Académique Documents

Professionnel Documents

Culture Documents

Worktips 31 Asphalt Paving Speed PDF

Transféré par

vamshiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Worktips 31 Asphalt Paving Speed PDF

Transféré par

vamshiDroits d'auteur :

Formats disponibles

Asphalt Paving Speed

work tips pavement work tips no. 31

INTRODUCTION Where:

November 2001

Key Summary

An important element in achieving smooth P = Paver forward

riding asphalt pavements is maintaining steady speed (metres/minute)

This issue provides

continuous paving. General guidance on smooth D = Delivery rate a guide to the

paver operation is provided in Work Tip No 3. (tonnes/hour)

calculation of paver

This Work Tip provides a guide to calculation w = width of spread forward speed for

of paver speed and roller capacity to enable (metres) smooth continuous

matching of: t = compacted paving and matching

Asphalt plant production rates to average paver thickness (mm) roller capacity to

speed so that the paver can be kept moving d = compacted density ensure effective

steadily forward, averaging out minor of asphalt (t/m3). compaction.

variations in arrival of delivery trucks. Alternatively, the rate

Paving speed to roller capacity so that the paver of delivery to match a particular paver forward

forward speed (and rate of supply) does not speed can be calculated from:

pavement

exceed the capacity of rollers to provide

effective compaction, or alternatively to P × w × t × d × 60

D=

determine the number of rollers required to 1000

achieve compaction for a given output. The above formulae can be used to develop

tables or charts for typical paving widths.

PAVER SPEED

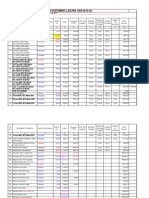

Figure 1 illustrates paver forward speed for

The general formula for calculating paver various thicknesses of asphalt, a spread width of

forward speed for a given rate of delivery of 3.7 m, and a typical density of 2.40 t/m3. In the

asphalt is: example of roller capacity (over), an average

D × 1000 forward speed of the rollers of 4.7 m per minute,

P= and compacted thickness of 40 mm, can be

60 × w × t × d

matched to a spreading output, or average mix

delivery rate, of 100 t/h.

Figure 1 Paver Speed continued on reverse

400

m

0m

Mix Deliveries - tonnes per hour

300

10

m

m

75

m

m

200 50

mm

40 th

Dep

t ed

o mpac

m C

25 m

100

AUSTROADS Example

Note: Paver speed

based on spread 3.7 m

wide and a compacted

density of 2.40 tonnes

3 6 9 12 15

per cubic metre Paver Speed - m/min

pavement work tips is produced by AUSTROADS in conjunction with AAPA

For more

Asphalt Paving Speed page 2 information on any

of the construction

practices discussed

COMPACTION CAPACITY The total number of passes is the number of in "pavement work

roller laps multiplied by the number of passes per tips", please contact

Rollers have to travel a much greater distance either your local

roller lap, plus any makeup pass the roller takes to

than the paver within a given time frame. The AUSTROADS

travel over the compacted section in order to reach Pavement Reference

number of roller passes does not increase in

fresh pavement. Group

proportion to the thickness of layer but net

forward travel speed is dependent on the rolling For example a roller of 1.4 m width will require representative or

3 laps to cover a paving width of 2.4 to 3.7 m. AAPA

speed and number of passes to cover the paving

One complete coverage (3 laps) with two passes tel (03) 9853 3595;

width. fax (03) 9853 3484;

per lap will require 6 passes. Two coverages of

The primary factors determining production e-mail:

the mat will require 6 laps (12 passes).

capacity of an asphalt roller are: info@aapa.asn.au

With an extra lap for the longitudinal joint, the A complete list of

Drum width total number of passes becomes 14. A makeup "pavement work

Number of passes pass brings the total to 15. tips" issues is

Roller speed. In the above example, a roller travelling at 6 available on AAPA's

km/h (100 m/min) and an overall efficiency of web site:

Other conditions must also be met, including www.aapa.asn.au

the number of roller passes required to compact factor of 0.7 for non-productive time and travel,

will result in an average forward speed of: Issues may be

the asphalt and the amount of time that the freshly downloaded using

placed asphalt is exposed before it is compacted. 100 x 0.7 / 15 = 4.7 m/min. Adobe Acrobat

The allowable time for compaction will be reduced Reader. Copies may

when placing thin layers, low pavement surface Typical speeds for steel drum vibratory rollers also be obtained

temperature or when cool winds increase the rate commonly used for primary compaction of from AAPA.

of cooling of the mix. asphalt, are 3 to 6 km/h for thick layers and up to Material may be

Allowance must also be made for short breaks 10 km/h for thin layers. freely reproduced

providing the source

(filling with water, etc.), joint compaction, extra

Efficiency of vibratory rollers diminishes with is acknowledged.

distance travelled in changing lanes, and time taken

increased speed. Speeds greater than 7 km/h are This edition was

to change direction. Typically, a roller can be

not commonly used where high density is prepared by

expected to work for 50 minutes per hour, with a John Rebbechi in

required.

further 10 to 15% loss for non-productive work, consultation with

taking the overall efficiency to around 70 to 75%. Forward speed should also be linked to members of the

Longitudinal overlaps will vary according to how frequency of vibration. Around 33 beats per metre National Asphalt

the drum width suits the overall paving width and is considered an optimum relationship between Research

is generally a minimum of 150 mm. frequency and forward speed. Coordination

Group (NARC).

Figure 2 Typical Rolling Pattern

Width of roller Direction of paving

1

Width of lane being paved

2 LAP 1

3

7 4 LAP 2

5

6 LAP 3

Every pass of the roller should proceed straight into the uncompacted mix and return on the same path.

After the required passes are completed, the roller should move back across the lane (path 7) and repeat

the procedure.

Austroads and AAPA believe this publication to be correct at the time of printing and do not accept responsibility for any consequences arising from the use of the information

herein. Readers should rely on their own skill and judgement to apply information to particular issues.

Vous aimerez peut-être aussi

- Certified Hot Mix Asphalt Technician ManualDocument485 pagesCertified Hot Mix Asphalt Technician Manualthewhitebunny6789Pas encore d'évaluation

- Sampling Aggregates: Standard Practice ForDocument6 pagesSampling Aggregates: Standard Practice ForBlack GokuPas encore d'évaluation

- Premix Bituminous CarpetingDocument5 pagesPremix Bituminous CarpetingNehaSharma100% (1)

- AustStab Model Specification For Insitu Stabilisation For Main RoadsDocument20 pagesAustStab Model Specification For Insitu Stabilisation For Main RoadsprmraoPas encore d'évaluation

- Do 249 s2022Document42 pagesDo 249 s2022Engr'Shemaiah JimenezPas encore d'évaluation

- 16.11.2021 - Method Statement - Road WorksDocument17 pages16.11.2021 - Method Statement - Road WorksHAKANPas encore d'évaluation

- Long Intl Construction Contract Notice LettersDocument21 pagesLong Intl Construction Contract Notice Lettersjose miguel lagumbayPas encore d'évaluation

- Dyno Blasters Handbook v4Document32 pagesDyno Blasters Handbook v4Manuel MolinaPas encore d'évaluation

- Asphalt and BitumenDocument22 pagesAsphalt and BitumenYinka OlatunjiPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationAnonymous 1gp9bFPas encore d'évaluation

- AdhesivesDocument136 pagesAdhesivesDeepak Kumar Gupta50% (2)

- RCC Construction, RCC Mixes, RCC Instrumentation & RCC Dams StudiedDocument35 pagesRCC Construction, RCC Mixes, RCC Instrumentation & RCC Dams StudiedlorikPas encore d'évaluation

- WSDOT FOP For AASHTO T 106Document14 pagesWSDOT FOP For AASHTO T 106malaya tripathyPas encore d'évaluation

- Sample BQDocument10 pagesSample BQmohdshahrircheabdul100% (1)

- CPC-18 Measurement of Hardened Concrete Carbonation Depth: Rilem Recommendations Recommandations de La RilemDocument3 pagesCPC-18 Measurement of Hardened Concrete Carbonation Depth: Rilem Recommendations Recommandations de La RilemmanuelisantosPas encore d'évaluation

- Astm D-113 PDFDocument3 pagesAstm D-113 PDFjulianovmPas encore d'évaluation

- Design of Storm Water Drainge Sytem HaruDocument22 pagesDesign of Storm Water Drainge Sytem HaruNadeem BakhshPas encore d'évaluation

- BS 1377 Part 9: 1990 StandardDocument9 pagesBS 1377 Part 9: 1990 StandardDetoned StonedPas encore d'évaluation

- LPG StandardsDocument115 pagesLPG StandardsKatie RamirezPas encore d'évaluation

- Construction and Quality Control of Flexible PavementsDocument83 pagesConstruction and Quality Control of Flexible PavementsSayan GharPas encore d'évaluation

- Standard Test Procedures Manual: 1. Scope 1.1. Description of TestDocument7 pagesStandard Test Procedures Manual: 1. Scope 1.1. Description of TestMuhsin KhanPas encore d'évaluation

- Highway Research Record No. 39Document187 pagesHighway Research Record No. 39Bilal Ahmed Barbhuiya100% (1)

- Panzer Aces Blitzkrieg PDFDocument76 pagesPanzer Aces Blitzkrieg PDFPrplknite100% (9)

- Trinidad & Tobago - 62.01 - Petroleum Act & RegsDocument160 pagesTrinidad & Tobago - 62.01 - Petroleum Act & RegsOilmanGH100% (1)

- Construction Delay Analysis TechniquesDocument26 pagesConstruction Delay Analysis Techniquesengmts1986Pas encore d'évaluation

- Design, Testing, and Construction of Slurry Seal: Standard Practices ForDocument8 pagesDesign, Testing, and Construction of Slurry Seal: Standard Practices ForaraPas encore d'évaluation

- Bulk Specific GravityDocument9 pagesBulk Specific Gravityelnaqa176Pas encore d'évaluation

- Method B7 - The Determination of The Treton Impact Value of Aggregate.Document3 pagesMethod B7 - The Determination of The Treton Impact Value of Aggregate.GUO LEI100% (1)

- 11 22 Emperical and Mechanistic Pavement Design 2Document55 pages11 22 Emperical and Mechanistic Pavement Design 2Shams KhattakPas encore d'évaluation

- TM 001Document11 pagesTM 001yassir dafallaPas encore d'évaluation

- Hot Mix Plant Calibration Laying TestingDocument55 pagesHot Mix Plant Calibration Laying TestingSanjayPas encore d'évaluation

- Wet Mix Macadam-WmmDocument7 pagesWet Mix Macadam-WmmCheng Engi33% (3)

- Fly Ash Rigid PavementDocument4 pagesFly Ash Rigid PavementRaghav100% (1)

- Cold-Mix RecyclingDocument6 pagesCold-Mix RecyclingKandikanti Ashok ChiganshiPas encore d'évaluation

- Effect of Varying Mixing & Compaction Temperature On Marshall Properties of Bituminous Concrete MixDocument44 pagesEffect of Varying Mixing & Compaction Temperature On Marshall Properties of Bituminous Concrete Mixshiva5059100% (1)

- Design of Hot Mix Asphalt Using Bailey Method of GradationDocument8 pagesDesign of Hot Mix Asphalt Using Bailey Method of GradationInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Preparation of Asphalt Mixture Specimens Using Marshall ApparatusDocument8 pagesPreparation of Asphalt Mixture Specimens Using Marshall ApparatusAnbuchelvan CPas encore d'évaluation

- Soundness TestDocument3 pagesSoundness TestYasirPas encore d'évaluation

- Irc 115 2014 FWD FLEXIBLEDocument4 pagesIrc 115 2014 FWD FLEXIBLESuyog GorePas encore d'évaluation

- Calibration Survey of Bump Integrator-MERLIN 2015 Non BUBDocument8 pagesCalibration Survey of Bump Integrator-MERLIN 2015 Non BUBMohan Mylarappa100% (1)

- Is 13311.2.1992 PDFDocument12 pagesIs 13311.2.1992 PDFTayyab AnwarPas encore d'évaluation

- Highway RehabilitationDocument31 pagesHighway Rehabilitationketh patrickPas encore d'évaluation

- TR 331 - HIGHWAY MATERIALS @udsm by BUJULU in Share With Christian Nicolaus MbiseDocument183 pagesTR 331 - HIGHWAY MATERIALS @udsm by BUJULU in Share With Christian Nicolaus MbiseChristian Nicolaus MbisePas encore d'évaluation

- MerlinDocument1 pageMerlinJairo RodriguezPas encore d'évaluation

- Aashto T 201Document3 pagesAashto T 201Mohammed AliPas encore d'évaluation

- Astm C 127 PDFDocument7 pagesAstm C 127 PDFNikolay DrumevPas encore d'évaluation

- 2143R 88Document17 pages2143R 88DIDIER ANGEL LOPEZ RINCONPas encore d'évaluation

- Bitumen Extraction Test PDFDocument4 pagesBitumen Extraction Test PDFAyat APas encore d'évaluation

- Pavement DistressesDocument45 pagesPavement DistresseswedjefdbenmcvePas encore d'évaluation

- DBM 507Document7 pagesDBM 507Mark Moni Mary ManoPas encore d'évaluation

- Viscosity TestDocument1 pageViscosity TestDeven PatlePas encore d'évaluation

- Los Angeles Abrasion Test AASHTO 96Document4 pagesLos Angeles Abrasion Test AASHTO 96Lava HimawanPas encore d'évaluation

- Polished Stone Value - Test Procedures and Equipment PDFDocument6 pagesPolished Stone Value - Test Procedures and Equipment PDFSuman GautamPas encore d'évaluation

- Interlocking Concrete Block Pavement ICBDocument24 pagesInterlocking Concrete Block Pavement ICBAbhishek RanaPas encore d'évaluation

- Pmgsy Circular About Rural Road GeometryDocument16 pagesPmgsy Circular About Rural Road Geometryprasadnn2001100% (1)

- Determining Longitudinal Peak Braking Coefficient of Paved Surfaces Using A Standard Reference Test TireDocument5 pagesDetermining Longitudinal Peak Braking Coefficient of Paved Surfaces Using A Standard Reference Test TireDannyChaconPas encore d'évaluation

- 1.01 The Updated Tex-248-F Test ProcedureDocument13 pages1.01 The Updated Tex-248-F Test ProcedureDavid Vaca OyolaPas encore d'évaluation

- Performance of Recycled Asphalt Pavement As Coarse Aggregate in ConcreteDocument12 pagesPerformance of Recycled Asphalt Pavement As Coarse Aggregate in ConcreteBrayan Stiven VIVIESCA GIRALDO100% (1)

- Plain and Steel-Laminated Elastomeric Bearings For BridgesDocument7 pagesPlain and Steel-Laminated Elastomeric Bearings For BridgesJhon EscobarPas encore d'évaluation

- Utilisation of Warm Mix Asphalt Technology To Improve Bituminous Mixtures Containing Reclaimed Asphalt PavementDocument31 pagesUtilisation of Warm Mix Asphalt Technology To Improve Bituminous Mixtures Containing Reclaimed Asphalt PavementdaniPas encore d'évaluation

- Embankment & Sub-Grade LayerDocument9 pagesEmbankment & Sub-Grade LayerPathankot MandiPas encore d'évaluation

- AASHTO t255Document6 pagesAASHTO t255Sabila IhsaniPas encore d'évaluation

- 6 Defects in Brickwork Due To Poor WorkmanshipDocument7 pages6 Defects in Brickwork Due To Poor WorkmanshipMichael Matshona100% (1)

- BISAR 3.0: Bitumen Business Group May 1998Document47 pagesBISAR 3.0: Bitumen Business Group May 1998rapax2450% (2)

- Highway Material Testing & Quality Control, 1/e: G. Venkatappa Rao, D.V. Bhavanna Rao, K. Ramachandra Rao & Kausik PahariDocument2 pagesHighway Material Testing & Quality Control, 1/e: G. Venkatappa Rao, D.V. Bhavanna Rao, K. Ramachandra Rao & Kausik Paharisunil777tvpm100% (1)

- 75 81 EngDocument84 pages75 81 Engmehrdad_so1981Pas encore d'évaluation

- Road Surface Profiler Mark III - A4 - WebDocument2 pagesRoad Surface Profiler Mark III - A4 - WebErwin KohlerPas encore d'évaluation

- Concrete SpecsDocument15 pagesConcrete SpecsNATHANPas encore d'évaluation

- Welcome To Fde-BookagdegnormgravmixhydDocument40 pagesWelcome To Fde-BookagdegnormgravmixhydstevePas encore d'évaluation

- Sediment Transport in Open ChannelsDocument3 pagesSediment Transport in Open Channelsomed muhammadPas encore d'évaluation

- Calculating Spread and Checking Intake Location: Office of DesignDocument7 pagesCalculating Spread and Checking Intake Location: Office of DesignpankajPas encore d'évaluation

- WER 301S Stormwater Sewer - M2Document45 pagesWER 301S Stormwater Sewer - M2Zithulele TreatwellPas encore d'évaluation

- Winding MC DesignDocument8 pagesWinding MC DesignTamil SelvanPas encore d'évaluation

- EPC Schedules Nh-48 Pack-2 - 15-05-15-2Document148 pagesEPC Schedules Nh-48 Pack-2 - 15-05-15-2vamshiPas encore d'évaluation

- Vertical Alignment PDFDocument3 pagesVertical Alignment PDFvamshiPas encore d'évaluation

- Upakarma Devanagari 1Document15 pagesUpakarma Devanagari 1Harish KNPas encore d'évaluation

- RFP PDFDocument241 pagesRFP PDFvamshiPas encore d'évaluation

- GanapatiAatharvashirshaEng PDFDocument3 pagesGanapatiAatharvashirshaEng PDFmagicalseasPas encore d'évaluation

- Upakarma Devanagari 1Document15 pagesUpakarma Devanagari 1Harish KNPas encore d'évaluation

- Singly Reinforced BeamDocument21 pagesSingly Reinforced BeamSaurabh GodhaPas encore d'évaluation

- 7 FIDIC Conditions of ContractDocument9 pages7 FIDIC Conditions of ContractvamshiPas encore d'évaluation

- 5 The Indian Contract ActDocument11 pages5 The Indian Contract ActvamshiPas encore d'évaluation

- Tor - Ii Kiship PDFDocument26 pagesTor - Ii Kiship PDFvamshiPas encore d'évaluation

- S-000-5317-001 SoharDocument33 pagesS-000-5317-001 SoharmilanPas encore d'évaluation

- SSM Profile 2018Document9 pagesSSM Profile 2018ooty.pradeepPas encore d'évaluation

- ASTM D 2042 - 01 Standard Test Method ForDocument3 pagesASTM D 2042 - 01 Standard Test Method Form_seyedPas encore d'évaluation

- Cold Recycler and Stabilizer WR SeriesDocument70 pagesCold Recycler and Stabilizer WR SeriesNguyen Ngoc75% (4)

- Sample Preparation and Polishing of Asphalt Mixture Specimens For Dynamic Friction TestingDocument9 pagesSample Preparation and Polishing of Asphalt Mixture Specimens For Dynamic Friction TestingHamdan BintaraPas encore d'évaluation

- Experiment No. 6 Specific Gravity of Coarse Aggregate: Department of Civil EngineeringDocument8 pagesExperiment No. 6 Specific Gravity of Coarse Aggregate: Department of Civil EngineeringAli EspinosaPas encore d'évaluation

- Cat WF GB 2015 0508 72dpiDocument89 pagesCat WF GB 2015 0508 72dpiDwi Febrianto Madao100% (1)

- Supreme PMB (Elastomeric) : Product DescriptionDocument2 pagesSupreme PMB (Elastomeric) : Product DescriptionUdaykumar GandhiPas encore d'évaluation

- Portal Ratol & Rates Premo: Cawangan Kontrak Dan Ukur Bahan 04.11.2019Document3 pagesPortal Ratol & Rates Premo: Cawangan Kontrak Dan Ukur Bahan 04.11.2019John SmithPas encore d'évaluation

- 00 Liquid Resins HandbookDocument84 pages00 Liquid Resins HandbookGita RahMaPas encore d'évaluation

- Information Archieve - 2-3-2020Document15 pagesInformation Archieve - 2-3-2020Mizanul HoquePas encore d'évaluation

- BOQ Dili Main Roads 1ADocument64 pagesBOQ Dili Main Roads 1ARey YnoPas encore d'évaluation

- Marshall Stability Test: (ASTM D-1663-73, ASTM D-1559-75)Document24 pagesMarshall Stability Test: (ASTM D-1663-73, ASTM D-1559-75)zain IshaqPas encore d'évaluation

- Model PMGSY Road Datas 2013-14-SSRDocument91 pagesModel PMGSY Road Datas 2013-14-SSRChManikumarPas encore d'évaluation

- Colrub: 1. Identification of SubstanceDocument5 pagesColrub: 1. Identification of SubstanceAndile NtuliPas encore d'évaluation

- Flexible Pavement DesignDocument39 pagesFlexible Pavement DesignSaurabh KumarPas encore d'évaluation

- Shreenath Soil Testing Lab RajkotDocument2 pagesShreenath Soil Testing Lab RajkotMital DamaniPas encore d'évaluation

- SQP 22204 Construction MaterialsDocument4 pagesSQP 22204 Construction MaterialsDipak vanjariPas encore d'évaluation

- FRAM Geolab LTD ProfileDocument25 pagesFRAM Geolab LTD ProfileSolomon Ndugwa BalemeziPas encore d'évaluation