Académique Documents

Professionnel Documents

Culture Documents

Boiler Chemical Cleaning: Operational and Start-Up Precommissioning

Transféré par

อนุตร เปียงแก้วDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Boiler Chemical Cleaning: Operational and Start-Up Precommissioning

Transféré par

อนุตร เปียงแก้วDroits d'auteur :

Formats disponibles

Boiler Chemical Cleaning

Operational and Start-up Precommissioning

BJ Process and Pipeline

Services (BJ PPS) has

extensive experience in

chemical cleaning of many

types and sizes of generating

boilers.

BJ PPS demonstrates time after

time a reduction of 15-20% in

the time required to complete

conventional methods of boiler

chemical cleaning.

Applications

The successful completion of the chemical cleaning of a large generating boiler requires extensive coordination

between plant maintenance, operations and usually several outside contractors. Time is of the essence due to

contractor stand-by costs and lost production days. BJ PPS has proven that as much as 1-2 days can be saved

in completing the chemical cleaning process with properly designed equipment, the right management tools, a

proven engineering approach and well-trained competent personnel. With the time between scheduled boiler

cleanings being extended, plant personnel have less exposure to chemical cleaning procedures. Boiler deposits

can also be layered due to heavier deposits than experienced in past cleanings. On site cleaning contractor

experience is invaluable in these situations.

BJ PPS has been proven to out perform other chemical-cleaning contractors with services that drive down the

costs of executing boiler chemical cleanings. The issues and drivers that increase the cost of completing boiler

chemical cleanings can be hidden and nebulous. Understanding the true costs of the entire operation is very

important in this respect.

Costs are reduced by the transportation of

compact equipment packages.

This equipment provides faster chemical

injections and faster draining of the boiler.

These “built for purpose” equipment packages

have proven to be quick to install and remove

from the plant and provide continuous flow rate

and temperature data to accurately predict

completion of each phase of the cleaning

process.

Fast, and accurate completion of

numerous analytical tests using BJ

PPS’s state of the art analytical mobile

laboratory, helps make informed

technical decisions on job chemistry

and when to determine the completion

of the cleaning.

BJ PPS Project Managers have

extensive experience in boiler chemical

cleanings and power plant outage

management. The BJ PPS Project

Manager stays involved in every step

of the chemical cleaning process with

close “hands on” involvement.

BJ PPS’s engineering approach

addresses site-specific needs and

conditions that can impact the cleaning

execution. As an example, “ on-line

tube specimen monitoring” has proven

to be a very effective tool for boilers

that are excessively fouled

BJ PPS delivers a comprehensive

Solvent Trend

post-job report of the chemical

cleaning service before leaving the 0.6 12

% Available Chelant

plant site. This detailed report

% Iron or Copper

0.5 10

digitally reviews every tie-in to the

0.4 8

plant from BJ PPS’s equipment Also

0.3 6

included in this job report are hour by

hour logs, safety reviews, 0.2 4

electronically logged and graphed 0.1 2

test results, before and after site 0 0

condition, post job analysis of any

00

00

00

00

00

00

issues or conditions that could be % Iron

12

13

14

15

16

17

corrected for improved future Time of Day % Copper

cleanings, and results. % Chelant

Vous aimerez peut-être aussi

- Sichuan Air SeparationDocument25 pagesSichuan Air SeparationFarshad Asgari0% (1)

- HEATEXDocument34 pagesHEATEXSiddharthPas encore d'évaluation

- Piping Systems and AccessoriesDocument16 pagesPiping Systems and AccessoriesYoussef100% (1)

- De Scaling Plate Heat ExchangersDocument2 pagesDe Scaling Plate Heat ExchangersKiran DuggarajuPas encore d'évaluation

- Presentation On Industrial Water Circulation SystemDocument19 pagesPresentation On Industrial Water Circulation Systembashok87Pas encore d'évaluation

- Cheema Boiler Limited: Presented To: MR - Deepak Bhandari (Document32 pagesCheema Boiler Limited: Presented To: MR - Deepak Bhandari (angenious100% (1)

- What Is Carry Over and Carry Under at The Boiler DrumDocument12 pagesWhat Is Carry Over and Carry Under at The Boiler Drumabdulyunus_amirPas encore d'évaluation

- Piping StudyDocument4 pagesPiping Studydablu kumarPas encore d'évaluation

- Dai SeminarDocument36 pagesDai SeminardocrafiPas encore d'évaluation

- 1 Process VesselsDocument4 pages1 Process VesselsARIANA NICOLE RELIGIOSOPas encore d'évaluation

- Efficient Steam Distribution SystemDocument8 pagesEfficient Steam Distribution Systempavan_chinta_2Pas encore d'évaluation

- Waste Incineration Heat Recovery at Roche IrelandDocument12 pagesWaste Incineration Heat Recovery at Roche IrelandidrieshamidiPas encore d'évaluation

- Boiler MaintenanceDocument77 pagesBoiler Maintenancekeerthi dayarathna0% (1)

- Boil Out ProcedureDocument2 pagesBoil Out Proceduremrizalygani99100% (1)

- Chapter 4 BoilerDocument66 pagesChapter 4 BoilerAnonymous YSdtimxAbPas encore d'évaluation

- Message From ChairmanDocument12 pagesMessage From ChairmanGajanan JagtapPas encore d'évaluation

- Boiler WaterDocument70 pagesBoiler Watertata_77Pas encore d'évaluation

- P103e Gas Scrubbing PlantsDocument12 pagesP103e Gas Scrubbing PlantsAswad Ali100% (1)

- Falsh Vessel RVDocument5 pagesFalsh Vessel RVJallu PratamaPas encore d'évaluation

- Guide To Steam Tracing and Condensate CollectionDocument34 pagesGuide To Steam Tracing and Condensate CollectionRAMPas encore d'évaluation

- Steam ChartDocument47 pagesSteam Chartamuronegadu100% (1)

- Bits, Pilani - K. K. Birla Goa Campus Process Design Principles IiDocument53 pagesBits, Pilani - K. K. Birla Goa Campus Process Design Principles IiAdheep DasPas encore d'évaluation

- Lect Slides - Catalytic ReformingDocument20 pagesLect Slides - Catalytic ReformingPRAJWAL RASTOGIPas encore d'évaluation

- AVU Critical EquipmentsDocument55 pagesAVU Critical EquipmentsmujeebtalibPas encore d'évaluation

- Uses and Applications of AmmoniaDocument5 pagesUses and Applications of AmmoniaSohail Asghar100% (2)

- Material Compatibility GuideDocument18 pagesMaterial Compatibility GuidearrancatetasPas encore d'évaluation

- Dattaproject DONEDocument25 pagesDattaproject DONEsumit potdarPas encore d'évaluation

- Introduction To BoilersDocument22 pagesIntroduction To BoilersaravindsnistPas encore d'évaluation

- 12-Design Fundamentals of BoilerDocument12 pages12-Design Fundamentals of BoilerVishalVaishPas encore d'évaluation

- Control of Emissions From Power PlantsLarge Scale IndustriesDocument48 pagesControl of Emissions From Power PlantsLarge Scale IndustriesSonu Kumar100% (1)

- Spent Caustic Recycle at Farleigh MillDocument9 pagesSpent Caustic Recycle at Farleigh MillyamakunPas encore d'évaluation

- Sulphuric AcidDocument2 pagesSulphuric Acidapi-239546340Pas encore d'évaluation

- Valves: An Introductory Guide To Valves For Chemical EngineersDocument21 pagesValves: An Introductory Guide To Valves For Chemical EngineersAhmed Ahmed100% (1)

- Need of Boiler Feed Water Treatment - Boiler Water Treatment ProcessDocument14 pagesNeed of Boiler Feed Water Treatment - Boiler Water Treatment ProcessjagjitPas encore d'évaluation

- Sulphur Acid Plant Modelling (PFD Detailed) PDFDocument5 pagesSulphur Acid Plant Modelling (PFD Detailed) PDFCristian GómezPas encore d'évaluation

- Ak Mühendislik Taahhüt San. Ve Tic. Ltd. ŞtiDocument75 pagesAk Mühendislik Taahhüt San. Ve Tic. Ltd. ŞtiVictorPas encore d'évaluation

- 2011 VND O&M ManualDocument12 pages2011 VND O&M Manualsequeira.cedric6742Pas encore d'évaluation

- CO&CCPDocument23 pagesCO&CCPApoorva RamagiriPas encore d'évaluation

- Pipe Schedule ChartDocument16 pagesPipe Schedule ChartSamir ChaudharyPas encore d'évaluation

- Double Effect Steam Driven Vapour Absorption Machine: 310 1 Shalina Laboratories PVT LTDDocument31 pagesDouble Effect Steam Driven Vapour Absorption Machine: 310 1 Shalina Laboratories PVT LTDBashir AliPas encore d'évaluation

- EPRI Field Guide For Boiler Tube Failures PDFDocument2 pagesEPRI Field Guide For Boiler Tube Failures PDFandi suntoroPas encore d'évaluation

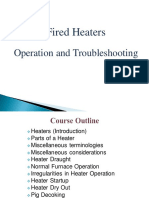

- Fired Heaters: An Introductory Guide To Fired Heaters For Chemical EngineersDocument31 pagesFired Heaters: An Introductory Guide To Fired Heaters For Chemical Engineerstonful143100% (1)

- Loading and Commissioning of Ion Exchange ResinsDocument5 pagesLoading and Commissioning of Ion Exchange ResinsSANTRAPas encore d'évaluation

- Boiler Blowdown Rate CalculationDocument1 pageBoiler Blowdown Rate CalculationkonarksenPas encore d'évaluation

- Bio Gas Plant From Kitchen WasteDocument5 pagesBio Gas Plant From Kitchen WasteArun GuptaPas encore d'évaluation

- PPE - Feed Water Treatment SystemDocument6 pagesPPE - Feed Water Treatment SystemSandeep ChhabraPas encore d'évaluation

- Lesson 11 Corrosion CalculationsDocument33 pagesLesson 11 Corrosion Calculationsعزت عبد المنعمPas encore d'évaluation

- Whrs ManualDocument41 pagesWhrs ManualAKHLESH JHALLAREPas encore d'évaluation

- Boiler Feed Water Specifications - Specifications of Boiler WaterDocument9 pagesBoiler Feed Water Specifications - Specifications of Boiler WaterJean YurePas encore d'évaluation

- 10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JHDocument26 pages10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JHvahidPas encore d'évaluation

- Refractory Thickness CalculationsDocument9 pagesRefractory Thickness CalculationsHsein WangPas encore d'évaluation

- Recommended Procedure For Alkali Boil OutDocument18 pagesRecommended Procedure For Alkali Boil OutsprotkarPas encore d'évaluation

- Tds Contro Heat RecoverylDocument31 pagesTds Contro Heat RecoverylHélder PascoalPas encore d'évaluation

- Fired Heaters Operation Troubleshooting 1589699753 PDFDocument80 pagesFired Heaters Operation Troubleshooting 1589699753 PDFAliPas encore d'évaluation

- Overcome Your Most Demanding Automation Challenges: Biffi Actuators and Control SystemsDocument20 pagesOvercome Your Most Demanding Automation Challenges: Biffi Actuators and Control SystemsDaniel ZhangPas encore d'évaluation

- MicrobEnergy Services PDFDocument8 pagesMicrobEnergy Services PDFanon_411130333Pas encore d'évaluation

- Work Instruction For Hydrostatic TestingDocument18 pagesWork Instruction For Hydrostatic TestingAlok SinghPas encore d'évaluation

- P-21, Optical Fibre Cable Blowing and Hdpe Duct Laying Jointing &testing - KKMBPL-R.1Document15 pagesP-21, Optical Fibre Cable Blowing and Hdpe Duct Laying Jointing &testing - KKMBPL-R.1Salamon Rajan100% (1)

- Tender Documents Other Than SCC 0fd1e7Document183 pagesTender Documents Other Than SCC 0fd1e7Ankit PatelPas encore d'évaluation

- Notice - Appeal Process List of Appeal Panel (Final 12.1.24)Document13 pagesNotice - Appeal Process List of Appeal Panel (Final 12.1.24)FyBerri InkPas encore d'évaluation

- Nitrogen CycleDocument12 pagesNitrogen Cycleasa bspcpkPas encore d'évaluation

- Accessories 162-USDocument20 pagesAccessories 162-USعايد التعزيPas encore d'évaluation

- Aesa Based Pechay Production - AbdulwahidDocument17 pagesAesa Based Pechay Production - AbdulwahidAnne Xx100% (1)

- AssignmentDocument13 pagesAssignmentSwakshar DebPas encore d'évaluation

- Practical 3.1 Determining The Specific Heat CapacityDocument3 pagesPractical 3.1 Determining The Specific Heat CapacityiAlex11Pas encore d'évaluation

- Video Tutorials of Read and Write Seagate F3 Series HDDs by MRT - MRT LabDocument1 pageVideo Tutorials of Read and Write Seagate F3 Series HDDs by MRT - MRT LabBusur DataPas encore d'évaluation

- Lesson PlanDocument18 pagesLesson PlanYasmin Abigail AseriosPas encore d'évaluation

- Ae 2 PerformanceDocument4 pagesAe 2 PerformanceankitPas encore d'évaluation

- Onitsuka Tiger PDFDocument67 pagesOnitsuka Tiger PDFAhmad Bilal MawardiPas encore d'évaluation

- Section 08630 Metal-Framed SkylightDocument4 pagesSection 08630 Metal-Framed SkylightMØhãmmed ØwięsPas encore d'évaluation

- Rezhna Hassan FarajDocument2 pagesRezhna Hassan FarajchristoptPas encore d'évaluation

- 33 Mpact - of - The - Great - Earthquake-2015 - On - Hospitality PDFDocument30 pages33 Mpact - of - The - Great - Earthquake-2015 - On - Hospitality PDFJoannabelPas encore d'évaluation

- Introduction To The New 8-Bit PIC MCU Hardware Peripherals (CLC, Nco, Cog)Document161 pagesIntroduction To The New 8-Bit PIC MCU Hardware Peripherals (CLC, Nco, Cog)Andres Bruno SaraviaPas encore d'évaluation

- Joseph Conrad - Heart of DarknessDocument86 pagesJoseph Conrad - Heart of DarknessCaztor SscPas encore d'évaluation

- Soccer Training DiaryDocument1 pageSoccer Training DiaryMark DeaconPas encore d'évaluation

- FP Lecture Midterm Exam Sec - Sem.2020Document4 pagesFP Lecture Midterm Exam Sec - Sem.2020SAEEDA ALMUQAHWIPas encore d'évaluation

- Annotated Bib-BirthingDocument3 pagesAnnotated Bib-Birthingapi-312719022Pas encore d'évaluation

- Module 02 Connect Hardware Peripherals EndaleDocument49 pagesModule 02 Connect Hardware Peripherals EndaleSoli Mondo100% (1)

- 基礎居合講座Document33 pages基礎居合講座任平生100% (1)

- Muharem Bazdulj - The Second Book (Writings From An Unbound Europe) - Northwestern University Press (2005) PDFDocument154 pagesMuharem Bazdulj - The Second Book (Writings From An Unbound Europe) - Northwestern University Press (2005) PDFjeff tehPas encore d'évaluation

- Thermobaric Effects Formed by Aluminum Foils Enveloping Cylindrical ChargesDocument10 pagesThermobaric Effects Formed by Aluminum Foils Enveloping Cylindrical ChargesAnonymous QFUEsUAnPas encore d'évaluation

- Editor: Lalsangliana Jt. Ed.: H.Document4 pagesEditor: Lalsangliana Jt. Ed.: H.bawihpuiapaPas encore d'évaluation

- B.Pharm - Semester - III-10.07.2018Document16 pagesB.Pharm - Semester - III-10.07.2018SAYAN BOSEPas encore d'évaluation

- Benefits of OTN in Transport SDNDocument9 pagesBenefits of OTN in Transport SDNGhallab AlsadehPas encore d'évaluation

- 114 The Letter S: M 'TafontDocument9 pages114 The Letter S: M 'TafontHarry TLPas encore d'évaluation

- Theory of Earth's Magnetism and It's Relation ToDocument15 pagesTheory of Earth's Magnetism and It's Relation ToMaster Irvin100% (1)

- 6.003 Homework #12 Solutions: ProblemsDocument9 pages6.003 Homework #12 Solutions: ProblemsSamu PacurucuPas encore d'évaluation

- Hazel Rhs Horticulture Level 2 Essay 1Document24 pagesHazel Rhs Horticulture Level 2 Essay 1hazeldwyerPas encore d'évaluation

- JDM B18C Type RDocument6 pagesJDM B18C Type RSeenka CapuqPas encore d'évaluation