Académique Documents

Professionnel Documents

Culture Documents

Polymer Centralizer

Transféré par

wijiestCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Polymer Centralizer

Transféré par

wijiestDroits d'auteur :

Formats disponibles

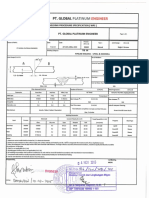

RUBICON OILFIELD INTERNATIONAL 32

Cementing Accessories: EzeeGLIDER®

A highly durable, wear-resistant

engineered polymer centralizer The tool has demonstrated

that reduces torque and drag and field proven lower friction

does not bind or jam. Increases the coefficients, leading to

length of open hole completion to superior drag and rotational

provide additional reservoir exposure. torque reduction

Applications

Benefits

• Sand screen and multi-lateral completions

• Extends the current well construction boundaries

• Extended reach/horizontal wells on ERD and highly deviated wells

• Cemented or non-cemented horizontal liners • Increases length of open hole completion

• Deploying deep set packers providing additional reservoir exposure

• Tough open hole conditions • Allows wells from fixed locations to access

bypassed oil

• Can eliminate the need for other friction reduction

tools

PRIVATE AND CONFIDENTIAL

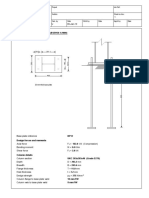

RUBICON OILFIELD INTERNATIONAL 33

Cementing Accessories: OptiMIZER™

A highly economical down-hole

centralization product with a low The tool has demonstrated

carbon footprint. High abrasion field proven lower friction

resistant proprietary engineered coefficients, leading to

polymer ensures maximum stand-off drag and rotational

superior dr

at TD. torque reduction

red

.

Applications

Benefits

• Lower sand screen

reen and multi

multi-lateral

lateral

completions • Proven to pass through casing exits and MLT

windows without snagging with metal debris

• Extended reach/horizontal wells causing casing or liners to stick

• Cemented or non-cemented horizontal liners • Provides thermal insulation/centralization on

• Deploying deep set packers production completions where the oil is waxy

• Tough open hole conditions • Protection of open hole packers/accessories on

long horizontal deployments such as multi zone

• Rotating cemented liners

fracture stimulation

PRIVATE AND CONFIDENTIAL

RUBICON OILFIELD INTERNATIONAL 35

Cementing Accessories: EzeeGLIDER®

High Strength Polymer Physical Comparison Matrix Typical EzeeGLIDER® OptiMIZER

Thermoset Composite Composite

Plastic

Properties Test Standard Units Values Values Values

Specific Gravity ASTM D792 g/cm3 1.03 1.56 1.55

Linear Mold Shrinkage ASTM D955 inches 0.009—0.011 0.0015 0.007

Tensile Strength @ Yield ASTM D638 psi 7,300 33,707 33,400

Tensile Modulus ASTM D638 psi 260,000 2,364,111 2,470,000

Flexural Modulus ASTM D790 psi 280,000 2,140,000 2,250,000

Flexural Strength ASTM D790 psi 11,000 58,740 46,400

Compressive Strength (@ Yield) ASTM D695 psi 8,788 39,600 37,600

Impact Strength Notched Izod @

ASTM D256 ft-lbs/in2 14 14 7

23° C

Static Coefficient of Friction ASTM D1894-08 μ 0.35 0.13 0.16

Kinetic Coefficient of Friction ASTM D1894-08 μ 0.31 0.13 0.16

Heat Deflect. Temp. (264 psi) ASTM D648 °C/°F 141/286 255/491 210/410

Note that figures for typical Thermoset plastic product are taken from competitor published information and Engineer’s Handbook for typical thermoset plastic materials

Rubicon Composites are significantly superior over

typical thermoset plastic type products

PRIVATE AND CONFIDENTIAL

RUBICON OILFIELD INTERNATIONAL 36

Cementing Accessories: EzeeGLIDER®

PRIVATE AND CONFIDENTIAL

RUBICON OILFIELD INTERNATIONAL 37

EzeeGLIDER®: Field Proven Friction Reduction Centralizers

Application Features

• Well: Bi-Lateral Well, Novara Field, Offshore Australia • Fiber-Reinforced Polymer composite centralizers with

• 9-5/8” Casing Depth: 1927. 52mMD (Step Out ratio: 2.97) ultra-low friction co-efficient.

• Challenge: To deploy 5.5”, 17# JFE Bear Screens with Swell • High durability and wear resistance

Packers and 2-7/8” 6.4ppf washpipe into Main Bore and • Thermal stability and insulation

Lateral #1 at maximum well inclination of 90deg.

• Melon shaped blade profile to ride over ledges, milled

• Main Bore: 8-1/2” HS TD @ 3580mMD windows and washouts.

– 16 stands x 5” DP • Patented EzeeGLIDER steel rings are fitted on each end

– 29 stands x 5” HWDP to maximize load capacity

– 20 stands x 5” DP

– 9-5/8” VCH Packers

– 23 joints x 5-1/2" 17# JFE Bear Blank Pipe

– 114 joints x 5-1/2”, 17# JFE Bear Screens + Swell

Packers + 2 7/8" 6.4ppf TSH 511 Wash Pipes

• Lateral #1: 8-1/2” HS TD @ 3857mMD

– 13 stands x 5” DP Benefits

– 29 stands x 5” HWDP • By running low friction composite EzeeGLIDER

– 20 stands x 5” DP centralizers at 1/joint on the completion screens, the

– 9-5/8” VCH Packers final Open Hole friction factor have reduced significantly

– 29 joints x 5-1/2" 17# JFE Bear Blank Pipe down to 0.2 in Main Bore and 0.23 in Lateral #1.

– 138 joints x 5-1/2”, 17# JFE Bear Screens + Swell • The EzeeGLIDER helped to lubricate the completion

Packers + 2 7/8" 6.4ppf TSH 511 Wash Pipes screens, reduces frictional drag along open hole section

and provided more weight for successful screens

• Completions Solutions: Rubicon supplied the 5-1/2” x 8- deployment.

1/4” Fiber-Reinforced Polymer composite EzeeGLIDER® • The installation of the EzeeGLIDER was efficient, thanks

centralizers to reduce frictional drag whilst RIH completion to their very light weight feature that improved overall

screens. operation and towards safer manual handling.

PRIVATE AND CONFIDENTIAL

RUBICON OILFIELD INTERNATIONAL 38

EzeeGLIDER®: Field Proven Friction Reduction Centralizers

Main Bore: 8-1/2” HS TD @ 3580mMD

Actual data vs Model:

9-5/8” casing

Global CHFF 0.2 & OHFF 0.2

shoe

PRIVATE AND CONFIDENTIAL

RUBICON OILFIELD INTERNATIONAL 39

EzeeGLIDER®: Field Proven Friction Reduction Centralizers

Lateral #1: 8-1/2” HS TD @ 3,857mMD

Actual data vs Model:

9-5/8” casing

Global CHFF 0.15 & OHFF 0.23

shoe

PRIVATE AND CONFIDENTIAL

Vous aimerez peut-être aussi

- P 902 CIGWELD (January 6, 2020)Document3 pagesP 902 CIGWELD (January 6, 2020)wijiestPas encore d'évaluation

- PT Sagatrade Murni: Appendix 1 Welded Joint Analysis & Base Metal Approval by Our Engineer Based On The Product FunctionDocument4 pagesPT Sagatrade Murni: Appendix 1 Welded Joint Analysis & Base Metal Approval by Our Engineer Based On The Product FunctionwijiestPas encore d'évaluation

- 1487 400 08 0616Document1 page1487 400 08 0616kalpesh parmarPas encore d'évaluation

- Brazing DescriptionDocument80 pagesBrazing Descriptiondanish0% (1)

- Cutting Process and EquipmentDocument8 pagesCutting Process and EquipmentwijiestPas encore d'évaluation

- Chapter 1D - OhjiDocument15 pagesChapter 1D - OhjiwijiestPas encore d'évaluation

- Furnace Hardening CNCDocument1 pageFurnace Hardening CNCwijiestPas encore d'évaluation

- Current Vs Wire Feed Speed For GmawDocument2 pagesCurrent Vs Wire Feed Speed For GmawwijiestPas encore d'évaluation

- Filler Material Selection GuideDocument32 pagesFiller Material Selection GuidemaknilePas encore d'évaluation

- WPS Example API 5LDocument13 pagesWPS Example API 5LwijiestPas encore d'évaluation

- Jsa 037Document1 pageJsa 037wijiestPas encore d'évaluation

- Fillet Weid Break and Macroetch Test PlateDocument1 pageFillet Weid Break and Macroetch Test PlatewijiestPas encore d'évaluation

- D7438 13 Standard Practice For Field PDFDocument10 pagesD7438 13 Standard Practice For Field PDFwijiest100% (1)

- Estimasi Biaya Build Axle BoxDocument1 pageEstimasi Biaya Build Axle BoxwijiestPas encore d'évaluation

- 76 Conversion de PresionDocument1 page76 Conversion de PresionEGROJDIVADPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Mechanical PropertiesDocument65 pagesMechanical PropertiesAdamSyukurPas encore d'évaluation

- Heat and Mass Transfer Contoh SoalDocument8 pagesHeat and Mass Transfer Contoh Soalaulia sarahPas encore d'évaluation

- Handbook Review Temporaywork Deep ExcavationDocument59 pagesHandbook Review Temporaywork Deep ExcavationKen LiewPas encore d'évaluation

- Chapt2 PDFDocument4 pagesChapt2 PDFDrjasmeet KaurPas encore d'évaluation

- WST - Hydraulic Fracturing Part 1 - S12020 PDFDocument23 pagesWST - Hydraulic Fracturing Part 1 - S12020 PDFShadishwaren ParameswaranPas encore d'évaluation

- Dielectrics: Unit V Dielectric MaterialsDocument20 pagesDielectrics: Unit V Dielectric MaterialsSpyx MeniPas encore d'évaluation

- Metal-Graphene Interfaces in Epitaxial and Bulk Systems (A Review) PDFDocument57 pagesMetal-Graphene Interfaces in Epitaxial and Bulk Systems (A Review) PDFAlejoVélezFernándezPas encore d'évaluation

- BEM PH613 Semester Exam Question PaperDocument1 pageBEM PH613 Semester Exam Question PaperAdarsh ChaturvediPas encore d'évaluation

- BS 7591-1-1992 - (2020-12-09 - 03-49-15 PM)Document16 pagesBS 7591-1-1992 - (2020-12-09 - 03-49-15 PM)benderman1Pas encore d'évaluation

- Tubular Chord Check Using Roark's Formula - Validation Type12 - 07-12-2019Document8 pagesTubular Chord Check Using Roark's Formula - Validation Type12 - 07-12-2019Pop JiPas encore d'évaluation

- Chapter 3 - The Structures of Crystalline SolidsDocument10 pagesChapter 3 - The Structures of Crystalline Solidstamania naeemPas encore d'évaluation

- PreviewpdfDocument41 pagesPreviewpdfJulio Cesar Tapia ReyesPas encore d'évaluation

- Spherical Plain BearingsDocument8 pagesSpherical Plain Bearingsabooali_abbadan4684Pas encore d'évaluation

- Scratch Test Methodology For Leadframe PlatingDocument5 pagesScratch Test Methodology For Leadframe PlatingMohamad Adli AbdullahPas encore d'évaluation

- Engineering MaterialsDocument9 pagesEngineering MaterialsJevan CalaquePas encore d'évaluation

- Datos Tecnicos ViscosimetroDocument12 pagesDatos Tecnicos ViscosimetroJose MxyzPas encore d'évaluation

- Viscous FlowDocument31 pagesViscous FlowNavinan SubramaniamPas encore d'évaluation

- Instabilities, Chaos, and Turbulence - Manneville PDFDocument406 pagesInstabilities, Chaos, and Turbulence - Manneville PDFFinalDanishPas encore d'évaluation

- Nanyang Technological University: Manufacturing Lab ReportDocument5 pagesNanyang Technological University: Manufacturing Lab ReportPrayogo TioPas encore d'évaluation

- Ce Mo 3Document12 pagesCe Mo 3Tanvir HossainPas encore d'évaluation

- Designation: E1867 13Document5 pagesDesignation: E1867 13Lupita RamirezPas encore d'évaluation

- Resnick Halliday Krane Vol 2Document695 pagesResnick Halliday Krane Vol 241Kevin Thomas XI-B100% (1)

- MagnesiumDocument9 pagesMagnesiumNAVNEET PARASHARPas encore d'évaluation

- Downhole Tubing/casingDocument6 pagesDownhole Tubing/casingDwiki RamadhaniPas encore d'évaluation

- Neha Nylon 6,6Document16 pagesNeha Nylon 6,6sakshi ranadePas encore d'évaluation

- Callister - Concept Check AnswersDocument58 pagesCallister - Concept Check AnswersGöksun Güven75% (4)

- Seismic Control Device PDFDocument60 pagesSeismic Control Device PDFRaden Budi HermawanPas encore d'évaluation

- Grobs Basic Electronics 13Th Edition Mitchel E Schultz Full ChapterDocument51 pagesGrobs Basic Electronics 13Th Edition Mitchel E Schultz Full Chapterbrandon.henderson521100% (6)

- BP2Document3 pagesBP2insane88Pas encore d'évaluation

- What Is Thermodynamics?: Course Catalog My ClassesDocument8 pagesWhat Is Thermodynamics?: Course Catalog My ClassesJosePas encore d'évaluation