Académique Documents

Professionnel Documents

Culture Documents

PIR1

Transféré par

jaja senipah0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues1 pageReport Documen

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentReport Documen

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues1 pagePIR1

Transféré par

jaja senipahReport Documen

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

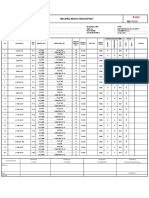

PAINTING & RUST PREVENTION INSPECTION REPORT

LAPORAN INSPEKSI PENGECATAN DAN PENCEGAHAN KARAT

Page : 1 of 1 Report Number : BRP-QC-0274-PIR-SNP-XII-2018

Hal No. Laporan

Project Name :

Nama Proyek

WORKSHOP STG HALL

Item No. / Item Name : COLUMN (SC1-1) Item Total :

1 EA

No. Item / Nama Item Jumlah Item

Dwg No. : BRP-SNP-DR-GA-004-A3 REV 0 Coating Sistem - Rev 0

No. Gambar Aturan Cat

1. WEATHER CONDITIONS 2. MATERIAL ABRASIVE

Rain Wind Grit/Spt Soluble Salt

Time Date Condition Type of Abrasive Grade Mixture Contamination Dry Storage

Light Mod Strong Light Mod Strong

% max 50 p.p.m

08.35 09/01/2019 clear - - - - - - Stell Greet G40 100 - Ok

15.15 11/01/2019 clear - - - - - -

08.15 12/01/2019 clear - - - - - -

3. AMBIENT / SURFACE CONDITION

Surface Condition Air/Dry Bulb Wet Bulb Humidity Material Temp. Dew Air Temp OK

Time Date

Checked ˚C ˚C % ˚C ˚C ˚C to Paint

08.35 09/01/2019 Before Application 1st Coat 32 28 74 33 27 32 ACC

15.15 11/01/2019 Before Application 2nd Coat 33 28 69 35 26 33 ACC

08.15 12/01/2019 Before Application 3rd Coat 32 28 74 33 27 32 ACC

Frequency Each Blasting Operation

Acceptance Criteria - ≤85% ; >20% >3˚C to <50˚C - 10˚ - 40˚C

4. SURFACE PREPARATION

Degree of Preparation Soluble

Roughness Blast Air Blotter

Cleanlines Visual Check Salt OK to Paint

Rust Grade

Standard (μm) Finished (μg/cm2) Check

N.A SA2.5 Good 50 Good - - ACC

Each Item Each Item Each Item Each Item Frequency

Free from oil and Acceptance

SA 2.5 Free From Surface Defect 40-90 Good <6 μg/cm2

/or water Criteria

Description Freq. Acceptance Criteria Actual Value Result

Surface Profile Roughness

Each Item 40-90 50 ACC

Press "O" Film (μm)

5. COATING IDENTIFICATION

Description 1st Coat 2nd Coat 3rd Coat

Coating Operation Start Stop Start Stop Start Stop

Date 09/01/2019 09/01/2019 11/01/2019 11/01/2019 12/01/2019 12/01/2019

Time 08.35 09.15 15.15 16.00 08.15 09.05

Coat Manufacture Hempel Hempel Hempel

Coating Type Hempels Zinc Metal Pigment 97170 Hempadur Mastic 45880 Hempathane 55210

Nozzle Tip Size 317 317 317

Application Method Airless Spray Airless Spray Airless Spray

Spray Equipment Airless Pump Airless Pump Airless Pump

Model 1:25 1:25 1:25

Color Signal Grey Signal Grey Signal Blue

Base (Batch No.) Hempels Zinc Metal Pigment 97170 Hempadur Mastic 45880 Top Coat 55210

Hardener (Batch No.) A15709 95881 B95370 (RAL 5012)

Tinner : (Batch No.) 08450 08450 08450

% Tinner 2.5 2.5 2.5

Mix Ratio 5:1 5:1 6:1

6. COATING INSPECTION

Dry Film Thick (DFT)

Layer of (μm) Visual

Position

Coat Check

Time Date Min Max Avg

1st Coat 09.15 09/01/2019 75 89 82 Ext ACC

2nd Coat 16.00 11/01/2019 156 180 168 Ext ACC

3rd Coat 09.05 12/01/2019 226 245 235.5 Ext ACC

Freq. Each Item Each Item

Criteria Total Min DFT 75μm + 75μm+75μm = 225μm and tolerance ±20%

RESULT OF INSPECTION :

ACCEPTED REJECTED

Approved By, Review By, Checked by Inspected by

Involvement Party

PT. KEP PT. TRUBA PT. REKACIPTA PT. Borneo Rotating Pratama

Signature

Name Mangapul J.S

Sign Date

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Mockery Breed Murder Birds PDFDocument12 pagesMockery Breed Murder Birds PDFLautaro BojanichPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Solutions GoldsteinDocument10 pagesSolutions GoldsteinAnyiPas encore d'évaluation

- Contemporary Philippine Arts From The Regions: Quarter 2 - Module 9 Different Contemporary Art Techniques and PerformanceDocument25 pagesContemporary Philippine Arts From The Regions: Quarter 2 - Module 9 Different Contemporary Art Techniques and PerformanceGrace06 Labin100% (7)

- Steel Work Inspection ReportDocument3 pagesSteel Work Inspection ReportAhmad Hasnan100% (1)

- Gamak MotorDocument34 pagesGamak MotorCengiz Sezer100% (1)

- Fighting Techniques of The Early Modern World AD 1500-AD 1763 - Equipment Combat Skills Amp Amp TacticsDocument258 pagesFighting Techniques of The Early Modern World AD 1500-AD 1763 - Equipment Combat Skills Amp Amp Tacticslupoeva100% (3)

- Dawn of Solar PV CookingDocument5 pagesDawn of Solar PV CookingAbhinav AgrawalPas encore d'évaluation

- Immigrant Italian Stone CarversDocument56 pagesImmigrant Italian Stone Carversglis7100% (2)

- API 652/653 - How It Apply' S To Internal Tank Linings: Presented By: Darryl Corbin Nov. 18, 2016Document31 pagesAPI 652/653 - How It Apply' S To Internal Tank Linings: Presented By: Darryl Corbin Nov. 18, 2016amit4179100% (1)

- API 652/653 - How It Apply' S To Internal Tank Linings: Presented By: Darryl Corbin Nov. 18, 2016Document31 pagesAPI 652/653 - How It Apply' S To Internal Tank Linings: Presented By: Darryl Corbin Nov. 18, 2016amit4179100% (1)

- Inferring The Speaker's Tone, ModeDocument31 pagesInferring The Speaker's Tone, Modeblessilda.delaramaPas encore d'évaluation

- Wir SC1-1Document1 pageWir SC1-1jaja senipahPas encore d'évaluation

- Bolt TableDocument1 pageBolt TableErebert C. CaracasPas encore d'évaluation

- Finding Report HRSG #1Document24 pagesFinding Report HRSG #1jaja senipahPas encore d'évaluation

- Persyaratan Kelengkapan DokumenDocument24 pagesPersyaratan Kelengkapan Dokumenjaja senipahPas encore d'évaluation

- Electric Arc WeldingDocument15 pagesElectric Arc WeldingvikneshPas encore d'évaluation

- Electric Arc WeldingDocument15 pagesElectric Arc WeldingvikneshPas encore d'évaluation

- 07ercoskun 05 01 PDFDocument23 pages07ercoskun 05 01 PDFjagmadridPas encore d'évaluation

- Niir Integrated Organic Farming Handbook PDFDocument13 pagesNiir Integrated Organic Farming Handbook PDFNataliePas encore d'évaluation

- Gemh 108Document20 pagesGemh 108YuvrajPas encore d'évaluation

- Toshiba: ® A20SeriesDocument12 pagesToshiba: ® A20SeriesYangPas encore d'évaluation

- Lesson Plan in Science 9: I. ObjectivesDocument8 pagesLesson Plan in Science 9: I. ObjectivesmarichuPas encore d'évaluation

- Why Are Solids Are Floating On My Secondary Clarifier - Biological Waste TreatmDocument6 pagesWhy Are Solids Are Floating On My Secondary Clarifier - Biological Waste TreatmIsaac FernándezPas encore d'évaluation

- Passenger Lift Alert - Health and Safety AuthorityDocument4 pagesPassenger Lift Alert - Health and Safety AuthorityReginald MaswanganyiPas encore d'évaluation

- Market AnalysisDocument4 pagesMarket AnalysisSaniya CharaniyaPas encore d'évaluation

- Lesson 1 Chapter 9 ErosiondepositionDocument1 pageLesson 1 Chapter 9 Erosiondepositionapi-249320969Pas encore d'évaluation

- Top Ten Myths About The BrainDocument5 pagesTop Ten Myths About The BrainfayazalamaligPas encore d'évaluation

- Determination of Drop-Impact Resistance of Plastic BottlesDocument11 pagesDetermination of Drop-Impact Resistance of Plastic BottlesAndres BrañaPas encore d'évaluation

- World's Standard Model G6A!: Low Signal RelayDocument9 pagesWorld's Standard Model G6A!: Low Signal RelayEgiPas encore d'évaluation

- Prestige Institute of Management & Research: Guided By:-Submitted By: - Prof. Arpit Loya Sumeet RattanDocument21 pagesPrestige Institute of Management & Research: Guided By:-Submitted By: - Prof. Arpit Loya Sumeet RattanSumeet700005Pas encore d'évaluation

- NF en Iso 5167-6-2019Document22 pagesNF en Iso 5167-6-2019Rem FgtPas encore d'évaluation

- Midterm Exam Gor Grade 11Document2 pagesMidterm Exam Gor Grade 11Algelle AbrantesPas encore d'évaluation

- Updated G10 Class Routine Effective From 12 January 2023Document1 pageUpdated G10 Class Routine Effective From 12 January 2023NiloyPas encore d'évaluation

- BC-6000 Installation Guide V7.0 enDocument111 pagesBC-6000 Installation Guide V7.0 enmentule88Pas encore d'évaluation

- HCPL 316J 000eDocument34 pagesHCPL 316J 000eElyes MbarekPas encore d'évaluation

- Main Girders: CrossDocument3 pagesMain Girders: Crossmn4webPas encore d'évaluation

- Tugas Dikumpulkan Pada Hari Sabtu, 11 April 2020. Apabila Email Bermasalah Dapat Mengirimkan Via WA PribadiDocument4 pagesTugas Dikumpulkan Pada Hari Sabtu, 11 April 2020. Apabila Email Bermasalah Dapat Mengirimkan Via WA PribadiFebry SugiantaraPas encore d'évaluation

- RACI Matrix Design For Managing Stakeholders in PRDocument12 pagesRACI Matrix Design For Managing Stakeholders in PRRheza Nugraha Prabareswara100% (1)

- Anxiety Disorders - Causes, Types, Symptoms, & TreatmentsDocument5 pagesAnxiety Disorders - Causes, Types, Symptoms, & Treatmentsrehaan662Pas encore d'évaluation