and SensibilityAnirban PalPas encore d'évaluation

- Engg DesignDocument13 pagesEngg DesignAnirban PalPas encore d'évaluation

- The Mechanical Design Process David G. UllmanDocument1 pageThe Mechanical Design Process David G. UllmanAnirban PalPas encore d'évaluation

- Bits Pilani Engg Tech PDFDocument8 pagesBits Pilani Engg Tech PDFAnirban PalPas encore d'évaluation

- Probability and Statistics For Engineers SolutionsDocument609 pagesProbability and Statistics For Engineers SolutionsAnirban PalPas encore d'évaluation

- Syllabus BEd PDFDocument144 pagesSyllabus BEd PDFtechnovPas encore d'évaluation

- Brochure New.2Document1 pageBrochure New.2Anirban PalPas encore d'évaluation

- New Doc 2018-11-15 22.07.26 - 20181115220757Document1 pageNew Doc 2018-11-15 22.07.26 - 20181115220757Anirban PalPas encore d'évaluation

- Manufacturing EngineeringDocument72 pagesManufacturing EngineeringAnirban PalPas encore d'évaluation

- Brochure New.1Document1 pageBrochure New.1Anirban PalPas encore d'évaluation

- C776-06 (2011) Standard Specification For Sintered Uranium Dioxide PelletsDocument4 pagesC776-06 (2011) Standard Specification For Sintered Uranium Dioxide PelletsAndré BerninzonPas encore d'évaluation

- Boron Carbide Paste (1 KG) : Kemet Code Description FEPA Grit Average Micron SizeDocument1 pageBoron Carbide Paste (1 KG) : Kemet Code Description FEPA Grit Average Micron SizeMarín HernándezPas encore d'évaluation

- Answer Key Chapter 1Document8 pagesAnswer Key Chapter 1ankit492Pas encore d'évaluation

- Science 8 Third Quarter ExamDocument3 pagesScience 8 Third Quarter ExamArgel Quilab LarongcoPas encore d'évaluation

- AAOs - Evaluation - 5 Sept - KEYDocument2 pagesAAOs - Evaluation - 5 Sept - KEYdPas encore d'évaluation

- B, ZN, Cu en AhuacateDocument7 pagesB, ZN, Cu en AhuacatesuaniPas encore d'évaluation

- Isotope PracticeDocument2 pagesIsotope PracticeSubashiиy PяabakaяaиPas encore d'évaluation

- Question Bank: Multiple Choice QuestionsDocument37 pagesQuestion Bank: Multiple Choice QuestionsDivya AgrawalPas encore d'évaluation

- Preparation and Reactions of Boric Acid, H3BO3Document8 pagesPreparation and Reactions of Boric Acid, H3BO3Sin YeePas encore d'évaluation

- Group Iiia: "The Boron Family" BalgaintlnhDocument8 pagesGroup Iiia: "The Boron Family" BalgaintlnhSherylene VillegasPas encore d'évaluation

- Boron in SteelDocument5 pagesBoron in SteelAara MeghPas encore d'évaluation

- File 4756Document27 pagesFile 4756kendalsjordanPas encore d'évaluation

- Unit 6Document144 pagesUnit 6Abraham ChankoPas encore d'évaluation

- Lesson 2 Fillers FibersDocument35 pagesLesson 2 Fillers FibersEr Ravindra JagdhanePas encore d'évaluation

- Product Profile: MSR B15 - 01/2016 Nacab5O9.8H2O Granular Ulexite 15%Document2 pagesProduct Profile: MSR B15 - 01/2016 Nacab5O9.8H2O Granular Ulexite 15%Ernesto ChiacchiariniPas encore d'évaluation

- National Project On Management of Soil HealthDocument17 pagesNational Project On Management of Soil HealthoberoitkPas encore d'évaluation

- Mecatome T260Document4 pagesMecatome T260Jacques LopezPas encore d'évaluation

- BORODocument11 pagesBOROAnonymous qKeDFDPas encore d'évaluation

- Meat ScienceDocument8 pagesMeat ScienceLatifatul FajriyahPas encore d'évaluation

- Ni-Boron System - 10.1.1.1089.3097Document12 pagesNi-Boron System - 10.1.1.1089.3097tp singhPas encore d'évaluation

- Rayner-Canham 5e Answers To Odd-Numbered Questions PDFDocument25 pagesRayner-Canham 5e Answers To Odd-Numbered Questions PDFDelvia MaulanaPas encore d'évaluation

- 2015 Issue1Document122 pages2015 Issue1Mahesh GunnalaPas encore d'évaluation

- Titanium Boron Aluminum Master Alloy For Use As Aluminum Grain Refiner and Process For Its Production Using UDS Induction FurnaceDocument1 pageTitanium Boron Aluminum Master Alloy For Use As Aluminum Grain Refiner and Process For Its Production Using UDS Induction Furnaceamitkkamble100% (1)

- January 2012 QP - Unit 2 Edexcel Chemistry A-LevelDocument24 pagesJanuary 2012 QP - Unit 2 Edexcel Chemistry A-LevelNabindra RuwaliPas encore d'évaluation

- Kovtyukhova 2013Document24 pagesKovtyukhova 2013Maria Monica Hernandez OrozcoPas encore d'évaluation

- Cutting Tool MaterialsDocument44 pagesCutting Tool MaterialsGokul AnugrahPas encore d'évaluation

- MC 2000-03 - Water Quality Variance For Geothermal ExplorationDocument6 pagesMC 2000-03 - Water Quality Variance For Geothermal ExplorationPacific SpectrumPas encore d'évaluation

- Panadyne Boron Carbide PowdersDocument2 pagesPanadyne Boron Carbide PowdersCorona DrawingPas encore d'évaluation

- Color Formulary DDocument1 pageColor Formulary DjzainounPas encore d'évaluation