Académique Documents

Professionnel Documents

Culture Documents

Rotar Plus 30 STC - 00 - GB

Transféré par

sebastianTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Rotar Plus 30 STC - 00 - GB

Transféré par

sebastianDroits d'auteur :

Formats disponibles

GB

use & maintenance

MANUAL

Rotar Plus

30 STC

Rotar Plus 30 STC - cod197AA3710 - Rev.00 02/2010

GENERAL INFORMATION GB

GENERAL INFORMATION .............................................. 3

SAFETY INDICATIONS .................................................. 4

INSTALLATION ................................................................ 6

TECHNICAL DATA ........................................................... 7

CONTROLS AND SETTINGS .......................................... 8

CONTROL FUNCTIONS ................................................ 10

OPERATION .................................................................. 11

START-UP ...................................................................... 11

MAINTENANCE ............................................................. 12

TROUBLESHOOTING ................................................... 15

WIRING DIAGRAM ........................................................ 16

STANDARD EQUIPMENT

Your compressor is delivered with the following accessories:

• user’s guide

• anti-vibration elements

• line cock + connection hose and Teflon tape

• key to open panels / electric box

• oil/condensate exhaust tube

Check that standard equipment is supplied with the machine. No claims after delivery will be accepted.

CONDITION OF THE MACHINE WHEN SUPPLIED

Every compressor is shop tested and delivered ready to be installed and put into operation.

Used oil is: RotEnergy Plus.

Rotar Plus 30 STC - cod197AA3710 - Rev.00 02/2010 3

GB SAFETY INDICATIONS

GENERAL

• Rotary compressors are intended for heavy continuous industrial use. They are especially suitable for industrial applications

requiring high air consumption for a long time.

• The compressor should be run and operated only in compliance with the indications given in this manual. Safely keep

this manual in a known and easily reachable place for the whole working life of the compressor.

• A supervisor shall be appointed in the company, in which the compressor is installed. He/she shall be responsible for

compressor inspections, adjustments and maintenance. Should a substitute be appointed for the supervisor, he/she shall

carefully read the user’s guide and all possible comment on service and maintenance carried out so far.

SYMBOLS USED IN THE MANUAL

Some symbols are used to highlight danger situations, give recommendations or information. These symbols are usually

positioned next to the text, a figure or at the top of a page (in this case they refer to all subjects dealt with in that page).

Carefully read symbol meaning below.

CAUTION! POWER OFF!

Important description on service, dangerous All operations to be strictly carried out only after

situation, safety, accident prevention powering off the machine.

recommendations and/or very important

information.

STOP MACHINE! SPECIALIZED PERSONNEL!

All operations to be strictly carried out only after All operations to be strictly carried out only by

stopping the machine. specialized technician.

SYMBOLS ON THE COMPRESSOR

The compressor has several labels to highlight possible danger and give recommendations on what to do during machine

operation or in special situations.

Please comply with these indications.

Danger! Hot! Prohibited! Do not open doors during

compressor operation

Prohibited! Press emergency button for

Danger! Electric shock! compressor immediate stop. Do not use line knife

switch.

Danger! Hot gas or harmful gas within working Prohibited! Do not use water on electric

area equipment to extinguish fire.

Danger! Pressurized container

Compulsory! Read instructions for use carefully.

Danger! Mechanical moving parts

Caution! Maintenance works in progress

4 Rotar Plus 30 STC - cod197AA3710 - Rev.00 02/2010

SAFETY INDICATIONS GB

WHAT TO DO:

Make sure that mains voltage corresponds to the voltage indicated on CE plate and that cable of suitable cross-section are

used for electric connections.

Always check oil level before starting the compressor.

Be familiar with emergency stop control and all other controls.

Unplug the connector before any maintenance work, so to avoid accidental start.

Ensure that all parts have been correctly reassembled after any maintenance work.

Keep children and animals off the working area to avoid injuries caused by devices connected to the compressor.

Ensure that temperature of the working environment ranges between +2 and + 45 ºC. Compressor working temperature

shall range between 70÷85°C (>20-25°C room temperature). Lower temperatures may causes condensate accumulation

inside the oil separator tank (inside the compressor). Check for condensate and if necessary, drain it (see maintenance).

The compressor should be installed and operated in a non-explosive environment.

Allow at least 80 cm between the compressor and the wall so to allow free air flow to the fan.

Press the emergency button on the control panel only in case of actual need so as to avoid possible damages to people or the

very compressor.

When calling for technical assistance and/or advice, always mention model and serial number indicated on CE plate.

Always follow the maintenance schedule specified in the user’s guide.

WHAT NOT TO DO:

Do not touch inner parts and pipes as they are very hot during compressor operation and stay hot for a certain time after

compressor stops.

Do not position inflammable or nylon objects or cloths close to and onto the compressor.

Do not move the compressor when the tank is under pressure.

Do not operate the compressor if the power cable is damaged or defective or if connection is unstable.

Do not operate the compressor in wet or dusty environments.

Never aim the air jet at people or animals.

Do not allow unauthorized people to operate the compressor and give them all required instructions.

Do not hit fans with blunt objects as they might break during compressor operation.

Never operate the compressor without air filter.

Do not tamper with safety and adjusting devices.

Never operate the compressor when doors/panels are open or removed.

PRODUCT IDENTIFICATION

The compressor Your have purchased has its own CE plate showing the following data:

1) Manufacturer’s data

2) CE mark – year of manufacture

3) TYPE = name of the compressor

CODE = compressor code

SERIAL NO. = serial number of the compressor You have purchased (to be always mentioned when calling for technical

assistance)

4) air delivered by the compressor expressed in (l/min) and (cfm)

5) max. operating pressure (bar and PSI) – compressor noise level in dB(A)

6) electric data: voltage (V/ph), frequency (Hz), absorption (A) - power (HP and kW), rotations per minute (Rpm).

7) other approvals

Rotar Plus 30 STC - cod197AA3710 - Rev.00 02/2010 5

GB INSTALLATION

COMPRESSOR DESCRIPTION (FIG. 1)

Compressors which are described in this guide are intended for industrial use. Models may include different outfit with/

without tank and/or drier.

The compressor essentially consists of the following:

1) Air/oil radiator 7) Motor

2) Electrical equipment 8) Screw compressor

3) Control panel 9) Suction regulator

4) Oil separator reservoir 10) Air filter

5) Oil separator filter 11) Oil filter

6) Minimum pressure valve 12) Inverter area

13) Inverter

UNPACKING AND HANDLING THE COMPRESSOR

The compressor is usually shipped to the customer with a carton cover.

Wear protective gloves and cut outer straps. Then remove the carton cover from the top. Before removing the compressor,

make sure it is intact (outside), open access doors and visually check components for damage. Check that all accessories are

included.

Lift the machine using a fork lift truck. Fit the anti-vibration elements into their seats and move the machine to the room

chosen for its location with maximum care.

Keep the packing material in case the compressor needs to be re-located. Keep the packing material at least for the whole

warranty period so that it can be used to safely deliver the compressor to the Service Center for repair works.

Dispose of the packing material in compliance with current laws at the end of the warranty period.

POSITIONING THE COMPRESSOR (FIG. 2)

The room chosen for the installation of the compressor should meet the following 2

requirements and comply with what specified in the current safety and accident

prevention regulations:

• low percentage of fine dust,

• proper room ventilation and size so to keep room temperature under

50°C. In the event of inadequate hot air discharge, fit one or more exhaust

fans. Fit the exhaust fans as high as possible

A drainage pit or can shall be used to collect tank condensate.

Dimensions are just approximate. Try nevertheless to respect them as much as

possible.

6 Rotar Plus 30 STC - cod197AA3710 - Rev.00 02/2010

INSTALLATION GB

POWER CONNECTION (FIG. 3)

• The mains cable should have a cross-section suitable for the

machine power and should include no. 3 phase wires and no. 1 earth wire.

• Between the mains cable and the compressor control panel a fused

switch near the point where the cables go into the machine is absolutely

necessary. This switch should be at least 1.7 m from the ground.

• Position the switch (A) so that it can be easily reached by the operator.

The cables should be of the approved type and installed with the following

grade of protection: at least IP44

NOTE: Follow the instructions in the table to select proper cable section.

Sizing according to “VDE 0100, Part 430 and 523”, star-delta starter, 30°

C ambient temperature and cable length lower than 50 meters.

Electric connection 400 V Plus 30 STC

3

Conductor min. section mm2 4G16

Magnetic thermal switch A 63

Fuses Agl 50

TECHNICAL DATA

Technical features Plus 30 STC Plus 30 STC

Pressure bar g 8 10

Compressor type type FS50TF FS50TF

Compressor rotation speed rpm 4300 3880

Air volume supplied (ISO 1217 annex C) l/min 3300 3050

Oil quantity l 7 7

Oil quantity for topping-up l 1,5 1,5

Max. final over temperature °C 15 15

Removed heat kJ/h 75240 75240

Fan flow rate m3/h 3300 3300

Oil residues in the air mg/m3 2-4 2-4

Electric motor type 160 B3B5 160 B3B5

Motor power kW 22 22

Max. power absorbed kW 24,5 24,5

Electrical box protection class IP 54 54

Max. Start-up per hour n° 10 10

Ambient limit temperature °C +2/+45 +2/+45

Noise level (Pneurop/Cagi PN2CPTC2) dB(A) 72 72

Electrical data

Voltage V/Hz 400/50 400/50

Auxiliary voltage V/Hz 24/50 24/50

Start-up Absorbed current Amp 30 30

Max. Absorbed current Amp 40 40

Max. Absorbed current (vacuum) Amp 7,3 7,3

Electrical motor protection class IP 55 55

Motor insulation class F F

Service factor 1,1 1,1

Protection devices

Max oil temperature °C 110 110

Pre-alarm Oil temperature °C 105 105

Motor thermal relay setting Amp 40 40

Safety valve setting bar 14 14

Dimensions

Length mm 1500 1500

Width mm 710 710

Height mm 1110 1110

Weight kg 440 440

Air fitting Rp 3/4" 3/4"

Rotar Plus 30 STC - cod197AA3710 - Rev.00 02/2010 7

GB CONTROLS AND SETTINGS

CONTROL PANEL (FIG. 4)

• All compressor power-on-and-off procedures are 4

controlled by the machine power unit. Furthermore, it signals

possible machine problems and gives information on the

operation times and servicing times.

1) Display on which information is displayed.

2) OK key: press confirm (see “Modifiable Parameters”)

3) Direction keys: to scroll the options of the menu

4) Alarm light: if the light turns on and compressor possibly

stops, it means that maintenance service is needed or a failure

in the system has occurred. Refer to “Alarm messages” to

identify proper service.

5) Reset key: to stop the alarm (see “Alarm Messages”)

6) ON/I key: to power the machine on.

The machine power-on cycle is divided into three phases.

• wait for power-on the (STAND_BY) message is

displayed. If compressor was switched off, 15 seconds are

required before the cycle is started; otherwise compressor

remains on stand-by until pressure transducer requires air.

• Starting: compressor power-on in the “star” mode: the

(LOADLESS)message is displayed

• Working cycle: shift from “star” mode to “delta” mode after five seconds.

After two seconds, if required by transducer, the load solenoid valve is excited and (LOAD) message is displayed.

NOTE: The cycle described is valid for compressors with remote starter, whereas for machines with direct start-up and with

variable speed the compressors start immediately after (STAND-BY) phase.

7) OFF/0 key: to power the machine off.

Load solenoid valve is disabled, loadless cycle starts, blinking (LOADLESS) message is displayed, once loadless cycle is over

compressor stops and “off” message is displayed.

8) Emergency stop switch: to stop compressor only in case of actual need.

9) Functioning diagram/ maintenance operations

WORKING TIMES

Automatic mode

• The compressor operation is controlled by the pressure transducer, which stops the machine when the max. pressure

value is reached and starts it again after the pressure has decreased to the min. set value.

However, the machine stop is of the delayed type, that is it does not occur exactly at the same time when the max. pressure

value is reached but after a certain time, during which no air is taken (see no. 7 of above paragraph).

• Standard setting is 75 seconds, but it is recommended to check that number of start-ups per hour does NOT exceed max

number of 10. Should it be a higher value, it is recommended to set longer loadless operation time (see no. 7, “Modifiable

parameters”).

PRESSURE REGULATOR

The User should install a pressure regulator downstream of the compressor to set the power line according to his/her needs.

REMOTE ON/OFF

• This function can also be managed through the “remote” terminal on the terminal box. In such case, manual controls

will be excluded. If the compressor starts up unexpectedly, persons happening to be nearby could be harmed or injured. With

this in mind, THIS USE IS GENERALLY NOT RECOMMENDED. The manufacturer will not be liable for any damages.

Any change must be carried out by a qualified technician.

MODIFIABLE PARAMETERS

By pressing the key the machine stops (OFF), access the functioning parameters menu. Sometimes the password

must be introduced in order to access modifications. Use the and keys to scroll the menu.

0) Control unit ID (assistance password): selects the identification of the control unit. It is possible to select several identifi-

cations if several compressors are connected to the same line RS485.

1) Pre-alarm time (assistance password): the counter is automatically graduated every hour of machine functioning, when

the counter arrives at 0 the control unit enters maintenance alarm conditions.

The counter with the negative sign (-) in front indicate show many hours have passed since the last maintenance alarm.

Using the and keys it is possible to set the new value desired (in this way excluding the previous alarm).

2) Historical alarms (no password required): by means of this menu it is possible to visualise the last 3° alarms.

3) Pre-alarm temperature (factory password): by means of this menu it is possible to set the temperature “delta” (expressed

in °C) with respect to the maximum alarm temperature. This value can be set from 1 to 20.

8 Rotar Plus 30 STC - cod197AA3710 - Rev.00 02/2010

CONTROLS AND SETTINGS GB

Example: if the maximum temperature is 120 °C and the delta value is 10°C, on reaching 110 °C the maximum temperature

pre-alarm will be tripped.

4) Maximum temperature (factory password): by means of this menu it is possible to set the maximum accepted tempera-

ture. The field of regulation goes from 0 to 150°C.

5) Minimum temperature (factory password): by means of this menu it is possible to set the minimum accepted temperature.

The field of regulation goes from 0 a -14 °C.

6) Fan temperature (assistance password): by means of this menu it is possible to adjust the activation temperature of the

cooling fan. The field of regulation is between 0 to 150°C. The fan starts at the pre-fixed temperature. The hysteresis is fixed by

10°C.

7) During the empty functioning cycle (assistance password): by means at of this menu it is possible to change the duration

time of the machine empty cycle. The field of regulation goes from 1 to 250 seconds.

8) Automatic Start (assistance password): if activated, this parameter enables automatic start-up if there is a power cut.

When the voltage is restored the compressor re-starts automatically.

9) Internal phase sequences (assistance password): this parameter allows the control on the internal phase sequences or

disables it by activating the phase sequence input on the terminal board.

10) Language (no password required): this parameter allows to change the language in which the messages are displayed.

There are 5 languages available (Italian, English, German, Spanish, French).

11) Enabling of RS485 (no password required): this parameter is used to enable the transmission by means of RS485 and

automatically disable that on RS232.

12) Pressure sensor (assistance password): enables “4-20 mA” input where the pressure sensor must be connected. By

enabling this parameter the pressure measurement appears on the display.

By enabling this parameter the external pressure gauge contact changes function and becomes the minimum pressure input

pressure gauge of the oil-separator. As such it prevents the re-start of the compressor if the pressure in the oil-separator is high.

13) PSI/BAR (no password required): selects the unit of measurement of the pressure.

14) Set empty/pressure functioning (no password required): using this parameter it is possible to set the pressure at which

the compressor must stop. If the inverter is activated this parameter indicates the functioning pressure at which the inverter

must start to choke in order to keep it stable.

15) Start enable delta pressure (password not required): the pressure at which the control unit enables compressor re-

starting.

Example: Assuming a 1 bar start enable delta pressure and 9 bar operating pressure, the compressor would stop at 9.5 bar

and would start again at 8.5 bar.

16) Maximum pressure (service password): this parameter sets the maximum pressure value permissible in operation, i.e.

the maximum pressure of point 14.

17) Maximum alarm pressure (factory password): this parameter sets the maximum pressure value at which an alarm is

tripped in the control unit.

18) Remote pressure (service password): this control is used to manage multi-compressor systems.

19) Inverter (service password): inverter enable. When enabled, the service pressure switch input serves as an input for

the oil separator minimum pressure switch and inhibits re-starting when the oil separator tank is pressurized.

20) Minimum operation rate (service password): minimum operation rate at which inverter must operate (max. rate is

100%).

21) Load delay (service password): this parameter is a time delay in seconds before load solenoid valve is energized to

bring compressor from minimum to maximum frequency.

22) Inverter integrative (service password): this parameter modifies the time constant of the integrative component of

inverter rate calculation.

STANDARD SETTINGS ALWAYS HIT KEYS AND PRESS TO CONFIRM ENTRY

PARAMETERS Min. Max. Standard

Oil temp. pre-alarm (delta) °C 0 20 5 Set empty/press.functioning bar 0 15 8/10/13

Maximum oil temperature °C 0 150 110 Delta functioning bar 0 2 1

Minimum oil temperature °C -14 0 -7 Max pressure that can be set bar 0 15 9/11/14

Empty time sec. 30 900 75 Max pressure alarm bar 0 16 14

Maintenance pre-alarm Hours 0 32768 4000 Load dela sec. 0 200 10

Fan temperature °C 0 150 80 Internal phase sequence YES NO YES

Automatic start YES NO NO Language ITA

Pressure sensor YES NO YES Display contrast level 1 20 5

PSI/BAR bar PSI BAR BAR Enabling of RS485 YES NO YES

Rotar Plus 30 STC - cod197AA3710 - Rev.00 02/2010 9

GB CONTROL FUNCTIONS

ALARM MESSAGES

In the event of a fault occurring or of set safety limits being exceeded, the red alarm light will appear and the current alarm

condition is displayed.

Display status

1) Check direction of rotation

Alarm trips in the event of incorrect phase sequence being detected. The compressor locks 30°C h00110 m05

up; to restore operation, the correct phase sequence must first be re-established.

Wrong rotation

NOTE: To reset the alarm, the equipment must be isolated from the a.c. power supply.

2) Check temperature sensor

Alarm trips in the event of temperature sensor fault (sensor open or short circuiting). The 30°C h00110 m05

compressor locks up; to restore operation, check the connection and/or replace the sensor,

Temp sensor faulty

then press .

3) Maximum oil temperature

Alarm trips when the maximum oil temperature is sensed. The compressor locks up; to 110°C h00110 m05

restore operation, wait for the temperature to fall below the programmed value, then press Max oil temp

.

4) Minimum oil temperature

Alarm trips when the minimum oil temperature is sensed. The compressor locks up; to restore -10°C h00110 m05

operation, wait for the temperature to rise above the programmed value, then press . Min oil temp

5) Oil temperature pre-alarm

Trips when the pre-alarm oil temperature is sensed. The compressor does not lock up. To 105°C h00110 m05

override the pre-alarm, press . Oil temp pre-alarm

6) Emergency

A circuit activates to lock up the compressor when the red emergency button is depressed.

74°C h00110 m05

To silence the alarm, first reset the emergency button, then press .

Emergency button

7) Machine maintenance pre-alarm

Trips to warn the user than that machine is due for routine maintenance (oil change,

service filters, etc.). The alarm must be silenced by the service technician, who when carrying 74°C h00110 m05

out maintenance operations will select the item “Pre-alarm hours” from the menu and reset Routine maintenance

the value as described under the heading “Modifiable parameters - point (1).

8) Separator pressure switch

Alarm trips in the event of the separator pressure switch contact opening. The compressor

75°C h00110 m05

locks up. To silence the alarm, first reset the separator pressure switch, then press . Separator p/switch

9) 4-20 mA fault (pressure sensor)

Alarm trips when the pressure sensor connected to the 4-20mA input does not operate

correctly. The compressor locks up. To silence the alarm, first restore the pressure switch to 74°C h00110 m05

4-20mA fault

normal status, then press .

10) Maximum pressure

Alarm trips when the maximum pressure setting is exceeded. The compressor locks up.

74°C h00110 m05

To silence the alarm, first restore the correct pressure, then press . Max pressure

11) Inverter faulty

Press the key to silence the alarm. If problem persists, contact a service center without 74°C h00110 m05

delay. Inverter faulty

SAFETY DEVICES (FIG. 5)

1) Electronic transducer: controls both STOP and

START pressure. 5

2) Pressure switch for oil separator filter clogging:

indicates efficiency limit of oil separator filter.

3) Minimum pressure switch:

4) Pressure switch for air filter clogging: indicates

air filter efficiency limit

5) Safety valve: opens the air bleeding unit when

the safety value is reached.

6) Max. temperature sensor: stops motor over

+110°C.

10 Rotar Plus 30 STC - cod197AA3710 - Rev.00 02/2010

OPERATION GB

WORKING CYCLE

• At the end of the starting cycle, the 6

compressor reaches maximum operating speed

and starts to compress air in the tank (5).

• When close to reaching desired operating

pressure, the compressor begins to vary motor

rotation frequency (max.100%, min. 50%) so as

to keep air delivery steady depending on operating

pressure.

• Compressed air cannot escape through

the min. pressure valve (7), which is set at 3÷4

bar.

• Compressed air compresses oil inside

tank (5) and causes it to flow through tube (8) to

the radiator (9).

Cooled oil is returned to filter (11) through tube

(10).

• From filter (11), oil reaches compressor

(3) through tube (12). Oil is mixed with sucked air

to form an air/oil mixture that provides sealing and

lubrication of compressor moving parts.

• The air/oil mixture goes back to tank (5),

where air and oil are first separated by

centrifugation and then by the oil separator filter (6).

• As a result, tank (5) will deliver air only to air radiator (9) through tube (13). Air is then conveyed to mains through a cut-

off cock.

• Min. pressure valve (7) serves also as a check valve.

• Compressor delivers compressed air to outer air tank.

• Tank inner pressure increases until reaching max. calibration value.

• Once min. value is reached, pressure gauge starts timer and powers off solenoid valve of regulator (2).

• Regulator (2) closes and compressor stops compressing and starts idling.

• Timer continues counting until reaching set value and, if pressure is unchanged, stops the electric motor. If pressure

drops to minimum value set on controller, solenoid valve is powered and opens before timer counting is over.

• Regulator (2) opens and compressor operates under normal load; timer is reset.

• This cycle is automatically repeated.

START-UP

FIRST START-UP

Before starting the machine up for the first time, make sure that:

• the mains voltage is the same as the voltage on the CE plate;

• the electric connections have been made using cables of proper cross-section;

• the (wall) main power switch has suitable fuses;

• the oil level is over the minimum level - top up with the same type of oil if necessary;

• the air outlet cock is completely open.

CONNECT THE TANK WITH A HOSE.

• Only specialized technicians can start the compressor (on-site testing) for the first time.

If the machine does not start and the display shows the alarm message “Wrong direction of rotation”, proceed as

follows:

break power supply through the wall switch;

open the electric box door and reverse the two phases in the terminal board;

close the door, power on and start the machine.

Display status during compressor operation

Display status at start (shown for 5 seconds) Display status during normal operation

oil temp pressure

Easy Tronic II

software

V.0.0.0 GG/MM/AA date 100°C 9.5Bar 100%

release

Stato=stand-by

percentage of

compressor input/motor speed

status

Press the key to see hours and minutes operation; the information is displayed for 20 seconds.

Rotar Plus 30 STC - cod197AA3710 - Rev.00 02/2010 11

GB MAINTENANCE

• Proper maintenance is fundamental to the efficiency of your compressor and for the prolongation of its operational

lifespan.

• It is also important to respect the manufacturer’s suggested maintenance schedule, keeping in mind that the compressor

has been constructed for use in the best possible environmental conditions. (see the chapter on “Installation”)

• The intervals between maintenance works might have to be reduced to counteract the effects of the environmental

conditions in which the compressor is used.

• The oil used is RotEnergy Plus. Use of a different type of oil could compromise the efficiency of the compressor and

frequency of maintenance work to be performed.

• The normal maintenance operations which can be performed by the person in charge of the compressor will be

described in the following pages. Extraordinary maintenance work must be performed by an authorised customer technical

assistance centre.

Maintenance table

Type of maintenance Maintenance schedule

Work hours O At least

ORDINARY MAINTENANCE

Condensation release - Twice per month

Oil level check and refill 500

Clean the air filter 1000

Check for clogging and clean the radiator 1000

Check the transmission belt 2000

Air filter substitution 2000 Once per year

Oil filter substitution 4000 Once per year

Discharge oil filter substitution 4000 Once per year

Total oil change 8000 Once per year

EXTRAORDINARY MAINTENANCE

One-way draining valve substitution 4000 Once per year

Suction valve overhaul 12000 -

Thermostatic valve overhaul 12000 -

Minimum pressure valve overhaul 12000 -

Solenoid-valve substitution 12000 -

Substitute the fexible tube 12000 -

Substitute the transmission belt 12000 -

Substitute the electric motor bearings 24000 -

Screw compressor overhaul 24000 -

• The maintenance operations indicated in bold type must be performed at least once a year, even if the machine has

not been run for the amount of hours prescribed for such maintenance.

• In order to assure the correct functioning of the compressor, the following items must be checked after the first one

hundred hours of operation:

Oil level: refill, if needed, with the same type of oil.

Make sure that the screws are still tightly screwed: in particular those of the high voltage electrical contacts.

Check to make sure, visually, that all of the connecting parts are still firmly in place.

Check the air temperature of the immediate area.

BEFORE CARRYING OUT ANY INTERVENTION ON THE MACHINE:

• Command compressor shutdown using the switch (do not use the emergency button).

• Place the line switch in the 0/OFF position so that the machine is in total safety conditions.

• Close the line tap and wait for the manometer positioned on the deoiler tank to show pressure equal to 0 (zero).

• Remove the air from the deoiler tank, by loosening the cap and only partially opening in the discharge tap (fig.7).

• Before removing any protections, ensure that the line switch has been positioned in the 0/OFF position.

12 Rotar Plus 30 STC - cod197AA3710 - Rev.00 02/2010

MANUTENZIONE GB

DRAIN CONDENSATE (SEE FIG. 7)

Always ensure that the oil separator tank is depressurized and blow all air 7

off the cock (A) before draining the condensate.

Twice a month, drain condensate before starting the compressor. Unscrew

the plug of the filler (D), connect the supplied hose to the cock (C) and let

condensate flow into a collection container. Disconnect the hose when oil starts

flowing out instead of water.

Check oil level and top up if necessary.

CONDENSATE IS A POLLUTING MIXTURE! It may not be discharged into the

sewage. Dispose of condensate in compliance with current laws on

environmental protection.

CHECK OIL LEVEL (FIG. 7)

Remember to bleed all air off oil separator reservoir before topping up: slowly

loosen cock (A) to bleed all air off, then tighten again.

Oil is at its max. level if it is at filler max. level; also check through oil sight

glass (B).

Oil amount necessary for topping up from min. level is about 1.5 liters.

WHEN DELIVERED, THE COMPRESSOR IS FILLED WITH RotEnergy Plus

CLEAN THE AIR FILTER

• Clean the air filter (Fig. 8) from the inside towards the outside using

compressed air.

• Look at filter against the light and check for tears. Always replace a torn

filter.

• Filter cartridge and cover should be carefully fitted or dust might enter the 8

compression unit.

CHANGE THE AIR FILTER AFTER FOUR CLEANINGS

CLEAN RADIATORS

For cleaning, proceed as follows:

• remove back and upper panel from compressor cabinet;

• place a protective plastic sheet under radiator fins;

• spray (spray gun + solvent) from the outside towards the inside;

• check that air flows freely through radiator.

CHANGE OIL FILTER (FIG. 9)

9

• Always blow off air from the oil separator tank before topping up: slowly

unscrew the cock (A) until all air has blown off and then screw it again.

Always apply some oil on filter edge and seal before refitting the filter.

CHANGE OIL SEPARATOR FILTER (FIG. 10)

• Always blow off air from the oil separator tank before topping up: slowly

unscrew the cock (A) until all air has blown off and then screw it again.

• Turn anticlockwise to unscrew the filter. Use a proper tool for filters, if

necessary.

• Replace with a new filter: first, apply a thin layer of oil to seal and O-ring into

the oil separator filter and then turn clockwise to fit.

10

CHANGE OIL (FIG. 7)

When the compressor is still warm, i.e. over 70°C.

• Always blow off air from the oil separator tank before topping up: slowly

unscrew the cock (A) until all air has blown off and then screw it again.

• Unscrew the plug of the filler (D), connect the hose to the cock (C) and let

all oil flow into a collection container. When finished, disconnect the hose.

• Pour fresh oil through the filler (D) - quantity for complete filling: 6 liters.

• Fit the plug.

• Power the machine on.

• Start the machine and wait for 5 minutes, then stop the machine.

Rotar Plus 30 STC - cod197AA3710 - Rev.00 02/2010 13

GB MANUTENZIONE

• Blow all air off.

• Wait for 3 minutes and check the oil level, top up if necessary. 11

WHEN DELIVERED, THE COMPRESSOR IS FILLED WITH RotEnergy Plus

EXHAUSTED OIL IS HIGHLY POLLUTANT! Dispose of exhausted oil in compliance

with current laws on environmental protection.

CHECK DRIVE BELT TENSION (FIG.11)

Use a frequency tester to carry out this check.

Proceed as follows:

• Move tester microphone closer to the belt about at mid length and hit the belt with

a wrench.

• Read value on tester. Stretch or slacken the belt if the value is different from values

indicated in the table:

Higher value = slacken

Lower value = stretch

• To adjust, proceed as follows:

loosen the nuts (E) and turn the screw (F) anti-clockwise to stretch the belt and

clockwise to slacken.

tighten nuts (E) and check frequency value once again. Repeat the above procedure,

if necessary, to reach optimal value.

When finished, re-assemble cabinet parts before starting the compressor.

V 400 / Hz 50 V 400 / Hz 60

Rotar Plus 3008 3010 3013 3008 3010

frequency (Hz) 68 71 71 72 72

Rotar Plus 4008 4010 4013 4008 4010

frequency (Hz) 87 81 81 78 79

MINIMUM PRESSURE VALVE (FIG. 12)

Close line cock and bleed all air off oil separator tank through the 12

valve (A).

Remove the fastening nuts from the flange and lift.

Replace gaskets: (1) (2).

REPLACE HOSES

Loosen hose fittings, replace the hose and then tighten the fittings.

Then follow last steps for oil change.

Thermostat – radiator oil tube

Radiator – thermostat oil tube

Thermostat – oil separator tank oil tube

Min. pressure valve – radiator air tube

Screw compressor – oil separator tank air tube

REPLACE THE DRIVE BELT (FIG. 11)

Proceed as follows:

• remove the belt guard;

• loosen the nuts (E) and turn the screw (F) clockwise until the belt is completely slack.

• remove the old belt and replace with a new one;

• turn the screw (F) counterclockwise a bit;

• tighten the nuts (E) and check for belt tension as described under “Check drive belt tension”. Adjust, if necessary.

14 Rotar Plus 30 STC - cod197AA3710 - Rev.00 02/2010

TROUBLESHOOTING GB

Problem Cause Remedy

Motor stop due to thermal relay Voltage too low Check voltage, press Reset and start once again

tripping

Overtemperature Check motor absorption and check relay settings. If absorption is

OK, press Reset and start once again

High oil consumption Defective drainage Check oil drainage tube and non-return valve

Oil level too high Check oil level and drain some, if necessary

Oil separator filter broken Change oil separator filter

Oil separator filter seals leaking Replace gaskets

Oil leakage from suction filter Suction regulator does not close Check regulator and solenoid valve

Safety valve open Pressure too high Check setting of pressure switch

Suction regulator does not close Check regulator and solenoid valve

at the end of the cycleI

Oil separator filter clogged Change oil separator filter

Compressor temperature Room temperature too high Improve ventilation

thermostat tripped

Radiator clogged Clean the radiator with solvent

Oil level too low Top up with oil

Thermostat faulty Replace thermostat, press Reset and start once again

Low compressor efficiency Belt is slack Stretch the belt, press Reset and start once again

Air filter dirty or clogged Clean or replace filter

The compressor is running but Regulator is closed and does not Remove the suction filter and check if regulator can be manually

does not compress air open because it is dirty opened. Remove and clean, if necessary.

Regulator is closed and does not Ensure that signal between pressure switch and solenoid valve is

open because it receives no available. Replace part, if damaged.

command signal

The compressor compresses air Regulator is open and does not Remove the regulator and clean

beyond set max. pressure close because it is dirty

Regulator is open and does not Ensure that signal between pressure switch and solenoid valve is

close because it receives no available. Replace part, if damaged.

command signal

Compressor does not restart Oil separator filter clogged Change oil separator filter

Min. pressure valve does not Remove and clean the valve. Replace the seal, if necessary

close perfectly

Difficult start Voltage too low Check mains voltage

Min. pressure valve does not seal Remove the valve, clean it and if necessary replace the sealing unit

correctly

Tube leaking Tighten fittings

Rotar Plus 30 STC - cod197AA3710 - Rev.00 02/2010 15

GB WIRING DIAGRAM - ROTAR PLUS 30 STC

BRIDGE ON-OFF REMOTE

TC1 Transformer pr.0/230/400 sec.0/24 150/VA

TC2 Transformer pr.0/400 sec.0/6

SB Emergency button+ n.2 NC 230V 10A

FU1-FU2-FU3 Fuses 6,3x32 GF 4A 500V

FU4-FU5 Fuses 6,3x32 GF 1A 500V

FU6 Fuses 6,3x32 GF 500 mA 500V

FU7 Three-pin fuse holder base 500V 63A Gg 22 x 58

KM Contactor, inverter coil supply 24V 50/60Hz 60A AC1

KA Aux. relay coil 24V 50/60Hz

GF Inverter filter 22 kw

YV Solenoid valve24/VAC 50/60 Hz

SP1 Minimum pressure switch 1NC

SP2 Pressure switch for oil separator filter 1NC

SP3 Pressure switch for air filter 1NC

BP Pressure transducer0-16 bar 4-20 mA

D Electronic controller Easytronic II 24VAC

ST Thermal feeler for electronic controller

Motor cable cross-section (sq mm) 4x16 SHIELDED

NOTE: 1) Connecting cable se c= 1mq / 2) (*) = 400V AC3 / 3) (**) = 400V

voltage - black-blue-brown/ yellow-green-white bridge

16 Rotar Plus 30 STC - cod197AA3710 - Rev.00 02/2010

Vous aimerez peut-être aussi

- Operating Manual Controls: AC1 AC2 AC3Document110 pagesOperating Manual Controls: AC1 AC2 AC3sebastian75% (4)

- Manual Fiac Airblock 20Document35 pagesManual Fiac Airblock 20Titus Dulacioiu100% (2)

- Manual Micro Compressor Controller (MCC)Document19 pagesManual Micro Compressor Controller (MCC)sebastianPas encore d'évaluation

- User Manual: Vortex Compressor Controller MAM860Document16 pagesUser Manual: Vortex Compressor Controller MAM860sebastian100% (4)

- r1 Control Panel Software enDocument56 pagesr1 Control Panel Software ensebastianPas encore d'évaluation

- Qx189860 Lb185-275-Lb185-275 Screw Air Compressor - Origional User ManualDocument50 pagesQx189860 Lb185-275-Lb185-275 Screw Air Compressor - Origional User Manualabdur rohmanPas encore d'évaluation

- Service Manual: Tecom Compressor AS SeriesDocument24 pagesService Manual: Tecom Compressor AS Serieskaanerman100% (1)

- User Interface 2946 1044 00Document27 pagesUser Interface 2946 1044 00gak66Pas encore d'évaluation

- 2946 1186 00 Maintenance Procedure GA 11-30 (VSD)Document9 pages2946 1186 00 Maintenance Procedure GA 11-30 (VSD)Rui FortunaPas encore d'évaluation

- 2015 Atlas Copco MR Warranty Policy Rev 012Document10 pages2015 Atlas Copco MR Warranty Policy Rev 012jogremaurPas encore d'évaluation

- APM Compressor Maintenance, Operation ManualDocument55 pagesAPM Compressor Maintenance, Operation ManualIngeniería AplicacionesPas encore d'évaluation

- Airtelligence 2.0 Modbus Anbindung enDocument9 pagesAirtelligence 2.0 Modbus Anbindung enPiotrPas encore d'évaluation

- Atlas Copco: Technical SpecificationDocument8 pagesAtlas Copco: Technical SpecificationRoger Antonio Mendoza GutierrezPas encore d'évaluation

- User Manual: Screw Air Compressor ControllerDocument26 pagesUser Manual: Screw Air Compressor Controllerlucas0% (1)

- Software Specification: Standard S1 ControllerDocument40 pagesSoftware Specification: Standard S1 ControllerAnonymous 6VCG1YRdPas encore d'évaluation

- (002, 003, 701, 743) Air Dryer, Screw Compressors ATLAS COPCO VorläufigDocument572 pages(002, 003, 701, 743) Air Dryer, Screw Compressors ATLAS COPCO VorläufigBata ZivanovicPas encore d'évaluation

- TI Overhaul - Transient Load Valve 2946 0797 00Document14 pagesTI Overhaul - Transient Load Valve 2946 0797 00khanh khanhPas encore d'évaluation

- Ba 155 GBDocument56 pagesBa 155 GBdubarPas encore d'évaluation

- CyberplusDocument108 pagesCyberplusAlberto Sanchez100% (1)

- PART LIST XRVS 476 - CompressedDocument491 pagesPART LIST XRVS 476 - CompressedGonzalo Hernández MelladoPas encore d'évaluation

- Atlas Copco Group Presentation 2005Document51 pagesAtlas Copco Group Presentation 2005Luis Eduardo Corzo Enriquez100% (1)

- AC260Document64 pagesAC260Elvis Lizarazo100% (1)

- Manual RLR 300 A 700 UKDocument49 pagesManual RLR 300 A 700 UKLucyan Ionescu100% (1)

- Refrigeration Dryer CD-seriesDocument8 pagesRefrigeration Dryer CD-series1hamdijaPas encore d'évaluation

- CPA Triplex H EN 1Document20 pagesCPA Triplex H EN 1Nguyễn Tấn KhiêmPas encore d'évaluation

- 2954 2880 04 - XR (Yxv) S 557-647 - en PDFDocument112 pages2954 2880 04 - XR (Yxv) S 557-647 - en PDFseanPas encore d'évaluation

- Transtig 16pi Transarc 16iDocument27 pagesTranstig 16pi Transarc 16ibill100% (1)

- EDE99N - Parts List 13-20-502 v02 - 2010-12-19 - SN S350021Document50 pagesEDE99N - Parts List 13-20-502 v02 - 2010-12-19 - SN S350021mantenimiento pierrotPas encore d'évaluation

- Manual Compressor de Ar Atlas Copco Ga 55Document4 pagesManual Compressor de Ar Atlas Copco Ga 55Junior Enrique Yataco Ariza100% (1)

- 5 15 Rs Electric ManualDocument32 pages5 15 Rs Electric ManualDustin ParscalPas encore d'évaluation

- Atlas Copco Warranty BookletDocument6 pagesAtlas Copco Warranty BookletEffendiCibuburPas encore d'évaluation

- GD Air CompressorsDocument60 pagesGD Air Compressorsmike_bdn100% (1)

- Instruction Book Xa (H) S 38-88 (G) KD S3a App 2954 9520 02 enDocument92 pagesInstruction Book Xa (H) S 38-88 (G) KD S3a App 2954 9520 02 enYERKO OVIEDOPas encore d'évaluation

- Ga 5 VSD, Ga 7 VSD, Ga 11 VSD: Instruction BookDocument98 pagesGa 5 VSD, Ga 7 VSD, Ga 11 VSD: Instruction BookMegamax1985Pas encore d'évaluation

- QGS 10-20S Parts Manual June 2019 PDFDocument138 pagesQGS 10-20S Parts Manual June 2019 PDFEnrique ZavalaPas encore d'évaluation

- Dec40 - User Service Rev5-0Document42 pagesDec40 - User Service Rev5-0Racob FherdzPas encore d'évaluation

- Addendum: LS12 & LS16Document36 pagesAddendum: LS12 & LS16jonathanPas encore d'évaluation

- 2 2 11 ST16189-00-000 ADocument36 pages2 2 11 ST16189-00-000 ALazaro GutierrezPas encore d'évaluation

- Mam 6090Document64 pagesMam 6090AmatorNikPas encore d'évaluation

- Demand Manager Manual TG TH TI PDFDocument28 pagesDemand Manager Manual TG TH TI PDFjuan carlosPas encore d'évaluation

- Original Operating Manual - SCC Compressors: Version 1.0 E - 28.05.2017Document104 pagesOriginal Operating Manual - SCC Compressors: Version 1.0 E - 28.05.2017lucasPas encore d'évaluation

- HV04 HV07 PDFDocument34 pagesHV04 HV07 PDFDiana ZarPas encore d'évaluation

- Manual ALUP FU EmotronDocument88 pagesManual ALUP FU EmotronfacebookszitykaPas encore d'évaluation

- Screw Compressor L22S - 37: Operating InstructionsDocument56 pagesScrew Compressor L22S - 37: Operating Instructionsfauzy syaeful100% (1)

- 4 Ceccato Compressor Training Materials 2012Document38 pages4 Ceccato Compressor Training Materials 2012King Max100% (3)

- Dsp-132 - 240a Mechanical Service ManualDocument50 pagesDsp-132 - 240a Mechanical Service ManualSVC ADM100% (1)

- 2946 1223 00 - Overhaul Inter Cooler - After CoolerDocument12 pages2946 1223 00 - Overhaul Inter Cooler - After CoolerMax JohnPas encore d'évaluation

- GA 18 PTM Compressor Mannual (AIB GA 15-22 RD) PDFDocument64 pagesGA 18 PTM Compressor Mannual (AIB GA 15-22 RD) PDFvirendra kumar singhPas encore d'évaluation

- Atlas Copco XATS 156-BrochureDocument4 pagesAtlas Copco XATS 156-BrochureramseyPas encore d'évaluation

- Technical Instruction: Pre Commissioning & Installation GuidelinesDocument13 pagesTechnical Instruction: Pre Commissioning & Installation GuidelinesHitesh sharmaPas encore d'évaluation

- Apex Single Stage Variable and Fixed Speed Base-Mounted and Tank Mounted CompressorsDocument86 pagesApex Single Stage Variable and Fixed Speed Base-Mounted and Tank Mounted CompressorsDan GillaspyPas encore d'évaluation

- Comparati DANFOSS PDFDocument7 pagesComparati DANFOSS PDFCesar VillarPas encore d'évaluation

- 2955 1220 01 - XAHS 237 CDDocument132 pages2955 1220 01 - XAHS 237 CDVinh KhangPas encore d'évaluation

- User Manual SmartAir LITEDocument35 pagesUser Manual SmartAir LITETrần Văn Toản100% (2)

- Fiac Spare Parts MAI 2022Document332 pagesFiac Spare Parts MAI 2022jairoPas encore d'évaluation

- Manual F FR FRD5 5-22 EN DE RU v1 4 0Document108 pagesManual F FR FRD5 5-22 EN DE RU v1 4 0Александр ЮферовPas encore d'évaluation

- Atlas Copco Stationary Air Compressors: GA5, GA7, GA11C With Elektronikon I or Elektronikon II RegulatorDocument78 pagesAtlas Copco Stationary Air Compressors: GA5, GA7, GA11C With Elektronikon I or Elektronikon II RegulatorKrzysiek PodsiadłoPas encore d'évaluation

- User'S, Maintenance and Spare Parts Manual: Refrigerating Air DryerDocument67 pagesUser'S, Maintenance and Spare Parts Manual: Refrigerating Air DryerValentin Bogdan100% (1)

- Tamrotor E3 and E6 Manual Book 2016Document20 pagesTamrotor E3 and E6 Manual Book 2016adrianPas encore d'évaluation

- Operator Manual M43Document288 pagesOperator Manual M43Anne S. Sokolovska100% (1)

- Air Control 3 Dynamic: ManualDocument53 pagesAir Control 3 Dynamic: ManualmadiPas encore d'évaluation

- 06-Srk-t-050 Technical Manual SRK ZD Ze R410aDocument297 pages06-Srk-t-050 Technical Manual SRK ZD Ze R410adfountoukidis100% (2)

- EASYTRONIC 2 Controller 000110062 - 23!09!14Document15 pagesEASYTRONIC 2 Controller 000110062 - 23!09!14Lin LeninPas encore d'évaluation

- MEGA 50-60 GB - PDF FiniDocument19 pagesMEGA 50-60 GB - PDF Finisebastian67% (3)

- Airman Air Compressor 6A Series 90S 130S 185SDocument71 pagesAirman Air Compressor 6A Series 90S 130S 185Ssebastian100% (1)

- Air Compressors Net Communication: How To Choose The Upgrading KitDocument7 pagesAir Compressors Net Communication: How To Choose The Upgrading KitsebastianPas encore d'évaluation

- 62 305 454 30 Ed 01 EN Creemers KompressorDocument28 pages62 305 454 30 Ed 01 EN Creemers KompressorsebastianPas encore d'évaluation

- Tec40 User v2Document45 pagesTec40 User v2sebastian100% (1)

- Controlador AlupDocument60 pagesControlador AlupLorena LozanoPas encore d'évaluation

- 2015 Logik 9 GBDocument2 pages2015 Logik 9 GBsebastianPas encore d'évaluation

- Infologic: User ManualDocument30 pagesInfologic: User ManualsebastianPas encore d'évaluation

- Vortex Air Compressors: Global Compressed Air Solutions ProviderDocument2 pagesVortex Air Compressors: Global Compressed Air Solutions ProvidersebastianPas encore d'évaluation

- DataKom 040 USERDocument45 pagesDataKom 040 USERsebastianPas encore d'évaluation

- Logika Control Electronic Controller Compressors Logik 9Document2 pagesLogika Control Electronic Controller Compressors Logik 9sebastian33% (3)

- Instructions and Advices To Use The Electronic Controller Logik 25-SDocument23 pagesInstructions and Advices To Use The Electronic Controller Logik 25-SsebastianPas encore d'évaluation

- Instructions and Advices To Use The Electronic Controller Logik 18Document25 pagesInstructions and Advices To Use The Electronic Controller Logik 18sebastianPas encore d'évaluation

- Logik15: Logika Control S.R.LDocument17 pagesLogik15: Logika Control S.R.LsebastianPas encore d'évaluation

- Instructions and Advices To Use The Electronic Controller Logik 8Document13 pagesInstructions and Advices To Use The Electronic Controller Logik 8sebastianPas encore d'évaluation

- Airsmart Controller User'S Manual (Compressor Application) : 13-17-600 October 2, 2009Document89 pagesAirsmart Controller User'S Manual (Compressor Application) : 13-17-600 October 2, 2009sebastian100% (4)

- Instructions and Advices To Use The Electronic Controller Logik 26-SDocument28 pagesInstructions and Advices To Use The Electronic Controller Logik 26-SsebastianPas encore d'évaluation

- NUAIR Cat MercurySirio CE-IE3!03!15 en 9041406Document24 pagesNUAIR Cat MercurySirio CE-IE3!03!15 en 9041406sebastianPas encore d'évaluation

- Silver 3-50 HP BrochureDocument24 pagesSilver 3-50 HP BrochuresebastianPas encore d'évaluation

- Instrukcja Obsługi Panelu DNAir 2Document16 pagesInstrukcja Obsługi Panelu DNAir 2sebastianPas encore d'évaluation

- EKO D UserManual R4Document29 pagesEKO D UserManual R4sebastian100% (3)

- Instrukcja Obsługi Panelu DNAir 1Document12 pagesInstrukcja Obsługi Panelu DNAir 1sebastian100% (1)

- HSS Stamping Design ManualDocument67 pagesHSS Stamping Design ManualjschuryPas encore d'évaluation

- Lateral Stiffness Characteristics of Tall PDFDocument19 pagesLateral Stiffness Characteristics of Tall PDFLaila Monteiro A MeloPas encore d'évaluation

- Effect of Additives On Formation of Natural Gas Hydrate: C.S. Zhang, S.S. Fan, D.Q. Liang, K.H. GuoDocument7 pagesEffect of Additives On Formation of Natural Gas Hydrate: C.S. Zhang, S.S. Fan, D.Q. Liang, K.H. GuopePas encore d'évaluation

- Insulation BOQ Area Wise (Square MTR.)Document11 pagesInsulation BOQ Area Wise (Square MTR.)Atiq Ur RehmanPas encore d'évaluation

- GPiLearn BrochureDocument44 pagesGPiLearn BrochuremurthykeshavaPas encore d'évaluation

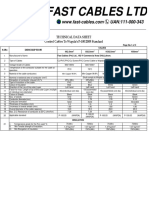

- TDS WAPDA Control CablesDocument3 pagesTDS WAPDA Control CablesAli ShahzadPas encore d'évaluation

- Particle Size AnalysisDocument36 pagesParticle Size AnalysisAayush Jha SauravPas encore d'évaluation

- Barekar2014P Overview of Twin Roll Casting of Al AlloysDocument12 pagesBarekar2014P Overview of Twin Roll Casting of Al AlloyskishorePas encore d'évaluation

- Basic Water ChemistryDocument4 pagesBasic Water ChemistryZAHID HUSSAINPas encore d'évaluation

- CHN Environmental Health & DisasterDocument20 pagesCHN Environmental Health & DisasterYsabellaPlarisanPas encore d'évaluation

- 2010 FP CatalogDocument28 pages2010 FP CatalogAnonymous j1dZUuTJ8OPas encore d'évaluation

- Life Cycle Costing - HVACDocument103 pagesLife Cycle Costing - HVACDaniel Henrique100% (1)

- Rev 8Document2 pagesRev 8api-273257329Pas encore d'évaluation

- Manual Taller Outlook Dierre 125 Efi Idioma Ingles PDFDocument173 pagesManual Taller Outlook Dierre 125 Efi Idioma Ingles PDFWalter Mikel Carrillo Castillo100% (1)

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya BaraniPas encore d'évaluation

- MaterialData 7754Document2 pagesMaterialData 7754Joko TriwardonoPas encore d'évaluation

- StrainerDocument2 pagesStrainermayPas encore d'évaluation

- Amca 211Document62 pagesAmca 211Raji PanickerPas encore d'évaluation

- Irrigation Department: Government of Khyber PakhtunkhwaDocument4 pagesIrrigation Department: Government of Khyber Pakhtunkhwaalamgir BachaPas encore d'évaluation

- Fire Endurance of Concrete Slabs As Influenced by Thickness, Aggregate Type, and MoistureDocument22 pagesFire Endurance of Concrete Slabs As Influenced by Thickness, Aggregate Type, and MoisturederpserPas encore d'évaluation

- PanelGrip - Glass Railing SystemDocument4 pagesPanelGrip - Glass Railing SystemSarinPas encore d'évaluation

- Ferrous Carbon Austenite, Equivalent Carbon ContentDocument2 pagesFerrous Carbon Austenite, Equivalent Carbon ContentAmirul NorshahPas encore d'évaluation

- Exercise 2.1 Concepts of MatterDocument3 pagesExercise 2.1 Concepts of MatterKesuma DewiPas encore d'évaluation

- SOP For Refrigeration PlantDocument37 pagesSOP For Refrigeration PlantGaurav Swarup67% (3)

- Modern Trends in Gold Processing - OverviewDocument21 pagesModern Trends in Gold Processing - Overviewcuberbill1980100% (1)

- ACI 207.1R - 1996 - Mass ConcreteDocument42 pagesACI 207.1R - 1996 - Mass ConcreteJOSEPas encore d'évaluation

- Phosphonics Catalogue 2011 FullDocument80 pagesPhosphonics Catalogue 2011 Fullapi-94537271Pas encore d'évaluation

- Assignment: Submitted by R.Deepa 116011001503 Ii Yr / Iv SemDocument6 pagesAssignment: Submitted by R.Deepa 116011001503 Ii Yr / Iv SemR. Deepa - APas encore d'évaluation

- Triangle VI SpecificationsDocument3 pagesTriangle VI Specificationscivil.jdriveroincPas encore d'évaluation

- Sika RaintiteDocument3 pagesSika RaintiteHoneyPas encore d'évaluation