Académique Documents

Professionnel Documents

Culture Documents

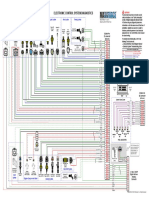

CPC Cascadia

Transféré par

Leonardo IglesiasCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CPC Cascadia

Transféré par

Leonardo IglesiasDroits d'auteur :

Formats disponibles

10 27-13

1 10 27-13

SUBJECT DATE

SPN 625/FMI 9 - EPA10 - GHG14 (CPC) October 2013

Additions, Revisions, or Updates

Publication Number / Title Platform Section Title Change

EPA10/

SPN 625/FMI 9 – EPA10 New diagnostics for CPC. ACM, MCM, and CPC are referred to

DDC-SVC-MAN-0084 GHG14 DD

- GHG14 (CPC) generically because this procedure covers more than one year.

Platform

All information subject to change without notice. 3

10 27-13 Copyright © 2013 DETROIT DIESEL CORPORATION

2 SPN 625/FMI 9 – EPA10 - GHG14

2 SPN 625/FMI 9 – EPA10 - GHG14

This procedure applies to the Common Powertrain Controller (CPC).

This diagnostic is typically Aftertreatment Control Module (ACM) PT-CAN DM1 Message Not Received or has Stopped

Arriving.

Table 1.

SPN 625/FMI 9

Description ACM PT-CAN DM1 Message Not Received or has Stopped Arriving

Monitored Parameter CAN Communication

Typical Enabling Conditions Always Enabled

Monitor Sequence None

Execution Frequency Always Enabled

Typical Duration 2 Seconds

Dash Lamps MIL, CEL

Engine Reaction None

Verification Ignition Cycle

Check as follows:

1. Are there any battery voltage faults (any SPN 168 FMI faults)?

a. Yes; troubleshoot battery voltage faults first.

b. No; Go to step 2.

2. Has the Aftertreatment Control Module (ACM), Motor Control Module (MCM), or Common Powertrain Controller

(CPC) been recently programmed?

4 All information subject to change without notice.

Copyright © 2013 DETROIT DIESEL CORPORATION 10 27-13

10 27-13

a. Yes; clear the fault codes. If faults do not become active, release the vehicle. If faults become active, Go to step

3.

b. No; Go to step 3.

NOTE: ACM, MCM, and CPC all communicate on the same CAN line. If water penetrates any connector, it can

short the CAN line and may prevent communications with other ECUs.

NOTE: Main battery power must be left ON.

NOTE: The five minute time-frame allows the ACM to go completely offline.

3. Turn ignition OFF and wait five minutes before proceeding.

4. Disconnect the CPC electrical harness connector #3.

5. Inspect the CPC connector for corroded, unseated (pushed out) or damaged pins, bent or spread pins; inspect the

connector seal for damage (signs of water or oil intrusion).

a. If contamination or damage is found, repair as necessary. Go to step 21.

b. If no contamination or damage is found, Go to step 6.

6. Check CPC internal terminating resistor by measuring the resistance across pins 19 and 21 of the CPC electrical

connector #3, component side.

a. If the resistance is between 110 to 130 ohms, Go to step 7.

b. If the resistance is not between 110 to 130 ohms, replace the CPC. Go to step 21.

7. Measure the resistance between pin 19 of the CPC #3 connector, harness side and battery ground.

a. If the resistance is greater than 10K ohms, Go to step 8.

b. If the resistance is less than 10K ohms, repair the wire short to ground between pin 19 of the CPC #3 connector,

harness side and pin 20 of the ACM 21-pin connector, harness side. Go to step 21.

8. Measure the resistance between pin 21 of the CPC connector #3, harness side and battery ground.

a. If the resistance is greater than 10K ohms, Go to step 9..

b. If the resistance is less than 10K ohms, repair the wire short to ground between pin 21 of the CPC #3 connector,

harness side and pin 10 of the ACM 21-pin connector, harness side. Go to step 21.

9. Disconnect ACM 21-pin connector.

10. Inspect the 21–pin Aftertreatment Control Module (ACM) connector for corroded, unseated (pushed out) or damaged

pins, bent or spread pins; inspect the connector seal for damage (signs of water or oil intrusion).

a. If contamination or damage is found, repair as necessary. Go to step 21.

b. If no contamination or damage is found, Go to step 11.

All information subject to change without notice. 5

10 27-13 Copyright © 2013 DETROIT DIESEL CORPORATION

2 SPN 625/FMI 9 – EPA10 - GHG14

11. Check ACM internal terminating resistor by measuring and recording the resistance across pins 10 and 20 of the ACM

21-pin connector, component side.

a. If the resistance is between 110 to 130 ohms, Go to step 12.

b. If the resistance is not between 110 to 130 ohms, replace the ACM. Go to step 21.

12. Check the resistance between pin 19 of the CPC connector #3, harness side and pin 20 of the ACM 21-pin connector,

harness side.

a. If the resistance is less than 5 ohms, Go to step 13.

b. If the resistance is greater than 5 ohms, repair the wire between pin 19 of the CPC connector #3, harness side and

pin 20 of the ACM 21-pin connector, harness side. Go to step 21.

13. Measure the resistance between pin 21 of the CPC connector #3, harness side and pin 10 of the ACM 21-pin connector,

harness side.

a. If the resistance is less than 5 ohms, Go to step 14.

b. If the resistance is greater than 5 ohms, repair the wire between pin 21 of the CPC connector #3, harness side and

pin 10 of the ACM 21-pin connector, harness side. Go to step 21.

14. Disconnect MCM 21-pin connector.

15. Inspect the 21–pin Motor Control Module (MCM) connector for corroded, unseated (pushed out) or damaged pins, bent

or spread pins; inspect the connector seal for damage (signs of water or oil intrusion).

a. If contamination or damage is found, repair as necessary. Go to step 21.

b. If no contamination or damage is found, Go to step 16.

16. Measure the resistance between pin 19 of the CPC connector #3, harness side and pin 19 of the MCM 21-pin connector,

harness side.

a. If the resistance is less than 5 ohms, Go to step 17.

b. If the resistance is greater than 5 ohms, repair the wire between pin 19 of the CPC connector #3, harness side and

pin 19 of the MCM 21-pin connector, harness side. Go to step 21.

17. Measure the resistance between pin 21 of the CPC connector #3, harness side and pin 13 of the MCM 21-pin harness

connector.

a. If the resistance is less than 5 ohms, Go to step 18.

b. If the resistance is greater than 5 ohms, repair the wire between pin 21 of the CPC connector #3, harness side and

pin 13 of the MCM 21-pin harness connector. Go to step 21.

NOTE: Ensure MCM and ACM connectors are disconnected during this step.

18. Measure the resistance between pins 19 and 21 of the CPC connector #3, harness side.

a. If the resistance is greater than 10K ohms, Go to step 19.

6 All information subject to change without notice.

Copyright © 2013 DETROIT DIESEL CORPORATION 10 27-13

10 27-13

b. If the resistance is less than 10K ohms, repair the harness shorted wires between pin 19 and pin 21 of the CPC

connector #3, harness side. Refer to Original Equipment Manufacturer (OEM) literature for schematic

information. Go to step 21.

19. If the resistance is less than 10K ohms, repair the harness shorted wires between pin 19 and pin 21 of the CPC

connector #3, harness side. Refer to Original Equipment Manufacturer (OEM) literature for schematic information.

a. If the resistance is less than 5 ohms, Go to step 20.

b. If the resistance is greater than 5 ohms, repair the wire between pin 19 of the MCM 21-pin connector, harness

side and pin 20 of the ACM 21-pin connector, harness side. Go to step 21.

20. Measure the resistance between pin 13 of the MCM 21-pin connector, harness side and pin 10 of the ACM 21-pin

connector, harness side.

a. If the resistance is less than 5 ohms, install a test CPC and retest. If code does not return, replace CPC. Go to step

21.

b. If the resistance is greater than 5 ohms, repair the wire between pin 13 of the MCM 21-pin connector, harness

side and pin 10 of the ACM 21-pin connector, harness side. Go to step 21.

21. Verify repairs. Restore all connections. Cycle the ignition key. Is fault code still active?

a. Yes; replace the CPC. Refer to OEM procedures.

b. No; If fault does not become active, clear the fault codes and release the vehicle.

All information subject to change without notice. 7

10 27-13 Copyright © 2013 DETROIT DIESEL CORPORATION

Vous aimerez peut-être aussi

- SPN 625/fmi 9 - Epa07Document4 pagesSPN 625/fmi 9 - Epa07Hyo Won LeePas encore d'évaluation

- Reparacion de Modulo CPCDocument4 pagesReparacion de Modulo CPCSiafor Adr SaPas encore d'évaluation

- DD13 Engine HarnessDocument1 pageDD13 Engine Harnessalejandro sanchez100% (5)

- Ddec V Egr VGT Delete InstructDocument2 pagesDdec V Egr VGT Delete InstructDagar GRPas encore d'évaluation

- Cascadia Diagramas PDFDocument1 pageCascadia Diagramas PDFDavidson Cruz100% (1)

- Sam Wall Chart Epa 07 and Epa 2010Document2 pagesSam Wall Chart Epa 07 and Epa 2010Jose Luis Calla Huanca94% (18)

- Sam Pin Layout: Sam Cab Sam ChassisDocument1 pageSam Pin Layout: Sam Cab Sam ChassisRobertoGomez0% (1)

- Parametros DD15 DDEC13Document83 pagesParametros DD15 DDEC13Harold Alberto Bautista Agudelo100% (1)

- Cascadia Diagramas-2Document1 pageCascadia Diagramas-2George Guerrero71% (7)

- Engine Wiring Diagram (Side 1)Document2 pagesEngine Wiring Diagram (Side 1)ORLANDO100% (1)

- 03-Datalink, Cabin CANDocument20 pages03-Datalink, Cabin CANEbied Yousif AlyPas encore d'évaluation

- Vehicle: 3HSDJAPT1CN082327: Detected ModulesDocument9 pagesVehicle: 3HSDJAPT1CN082327: Detected ModulesGerardo DelgadoPas encore d'évaluation

- FL Cascadia SAM Cab Chas EPA07Document2 pagesFL Cascadia SAM Cab Chas EPA07Ivan Rekiem CasillasPas encore d'évaluation

- Cpc2 Pgr035 Digital OutputsDocument3 pagesCpc2 Pgr035 Digital OutputsJose Santos67% (3)

- CPC2+ WiringDocument27 pagesCPC2+ Wiringalejandro sanchez100% (7)

- X15 Cm2350 X116B - Performance Series Wiring DiagramDocument1 pageX15 Cm2350 X116B - Performance Series Wiring DiagramVeterano del Camino100% (3)

- 1618 - SAM Cab Fault Codes 6.0Document125 pages1618 - SAM Cab Fault Codes 6.0Tobias Ken89% (9)

- Epa07 Ddec Vi Electronic Controls A I Manual (Ddc-Svc-Man-0054)Document39 pagesEpa07 Ddec Vi Electronic Controls A I Manual (Ddc-Svc-Man-0054)Jose Amador Guardado100% (1)

- Sensor Location DDC15 EP10Document15 pagesSensor Location DDC15 EP10Jose Alanis100% (1)

- DDC-SVC-BRO-0118 - Jun2020 DETROIT DIESEL TRANSMISIONESDocument22 pagesDDC-SVC-BRO-0118 - Jun2020 DETROIT DIESEL TRANSMISIONESangel017100% (1)

- Cecu 3 KW T800 PDFDocument6 pagesCecu 3 KW T800 PDFAnonymous nhF45C60% (5)

- DDVDocument1 pageDDVRodolfo Acosta MartinezPas encore d'évaluation

- GHG17 Heavy Duty MCM-CPC-ACMDocument21 pagesGHG17 Heavy Duty MCM-CPC-ACMJr Rico100% (7)

- ICU4Me+Instrument+ ClusterDocument32 pagesICU4Me+Instrument+ ClusterJuan Mendoza100% (4)

- Parametros Vcu Mercedes BenzDocument2 pagesParametros Vcu Mercedes BenzMarco MelchorPas encore d'évaluation

- Ddec V Egr VGT Delete InstructDocument1 pageDdec V Egr VGT Delete InstructCharly Ramos70% (10)

- DD15Document4 pagesDD15Eduardo Sanchez100% (1)

- Ddec VIDocument2 pagesDdec VIramsi1733% (3)

- MBE CodesDocument9 pagesMBE CodesPedro AparicioPas encore d'évaluation

- Cascadia ManualDocument25 pagesCascadia ManualArt Janshyan100% (11)

- Cascadia HVAC Operation Part OneDocument1 pageCascadia HVAC Operation Part OneDonald Charles FernoughtyPas encore d'évaluation

- Maxxforce 11-13 (2010)Document2 pagesMaxxforce 11-13 (2010)Dennito Cumito67% (3)

- 1620 - Central Gateway Fault Codes 6.0Document4 pages1620 - Central Gateway Fault Codes 6.0Tobias KenPas encore d'évaluation

- PDM ColumbiaDocument20 pagesPDM ColumbiaAlex Bravo100% (6)

- DDEC VI S60 MCMdadDocument2 pagesDDEC VI S60 MCMdadgiapy0000100% (6)

- PACCAR Y Cable PDFDocument1 pagePACCAR Y Cable PDFLucas Lake100% (1)

- 2011-12 Detroit DDEC-II WiringDocument3 pages2011-12 Detroit DDEC-II WiringRómulo Simón Lizarraga León100% (10)

- Arnes Motor MBE900 EPA 04 PDFDocument1 pageArnes Motor MBE900 EPA 04 PDFDagar GR0% (1)

- This Instruction Show You Guide On How To Use DDDL Engine Software To Do DPF Delete Programming For Detroit Diesel DD15 EPA 10Document13 pagesThis Instruction Show You Guide On How To Use DDDL Engine Software To Do DPF Delete Programming For Detroit Diesel DD15 EPA 10gustavoqr2781% (16)

- Pinout dd13 dd15Document10 pagesPinout dd13 dd15gustavoqr2782% (11)

- CPC Fault Codes DDEC VIDocument7 pagesCPC Fault Codes DDEC VILaura Mendoza71% (7)

- Volvo - VNL, VNM Electrical Schematic - Engine ECU - Cummins ISX - From Build Date 9.98Document5 pagesVolvo - VNL, VNM Electrical Schematic - Engine ECU - Cummins ISX - From Build Date 9.98Raul E. Soli100% (2)

- Newsletter Sam ChassisDocument14 pagesNewsletter Sam ChassisErik Shelber Calcina CalcinaPas encore d'évaluation

- PLV DD15Document4 pagesPLV DD15ttrPas encore d'évaluation

- DDEC VI Place MatDocument2 pagesDDEC VI Place Matchris5depasquale100% (2)

- Codigo de Falla DdecDocument9 pagesCodigo de Falla DdecAnonymous nhF45CPas encore d'évaluation

- Codigos de Falla Prostar (ING)Document133 pagesCodigos de Falla Prostar (ING)Kristen Holmes100% (2)

- MC 10141860 9999Document10 pagesMC 10141860 9999Jr RicoPas encore d'évaluation

- Additions, Revisions, or Updates: Subject DateDocument19 pagesAdditions, Revisions, or Updates: Subject DateBujar SulejmaniPas encore d'évaluation

- 140M Motor Grader B9D00001-UP (MACHINE) (SEBP4976 - 102) - Código SMCS J1939Document6 pages140M Motor Grader B9D00001-UP (MACHINE) (SEBP4976 - 102) - Código SMCS J1939Douglas GomesPas encore d'évaluation

- Generator Output Power SensorDocument11 pagesGenerator Output Power SensorHugo CiprianiPas encore d'évaluation

- Mb900 Trouble Guide - Part3Document106 pagesMb900 Trouble Guide - Part3Eckard GuendelPas encore d'évaluation

- 1-SECM-04a Check For Shorted Data LinkDocument6 pages1-SECM-04a Check For Shorted Data LinkMarco Antonio Rubiano Gómez100% (1)

- Falla Data CanDocument4 pagesFalla Data CanGrupo Alber SACPas encore d'évaluation

- Codigo 0070-02 de D6N AkmDocument5 pagesCodigo 0070-02 de D6N AkmMiguel LopezPas encore d'évaluation

- QuickServe Online CENTRY™ Electronic Control System Troubleshooting and Repair ManualDocument6 pagesQuickServe Online CENTRY™ Electronic Control System Troubleshooting and Repair ManualidhamPas encore d'évaluation

- 49-90-00-810-812-A - Lube Pump Filter SW P9/GEN SCAV Filter SW P5 Fault (131-9 (A) )Document4 pages49-90-00-810-812-A - Lube Pump Filter SW P9/GEN SCAV Filter SW P5 Fault (131-9 (A) )Rahul SharmaPas encore d'évaluation

- Generator Output Power SensorDocument10 pagesGenerator Output Power Sensorwagner_guimarães_1Pas encore d'évaluation

- Cid 2930 (Mid082)Document5 pagesCid 2930 (Mid082)Moch SuyonoPas encore d'évaluation

- CAN Data Link (RENR5059)Document3 pagesCAN Data Link (RENR5059)PramodPas encore d'évaluation

- 19SI, 21SI, 22SI - 23SI Installation Instructions - 10511258Document1 page19SI, 21SI, 22SI - 23SI Installation Instructions - 10511258juanca9_8Pas encore d'évaluation

- Diagrama de Motor DetroitDocument1 pageDiagrama de Motor Detroitstichi0911100% (18)

- Ddec IV EgrDocument2 pagesDdec IV EgrLeonardo Iglesias100% (1)

- Ddec IV EgrDocument2 pagesDdec IV EgrLeonardo Iglesias100% (1)

- Diagrama Ddec VIDocument2 pagesDiagrama Ddec VILeonardo Iglesias100% (4)

- Unit 1 Module 2 Air Data InstrumentsDocument37 pagesUnit 1 Module 2 Air Data Instrumentsveenadivyakish100% (1)

- Spring Setting of Piping Connected To A CompressorDocument4 pagesSpring Setting of Piping Connected To A CompressorSharun SureshPas encore d'évaluation

- Aiwa MC CSD-A120, A140 PDFDocument35 pagesAiwa MC CSD-A120, A140 PDFRodrigo NegrelliPas encore d'évaluation

- EE020-Electrical Installation 1-Th-Inst PDFDocument69 pagesEE020-Electrical Installation 1-Th-Inst PDFSameera KodikaraPas encore d'évaluation

- PC Hardware Servicing Teacher's GuideDocument7 pagesPC Hardware Servicing Teacher's GuidedanballaisPas encore d'évaluation

- Incident Report: Executive Vice PresidentDocument1 pageIncident Report: Executive Vice PresidentEvan MoraledaPas encore d'évaluation

- "Truthland": Chesapeake S Rebuttal To GaslandDocument14 pages"Truthland": Chesapeake S Rebuttal To GaslandJames "Chip" NorthrupPas encore d'évaluation

- Philips AZ 1839 Service ManualDocument7 pagesPhilips AZ 1839 Service ManualEdwardPas encore d'évaluation

- Pooja CVDocument3 pagesPooja CVEl Cajon de AmeliaPas encore d'évaluation

- Física Básica II - René CondeDocument210 pagesFísica Básica II - René CondeYoselin Rodriguez C.100% (1)

- Aniuk SpecimenDocument10 pagesAniuk SpecimenMario ParraPas encore d'évaluation

- Resume Example 102017Document2 pagesResume Example 102017CharlyPas encore d'évaluation

- Tquins Resources Training Template For MT Work Programme SCS RevisedDocument12 pagesTquins Resources Training Template For MT Work Programme SCS RevisedLileth LagasimPas encore d'évaluation

- A Grand Vision of Man's Role in Colonizing The Universe: BooksDocument3 pagesA Grand Vision of Man's Role in Colonizing The Universe: Bookspeter lonterPas encore d'évaluation

- OZONE 70W Programmable LED Drivers :: ROAL Living EnergyDocument12 pagesOZONE 70W Programmable LED Drivers :: ROAL Living EnergyroalscribdPas encore d'évaluation

- Altman Fall Winter 2012 Product Showcase FlyerDocument32 pagesAltman Fall Winter 2012 Product Showcase FlyerИлия ГеоргиевPas encore d'évaluation

- SYS600 System ConfigurationDocument256 pagesSYS600 System ConfigurationDang JinlongPas encore d'évaluation

- Convention On Cybercrime BudafestDocument26 pagesConvention On Cybercrime BudafestWinardiPas encore d'évaluation

- Dn7064519 - Installing Flexi Cabinet For IndoorDocument63 pagesDn7064519 - Installing Flexi Cabinet For Indoorlettymc100% (1)

- 7810-8110-Ca-1540-651-001 - HP FG KodDocument68 pages7810-8110-Ca-1540-651-001 - HP FG Kodgopal krishnan0% (1)

- Dimetra Ip CompactDocument2 pagesDimetra Ip CompactGrompolLopmorgPas encore d'évaluation

- FraceDocument12 pagesFraceIra MejiaPas encore d'évaluation

- Lesson Plan 2Document3 pagesLesson Plan 2api-260894328Pas encore d'évaluation

- AN3785 MAX3421E Programming Guide PDFDocument63 pagesAN3785 MAX3421E Programming Guide PDFtaccituaPas encore d'évaluation

- 002 SM MP4054Document2 009 pages002 SM MP4054tranquangthuanPas encore d'évaluation

- Dell's Marketing Strategy - 2006Document58 pagesDell's Marketing Strategy - 2006Preeti IyerPas encore d'évaluation

- Resume FormatDocument2 pagesResume Formatअंकित चौहानPas encore d'évaluation

- Digital Market Space in BeautyDocument48 pagesDigital Market Space in BeautyInaPas encore d'évaluation

- Reading Passage 1: You Should Spend About 20 Minutes On Questions 1-12 Which Are Based On Reading Passage 1Document2 pagesReading Passage 1: You Should Spend About 20 Minutes On Questions 1-12 Which Are Based On Reading Passage 1Melisa CardozoPas encore d'évaluation

- B31.3 Process Piping Course - 08 FlexibilityDocument23 pagesB31.3 Process Piping Course - 08 FlexibilityRyan Goh Chuang HongPas encore d'évaluation