Académique Documents

Professionnel Documents

Culture Documents

Seismic Design For Special Moment

Transféré par

reynoldTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Seismic Design For Special Moment

Transféré par

reynoldDroits d'auteur :

Formats disponibles

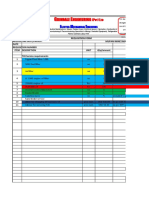

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

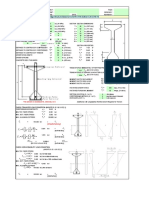

Seismic Design for Special Moment Resisting Frames Based on CBC 2001 - ASD

INPUT DATA & DESIGN SUMMARY

COLUMN SECTION => W14X176

A d tw bf tf Sx Ix rx ry Zx k

51.8 15.2 0.83 15.65 1.31 281 2140 6.43 4.02 320 2.00

BEAM SECTION = > W30X108

A d tw bf tf Sx Ix rx ry Zx k

31.7 29.8 0.55 10.48 0.76 299 4470 11.87 2.15 346 1.56

STRUCTURAL STEEL YIELD STRESS Fy = 50 ksi THE SMRF DESIGN IS ADEQUATE.

THE GRAVITY LOAD (1.2D + 0.5 L) ON THE BEAM wg = 2 klf (Continuity column stiffeners 13/16 x 7

BEAM LENGTH BETWEEN COL. CENTERS l= 28 ft with 1/2" fillet weld to web & CP to flanges.

COLUMN AXIAL LOAD AT SERVICE LEVEL D= 113 kips A doubler plate is required with thickness of 1-1/16 in. )

L= 75 kips

COLUMN AXIAL LOAD AT HORIZ. SEISMIC Eh = 5.5 kips (CBC 30A-1)

SEISMIC COEFFICIENT Ca = 0.44 (CBC Tab. 16A-Q)

IMPORTANCE FACTOR I= 1.15 (CBC Tab. 16A-K)

REDUNDANCY FACTOR r= 1.25

AVERAGE STORY HEIGHT OF ABOVE & BELOW h= 12 ft

REDUCED SECTION DIMENSIONS a= 6 in, [0.5~0.75bf]

b= 24 in, [0.65~0.85db]

c= 2.25 in, [ < 0.25bf]

ANALYSIS r = (4c2 + b2 ) / 8c = 33.1 in

Sh = dc/2 + a + b/2 = 25.6 in

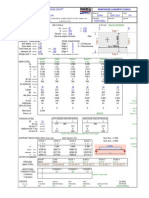

THE BEAM LOCAL BUCKLING LIMITATION (CBC 2213A.7.3)

bf / (2tf ) = 6.89 < 52 / (Fy)0.5 = 7.35 [Satisfactory]

d / tw = 54.73 < 640 / (Fy)0.5 = 90.51 [Satisfactory]

THE BEAM BRACING LIMITATION (CBC 2213A.7.8)

Smax = 96ry = 17.17 ft

Hence, both flanges of beam shall be braced at maximum spacing 17.17 ft.

THE COLUMN LOCAL BUCKLING LIMITATION (CBC 2213A.7.3 & ASD N7, Pg 5-96)

bf / (2tf ) = 5.97 < 7.00 [Satisfactory]

THE ALLOWABLE COLUMN DESIGN LOADS (CBC 1612A.3.1, 2213A.8.2, & 2213A.8.4.1)

Pt = 0.9D - (rEh + 0.5CaID) / 1.4 = 76 kips (Compression)

Pc = D + 0.75[L + (rEh + 0.5CaID) / 1.4] = 188 kips (Compression, Governs)

Pc = D + (rEh + 0.5CaID) / 1.4 = 138 kips (Compression)

THE BEAM - COLUMN RATIO REQUIREMENT (CBC2213A.7.5)

SMpc* / (SMpb* ) = 1.64 > 1.00 [Satisfactory]

( > 1.25 The column flanges need to be laterally supported only at the beam top flange.

Where SMpc* = SZc (Fyc - Pc / Ag ) = 2473 ft-kips CBC 2213A.7.7.1)

SMpb* = S(Mpr + Mv) = 1505 ft-kips

Mv = [2Mpr /(L-2Sh)+wg(L-2Sh)/2] Sh= 272 ft-kips

Mpr = b Fyb zb = 1233 ft-kips

3

zb = Zb - 2c tf (d - tf) = 247 in

b= 1.2 (FEMA Sec. 7.5.2.2)

THE BENDING MOMENT AT THE COLUMN FACE (CBC2213A.4.2)

Mf = Mpr + [2Mpr / (L - 2Sh) + wg(L - 2Sh)/2] (a + b/2)

= 1424 ft-kips < Fyb Zb = 1442 ft-kips [Satisfactory]

(Cont'd)

THE COLUMN DESIGN LOADS (CBC 2213A.5.1)

Pt = 0.85D - W0Eh = 81 kips (Compression)

Pc = D + 0.7L + W0Eh = 181 kips (Compression, Governs)

Where W0 = 2.8 (CBC Tab. 16A-N)

THE COLUMN COMPRESSION CAPACITY (CBC 2213A.4.2 & ASD E2)

Pc,allow = 1.7FaA = 1890.6 kips > Pc [Satisfactory]

Where K = 1.0

Es = 29000 ksi (1-F2/2)Fy / (5/3+3F/8-F3/8) = 21.47 kis, for Cc > (Kl/r)

2

Cc = (2p Es/Fy) 0.5

= 107

Fa = { 12p2Es/[23(Kl/r)2] = N/A kis, for Cc < (Kl/r)

MAX(Klx/rx, Kly/ry) = 67.10 < 200 [Satisfactory]

F = (K l / r) / Cc = 0.63

THE CONTINUITY PLATE REQUIREMENT (FEMA Sec. 3.3.3.1 & CBC 2213A.7.4)

tst = tbf for interior connection, or (tbf /2) for exterior connection = 0.76 in,USE 0.81 in, ( 13/16 in )

bst = 7 in > bfb /3 - twc /2 = 3.08 in, (ASD Sec. K1.8) [Satisfactory]

Ast = [Pbf - Fyc twc(tfb + 5kc)] / Fyst = -7.498 in2, (ASD K1-9) < tst bst [Satisfactory]

Where Pbf = 0.18bfbtfbFyb = 71.6 kips, (CBC 2213A.7.4)

The best fillet weld size (ASD Sec.J2.2b)

> wMIN = 0.25 in

w= 1/2 in

< wMAX = 0.6875 in

[Satisfactory]

The required weld length between A36 continuity plates and column web (FEMA Fig 3-6)

Lw = Pbf / [(2) 1.7 (0.3Fu )(0.707 w)] = 71.6 / [(2) 1.7 (0.3x70)(0.707x1/2)] = 2.14 in

< 2(Lnet) [Satisfactory]

Where Lnet = dc - 2(kc) = 11.2

(Use complete joint penetration groove welds between continuity plates & column flanges.)

THE PANEL ZONE THICKNESS REQUIREMENT (CBC 2213A.7.2)

tReqD = MAX (t1, t2) = 1.59 in

t1 = Vz / (0.55Fycdc) - 3bfctfc2 / (dcdb) = 1.59 in, (CBC 13A-1)

Where Vz = 2(0.8) SMf / (db - tfb/2) - 2(0.8)Mf / h = 738.7 kips

(SEAOC Design Manual, Vol. III, Pg 182)

t2 = (dz + wz ) / 90 = (db -2tst + dc - 2kc) / 90 = 0.44 in

Since twc = 0.55 in < tReqD , a doubler plate is

required with thickness of 1-1/16 in.

Techincal References:

1. ICBO: "2001 California Building Code, Title 24, Part 2, Volume 2", 2002.

2. SEAOC: "Seismic Design Manual - Volume 3", International Code Council, 2000.

3. AISC: "Manual of Steel construction 9th", American Institute of Steel Construction, 1990.

Vous aimerez peut-être aussi

- Bsep SMFDocument6 pagesBsep SMFamirgholami1100% (1)

- Wood Member (Beam, Column, Brace, Truss Web & Chord) Design Based On NDS 2015Document3 pagesWood Member (Beam, Column, Brace, Truss Web & Chord) Design Based On NDS 2015Janaka SenanayakaPas encore d'évaluation

- ACI Shrinkage CalculationDocument15 pagesACI Shrinkage CalculationHussein BeqaiPas encore d'évaluation

- RCC32 Ribbed Slabs (A & D) GFDGDocument26 pagesRCC32 Ribbed Slabs (A & D) GFDGLove SemsemPas encore d'évaluation

- Coupling BeamDocument2 pagesCoupling Beamwilliam6703100% (1)

- Bridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryDocument5 pagesBridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryPn EkanayakaPas encore d'évaluation

- Daniel Tian Li: Concrete Column Design Based On ACI 318-05Document3 pagesDaniel Tian Li: Concrete Column Design Based On ACI 318-05Lee Kar FungPas encore d'évaluation

- MasonryBearingWall IBCDocument8 pagesMasonryBearingWall IBCAbdul WahabPas encore d'évaluation

- Lecture 6 Composite ColumnsDocument66 pagesLecture 6 Composite Columnsabdelrahman emad100% (1)

- Shear Wall Design, Using Cross-Laminated Timber (CLT), Based On NDS 2018 Design CriteriaDocument1 pageShear Wall Design, Using Cross-Laminated Timber (CLT), Based On NDS 2018 Design Criteriaridho ziskaPas encore d'évaluation

- Basement Masonry Wall Design Based On TMS 402-16/13: Input Data & Design SummaryDocument2 pagesBasement Masonry Wall Design Based On TMS 402-16/13: Input Data & Design SummaryRidho ZiskaPas encore d'évaluation

- Cable Structure Design Based On ASCE 19-10 & AASHTO 17th: Project: Client: Design By: Job No.: Date: Review byDocument1 pageCable Structure Design Based On ASCE 19-10 & AASHTO 17th: Project: Client: Design By: Job No.: Date: Review byjklo12Pas encore d'évaluation

- Daniel Tian Li: Input Data & Design SummaryDocument4 pagesDaniel Tian Li: Input Data & Design SummaryARSEPas encore d'évaluation

- TR12 PDFDocument24 pagesTR12 PDFramorusoPas encore d'évaluation

- W14x43 To HSS6x6x1 - 2 Moment ConnDocument21 pagesW14x43 To HSS6x6x1 - 2 Moment ConnrajedmaglintePas encore d'évaluation

- Composite Floor Deck Design PDFDocument4 pagesComposite Floor Deck Design PDFsaipodinPas encore d'évaluation

- Ordinary Shear WallDocument1 pageOrdinary Shear WallArwen CerenoPas encore d'évaluation

- Plain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryDocument4 pagesPlain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryShadin Asari ArabaniPas encore d'évaluation

- Multi-Tiered Braced Frame Design Based On AISC 341-16: Project: Client: Design By: Job No.: Date: Review byDocument2 pagesMulti-Tiered Braced Frame Design Based On AISC 341-16: Project: Client: Design By: Job No.: Date: Review byRidho ZiskaPas encore d'évaluation

- Pipe Concrete Column Design Based On ACI 318-11: Input Data & Design SummaryDocument1 pagePipe Concrete Column Design Based On ACI 318-11: Input Data & Design SummaryYatsen Jepthe Maldonado SotoPas encore d'évaluation

- AISC - Design Guide 10 - Errata - Erection Bracing of Low - Rise Structural Steel Buildings PDFDocument2 pagesAISC - Design Guide 10 - Errata - Erection Bracing of Low - Rise Structural Steel Buildings PDFapuhapuh_153349Pas encore d'évaluation

- LRFD Composite Beam DesignDocument261 pagesLRFD Composite Beam DesignJuan Carlos FloresPas encore d'évaluation

- Civil Engineering Tools - TUYEN NGUYENNGOC List PDFDocument4 pagesCivil Engineering Tools - TUYEN NGUYENNGOC List PDFCheng Por EngPas encore d'évaluation

- Combined Systems SEAOC Blue BookDocument3 pagesCombined Systems SEAOC Blue BookHirad GrivaniPas encore d'évaluation

- Moment Connection Using Mathcad PDFDocument11 pagesMoment Connection Using Mathcad PDFbong2rmPas encore d'évaluation

- Shear Key or Shear Lug Design - US AISC SectionDocument3 pagesShear Key or Shear Lug Design - US AISC SectionYash PaulPas encore d'évaluation

- Composite ColumnDocument73 pagesComposite ColumnraymondPas encore d'évaluation

- URI T150 1,25 2x7,35m - Internal Zones OKDocument5 pagesURI T150 1,25 2x7,35m - Internal Zones OKDragan Madalin CosminPas encore d'évaluation

- Staggered Truss ExampleDocument5 pagesStaggered Truss ExampleFrederico DonagemmaPas encore d'évaluation

- Practical Design To Eurocode 2: Outline - Week 4Document46 pagesPractical Design To Eurocode 2: Outline - Week 4maminu1Pas encore d'évaluation

- Pile Cap Design For 3-Piles Pattern Based On ACI 318-14Document6 pagesPile Cap Design For 3-Piles Pattern Based On ACI 318-14Anjo BalucasPas encore d'évaluation

- Kloeckner Westok A5 Pocket GuideDocument36 pagesKloeckner Westok A5 Pocket GuidekylePas encore d'évaluation

- Steel Beams With Web Openings-V2Document369 pagesSteel Beams With Web Openings-V2Brian Krug100% (1)

- Design of Doubly Reinforced RC Beam (ACI 318-14) : Particulars Remarks 1 Material Properties Codes and SectionsDocument71 pagesDesign of Doubly Reinforced RC Beam (ACI 318-14) : Particulars Remarks 1 Material Properties Codes and SectionsLavender HoneyPas encore d'évaluation

- Çeşitli Bağlantı Tiplerinin HesabıDocument63 pagesÇeşitli Bağlantı Tiplerinin HesabıblueswanPas encore d'évaluation

- Concentrically Braced FramesDocument121 pagesConcentrically Braced FramesAkshay Reddy100% (1)

- Filled Composite ColumnDocument1 pageFilled Composite ColumnAlphaPas encore d'évaluation

- ACI-350 P-M Interaction 1.1Document6 pagesACI-350 P-M Interaction 1.1ronpauccarPas encore d'évaluation

- Anchorbolt R1Document12 pagesAnchorbolt R1Matheus HenrichPas encore d'évaluation

- تصميم الكمرات بطريقة ultimate PDFDocument42 pagesتصميم الكمرات بطريقة ultimate PDFqaisalkurdyPas encore d'évaluation

- Prestressed Concrete Girder Design For Bridge Structure Based On AASHTO 17th Edition & ACI 318-14Document3 pagesPrestressed Concrete Girder Design For Bridge Structure Based On AASHTO 17th Edition & ACI 318-14jklo12Pas encore d'évaluation

- Free Standing Masonry Wall Design Based On ACI 530-05 & ACI 318-05Document9 pagesFree Standing Masonry Wall Design Based On ACI 530-05 & ACI 318-05SadatcharaMoorthi NPas encore d'évaluation

- Concrete HW 2Document6 pagesConcrete HW 2Ramla QureshiPas encore d'évaluation

- Tables For Wood Post Design Based On NDS 2005: Post Axial Capacity For Douglas Fir-Larch # 1, (Kips)Document22 pagesTables For Wood Post Design Based On NDS 2005: Post Axial Capacity For Douglas Fir-Larch # 1, (Kips)leroytuscanoPas encore d'évaluation

- 1-RC DesignDocument4 pages1-RC DesignOSCARTAWNPas encore d'évaluation

- Crack Width ConcreteDocument1 pageCrack Width ConcreteRuemu Godwin InikoriPas encore d'évaluation

- Daniel Tian Li: Circular Column Design Based On ACI 318-05Document1 pageDaniel Tian Li: Circular Column Design Based On ACI 318-05OswardMorenoPas encore d'évaluation

- AISC Design Guide 10 Revisions-And-Errata-List PDFDocument2 pagesAISC Design Guide 10 Revisions-And-Errata-List PDFCarlo DizonPas encore d'évaluation

- Composite Deck DesignDocument16 pagesComposite Deck DesignAhmad FitrahPas encore d'évaluation

- Flexural Design of Singly Reinforced Section According To ACI 318-02Document41 pagesFlexural Design of Singly Reinforced Section According To ACI 318-02Branko ĐokovićPas encore d'évaluation

- REBARS (318-05) (Engineersdaily - Com)Document8 pagesREBARS (318-05) (Engineersdaily - Com)sawahPas encore d'évaluation

- CIE 525 HW 3 - Mkumar2Document13 pagesCIE 525 HW 3 - Mkumar2xxazninvasionxx2697Pas encore d'évaluation

- Beam With TorsionDocument11 pagesBeam With TorsionR ASTUSPas encore d'évaluation

- Appendix A - Example 2.1Document71 pagesAppendix A - Example 2.1JustinPas encore d'évaluation

- Portal Frame Practice ProblemsDocument10 pagesPortal Frame Practice ProblemsBoyzz ChinPas encore d'évaluation

- Seismic Analysis of Highway BridgesDocument40 pagesSeismic Analysis of Highway BridgesAsifAliPas encore d'évaluation

- AISI Appendix BDocument9 pagesAISI Appendix Brk_vijay81Pas encore d'évaluation

- Cie 525 - Reinforced Concrete Structures: Thursday SEPTEMBER 22, 2016Document10 pagesCie 525 - Reinforced Concrete Structures: Thursday SEPTEMBER 22, 2016Bodhi RudraPas encore d'évaluation

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionD'EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionPas encore d'évaluation

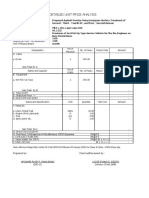

- Detailed Unit Price AnalysisDocument7 pagesDetailed Unit Price AnalysisreynoldPas encore d'évaluation

- Electrical QuotationDocument2 pagesElectrical QuotationreynoldPas encore d'évaluation

- Trip TicketDocument1 pageTrip TicketreynoldPas encore d'évaluation

- Trip TicketDocument1 pageTrip TicketreynoldPas encore d'évaluation

- Mechanically Stabilized EarthDocument8 pagesMechanically Stabilized EarthreynoldPas encore d'évaluation

- Item No./Description: Unit of Measurement: Output Per HourDocument4 pagesItem No./Description: Unit of Measurement: Output Per Hourreynold0% (1)

- MSE Wall SpecsDocument44 pagesMSE Wall SpecsreynoldPas encore d'évaluation

- Foreman 161.14 404 (2) 150 Electrician 147.25 405 (1) A 30 Operator 134.99 414 (1) A 5 Driver 122.73 505 (5) 1.25 Skilled 114.35 500 2 Labor 88.17Document1 pageForeman 161.14 404 (2) 150 Electrician 147.25 405 (1) A 30 Operator 134.99 414 (1) A 5 Driver 122.73 505 (5) 1.25 Skilled 114.35 500 2 Labor 88.17reynoldPas encore d'évaluation

- Wind Load CalculationDocument9 pagesWind Load CalculationManoj Manoharan0% (1)

- Jerv Works Const. Ref: Reinforced Concrete Structures, Pg. 149 By: R. Park & T. Paulay Circular ColumnDocument3 pagesJerv Works Const. Ref: Reinforced Concrete Structures, Pg. 149 By: R. Park & T. Paulay Circular ColumnreynoldPas encore d'évaluation

- Input Data in Green CellsDocument5 pagesInput Data in Green CellsreynoldPas encore d'évaluation

- Design CriteriaDocument2 pagesDesign CriteriareynoldPas encore d'évaluation

- Bill of Quantities-Amai Pakpak Medical Center: General RequirementsDocument8 pagesBill of Quantities-Amai Pakpak Medical Center: General RequirementsreynoldPas encore d'évaluation

- Seismic Zones Factor Zone 4 Normal Occupancies 8: I Occupancy Requirements Table 2.2DDocument5 pagesSeismic Zones Factor Zone 4 Normal Occupancies 8: I Occupancy Requirements Table 2.2DreynoldPas encore d'évaluation

- US Stair oDocument3 pagesUS Stair oRenvil PedernalPas encore d'évaluation

- Box Culvert Design CalculationDocument15 pagesBox Culvert Design CalculationYoshua Yang62% (21)

- Structural Analysis and DesignDocument354 pagesStructural Analysis and DesignreynoldPas encore d'évaluation

- Production RatesDocument17 pagesProduction Ratesyonatan1351Pas encore d'évaluation

- Bar Chart Project Schedule Rainy DaysDocument6 pagesBar Chart Project Schedule Rainy DaysreynoldPas encore d'évaluation

- Hydraulic CalculationsDocument2 pagesHydraulic CalculationsreynoldPas encore d'évaluation

- Bearing Capacity Computation PDFDocument1 pageBearing Capacity Computation PDFreynoldPas encore d'évaluation

- Bar Chart Project Schedule Rainy DaysDocument6 pagesBar Chart Project Schedule Rainy DaysreynoldPas encore d'évaluation

- Wind Load CalculationDocument9 pagesWind Load CalculationManoj Manoharan0% (1)

- Gi & PVC Pipes Under PresureDocument1 pageGi & PVC Pipes Under PresurereynoldPas encore d'évaluation

- Design of Pipe of 1Document2 pagesDesign of Pipe of 1Carlos Valverde PortillaPas encore d'évaluation

- Head Piles in Cohesive SoilDocument1 pageHead Piles in Cohesive SoilreynoldPas encore d'évaluation

- Hydraulic CalculationsDocument2 pagesHydraulic CalculationsreynoldPas encore d'évaluation

- Storey LevelDocument3 pagesStorey LevelreynoldPas encore d'évaluation

- Beam DesignDocument2 pagesBeam DesignreynoldPas encore d'évaluation

- Work Methodology For Clearing and Grubbing of Trees and ShrubsDocument2 pagesWork Methodology For Clearing and Grubbing of Trees and ShrubsNasser Issa Abu HalimehPas encore d'évaluation

- Upright Drilling MachineDocument3 pagesUpright Drilling Machinevenkateshyadav2116100% (2)

- HVAC Calculations GuideDocument36 pagesHVAC Calculations GuideAS HASPas encore d'évaluation

- SolManEngineering Vibration 4th Edition by InmanDocument36 pagesSolManEngineering Vibration 4th Edition by Inmansmirnov2591100% (1)

- Application of Adomian's Approximations To The Navier-Stokes Equations in Cylindrical CoordinatesDocument5 pagesApplication of Adomian's Approximations To The Navier-Stokes Equations in Cylindrical CoordinateswahabmathsPas encore d'évaluation

- 01 CylindersDocument20 pages01 CylindersAmit GauravPas encore d'évaluation

- c140 Compair Compressor Parts Manual You Are Looking For A Book c140 Compair CompressorDocument7 pagesc140 Compair Compressor Parts Manual You Are Looking For A Book c140 Compair CompressorMgc ElektronikPas encore d'évaluation

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 7Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 7amir moniriPas encore d'évaluation

- TLB ServiceDocument5 pagesTLB ServiceHugh O'Brien GwazePas encore d'évaluation

- BS 1139-2-2Document14 pagesBS 1139-2-2murali krishPas encore d'évaluation

- Chapter 4Document25 pagesChapter 4Victoria JungPas encore d'évaluation

- Few Words About Stepper Motor Advantages Disadvantages and ClassificationDocument4 pagesFew Words About Stepper Motor Advantages Disadvantages and ClassificationDeepak Jha KashyapPas encore d'évaluation

- Xtra Strong (XS) Size Steel Pipe Weights TAble CalculatorDocument1 pageXtra Strong (XS) Size Steel Pipe Weights TAble CalculatorshownpuPas encore d'évaluation

- 3in Elamr Drawing Illustration in One FileDocument43 pages3in Elamr Drawing Illustration in One FileusamakhattakPas encore d'évaluation

- The Marinov Generator1Document7 pagesThe Marinov Generator1Ioan CozmaPas encore d'évaluation

- CH 05Document59 pagesCH 05RODRIGO JAVIER BRIZUELA PADILLAPas encore d'évaluation

- Pulsar 220 - FI PDFDocument46 pagesPulsar 220 - FI PDFMeenakshi IllamPas encore d'évaluation

- Active Suspension SystemDocument25 pagesActive Suspension SystemAhmedAlMeghalawyPas encore d'évaluation

- Lecture 3 Kinematics in One Dimension - StudentDocument51 pagesLecture 3 Kinematics in One Dimension - StudentSmurf TanPas encore d'évaluation

- Preparation Exam ICP API 510 API 650 Chapitre 1-3 Answers N°01Document7 pagesPreparation Exam ICP API 510 API 650 Chapitre 1-3 Answers N°01korichiPas encore d'évaluation

- Gen II Automated Transmissions - TRTS0062 EN-US PDFDocument314 pagesGen II Automated Transmissions - TRTS0062 EN-US PDFsherzadPas encore d'évaluation

- High-Performance Condenser Tube Cleaning System Featuring Advanced Ball Collecting Technology - r2005 - 03 - 104 PDFDocument5 pagesHigh-Performance Condenser Tube Cleaning System Featuring Advanced Ball Collecting Technology - r2005 - 03 - 104 PDFnur hamzahPas encore d'évaluation

- Hilti - Rebar For Engineers - Hit-Rebar MethodDocument20 pagesHilti - Rebar For Engineers - Hit-Rebar MethodMunduluPas encore d'évaluation

- List of Recomended ManufacturersDocument16 pagesList of Recomended ManufacturersMostafa SalemPas encore d'évaluation

- Section - 1: Page 1 of 3Document3 pagesSection - 1: Page 1 of 3majjisatPas encore d'évaluation

- Rev 2 Summarised Report Izki RF BM Cracks 03 Aug 2017Document4 pagesRev 2 Summarised Report Izki RF BM Cracks 03 Aug 2017WilfredoEnghoyPas encore d'évaluation

- Safe Operation of ForkliftDocument44 pagesSafe Operation of Forkliftkarvad100% (1)

- John Deere STX30 Technical - Manual - DownloadDocument314 pagesJohn Deere STX30 Technical - Manual - DownloadHansruedi Stebler100% (1)

- Oxygen Sensor Certification ManualDocument20 pagesOxygen Sensor Certification ManualSR BangashPas encore d'évaluation

- The Implementation of API RP 1102 Code To Evaluate Gas Pipeline Road CrossingDocument10 pagesThe Implementation of API RP 1102 Code To Evaluate Gas Pipeline Road CrossingRagil Siswo UtomoPas encore d'évaluation

- Physics Spectrum December 2015 PDFDocument100 pagesPhysics Spectrum December 2015 PDFParvinder BhardwajPas encore d'évaluation