Académique Documents

Professionnel Documents

Culture Documents

Aluminium Alloy Ingots PDF

Transféré par

bashaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Aluminium Alloy Ingots PDF

Transféré par

bashaDroits d'auteur :

Formats disponibles

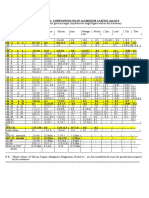

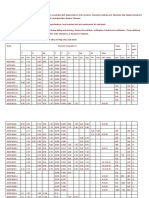

CHEMICAL COMPOSITION (%) OF ALUMINIUM CASTING ALLOYS

(Alloying elements are given in ranges, Impurities are single figures and are the maximum)

____________________________________________________________________________________________________________

_

BS IS. 617 | Copper | Magne- | Silicon | Iron | Manga- | Nickel | Zinc | Lead | Tin | Tita-

1490 1959 | | sum | | | nse | | | |

| nium

LM 1 A 1 | 6.0-8.0 | 0.15 | 2.0-4.0 | 1.0 | 0.6 | 0.5 | 2.0-4.0 | 0.3 | 0.2 | -

LM 2 A 2 | 0.7-2.5 | 0.3 | 9.0-11.5 | 1.0 | 0.5 | 1.0 | 1.2 | 1.2 | 0.3 | 0.2

LM 3 - | 2.5-4.5 | 0.1 | 1.3 | | 1.0 | 0.5 | 0.5 | 9.0-13.0| 0.3 |

0.2

LM 4 A 4 | 2.0-4.0 | 0.15 | 4.0-6.0 | 0.8 | 0.3-0.7 | 0.3 | 0.5 | 0.1 | 0.05 | 0.2

LM 5 A 5 | 0.1 | 3.0-6.0 | 0.3 | 0.6 | 0.3-0.7 | 0.1 | 0.1 | 0.05 | 0.05 | 0.2

LM 6 A 6 | 0.1 | 0.1 | 10.0-13.0 | 0.6 | 0.5 | 0.1 | 0.1 | 0.1 | 0.1 | -

LM 7 A 7 | 1.0-2.5 | 0.05-0.2 | 1.5-3.5 | 0.3-0.4 | 0.1 | 0.5-1.7 | 0.1 | 0.05 | 0.05 | 0.05-0.3

LM 8 A 8 | 0.1 | 0.3-0.8 | 3.5-6.0 | 0.6 | 0.5 | 0.1 | 0.1 | 0.1 | 0.05 | 0.2

LM 9 A 9 | 0.1 | 0.2-0.6 | 10.0-13.0 | 0.6 | 0.3-0.7 | 0.1 | 0.1 | 0.1 | 0.05 | 0.2

LM 10 A 10 | 0.1 | 9.5-11.0 | 0.25 | 0.35 | 0.1 | 0.1 | 0.1 | 0.05 | 0.05 | 0.2

LM 11 A 11 | 4.0-5.0 | 0.1 | 0.25 | 0.25 | 0.1 | 0.1 | 0.1 | 0.05 | 0.05 | 0.05-0.3

LM 12 A 12 | 9.0-10.5 | 0.15-0.35 | 2.0 | 0.5-1.5 | 0.6 | 0.5 | 0.1 | 0.1 | 0.1 |

-

LM 13 A 13 | 0.5-1.3 | 0.8-1.5 | 11.0-13.0 | 0.8 | 0.5 | 2.0-3.0 | 0.1 | 0.1 | 0.1 | 0.2

LM 14 A 14 | 3.5-4.5 | 1.2-1.7 | 0.6 | 0.6 | 0.6 | 1.8-2.3 | 0.1 | 0.05 | 0.05 | 0.2

LM 15 A 15 | 0.3-3.0 | 0.5-1.7 | 0.6-2.0 | 0.8-1.4 | 0.1 | 0.5-2.0 | 0.1 | 0.05 | 0.05 | 0.05-0.3

LM 16 A 16 | 1.0-1.5 | 0.4 – 0.6 | 4.5-5.5 | 0.6 | 0.5 | 0.25 | 0.1 | 0.05 | 0.05 | -

LM 18 A 18 | 0.1 | 0.1 | 4.5-6.0 | 0.6 | 0.5 | 0.1 | 0.1 | 0.1 | 0.05 | 0.2

LM 20 - | 0.4 | 0-15 | 10.0-13.0 | 0.7 | 0.5 | 0.1 | 0.2 | 0.1 | 0.05 | 0.2

LM 21 A | 2.0-4.0 | 0.15 | 4.0-6.0 | 0.8 | 0.3-0.7 | 0.3 | 2.0 | 0.1 | 0.05 | 0.2

LM 22 A 22 | 2.8-3.8 | 0.05 | 4.0-6.0 | 0.7 | 0.3-0.6 | 0.15 | 0.15 | 0.05 | 0.05 | 0.2

LM 23 - | 0.8-2.0 | 0.05-0.2 | 1.5-2.8 | 0.8-1.4 | 0.1 | 0.8-1.7 | 0.1 | 0.05 | 0.05 | 0.05-0.3

LM 24 A 24 | 3.0-4.0 | 0.1 | 7.5-9.5 | 1.3 | 0.5 | 0.5 | 1.0 | 0.3 | 0.2 | -

LM 25 A 25 | 0.1 | 0.2-0.45 | 6.5-7.5 | 0.5 | 0.3 | 0.1 | 0.1 | 0.1 | 0.05 | 0.2

LM 26 A 26 | 2.4 | 0.5-1.5 | 8.5-10.5 | 1.2 | 0.5 | 1.0 | 1.0 | 0.2 | 0.1 | 0.2

LM 27 A 27 | 1.5-2.5 | 0.3 | 6.0-8.0 | 0.8 | 0.2-0.6 | 0.3 | 1.0 | 0.2 | 0.1 | 0.2

LM 28 A 28 | 1.3-1.8 | 0.8-1.5 | 1.7-2.0 | 0.7 | 0.6 | 0.8-1.5 | 0.2 | 0.1 | 0.1 | 0.2

LM 29 A 29 | 0.8-1.3 | 0.8-1.3 | 2.2-2.5 | 0.7 | 0.6 | 0.8-1.5 | 0.2 | 0.1 | 0.1 | 0.2

LM 30 A 30 | 4.5 | 0.4 – 0.7 | 1.6-1.8 | 1.1 | 0.3 | 0.1 | 0.2 | 0.1 | 0.1 | 0.2

AISI-62 | 1.8-2.5 | 0.3-0.7 | 5.5-7.0 | 0.4 | 0.2-0.6 | 0.1 | - | - | - | 0.2

AISI-92 | 1.6-2.5 | 0.3-0.7 | 8.5-9.5 | 0.4 | 0.2-0.6 | 0.1 | - | - | - |

0.2

AISI-132 | 1.75-2.50 | 0.3 | 11.0-12.5 | 0.7-1.0 | 0.5 | 0.3 | - | - | - | -

Eicher Alloy | 0.1 | 1.4-1.8 | 5.0-6.0 | 0.4 | 0.1 | 0.2 | - | - | - |

0.2

ADC-10 Japanese| 2.0-4.0 | 0.3 Max | 7.5-9.5 | 1.3 Max | - | - | - | - | - | -

ADC-12 Specifn | 1.5-3.5 | 0.3 Max | 9.6-12.0 | 1.3 Max | - | - | - | - | - | -

AC-4B ,, | 2.0-4.0 | 0.5 Max | 7.0-10.0 | 1.0 Max | - | - | - | - | - | -

AC-8A ,, | 0.8-1.3 | 0.7-1.3 | 11.0-13.0 | 0.8 Max | - | - | - | - | - | -

JIS No. H 5202 | 0.25 Max | 9.3-0.6 | 8.10 | 0.55 Max | - | - | - | - | - | -

AC4A | | | | | | | | | |

_______________|__________ ___|_________ |__________ |_________ |________ |_______ |_______ |_______ |_______|________

N.B :- Master Alloys of Silicon, Copper, Manganese, Magnesium, Nickel etc., are also manufactured as per the specification required

by the customers.

===============================================================================================

Vous aimerez peut-être aussi

- Aluminium Alloy Ingots PDFDocument1 pageAluminium Alloy Ingots PDFraghulramasamyPas encore d'évaluation

- Aluminium Alloy Ingots PDFDocument1 pageAluminium Alloy Ingots PDFsingaravelan narayanasamyPas encore d'évaluation

- Aluminium Alloy Ingots PDFDocument1 pageAluminium Alloy Ingots PDFbashaPas encore d'évaluation

- Aluminium Chemical PropertieDocument9 pagesAluminium Chemical PropertieShreenivas ThakurPas encore d'évaluation

- Engineering Metallurgy by RA HigginsDocument5 pagesEngineering Metallurgy by RA HigginsAnonymous cgcKzFtXPas encore d'évaluation

- Project Report On Aluminium Dross Processing and Scrap Melting UnitDocument8 pagesProject Report On Aluminium Dross Processing and Scrap Melting UnitEIRI Board of Consultants and PublishersPas encore d'évaluation

- Adamite RollsDocument1 pageAdamite RollsPradeepPas encore d'évaluation

- All Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconDocument3 pagesAll Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconkartikPas encore d'évaluation

- Metal-Solid-Other BrammerDocument23 pagesMetal-Solid-Other BrammerĐức BkPas encore d'évaluation

- 204e1139-ecee-47eb-8cf4-d740c90a92a7Document4 pages204e1139-ecee-47eb-8cf4-d740c90a92a7digitallibrary972Pas encore d'évaluation

- Metal Solid OtherDocument23 pagesMetal Solid Otherdpk.kushwahPas encore d'évaluation

- Emisario Calc.1 CorrDocument7 pagesEmisario Calc.1 CorrVictor CaritaPas encore d'évaluation

- astm-b348-asme-sb348 не полныйDocument7 pagesastm-b348-asme-sb348 не полныйtit3dpowderPas encore d'évaluation

- Aluminum Raw Material Composition StandardDocument1 pageAluminum Raw Material Composition Standardatul sachanPas encore d'évaluation

- B 26 - B 26M - 02 - Qji2l0iynk0tukve PDFDocument16 pagesB 26 - B 26M - 02 - Qji2l0iynk0tukve PDFDaniel ReyesPas encore d'évaluation

- Moment Distribution MethodDocument101 pagesMoment Distribution MethodLourdesPas encore d'évaluation

- Figura 8 Dimensiones VENGEANCEDocument16 pagesFigura 8 Dimensiones VENGEANCERicPas encore d'évaluation

- Item ListDocument5 pagesItem ListMadhu BabuPas encore d'évaluation

- Sem AllDocument20 pagesSem AllDogol HarjonoPas encore d'évaluation

- Standard Specifications For Metal Casting TolerancesDocument1 pageStandard Specifications For Metal Casting TolerancesJohn ChanPas encore d'évaluation

- Research Paper MDMDocument100 pagesResearch Paper MDMLourdesPas encore d'évaluation

- MDM Frame 1-6 Frame A-FDocument202 pagesMDM Frame 1-6 Frame A-FLourdesPas encore d'évaluation

- MDM Example ComputationDocument100 pagesMDM Example ComputationLourdesPas encore d'évaluation

- TIP MDM ExampleDocument100 pagesTIP MDM ExampleLourdesPas encore d'évaluation

- MDM (5-Storey Condo)Document100 pagesMDM (5-Storey Condo)LourdesPas encore d'évaluation

- Moment-Distribution-Method Due To Dead Load (Frame A) : InertiaDocument100 pagesMoment-Distribution-Method Due To Dead Load (Frame A) : InertiaLourdesPas encore d'évaluation

- Cummins Acceptable Oil Consumption LimitsDocument1 pageCummins Acceptable Oil Consumption LimitsEKO RANDI100% (2)

- Dori - Lista de Corte Estrutura CozinhaDocument6 pagesDori - Lista de Corte Estrutura Cozinhaelezio batistaPas encore d'évaluation

- Metrados JaboDocument124 pagesMetrados JaboCatalina ChapoñanPas encore d'évaluation

- Electrification Products: Others DetailsDocument4 pagesElectrification Products: Others Detailsjoel marshallPas encore d'évaluation

- Lift StructureDocument24 pagesLift Structureahmad khalilurahmanPas encore d'évaluation

- NR CRT.: TP /TPDocument5 pagesNR CRT.: TP /TPLUCIAN BUZOIANUPas encore d'évaluation

- 1 Item MeasureDocument3 pages1 Item MeasureMusik&PuisiPas encore d'évaluation

- Shock Absorber Type Akcc Russian GostDocument2 pagesShock Absorber Type Akcc Russian Gostintel pcPas encore d'évaluation

- Akcc - 1Document2 pagesAkcc - 1intel pcPas encore d'évaluation

- Sudarea Otelurilor Stainless-HandbookDocument92 pagesSudarea Otelurilor Stainless-HandbookPetru AncaPas encore d'évaluation

- asme-ii-part-c-ed2019-specifications-for-welding-rods-electrodes-and-filler-metals-CHEMICAL COMPOSITIONpdfDocument1 pageasme-ii-part-c-ed2019-specifications-for-welding-rods-electrodes-and-filler-metals-CHEMICAL COMPOSITIONpdfBentles WrokPas encore d'évaluation

- Valve MOC and ImportantDocument22 pagesValve MOC and ImportantUdhayakumar VenkataramanPas encore d'évaluation

- Urals 304Document3 pagesUrals 304Himanshu SharmaPas encore d'évaluation

- TLug CatalogDocument27 pagesTLug Cataloglongyoko86Pas encore d'évaluation

- ESAB - Stainless Handbook PDFDocument92 pagesESAB - Stainless Handbook PDFfarshid KarpasandPas encore d'évaluation

- Codes For Staad Pro IndiaDocument185 pagesCodes For Staad Pro IndiamutashimaPas encore d'évaluation

- Stock Take Sistem SopDocument230 pagesStock Take Sistem Sopaldhy wahabPas encore d'évaluation

- Table: Joint Displacements Joint Outputcase Casetype Steptype Stepnum U1 U2 U3 R1Document8 pagesTable: Joint Displacements Joint Outputcase Casetype Steptype Stepnum U1 U2 U3 R1Chris M.Pas encore d'évaluation

- Surface Roughness-Conersion Chart TableDocument2 pagesSurface Roughness-Conersion Chart TableAnonymous w1yuNZTqONPas encore d'évaluation

- Test Report AngulosDocument2 pagesTest Report Angulosdeportesaldia2014Pas encore d'évaluation

- AS2074 CastSteel Specifications PDFDocument5 pagesAS2074 CastSteel Specifications PDFZac NastPas encore d'évaluation

- Bolted Joint DesignDocument12 pagesBolted Joint DesignsivagulfPas encore d'évaluation

- MassDocument5 pagesMassLenjerTVPas encore d'évaluation

- Perhitungan AbsorpsiDocument40 pagesPerhitungan AbsorpsizakariaPas encore d'évaluation

- Casting AlloysDocument2 pagesCasting Alloysgalvaosilva100% (1)

- Table: Element Forces - Frames Frame Station Outputcase Casetype P V2 V3 T M2Document6 pagesTable: Element Forces - Frames Frame Station Outputcase Casetype P V2 V3 T M2hendraPas encore d'évaluation

- Prediction of Effect of Process Parameters On Friction Stir Welded Joints of Dissimilar Aluminium Alloy AA2014 & AA6061 Using Taper Pin ProfileDocument10 pagesPrediction of Effect of Process Parameters On Friction Stir Welded Joints of Dissimilar Aluminium Alloy AA2014 & AA6061 Using Taper Pin ProfileR JPas encore d'évaluation

- Conexoes Tubulares Solda - 1470137516Document16 pagesConexoes Tubulares Solda - 1470137516Felipe Cruvinel DamascenoPas encore d'évaluation

- PEB 40x40 Trial 1 3Document4 pagesPEB 40x40 Trial 1 3sreerahPas encore d'évaluation

- ASTM A789 Duplex Stainless TubingDocument10 pagesASTM A789 Duplex Stainless Tubingmathew holeyPas encore d'évaluation

- Laser Cutting Process Parameters - O2&N2: Material Thickness Speed M/min Speed M/min Speed M/minDocument2 pagesLaser Cutting Process Parameters - O2&N2: Material Thickness Speed M/min Speed M/min Speed M/minbeemasundarPas encore d'évaluation

- Power Electronics and Electric Drives for Traction ApplicationsD'EverandPower Electronics and Electric Drives for Traction ApplicationsPas encore d'évaluation

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersD'EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersÉvaluation : 3.5 sur 5 étoiles3.5/5 (19)

- Reach Information Letter enDocument2 pagesReach Information Letter enbashaPas encore d'évaluation

- CopperDocument17 pagesCopperbashaPas encore d'évaluation

- B455Document3 pagesB455basha100% (1)

- v2 - Airbus Ds Supplier QuestionnaireDocument7 pagesv2 - Airbus Ds Supplier QuestionnairebashaPas encore d'évaluation

- Astm-B26-B26m Adoption Notice PDFDocument1 pageAstm-B26-B26m Adoption Notice PDFbashaPas encore d'évaluation

- Astm-A182 PDFDocument15 pagesAstm-A182 PDFbashaPas encore d'évaluation

- Astm B26/B26MDocument1 pageAstm B26/B26MbashaPas encore d'évaluation

- EvaluatingThe CAF ResistanceOfMulti-layered PWBsDocument17 pagesEvaluatingThe CAF ResistanceOfMulti-layered PWBsbashaPas encore d'évaluation

- Astm-A182 PDFDocument15 pagesAstm-A182 PDFbashaPas encore d'évaluation

- Science News Explores-June July 2023Document36 pagesScience News Explores-June July 2023Tobei AchimPas encore d'évaluation

- Kayako Support Suite User Manual PDFDocument517 pagesKayako Support Suite User Manual PDFallQoo SEO BaiduPas encore d'évaluation

- A CMOS Current-Mode Operational Amplifier: Thomas KaulbergDocument4 pagesA CMOS Current-Mode Operational Amplifier: Thomas KaulbergAbesamis RanmaPas encore d'évaluation

- ECO 101 Assignment - Introduction To EconomicsDocument5 pagesECO 101 Assignment - Introduction To EconomicsTabitha WatsaiPas encore d'évaluation

- AkDocument7 pagesAkDavid BakcyumPas encore d'évaluation

- LICDocument82 pagesLICTinu Burmi Anand100% (2)

- Engagement Letter TrustDocument4 pagesEngagement Letter Trustxetay24207Pas encore d'évaluation

- Entrep Q4 - Module 7Document5 pagesEntrep Q4 - Module 7Paula DT PelitoPas encore d'évaluation

- PartitionDocument5 pagesPartitionKotagiri AravindPas encore d'évaluation

- Switch CondenserDocument14 pagesSwitch CondenserKader GüngörPas encore d'évaluation

- SDFGHJKL ÑDocument2 pagesSDFGHJKL ÑAlexis CaluñaPas encore d'évaluation

- Durga Padma Sai SatishDocument1 pageDurga Padma Sai SatishBhaskar Siva KumarPas encore d'évaluation

- Tenancy Law ReviewerDocument19 pagesTenancy Law ReviewerSef KimPas encore d'évaluation

- VP Construction Real Estate Development in NY NJ Resume Edward CondolonDocument4 pagesVP Construction Real Estate Development in NY NJ Resume Edward CondolonEdwardCondolonPas encore d'évaluation

- Home Guaranty Corp. v. Manlapaz - PunzalanDocument3 pagesHome Guaranty Corp. v. Manlapaz - PunzalanPrincess Aliyah Punzalan100% (1)

- CSA Report Fahim Final-1Document10 pagesCSA Report Fahim Final-1Engr Fahimuddin QureshiPas encore d'évaluation

- Codex Standard EnglishDocument4 pagesCodex Standard EnglishTriyaniPas encore d'évaluation

- tdr100 - DeviceDocument4 pagestdr100 - DeviceSrđan PavićPas encore d'évaluation

- Mobile Based IVR SystemDocument17 pagesMobile Based IVR SystemIndraysh Vijay [EC - 76]Pas encore d'évaluation

- Bismillah SpeechDocument2 pagesBismillah SpeechanggiPas encore d'évaluation

- The Finley ReportDocument46 pagesThe Finley ReportToronto StarPas encore d'évaluation

- Sign Language To Speech ConversionDocument6 pagesSign Language To Speech ConversionGokul RajaPas encore d'évaluation

- Document 3Document3 pagesDocument 3AdelePas encore d'évaluation

- Risk Analysis and Management - MCQs1Document7 pagesRisk Analysis and Management - MCQs1Ravi SatyapalPas encore d'évaluation

- INTERNSHIP PRESENTATION - Dhanya - 2020Document16 pagesINTERNSHIP PRESENTATION - Dhanya - 2020Sanitha MichailPas encore d'évaluation

- Syed Hamid Kazmi - CVDocument2 pagesSyed Hamid Kazmi - CVHamid KazmiPas encore d'évaluation

- Algorithm - WikipediaDocument34 pagesAlgorithm - WikipediaGilbertPas encore d'évaluation

- 87 - Case Study On Multicomponent Distillation and Distillation Column SequencingDocument15 pages87 - Case Study On Multicomponent Distillation and Distillation Column SequencingFranklin Santiago Suclla Podesta50% (2)

- Business Testimony 3Document14 pagesBusiness Testimony 3Sapan BanerjeePas encore d'évaluation