Académique Documents

Professionnel Documents

Culture Documents

Agriculture Notes

Transféré par

neelTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Agriculture Notes

Transféré par

neelDroits d'auteur :

Formats disponibles

• Sprinkler selection and spacing: The required discharge of an individual sprinkler is a function of the water application rate and

the two-way spacing of the

sprinklers. It may be determined by the following formula: q Sl S m I ; in which, q = required discharge of individual sprinkler, litres/second; Sl = spacing of

360

sprinklers along the laterals, metres; Sm = spacing of laterals along the main, metres; I = optimum application rate, cm/hr.

Height of sprinkler riser pipes: The height of the risers depends upon the maximum height of the crop. To avoid excessive turbulence in the riser pipes, the

minimum height of riser is 30 cm when the riser pipe is of 2.5 cm diameter and 15 cm when it is of 1.8 to 2 cm diameter.

• Capacity of the Sprinkler System: depends on the size of the area to be irrigated (design area), the gross depth of water applied at each irrigation, and the net

operating time allowed to apply water to this depth. System capacity may be calculated as follow: Q 2780 A d ; in which, Q = discharge capacity of the pump,

FH E

litres/sec; A = area to be irrigated, hectares; d = net depth of water application, cm; F = number of days allowed for the completion of one irrigation; H = number of

actual operating hours/day; E = water application efficiency, %. F and H are of major importance as they have a direct bearing on the capital investment per hectare

required for equipment. Greater the product of these two factors (operating time) the smaller is the system capacity (hence the cost) for a given area.

• Hydraulic Design of sprinkler systems: The hydraulic design of sprinklers is aimed at obtaining a uniform irrigation coverage, the desired rate of application, the

breakup of sprinkler drops necessary to minimize structural deterioration of the soil surface, and the efficiency desired to reduce the energy requirement in

operating the system and to maximise the area of coverage. The main hydraulic principles involved in a sprinkler system design are given below.

Discharge of sprinkler nozzle: The discharge of a sprinkler nozzle may be computed from the following orifice flow formula derived by Toricelli:

3 2

q Cd a 2 gH ; in which, q = nozzle discharge, m /sec, a = cross-sectional area of nozzle or orifice, m , H = pressure head at the nozzle, metres, g =

acceleration due to gravity, m/sec2, Cd = coefficient of discharge which is a function of friction and contraction losses (the coefficient Cd of good nozzles should be

0.95 to 0.96).

Water spread area of sprinkler: The area covered by a rotating head sprinkler may be estimated by the following formula suggested by Cavazza: R 1.35 dH ;

in which, R = radius of wetted area covered by the sprinkler, metres, d = diameter of nozzle, metres, H = pressure head at the nozzle, metres. Maximum coverage is

attained when the jet emerges from the sprinkler at an angle of 30° to 32° above the horizontal. Most rotating sprinklers are standardised at 30°.

Break-up of jet: Some break-up of the jet of water is necessary to attain uniformity of coverage and to minimize the presence of excessively large drops. The larger

drops lose less velocity and travel farther. They also strike the soil surface at a higher velocity, with more energy to cause structural deterioration of the soil surface.

There is need for some compromise among distance of throw, uniformity of coverage, and effect on the soil surface. There is a natural tendency of jets to break-up

because of air resistance, and the break-up increases with pressure. The break-up is usually increased by having slots in the nozzle or by a pin impinging on the jet.

Slow rotation sprinklers, which make about 0.67 to 1 rpm for small sprinklers and 0.25 to 0.5 rpm for large sprinklers, provide good coverage. The following

empirical formula suggested by Tanda (Pillsbury, 1968) provides an index of jet break-up: P H 10q 0.4 ; in which Pd = index for jet break-up, H = pressure

d

head at nozzle, metres, q = sprinkler discharge, litres/sec. It has been noticed that if Pd is greater than 2, the condition of drop size is good; if 4, the condition of

drop size is best; and if greater than 4, pressure is being wasted.

Rate of application: The average rate of application, often called “precipitation intensity”, for a single sprinkler may be estimated by the following formula:

R

q in which Ra = water application rate, cm/hour, q = rate of discharge of sprinkler, litres/sec, A = wetted area of sprinkler, m2

360 A

a

• Design of Sprinkler Laterals: A sprinkler lateral has equally spaced sprinklers along its length. In the beginning the flow will equal the combined discharge of all

the sprinklers. This will decrease along the line until, at the farthest end, there will be only the flow of the last sprinkler. Therefore, the friction loss in a lateral will

be much less than if the total flow were carried through the entire length of the line. However, many authorities advise against „tapering‟ of pipe diameters in

laterals, as it then becomes necessary to keep the various pipe size in the same relative position. The system may also be less adaptable to other fields and

situations. It is recommended that the total pressure variation in the laterals, when practicable, should not be more than 20 % of the higher pressure. If the lateral

runs uphill or downhill, allowance for this difference in elevation should be made if determining the variation in head. If the water runs uphill, less pressure will be

available at the nozzle; if it runs downhill, there will be a tendency to balance the loss of head due to friction. It is necessary to compute the friction loss in the

lateral line where flow decreases along its length. A simple approximate procedure, devised by Christiansen (1942), has become standard. First, ascertain the

friction loss with full flow to the end of the line, using appropriate formulae or the values given in Appendix H, Table H1 to H5 (based on Scobey‟s formula). Next,

refer to Table given below for “F” factors by which the friction loss with full flow to the end of the line are multiplied to obtain the approximate friction loss in the

lateral. By this method and through trial and error, it will be possible to select a lateral of the proper size, so that the friction loss will not exceed that which is

allowable.

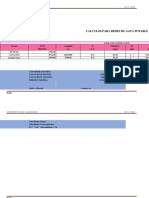

Table: Correction factor „F‟ for friction losses in aluminium pipes with multiple outlets

Correction factor F when Correction factor F when

Number of Number of

1st sprinkler is 1 1st sprinkler is ½ 1st sprinkler is 1 1st sprinkler is ½

sprinklers sprinklers on

sprinkler interval sprinkler interval sprinkler interval sprinkler interval

on lateral lateral

from main from main from main from main

1 1.000 1.000 16 0.365 0.345

2 0.625 0.500 17 0363 0.344

3 0.518 0.422 18 0.361 0.343

4 0.469 0393 19 0.360 0.343

5 0.440 0.378 20 0.359 0.342

6 0.421 0.369 22 0.357 0.341

7 0.408 0.363 24 0.355 0341

8 0398 0.358 26 0.353 0.340

9 0.391 0.355 28 0.351 0.340

10 0.385 0.353 30 0.350 0.339

11 0.380 0.351 35 0.347 0.338

12 0.376 0.349 40 0.345 0.338

13 0.373 0.348 50 0.343 0.337

14 0.370 0.347 100 0.338 0.337

15 0.367 0.346 > 100 0.335 0.335

The design capacity for sprinklers on a lateral is based on the average operating pressure. Where the friction loss, Hf, in the laterals is within 20 % of the

average pressure, the average head, Ha, for design in a sprinkler line can be expressed approximately by Ha = Ho + ¼ Hf; in which Ho is the pressure at the sprinkler

on the farthest end. Thus, the average pressure is equal to the pressure at the farthest end plus one-fourth the friction loss. Where the lateral is on nearly level land

or on the contour, the head (pressure) Hn at the main is Hn = Ho + Hf.

By Solving for Ho in equation Ha = Ho + ¼ Hf, by substituting in equation Hn = Ho + Hf and by making an allowance for differences in elevation along the

lateral. Hn = Ha + ¾ Hf ± ¾ He + Hr; in which, He = maximum difference in elevation between the first and last sprinklers on the lateral, metres, and Hr = the riser

height, metres. The term ¾ He is positive if the lateral runs up the slope and negative if it runs down the slope. This term is an approximation since the allowance

for the difference in elevation varies with the number of sprinklers on the lateral.

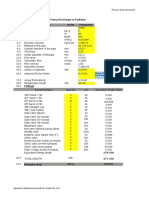

Pressure profile in sprinkler irrigation lateral laid uphill Pressure profile in sprinkler irrigation line laid downhill

• Main Line Pipe Size: The function of the main lines and sub-mains is to convey the required quantity of water at the desired pressure to all lateral lines under

maximum pressure conditions. The selection should be based on economic considerations. Main line friction loss of about 3 m for small systems and 12 m for large

systems may be allowed. The friction losses in main lines of the portable aluminium pipe can be determined Appendix H, Tables H1 and H3. Semi-rigid plastic

irrigation pipelines manufactured of PVC or asbestos compound are also used in sprinkler irrigation. In designing sprinkler irrigation, water may be pumped

through low pressure reinforced cement concrete (RCC) pipes to a booster pump employed to pump water directly in the laterals. Appendix H Tables H4 and H5

provide, respectively, the friction loss in PVC or asbestos compounds and asbestos cement pressure pipes.

• Pumps and power Units: In selecting a suitable pump, it is necessary to determine the total head against which the pump is working. This may be determined by:

Ht = Hn + Hm + Hj + Hs in which Ht = total design head against which the pump is working, m, Hn = maximum head required at the main to operate the sprinklers

on the lateral at the required average pressure, including the riser height, m, Hm = maximum friction loss in the main and in the suction line, m, Hj = elevation

difference between the pump and the junction of the lateral and the main, m, and Hs = elevation difference between the pump and the source of water after

drawdown, m. The amount of water that will be required is determined by multiplying the number of sprinklers by the capacity of each. When the total head and

rate of pumping are known, the pump may be selected from rating curves or tables furnished by the manufacturer.

Vous aimerez peut-être aussi

- Cylindrical Compression Helix Springs For Suspension SystemsD'EverandCylindrical Compression Helix Springs For Suspension SystemsPas encore d'évaluation

- Hydrometer AnalysisDocument5 pagesHydrometer Analysissubash chandra prustyPas encore d'évaluation

- 2021-ME-54 Lab ReportDocument31 pages2021-ME-54 Lab ReportAbdullah ArshadPas encore d'évaluation

- Vacuum PumpDocument20 pagesVacuum PumpRodrigo Heraldo Olmedo ViverosPas encore d'évaluation

- Nozzle Total Flow Area (TFA)Document1 pageNozzle Total Flow Area (TFA)MarcoAntonioSerranoBazanPas encore d'évaluation

- RCC Girder DesignDocument32 pagesRCC Girder DesignAnkush SharmaPas encore d'évaluation

- Minor Pipe CalculationsDocument16 pagesMinor Pipe CalculationsAbdul RahimPas encore d'évaluation

- Experiment No: 03 TitleDocument3 pagesExperiment No: 03 TitleKamran AliPas encore d'évaluation

- Berrien County Detention Pond Design Calculation SpreadsheetDocument2 pagesBerrien County Detention Pond Design Calculation SpreadsheetFernando De Jesús LemusPas encore d'évaluation

- Bench Drain Left Area Drainage CalculationsDocument7 pagesBench Drain Left Area Drainage CalculationsNur Syahira Afini Binti RamliPas encore d'évaluation

- Duct Pressure Loss Calculations For Air - Handling Units: Tersam UtilityDocument10 pagesDuct Pressure Loss Calculations For Air - Handling Units: Tersam UtilityVipul HodawdekarPas encore d'évaluation

- To Study and Draw The Characteristics Curve of Francis Turbine ObjectivesDocument5 pagesTo Study and Draw The Characteristics Curve of Francis Turbine ObjectivesMuhammad TaimoorPas encore d'évaluation

- Reporte SedimentscionDocument13 pagesReporte SedimentscionANDREA CAMARGOPas encore d'évaluation

- Part Number EE170950 - 171400, Tapered Roller Bearings - TS (Tapered Single) ImperialDocument5 pagesPart Number EE170950 - 171400, Tapered Roller Bearings - TS (Tapered Single) ImperialWildan PriatnaPas encore d'évaluation

- Waterpipe v1Document19 pagesWaterpipe v1NghiaPas encore d'évaluation

- Norgren Sizing Calculations Cylinder Sizing Calculations Force Pressure X Area of Piston (F PA)Document5 pagesNorgren Sizing Calculations Cylinder Sizing Calculations Force Pressure X Area of Piston (F PA)navneetPas encore d'évaluation

- Design Irrigation SystemDocument153 pagesDesign Irrigation Systemlsaishankar100% (1)

- 26.12.2018 Overview and Details Regarding Sewerage SchemesDocument51 pages26.12.2018 Overview and Details Regarding Sewerage SchemesAmandeep Singh100% (1)

- Major Losses ExperimentDocument5 pagesMajor Losses ExperimentMADHAVPas encore d'évaluation

- Rising Mail DesignDocument12 pagesRising Mail DesignBhupendra KumarPas encore d'évaluation

- Pressure Drop CalcDocument24 pagesPressure Drop CalcKorcan ÜnalPas encore d'évaluation

- RW Pipe CalculationDocument5 pagesRW Pipe Calculationrangarajan100% (1)

- ENG RS Drum Screen Data SheetDocument5 pagesENG RS Drum Screen Data Sheetflorencio medina pumaPas encore d'évaluation

- Mapua Hydraulics Lab Energy Loss ExperimentDocument12 pagesMapua Hydraulics Lab Energy Loss ExperimentNarciso Noel Sagun100% (1)

- 878 - Perhitungan Pompa ZevDocument7 pages878 - Perhitungan Pompa ZevzevanyaPas encore d'évaluation

- Calculos para Redes de Agua PotableDocument12 pagesCalculos para Redes de Agua Potablefelicitas herrera caceresPas encore d'évaluation

- Service Manual: For The HM40B and HM47B Rider Sweeper Sweeper For: Training Troubleshooting Adjustments JDocument39 pagesService Manual: For The HM40B and HM47B Rider Sweeper Sweeper For: Training Troubleshooting Adjustments JMiao MikePas encore d'évaluation

- AAMA Metal Curtain Wall FastenersDocument3 pagesAAMA Metal Curtain Wall FastenersAthumizPas encore d'évaluation

- Example Problems - 2017 - Hydraulic Fracturing in Unconventional ReservoirsDocument8 pagesExample Problems - 2017 - Hydraulic Fracturing in Unconventional ReservoirsAndré BrasilPas encore d'évaluation

- Experiment No 8Document4 pagesExperiment No 8sajid ullahPas encore d'évaluation

- Fluids EXPERIMENT 3Document9 pagesFluids EXPERIMENT 3Dazzle Njabs MbungelePas encore d'évaluation

- Sieve-Tray Tower Design and Operation PrinciplesDocument61 pagesSieve-Tray Tower Design and Operation PrinciplesM.H vafaeiPas encore d'évaluation

- RCC Girder DesignDocument15 pagesRCC Girder DesignAnkush Sharma100% (2)

- Analysis of Lines To API-650 NozzlesDocument112 pagesAnalysis of Lines To API-650 NozzleszahoorPas encore d'évaluation

- Lab 4 EXP 7Document16 pagesLab 4 EXP 7LiHong KhawPas encore d'évaluation

- Kartas2019 Article SelectionOfTheTurbulentViscosiDocument5 pagesKartas2019 Article SelectionOfTheTurbulentViscosiLilou MGKPas encore d'évaluation

- Standard Taper Pipe Threads NPT Basic Dimensions, American National StandardDocument3 pagesStandard Taper Pipe Threads NPT Basic Dimensions, American National StandardEku AkhmadPas encore d'évaluation

- Base Plate & Anchor Bolt - BP1Document20 pagesBase Plate & Anchor Bolt - BP1munishant1Pas encore d'évaluation

- Module 4.1 Angle MeasurementDocument29 pagesModule 4.1 Angle MeasurementonemillionsubinPas encore d'évaluation

- Hydraulic Calculation For 18+430Document16 pagesHydraulic Calculation For 18+430designbridgeeng geo groupPas encore d'évaluation

- HY-8 Culvert Analysis ReportDocument9 pagesHY-8 Culvert Analysis ReportVYOINGENIERIA SASPas encore d'évaluation

- Review - 2 - 20bt01d079Document25 pagesReview - 2 - 20bt01d079Jay Sheth9Pas encore d'évaluation

- Cuadro de unidades de gasto y presión requeridaDocument11 pagesCuadro de unidades de gasto y presión requeridaLeo VelasquezPas encore d'évaluation

- Stair Case Pressurization - DARDocument4 pagesStair Case Pressurization - DARminn pyae son ePas encore d'évaluation

- Slab Thickness: Short Length FT Long Length FT 2.133333Document18 pagesSlab Thickness: Short Length FT Long Length FT 2.133333Saeed AyeenPas encore d'évaluation

- Experiment 5 DrawDocument16 pagesExperiment 5 DrawmonPas encore d'évaluation

- Lab 7Document7 pagesLab 7Falcon TechPas encore d'évaluation

- Hydraulic Analysis On Highway CulvertDocument8 pagesHydraulic Analysis On Highway CulvertWai linn zawPas encore d'évaluation

- Irrigation System EvaluationDocument44 pagesIrrigation System Evaluationmatyanga samuelPas encore d'évaluation

- Pressure Drop Calculation ExampleDocument1 pagePressure Drop Calculation ExamplePANDIARAJ KARUPPATHEVARPas encore d'évaluation

- Clarifier BrochureDocument12 pagesClarifier Brochuregesap35224Pas encore d'évaluation

- Tutorial 1Document12 pagesTutorial 1MAHLATSE MULALAPas encore d'évaluation

- Example Design of A Yagi-Uda AntennaDocument9 pagesExample Design of A Yagi-Uda AntennaKiều DũngPas encore d'évaluation

- Sediment Basin DesignDocument8 pagesSediment Basin DesignAgus FirdausPas encore d'évaluation

- Storage Outflow RoutingDocument5 pagesStorage Outflow RoutingMaricar De LeonPas encore d'évaluation

- Cooling of CPU Fan PDFDocument10 pagesCooling of CPU Fan PDFLeonard LiangPas encore d'évaluation

- Quantity Surveying: Sub-Structure Concrete WorksDocument56 pagesQuantity Surveying: Sub-Structure Concrete WorksrssdpmPas encore d'évaluation

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2D'EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2Pas encore d'évaluation

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementD'EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementPas encore d'évaluation

- Home Work CEM 601 Design of Steel ElementsDocument2 pagesHome Work CEM 601 Design of Steel ElementsneelPas encore d'évaluation

- COVID 19 Impact on Education - Dramatic Changes at All LevelsDocument2 pagesCOVID 19 Impact on Education - Dramatic Changes at All LevelsneelPas encore d'évaluation

- Home Work-Cem607Document2 pagesHome Work-Cem607neelPas encore d'évaluation

- Home Work - Cem605Document5 pagesHome Work - Cem605neelPas encore d'évaluation

- 18 - Chapter 9 PDFDocument14 pages18 - Chapter 9 PDFneelPas encore d'évaluation

- Structural Stability and Design Course OverviewDocument146 pagesStructural Stability and Design Course OverviewAghil BuddyPas encore d'évaluation

- Declaration For Refund Processing 18 - 20Document1 pageDeclaration For Refund Processing 18 - 20neelPas encore d'évaluation

- CEM 602 HomeWorkDocument5 pagesCEM 602 HomeWorkneelPas encore d'évaluation

- B.Tech (6th Semester), End Semester Examination (Home Assignment), March 2020Document1 pageB.Tech (6th Semester), End Semester Examination (Home Assignment), March 2020neelPas encore d'évaluation

- Live Class Notes Vaibhav Sir 09 12 2021Document87 pagesLive Class Notes Vaibhav Sir 09 12 2021neelPas encore d'évaluation

- Floor PlansDocument4 pagesFloor PlansneelPas encore d'évaluation

- Flutter Bootcamp SyllabusDocument3 pagesFlutter Bootcamp SyllabusWahyu Tri Prasetyo0% (1)

- Structural Planning As Per Is 456 2000 and Is 13920 2016Document6 pagesStructural Planning As Per Is 456 2000 and Is 13920 2016neelPas encore d'évaluation

- Parent consent for student safety protocolsDocument2 pagesParent consent for student safety protocolsneelPas encore d'évaluation

- Invitation Letter Format Charpak LabDocument1 pageInvitation Letter Format Charpak LabneelPas encore d'évaluation

- New COVID-19 travel protocols for passengers to and from NepalDocument2 pagesNew COVID-19 travel protocols for passengers to and from NepalneelPas encore d'évaluation

- Structure Lab FileDocument36 pagesStructure Lab FileneelPas encore d'évaluation

- Revised M.Tech Curricula in Civil Engineering SpecializationsDocument32 pagesRevised M.Tech Curricula in Civil Engineering SpecializationsMunaganti KiranPas encore d'évaluation

- QB CEM611 Modified - Jinshad PDFDocument9 pagesQB CEM611 Modified - Jinshad PDFneelPas encore d'évaluation

- QB CEM611 Modified - Jinshad PDFDocument9 pagesQB CEM611 Modified - Jinshad PDFneelPas encore d'évaluation

- Cem 711 Sustainable Construction DHA No: 6Document2 pagesCem 711 Sustainable Construction DHA No: 6neelPas encore d'évaluation

- Ais-11 Half Yearly PaperDocument4 pagesAis-11 Half Yearly PaperneelPas encore d'évaluation

- CEM603 - Home WorkDocument1 pageCEM603 - Home WorkneelPas encore d'évaluation

- Properties of MilkDocument1 pageProperties of MilkneelPas encore d'évaluation

- QBQDocument5 pagesQBQneelPas encore d'évaluation

- Engineering Geology Course MaterialDocument220 pagesEngineering Geology Course Materialshersinghb12Pas encore d'évaluation

- 2D Triangular ElementsDocument24 pages2D Triangular ElementsAmmir SantosaPas encore d'évaluation

- PhotogrammetryDocument36 pagesPhotogrammetryneelPas encore d'évaluation

- 7 PDFDocument8 pages7 PDFneelPas encore d'évaluation

- Comparison of Kennedy's and Lacey's TheoriesDocument1 pageComparison of Kennedy's and Lacey's TheoriesneelPas encore d'évaluation

- Flow Properties of Stirred Yogurt Calculation of The PDFDocument22 pagesFlow Properties of Stirred Yogurt Calculation of The PDFandres332Pas encore d'évaluation

- Omv Comp VDL S 100Document2 pagesOmv Comp VDL S 100Robert IsacPas encore d'évaluation

- CNG Valves Automatic CylinderDocument1 pageCNG Valves Automatic CylinderMisaelPas encore d'évaluation

- Abstract/Summary: V K M DP DLDocument17 pagesAbstract/Summary: V K M DP DLAdnan Nanda100% (1)

- Water Conservation at Different Levels: Module - 8ADocument21 pagesWater Conservation at Different Levels: Module - 8Aarjmandquest100% (2)

- Phy 061 Chapter 7 Fluid MechanicsDocument5 pagesPhy 061 Chapter 7 Fluid MechanicsAngel Lou LiwagonPas encore d'évaluation

- PSV-1404Document1 pagePSV-1404Tomás MercadoPas encore d'évaluation

- Review in Causes of Viscosity in FluidsDocument7 pagesReview in Causes of Viscosity in FluidsSaryth Darianna Cardenas FPas encore d'évaluation

- Hydrostatic ThrustDocument9 pagesHydrostatic ThrustAngelica Gicom100% (1)

- Pressure Drop Measurements in Distillatio ColumnsDocument5 pagesPressure Drop Measurements in Distillatio Columnsdonya100% (1)

- Water Safety Flow Control & BFP ProductsDocument140 pagesWater Safety Flow Control & BFP ProductsLuis Gabriel BautistaPas encore d'évaluation

- Fundamentals of Orifice Metering FMCDocument7 pagesFundamentals of Orifice Metering FMCapply19842371Pas encore d'évaluation

- Ce-413 Lab1Document7 pagesCe-413 Lab1VOJPas encore d'évaluation

- Bobcat T2556 Hydraulic Schematic PDFDocument3 pagesBobcat T2556 Hydraulic Schematic PDFAnonymous HxADrI1bPas encore d'évaluation

- Dari Chemical Engineering Design Principles, Practice and Economics of Plant and Process DesignDocument5 pagesDari Chemical Engineering Design Principles, Practice and Economics of Plant and Process DesignJulius Ferdinand TariganPas encore d'évaluation

- Hi Ride Mud HopperDocument4 pagesHi Ride Mud HopperAnonymous VNu3ODGav100% (1)

- Chapter 25 Drinking Water 2010Document11 pagesChapter 25 Drinking Water 2010Jenny NgoPas encore d'évaluation

- IE - LESSON 11 Open Channel FlowDocument8 pagesIE - LESSON 11 Open Channel FlowEfremWakjiraHodePas encore d'évaluation

- Gmail - Quality Grade 99.9% Virgin and Recycled Base Oil SN150, SN350, SN500, SN650 For Sale..Document4 pagesGmail - Quality Grade 99.9% Virgin and Recycled Base Oil SN150, SN350, SN500, SN650 For Sale..stalin fernandesPas encore d'évaluation

- A Review On Design and Flow Simulation in An Axial Flow Hydro TurbineDocument3 pagesA Review On Design and Flow Simulation in An Axial Flow Hydro TurbineAron H OcampoPas encore d'évaluation

- Artificial LiftDocument11 pagesArtificial Liftdriller22100% (2)

- Reservoir Unit MDDF TVDDF Tvdss Gradient Pressure: InternalDocument27 pagesReservoir Unit MDDF TVDDF Tvdss Gradient Pressure: InternalYber LexPas encore d'évaluation

- Degassing Boot SizingDocument31 pagesDegassing Boot SizingRexx Mexx50% (2)

- APEXDocument1 pageAPEXsswahyudiPas encore d'évaluation

- 9com No PDFDocument2 pages9com No PDFbalajiPas encore d'évaluation

- 250 LPH Ro PlantDocument4 pages250 LPH Ro PlantKamatchi NathanPas encore d'évaluation

- 05 V4+R VRF Service ManualDocument104 pages05 V4+R VRF Service ManualMAQNAARZH COOLTECHPas encore d'évaluation

- Ijes Project FileDocument17 pagesIjes Project FilebhargavPas encore d'évaluation

- Compression Stations and Pumping by Erick Martin Ceballos RetanaDocument14 pagesCompression Stations and Pumping by Erick Martin Ceballos RetanaerickPas encore d'évaluation

- AMSOIL European Motor - 5W40Document2 pagesAMSOIL European Motor - 5W40Rafael Canizares ChiarandiPas encore d'évaluation