Académique Documents

Professionnel Documents

Culture Documents

SDSDSDSD

Transféré par

7761430Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SDSDSDSD

Transféré par

7761430Droits d'auteur :

Formats disponibles

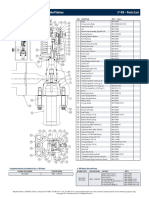

Configurations

There are two types of rods which are commonly used in the lighting

industry: thread-each-end rods and fully threaded rods. Anchor rods are embedded into

the concrete with large templates to provide pullout resistance and proper spacing for

the anchor bolts to match the base of the light pole or traffic signal. Depending on the

style of the pole, the base plate for the pole will have a bolt pattern which the anchor

rods must align with for a perfect fit. This is why many anchor rod assemblies for the

lighting industry are sold with bolt templates or template straps to match the

configuration of the base plate on the pole.

If the pole base has a triangular bolt pattern, the rods will commonly have 6 nuts, 2

washers and 2 template straps per rod. For circular and square bolt patterns, anchor

rods commonly have 6 nuts and 6 washers per rod with 2 templates per set of anchor

bolts (1 set = 4 anchor rods).

Grades

Anchor rods for the lighting industry are most commonly manufactured in two grades of

the F1554 specification, Grade 55 and Grade 105. However, they are also

manufactured in Grade 36 and A449, as well as other grades depending on the

situation. Portland Bolt keeps a variety of WSDOT and ODOT standard anchor rods in

stock and these sizes can be found below.

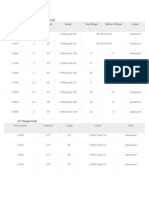

Common Sizes

The following tables show the available stock parts at Portland Bolt. These tables give

an idea of what sizes and configurations of light pole anchor bolts are readily

available. Nonstandard light pole anchor bolts in virtually any ASTM grade, size, and

configuration can be manufactured with very short lead times.

Vous aimerez peut-être aussi

- CompoDocument1 pageCompo7761430Pas encore d'évaluation

- Tell Me About An Exhibition You Have Been ToDocument1 pageTell Me About An Exhibition You Have Been To7761430Pas encore d'évaluation

- 213vs 312Document1 page213vs 3127761430Pas encore d'évaluation

- API Prs RatingDocument1 pageAPI Prs Rating7761430Pas encore d'évaluation

- Large Rectangular Flange1Document1 pageLarge Rectangular Flange17761430Pas encore d'évaluation

- UG-25 RefDocument1 pageUG-25 Ref7761430Pas encore d'évaluation

- Extreme Fiber Elongation CalculationsDocument1 pageExtreme Fiber Elongation Calculations7761430Pas encore d'évaluation

- Geography Cut OutDocument1 pageGeography Cut Out7761430Pas encore d'évaluation

- Step by Step Methods For WRC 107 (WRC 537) and WRC 297 CDocument13 pagesStep by Step Methods For WRC 107 (WRC 537) and WRC 297 C7761430Pas encore d'évaluation

- 6061 - T6 Aluminum Association I-BeamDocument1 page6061 - T6 Aluminum Association I-Beam7761430Pas encore d'évaluation

- API 6A Gate Valves Technical SpecificationsDocument3 pagesAPI 6A Gate Valves Technical Specifications7761430Pas encore d'évaluation

- SkidDocument1 pageSkid7761430Pas encore d'évaluation

- How To Calculate Markup PercentageDocument4 pagesHow To Calculate Markup Percentage7761430Pas encore d'évaluation

- VSL 3dview PDFDocument1 pageVSL 3dview PDF7761430Pas encore d'évaluation

- Navigating in Catalog Manager: Connect To A DatabaseDocument3 pagesNavigating in Catalog Manager: Connect To A Database7761430Pas encore d'évaluation

- Pipees ReportDocument17 pagesPipees Report7761430Pas encore d'évaluation

- PTS1Document1 pagePTS17761430Pas encore d'évaluation

- SdsdsDocument3 pagesSdsds7761430Pas encore d'évaluation

- Anchor Rods (Thread Each End) : Part Number Diameter Length Grade Top Thread Bottom Thread FinishDocument2 pagesAnchor Rods (Thread Each End) : Part Number Diameter Length Grade Top Thread Bottom Thread Finish7761430Pas encore d'évaluation

- Galvanized Anchor Bolts for Light Pole InstallationDocument1 pageGalvanized Anchor Bolts for Light Pole Installation7761430Pas encore d'évaluation

- 1Document2 pages17761430Pas encore d'évaluation

- Design Problems of Anchoring of Aboveground Steel Tanks: Lyubomir ZdravkovDocument1 pageDesign Problems of Anchoring of Aboveground Steel Tanks: Lyubomir Zdravkov7761430Pas encore d'évaluation

- Model T TableDocument1 pageModel T Table7761430Pas encore d'évaluation

- Engineering Sugar UtilizationDocument7 pagesEngineering Sugar Utilization7761430Pas encore d'évaluation

- TPG Mobile Terms and Conditions: 1. The AgreementDocument5 pagesTPG Mobile Terms and Conditions: 1. The Agreement7761430Pas encore d'évaluation

- 13 Heat Exchanger TubesheetsDocument1 page13 Heat Exchanger Tubesheets7761430Pas encore d'évaluation

- Wm1 - Bolt Load Calculation: (Channel Flange)Document5 pagesWm1 - Bolt Load Calculation: (Channel Flange)7761430Pas encore d'évaluation

- Zone DampersDocument1 pageZone Dampers7761430Pas encore d'évaluation

- Automated Zone DampersDocument2 pagesAutomated Zone Dampers7761430Pas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Liebert Gxt4 230V, 5000-10,000VA: User ManualDocument56 pagesLiebert Gxt4 230V, 5000-10,000VA: User ManualEmerson Müller Juarez AvilaPas encore d'évaluation

- UT58D Eng ManualDocument34 pagesUT58D Eng ManualkalizamPas encore d'évaluation

- Manual Valvula 3'' Titan RXDocument2 pagesManual Valvula 3'' Titan RXrolandPas encore d'évaluation

- TW2022 CatalogueDocument41 pagesTW2022 Catalogueeng.abdullrahmanPas encore d'évaluation

- Microprocessor Lab Manual - FinalDocument157 pagesMicroprocessor Lab Manual - FinalDr. N.Shanmugasundaram100% (6)

- Ldb-Ac-Cal-001 - Ac Calculation - Rev.d - 15.11.18 + CRSDocument32 pagesLdb-Ac-Cal-001 - Ac Calculation - Rev.d - 15.11.18 + CRSArys FarandyPas encore d'évaluation

- Electronics Engineering Mastery Test 7 ECE Pre-Board PDFDocument29 pagesElectronics Engineering Mastery Test 7 ECE Pre-Board PDFXyPas encore d'évaluation

- Kil Gu-Un Series UnionsDocument2 pagesKil Gu-Un Series UnionsNoe AlvarezPas encore d'évaluation

- Clipper Wind PDFDocument13 pagesClipper Wind PDFyanaziPas encore d'évaluation

- Application Note Gan Bias Circuit DesignDocument6 pagesApplication Note Gan Bias Circuit DesignAnonymous 3mJfZEPas encore d'évaluation

- MSA M1 SCBA LeafletDocument5 pagesMSA M1 SCBA LeafletForum PompieriiPas encore d'évaluation

- Audi AC Control UnitDocument19 pagesAudi AC Control Unitredmouse10Pas encore d'évaluation

- User Manual - TSOL-M350 - M400 - M800 - M1600 - EN - V1.21Document25 pagesUser Manual - TSOL-M350 - M400 - M800 - M1600 - EN - V1.21octavvvianPas encore d'évaluation

- Onkyo TX-NR646Document132 pagesOnkyo TX-NR646gcataPas encore d'évaluation

- DWE4120 B3 T1 Dewalt PBDocument4 pagesDWE4120 B3 T1 Dewalt PBJose MolinaPas encore d'évaluation

- Buell Ulisses Diagrama ElectricoDocument1 pageBuell Ulisses Diagrama ElectricoHugo GonzalezPas encore d'évaluation

- Fakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaDocument6 pagesFakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia Melakaa syukzPas encore d'évaluation

- Ahu ControlDocument13 pagesAhu ControleslamPas encore d'évaluation

- User Manual: 3.6KW/5.6KW Solar Inverter / ChargerDocument82 pagesUser Manual: 3.6KW/5.6KW Solar Inverter / ChargerStLisPas encore d'évaluation

- Cata B 600Document33 pagesCata B 600Ionuţ Florin RaclăuPas encore d'évaluation

- NEW SO# Draft: No. Description Part NumberDocument5 pagesNEW SO# Draft: No. Description Part NumberLayth S. ChalloobPas encore d'évaluation

- Supplement Schematic For The Electrical System Emcp Ii+Document4 pagesSupplement Schematic For The Electrical System Emcp Ii+Эльдар АптрахимовPas encore d'évaluation

- Title: Model Ut50A/B/C: Operating ManualDocument33 pagesTitle: Model Ut50A/B/C: Operating ManualEibar016Pas encore d'évaluation

- 400 Series Skid Steer Engine OverviewDocument19 pages400 Series Skid Steer Engine OverviewJuan Betancur OsorioPas encore d'évaluation

- 350X2 Manual de ServicioDocument1 154 pages350X2 Manual de ServicioJuan David Gomez Avella100% (1)

- High Horsepower Subsea 14Document30 pagesHigh Horsepower Subsea 14FlorincrihanPas encore d'évaluation

- 3com Officeconnect Switch 8Document2 pages3com Officeconnect Switch 8tengersamPas encore d'évaluation

- Rockwell JointerDocument18 pagesRockwell Jointernotjustsomeone100% (2)

- UAND-specs Rudd Achiever Series PDFDocument16 pagesUAND-specs Rudd Achiever Series PDFBen KuxhousePas encore d'évaluation

- Band Saw G5018WA: Features of Metal Band Sawing Machine From Hoton MachineryDocument1 pageBand Saw G5018WA: Features of Metal Band Sawing Machine From Hoton MachineryMantención FastpackPas encore d'évaluation