Académique Documents

Professionnel Documents

Culture Documents

Welding capacity analysis: determining allowable loads for fillet welds

Transféré par

Engr Benalito A Catap IIIDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Welding capacity analysis: determining allowable loads for fillet welds

Transféré par

Engr Benalito A Catap IIIDroits d'auteur :

Formats disponibles

a

t

i

o

n

M

a

g

tr

e

o

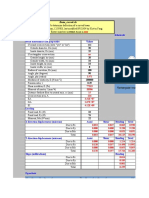

WELD OUTLINE CASE Table 9-6 from "Mechanical Engineering rL oDesign", Shigley, 7t

ie

v

a

g

e

Schedule A: Allowable Load forl Various Sizes of Fi

WELDING CAPACITY ANALYSIS 1

S

w

Strength Level of Weld

T

ie Metal (EXX)

60* h

z

l

ie

d

(tau)cτ =

k

2 Allowable Unit Force on w Fillet Weld, kip/linear

n

,

f =e

s

i

DEFINITION OF SYMBOLS s

n

Aw = Length of weld, in ###

o

f= Allowable unit force on weld, kip per lin in of weld 3 7/8

f

M= Bending moment, kip-in 3/4

l= Bending moment arm length, in 5/8

T

P= Tension or Compression Load h

1/2

Sw = i

Section Modulus of weld lines subjected to bending moment, in^2 7/16

c

V= Vertical load for bending and/or shear, kip 3/8

k

w= Fillet weld leg dimension, in 4 5/16

e

Wn = Tensive or compressive force on weld, kip per lineal inch of weld r

1/4

Ws = Average vertical shear on fillet weld, kip per lineal inch of weld 3/16

P

Wb = Bending force on weld, kip per lineal inch of weld a

1/8

Wr = r

Resultant load on fillet weld, kip per lineal inch of weld 1/16

t

FORMULAS FOR FORCES ON WELD J

TENSION OR COMPRESSION VERTICAL SHEAR BENDING o

i

5

n

P V M e

Wn = Ws = Wb =

Aw Aw Sw d Fillet Weld Size, h

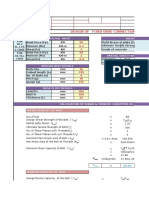

Schedule B: Minimum

RESULTANT FORCE: Wr = √(Wn2 + Ws2 + Wb2) ,

i

Weld is adequate & stress ratio = 0.86 n

INPUT 6 * To 1/4 incl.

Weld Outline Case: 3 Over 1/4

Strength Level of Weld Metal: 70* Over 1/2

Loading condition for bending, ie…Cantilever or Mid-Span

of Simply Supported Beam N/A τ

Over 3/4

w= 6mm 1/4 in Over 1 1/2

P= 105 KN 23.60 kip If no tension or compression is present, P = 0 Over 2 1/4

V= 5.17 KN 10.00 kip If only tension or compression is present, V = 0 7 Over 6

b= 100 mm 4 in Weld dimension; refer to figure on right ###

d= 50 mm 2 in Weld dimension; refer to figure on right Not to exceed the thic

l= 0 in If bending is not to be considered, l = 0

Vous aimerez peut-être aussi

- Discrete Element Method to Model 3D Continuous MaterialsD'EverandDiscrete Element Method to Model 3D Continuous MaterialsPas encore d'évaluation

- Atasehir Gardens Podium OF: Member: LocationDocument7 pagesAtasehir Gardens Podium OF: Member: LocationAlphyl BalasabasPas encore d'évaluation

- Bolted Connection ToolDocument56 pagesBolted Connection ToolPrakash Singh RawalPas encore d'évaluation

- AnchorboltsDocument2 pagesAnchorboltsrammohanPas encore d'évaluation

- 380-R2-20191112 - Wind Load Calculation As Per GFF Method For 60 M Microwave TowerDocument12 pages380-R2-20191112 - Wind Load Calculation As Per GFF Method For 60 M Microwave TowerNeelesh DabholkarPas encore d'évaluation

- Design of Stairs Design of Stairs From Ground To Landing Material PropertiesDocument3 pagesDesign of Stairs Design of Stairs From Ground To Landing Material PropertiesJohn Paul Hilary EspejoPas encore d'évaluation

- Lifting LugDocument17 pagesLifting LugbkprodhPas encore d'évaluation

- Design of Ring Girder SupportDocument3 pagesDesign of Ring Girder Supportvishal guptaPas encore d'évaluation

- Zee Purlin Design Sheet AnalysisDocument4 pagesZee Purlin Design Sheet AnalysisShawkat Ali KhanPas encore d'évaluation

- Design Criteria/Design Check For Star Deck Sheet (44/130)Document2 pagesDesign Criteria/Design Check For Star Deck Sheet (44/130)Advanced Structural EngineeringPas encore d'évaluation

- Design of Plate GirdersDocument2 pagesDesign of Plate GirdersDipak BorsaikiaPas encore d'évaluation

- Sectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)Document49 pagesSectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)rohitnrgPas encore d'évaluation

- Design of Base PlateDocument26 pagesDesign of Base Plateraghav abudhabiPas encore d'évaluation

- Engineering and Development Corporation of The Philippines: Reference: Ubc 1997 Static Load ParametersDocument3 pagesEngineering and Development Corporation of The Philippines: Reference: Ubc 1997 Static Load ParametersMARK VINCENT NAVARROPas encore d'évaluation

- Turkey temporary facility pedestal designDocument23 pagesTurkey temporary facility pedestal designMyunSu GooPas encore d'évaluation

- Space 2001Document43 pagesSpace 2001Nguyen Duc CuongPas encore d'évaluation

- Beam Design 1Document22 pagesBeam Design 1shamen amarasekaraPas encore d'évaluation

- Steel ColumnDocument33 pagesSteel Columnelect aksPas encore d'évaluation

- Beam GravityDocument11 pagesBeam GravitylucianduPas encore d'évaluation

- Design of Column Excel SheetDocument2 pagesDesign of Column Excel SheetAnand K RajPas encore d'évaluation

- Schematic Beam Dimensions and Properties ValuesDocument4 pagesSchematic Beam Dimensions and Properties ValuesFredy Campos FloresPas encore d'évaluation

- Circular Platform Design AISC - ImperialDocument54 pagesCircular Platform Design AISC - ImperialRajveer SinghPas encore d'évaluation

- Steel Connections v1.3Document83 pagesSteel Connections v1.3Mateus GehlenPas encore d'évaluation

- Base Plate Hinged - Moment On Anchors Adjusted 09-06-2021Document2 pagesBase Plate Hinged - Moment On Anchors Adjusted 09-06-2021ahmed osmanPas encore d'évaluation

- Jabacus - Wind Load CalculatorDocument1 pageJabacus - Wind Load Calculatorharishram123456Pas encore d'évaluation

- Bearing CheckDocument6 pagesBearing CheckdhanushkaPas encore d'évaluation

- Design of Column and Lacings for Axial and Bending LoadsDocument160 pagesDesign of Column and Lacings for Axial and Bending LoadsVignesh VenkatasubramanianPas encore d'évaluation

- Costing Calculations:: Date: 31-Mar-2016 Revision: 0 Costing Preet Vihar MezzanineDocument5 pagesCosting Calculations:: Date: 31-Mar-2016 Revision: 0 Costing Preet Vihar MezzanineRakesh SharmaPas encore d'évaluation

- Calculate area, centroid and moment of inertiaDocument77 pagesCalculate area, centroid and moment of inertiaAmit Kumar PaulPas encore d'évaluation

- 111.872 KN Section Properties B 203.1 D 203.2 T 11 T 7.24Document7 pages111.872 KN Section Properties B 203.1 D 203.2 T 11 T 7.24ItsmejanuPas encore d'évaluation

- STIFF (Version 1)Document33 pagesSTIFF (Version 1)maheshbandhamPas encore d'évaluation

- Duct Design With StiffenersDocument67 pagesDuct Design With StiffenersRico CaraPas encore d'évaluation

- API 650 Pipe Column DesignDocument4 pagesAPI 650 Pipe Column DesignJoselito CalagosPas encore d'évaluation

- Eccentric Loads on Vertical Parallel Weld GroupsDocument1 pageEccentric Loads on Vertical Parallel Weld GroupsPriodeep ChowdhuryPas encore d'évaluation

- Design of Secondary Beams For U.D.L Proj.-Lab (Upper Flange Is Considered To Be Effectively Held) Dimensions of BeamDocument6 pagesDesign of Secondary Beams For U.D.L Proj.-Lab (Upper Flange Is Considered To Be Effectively Held) Dimensions of BeamRakesh SharmaPas encore d'évaluation

- Design Cold-Formed Steel PurlinsDocument9 pagesDesign Cold-Formed Steel PurlinsAmihan De GuzmanPas encore d'évaluation

- Building - B: Vertical Haunch Conn Along Line-A & B: Mark:-NONEDocument18 pagesBuilding - B: Vertical Haunch Conn Along Line-A & B: Mark:-NONEmaheshbandhamPas encore d'évaluation

- IP4 design reaction summary and analysisDocument8 pagesIP4 design reaction summary and analysisFarhan DanishPas encore d'évaluation

- Welded & Pinned Connection Design CalculationDocument14 pagesWelded & Pinned Connection Design CalculationPrakash Singh RawalPas encore d'évaluation

- A23.3-04 CorbelsDocument3 pagesA23.3-04 CorbelsDivyesh MistryPas encore d'évaluation

- 21.65 Kips/bolt Shear Strength Controls: Section at ADocument3 pages21.65 Kips/bolt Shear Strength Controls: Section at ASuneesh PPas encore d'évaluation

- Escaltor Cantilever Beam: Load CalculationDocument6 pagesEscaltor Cantilever Beam: Load CalculationJAYASHREEBHUVANAPas encore d'évaluation

- Brace DesignDocument457 pagesBrace DesignRyan Goh Chuang HongPas encore d'évaluation

- Pedestal DesignDocument11 pagesPedestal DesignNikhil TawadePas encore d'évaluation

- Embedded PlateDocument2 pagesEmbedded PlateAlma M. LaraPas encore d'évaluation

- MDOT GussetPlate LFR Analysis 263315 7Document27 pagesMDOT GussetPlate LFR Analysis 263315 7ankitPas encore d'évaluation

- Steel Beam DesignDocument36 pagesSteel Beam DesignTan Choon LengPas encore d'évaluation

- Rect TankDocument6 pagesRect TankSasikumar JothiPas encore d'évaluation

- Design of Fixed Base Connection (BP) : Reactions Input Material PropertiesDocument10 pagesDesign of Fixed Base Connection (BP) : Reactions Input Material PropertiesAnand.5Pas encore d'évaluation

- 06) UB254x146x43TOUB356x171x51 Beam To Beam End PlateDocument121 pages06) UB254x146x43TOUB356x171x51 Beam To Beam End PlateAsaru DeenPas encore d'évaluation

- DG Consulting EngineersDocument8 pagesDG Consulting EngineersThakshayani SellavelPas encore d'évaluation

- Design of base plate connection checkedDocument9 pagesDesign of base plate connection checkedmoseslugtu6324Pas encore d'évaluation

- Column Properties:-: Due To UplitDocument2 pagesColumn Properties:-: Due To UplitRohit SinghPas encore d'évaluation

- Weld Is Adequate & Stress Ratio 0.51Document1 pageWeld Is Adequate & Stress Ratio 0.51eric escobarPas encore d'évaluation

- Case List For LLB 1st Semester Constitutional LawDocument16 pagesCase List For LLB 1st Semester Constitutional LawSabya Sachee RaiPas encore d'évaluation

- PingDocument15 pagesPingapi-3844182Pas encore d'évaluation

- Identify, negotiate and document project boundariesDocument3 pagesIdentify, negotiate and document project boundariesAxelPas encore d'évaluation

- T2 - Part C - Q2 - Manage Scope ChangesDocument3 pagesT2 - Part C - Q2 - Manage Scope ChangesAxelPas encore d'évaluation

- Business tax services in Wichita, KSDocument2 pagesBusiness tax services in Wichita, KSHoang BachPas encore d'évaluation

- Reading SWBSDocument1 pageReading SWBSMariana Panypani ContrerasPas encore d'évaluation

- 2016 Tekla Steel BrochureDocument8 pages2016 Tekla Steel BrochureEngr Benalito A Catap IIIPas encore d'évaluation

- 2016 Tekla TSD BrochureDocument4 pages2016 Tekla TSD BrochureEngr Benalito A Catap IIIPas encore d'évaluation

- Two Way Flat Plate Concrete Floor Slab Design Detailing PDFDocument64 pagesTwo Way Flat Plate Concrete Floor Slab Design Detailing PDFLe Duc ToanPas encore d'évaluation

- Purlin DesignDocument5 pagesPurlin DesignEngr Benalito A Catap IIIPas encore d'évaluation

- Assignment 1.2.2 Creation of Bar ChartDocument32 pagesAssignment 1.2.2 Creation of Bar ChartEngr Benalito A Catap IIIPas encore d'évaluation

- GL19 051 JB Cresta M300 800kg September 13 2019 p1 PDFDocument1 pageGL19 051 JB Cresta M300 800kg September 13 2019 p1 PDFEngr Benalito A Catap IIIPas encore d'évaluation

- Net Total 52.56 Room 2 Length Height Area RemarksDocument2 pagesNet Total 52.56 Room 2 Length Height Area RemarksEngr Benalito A Catap IIIPas encore d'évaluation

- Company Profile2018 (Latest Version) V 8Document12 pagesCompany Profile2018 (Latest Version) V 8Engr Benalito A Catap IIIPas encore d'évaluation

- Question No.1Document2 pagesQuestion No.1Engr Benalito A Catap IIIPas encore d'évaluation

- Material CostDocument4 pagesMaterial CostEngr Benalito A Catap IIIPas encore d'évaluation

- Porac - Two Storey Residence-STRUCTURAL PDFDocument1 pagePorac - Two Storey Residence-STRUCTURAL PDFEngr Benalito A Catap IIIPas encore d'évaluation

- Bar Bending DiagramDocument33 pagesBar Bending DiagramEngr Benalito A Catap IIIPas encore d'évaluation

- Retaining Wall DesignDocument9 pagesRetaining Wall DesignEngr Benalito A Catap IIIPas encore d'évaluation

- Asep Membership Application Form Rev201309 FinalDocument9 pagesAsep Membership Application Form Rev201309 FinalBT JumaaniPas encore d'évaluation

- 02-May-19 03-May-2019 00:27 Gestation - STD: Job No Sheet No RevDocument1 page02-May-19 03-May-2019 00:27 Gestation - STD: Job No Sheet No RevEngr Benalito A Catap IIIPas encore d'évaluation

- Door and Window ScheduleDocument2 pagesDoor and Window ScheduleEngr Benalito A Catap IIIPas encore d'évaluation

- Labour Productivity Chart in UaeDocument9 pagesLabour Productivity Chart in UaeAbraham Alex91% (32)

- Reinforced Concrete One Way Slab DesignDocument7 pagesReinforced Concrete One Way Slab DesignEngr Benalito A Catap IIIPas encore d'évaluation

- Target PriceDocument61 pagesTarget PriceEngr Benalito A Catap IIIPas encore d'évaluation

- PICQS Membership Form - Catap, Benalito III A. (PHL)Document4 pagesPICQS Membership Form - Catap, Benalito III A. (PHL)Engr Benalito A Catap IIIPas encore d'évaluation

- PICQS Membership Form - Catap, Benalito III A. (PHL)Document4 pagesPICQS Membership Form - Catap, Benalito III A. (PHL)Engr Benalito A Catap IIIPas encore d'évaluation

- PICQS Membership Form - Catap, Benalito III A. (PHL)Document4 pagesPICQS Membership Form - Catap, Benalito III A. (PHL)Engr Benalito A Catap IIIPas encore d'évaluation

- Peregrine: Renovation of American Chamber Foundation &leonard Brnjamin Development CenterDocument5 pagesPeregrine: Renovation of American Chamber Foundation &leonard Brnjamin Development CenterEngr Benalito A Catap IIIPas encore d'évaluation

- PICQS Membership Form - Catap, Benalito III A. (PHL)Document4 pagesPICQS Membership Form - Catap, Benalito III A. (PHL)Engr Benalito A Catap IIIPas encore d'évaluation

- General Requirements through Electrical Divisions Construction Document SectionsDocument5 pagesGeneral Requirements through Electrical Divisions Construction Document SectionsDaryl Gomez TimatimPas encore d'évaluation

- Amcham As Built BoqDocument4 pagesAmcham As Built BoqEngr Benalito A Catap IIIPas encore d'évaluation

- PICQS Membership Form - Catap, Benalito III A. (PHL)Document4 pagesPICQS Membership Form - Catap, Benalito III A. (PHL)Engr Benalito A Catap IIIPas encore d'évaluation

- Amcham As Built BoqDocument4 pagesAmcham As Built BoqEngr Benalito A Catap IIIPas encore d'évaluation

- Amcham As Built BoqDocument4 pagesAmcham As Built BoqEngr Benalito A Catap IIIPas encore d'évaluation

- Pub - Essentials of Nuclear Medicine Imaging 5th Edition PDFDocument584 pagesPub - Essentials of Nuclear Medicine Imaging 5th Edition PDFNick Lariccia100% (1)

- Google Dorks For PentestingDocument11 pagesGoogle Dorks For PentestingClara Elizabeth Ochoa VicentePas encore d'évaluation

- Nursing Care Management of a Client with Multiple Medical ConditionsDocument25 pagesNursing Care Management of a Client with Multiple Medical ConditionsDeannPas encore d'évaluation

- Column Array Loudspeaker: Product HighlightsDocument2 pagesColumn Array Loudspeaker: Product HighlightsTricolor GameplayPas encore d'évaluation

- Sysmex Xs-800i1000i Instructions For Use User's ManualDocument210 pagesSysmex Xs-800i1000i Instructions For Use User's ManualSean Chen67% (6)

- Biagioli Did Galileo Copy The TelescopeDocument28 pagesBiagioli Did Galileo Copy The TelescopeGregory HooPas encore d'évaluation

- Malware Reverse Engineering Part 1 Static AnalysisDocument27 pagesMalware Reverse Engineering Part 1 Static AnalysisBik AshPas encore d'évaluation

- Evaluating Sources IB Style: Social 20ib Opvl NotesDocument7 pagesEvaluating Sources IB Style: Social 20ib Opvl NotesRobert ZhangPas encore d'évaluation

- Nokia MMS Java Library v1.1Document14 pagesNokia MMS Java Library v1.1nadrian1153848Pas encore d'évaluation

- Rishte ki baat SMS messages collectionDocument108 pagesRishte ki baat SMS messages collectionTushar AggarwalPas encore d'évaluation

- India: Kerala Sustainable Urban Development Project (KSUDP)Document28 pagesIndia: Kerala Sustainable Urban Development Project (KSUDP)ADBGADPas encore d'évaluation

- CAS-GEC04 Module11 Food-SecurityDocument6 pagesCAS-GEC04 Module11 Food-SecurityPermalino Borja Rose AnnePas encore d'évaluation

- PLC Networking with Profibus and TCP/IP for Industrial ControlDocument12 pagesPLC Networking with Profibus and TCP/IP for Industrial Controltolasa lamessaPas encore d'évaluation

- Sanhs Ipcrf TemplateDocument20 pagesSanhs Ipcrf TemplateStephen GimoteaPas encore d'évaluation

- Marine Engineering 1921Document908 pagesMarine Engineering 1921Samuel Sneddon-Nelmes0% (1)

- S5-42 DatasheetDocument2 pagesS5-42 Datasheetchillin_in_bots100% (1)

- Log File Records Startup Sequence and Rendering CallsDocument334 pagesLog File Records Startup Sequence and Rendering CallsKossay BelkhammarPas encore d'évaluation

- Break Even AnalysisDocument4 pagesBreak Even Analysiscyper zoonPas encore d'évaluation

- Guidelines On Occupational Safety and Health in Construction, Operation and Maintenance of Biogas Plant 2016Document76 pagesGuidelines On Occupational Safety and Health in Construction, Operation and Maintenance of Biogas Plant 2016kofafa100% (1)

- DMDW Mod3@AzDOCUMENTS - inDocument56 pagesDMDW Mod3@AzDOCUMENTS - inRakesh JainPas encore d'évaluation

- ERP Complete Cycle of ERP From Order To DispatchDocument316 pagesERP Complete Cycle of ERP From Order To DispatchgynxPas encore d'évaluation

- Manual Analizador Fluoruro HachDocument92 pagesManual Analizador Fluoruro HachAitor de IsusiPas encore d'évaluation

- DLP in Health 4Document15 pagesDLP in Health 4Nina Claire Bustamante100% (1)

- Math5 Q4 Mod10 DescribingAndComparingPropertiesOfRegularAndIrregularPolygons v1Document19 pagesMath5 Q4 Mod10 DescribingAndComparingPropertiesOfRegularAndIrregularPolygons v1ronaldPas encore d'évaluation

- Web Api PDFDocument164 pagesWeb Api PDFnazishPas encore d'évaluation

- AFNOR IPTDS BrochureDocument1 pageAFNOR IPTDS Brochurebdiaconu20048672Pas encore d'évaluation

- Why Genentech Is 1Document7 pagesWhy Genentech Is 1panmongolsPas encore d'évaluation

- Mercedes BenzDocument56 pagesMercedes BenzRoland Joldis100% (1)

- Non Circumvention Non Disclosure Agreement (TERENCE) SGDocument7 pagesNon Circumvention Non Disclosure Agreement (TERENCE) SGLin ChrisPas encore d'évaluation

- DECA IMP GuidelinesDocument6 pagesDECA IMP GuidelinesVuNguyen313Pas encore d'évaluation