Académique Documents

Professionnel Documents

Culture Documents

Solenoid Types and Circuits: Tech Tips

Transféré par

Vinod Thekke VeetilTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Solenoid Types and Circuits: Tech Tips

Transféré par

Vinod Thekke VeetilDroits d'auteur :

Formats disponibles

TECH TIPS

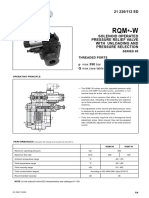

SOLENOID TYPES AND CIRCUITS

Many of the remote mount solenoids look identical on the outside.

However, they can be very different on the inside. Beside the different internal circuits, these can be rated for continuous duty or

intermittent duty use.

Continuous duty solenoids are wound with very fine wire and draw very little amperage. The contacts in continuous duty solenoids

will usually have a lower amperage rating than that of the intermittent duty type. These are normally used as tilt trim relays. This

type of solenoid can also be used for a variety of applications where a remote relay is needed to power a motor or other device.

Intermittent duty solenoids are wound with much heavier wire and draw more amperage. The contacts have a very high amperage

rating. If these stay energized for extended periods of time they heat up and eventually burn out the coil inside the solenoid. This

type of solenoid is normally used as a starter motor relay.

GROUNDED BASE

SOLENOIDS

One end of the coil is grounded

to the mounting base. This type

solenoid must mount on a

grounded surface or a ground must

be attached to the base.

INSULATED BASE

SOLENOIDS

Both ends of the coil in this unit

are insulated. A separate ground

must be connected and this type

of solenoid can be mounted on any

surface.

SOLENOIDS EQUIPPED

WITH RELAY TERMINAL

This type of solenoid is normally

used for starting motors. Since

conventional ignition coils operate on

7 volts, the relay terminal supplies

12 volts to the ignition coil during

starting for easier starts. The base of

this solenoid must be grounded.

ARCO STARTING & CHARGING SPECIALISTS ©

TOLL FREE 800-722-2720 • PHONE: 850-455-5476 • FAX: 850-453-2630 • WWW.ARCOMARINE.COM

TECH TIPS

SIMPLE SOLENOID TESTING: GROUNDED BASE REMOTE SOLENOIDS

NOTE: Before Performing These Tests You Must Fully Charge and Load Test The Battery to Verify It Is Good.

Step 1: Check the voltage on the battery side of the solenoid

as shown on the left. The reading should be the same as the

To Battery + battery reading (12.6V = Full Charged Battery).

Step 2: With the voltmeter still connected, turn the key to the

start position and read the voltage. The voltage should not drop

below 10.0 volts on this terminal. If the voltage drops below 10.0

volts, The battery cable should be cleaned or replaced. If the

reading is 10.0 volts or more move on to step 3.

Step 3: Keep the negative voltmeter lead on the metal base

of the solenoid and move the positive voltmeter lead to the

terminal marked “S” on the solenoid. Turn the key to the start

position and read the voltage. The Voltage could read a little

lower than the previous reading but should never be below

10.0 volts. If the voltage is lower than 10.0 volts, You must

troubleshoot the start circuit (ignition switch, voltage supply

to the ignition switch, neutral safety switch).

To Ignition Switch

Step 4: Move the positive voltmeter lead to the battery

terminal on the solenoid and the negative voltmeter lead to

To Battery + the terminal that the starter cable is attached. Turn the key

to the start position and read the voltage. The voltage should

read no more than .3 volts. If the reading is more than .3 volts

the contacts have excessive resistance and the solenoid should

To Starter be replaced.

Step 5: Some solenoids use a relay terminal on the solenoid to

To Battery + power fuel pumps or supply full battery voltage to ignition coils

when the starter is activated. This terminal is usually marked “I”

or “R”. Connect the voltmeter a shown. Turn the key to the start

position. You should read no more than 0.3 volts. If you have

more than 0.3 volts the solenoid should be replaced.

To Ignition Coil +

or Fuel Pump Relay

ARCO STARTING & CHARGING SPECIALISTS ©

TOLL FREE 800-722-2720 • PHONE: 850-455-5476 • FAX: 850-453-2630 • WWW.ARCOMARINE.COM

TECH TIPS

SIMPLE SOLENOID TESTING: INSULATED BASE REMOTE SOLENOIDS

NOTE: Before Performing These Tests You Must Fully Charge and Load Test The Battery to Verify It Is Good.

To Battery + Step 1: Check the voltage on the battery side of the solenoid as

shown on the left. The reading should be the same as the battery

reading (12.6V = Full Charged Battery).

To Ground -

To Battery + Step 2: With the voltmeter still connected, activate the switch and

read the voltage. The voltage should not drop below 10.0 volts on

this terminal. If the voltage drops below 10.0 volts, the battery

cable should be cleaned or replaced. If the reading is 10.0 volts or

more move on to step 3.

To Ground -

To Ground -

Step 3: Keep the negative voltmeter lead on the ground terminal

of the solenoid and move the positive voltmeter lead to the

terminal marked “S” on the solenoid. Activate the switch and

read the voltage. The Voltage could read a little lower than the

previous reading but should never be below 10.0 volts. If the

voltage is lower than 10.0 volts, you must troubleshoot the switch

circuit (toggle switch, push button switch, or voltage supply to

these switches).

To Switch +

Step 4: Move the positive voltmeter lead to the battery terminal

To Battery + on the solenoid and the negative voltmeter lead to the terminal

that the starter cable is attached. Activate the switch and read

the voltage. The voltage should read no more than .3 volts. If

the reading is more than .3 volts the contacts have excessive

resistance and the solenoid be replaced.

To Load or Device

ARCO STARTING & CHARGING SPECIALISTS ©

TOLL FREE 800-722-2720 • PHONE: 850-455-5476 • FAX: 850-453-2630 • WWW.ARCOMARINE.COM

Vous aimerez peut-être aussi

- 4L60E Converter Valves:: Operation, Test Procedures and The Effects of WearDocument5 pages4L60E Converter Valves:: Operation, Test Procedures and The Effects of WeartranstechozPas encore d'évaluation

- Troubleshooting Electronic Components With The PET BloodhoundD'EverandTroubleshooting Electronic Components With The PET BloodhoundPas encore d'évaluation

- 950F Wheel Loader Electrical System: Vehicle Harness Connector and Component LocationsDocument2 pages950F Wheel Loader Electrical System: Vehicle Harness Connector and Component LocationsBrahian Mijael Garrado Gonzales100% (1)

- Batery Minum VoltageDocument3 pagesBatery Minum VoltageSunariaman MansyurdinPas encore d'évaluation

- Brake Air SystemDocument24 pagesBrake Air SystemIzz Bahar100% (1)

- R List of Replacement Parts Under 40 CharactersDocument590 pagesR List of Replacement Parts Under 40 CharactersErika Loayza Oliden100% (4)

- 89149853-Wiring Diagram FH (4), Dual-Stage Turbo (EN) PDFDocument7 pages89149853-Wiring Diagram FH (4), Dual-Stage Turbo (EN) PDFИгорь КрюковPas encore d'évaluation

- Zener Diode As Voltage Regulator and Its V-I CharacteristicsDocument13 pagesZener Diode As Voltage Regulator and Its V-I CharacteristicsRUPAM GHOSHPas encore d'évaluation

- ELECTROSTATICS PROBLEM SOLUTIONSDocument22 pagesELECTROSTATICS PROBLEM SOLUTIONSsreejusl50% (2)

- Cat Dcs Sis Controllerelectrico730 PDFDocument2 pagesCat Dcs Sis Controllerelectrico730 PDFJorge VeraPas encore d'évaluation

- MANUAL DEFROST AND ALARM CODESDocument2 pagesMANUAL DEFROST AND ALARM CODESAdal Vera100% (2)

- Arihant Sample Paper Term 1 Class 12 PhysicsDocument17 pagesArihant Sample Paper Term 1 Class 12 PhysicsHitesh Yadav100% (1)

- FMSDocument38 pagesFMSsyedamiriqbalPas encore d'évaluation

- Solenoid Valve Block, AirDocument14 pagesSolenoid Valve Block, AirHAIPas encore d'évaluation

- Guide to Common PLC Input and Output DevicesDocument10 pagesGuide to Common PLC Input and Output Devicesletz277100% (4)

- Zener Diode: Prepared By: Elman John Cabacang Bsece Ii-7Document23 pagesZener Diode: Prepared By: Elman John Cabacang Bsece Ii-7Elman CabacangPas encore d'évaluation

- Finding The Cause of Solenoid Coil Burn OutDocument2 pagesFinding The Cause of Solenoid Coil Burn OutIago SalvadorPas encore d'évaluation

- Soneloid FailureDocument2 pagesSoneloid FailureIago SalvadorPas encore d'évaluation

- Understanding Pull & Push SolenoidsDocument12 pagesUnderstanding Pull & Push Solenoidsfahad pirzadaPas encore d'évaluation

- Popular Mechanics - Curing A Clicking StarterDocument4 pagesPopular Mechanics - Curing A Clicking StarterGeorgiana MarinPas encore d'évaluation

- Zener DiodeDocument23 pagesZener DiodeMourish Charlze J. OnguePas encore d'évaluation

- KENDRIYA VIDYALAYA BARWAHA Solenoid ProjectDocument4 pagesKENDRIYA VIDYALAYA BARWAHA Solenoid ProjectVishal Tiwari100% (1)

- How To Test A SolenoidDocument3 pagesHow To Test A SolenoidVyas SrinivasanPas encore d'évaluation

- Relay Operation Types Symbols & CharacteristicsDocument13 pagesRelay Operation Types Symbols & CharacteristicsInférus AdvenæPas encore d'évaluation

- AT 17503 AEE Session 27Document18 pagesAT 17503 AEE Session 27pavanranePas encore d'évaluation

- 90486123-722d-4450-aea5-d30f0a7f54ecDocument7 pages90486123-722d-4450-aea5-d30f0a7f54ecjhoseguillo07Pas encore d'évaluation

- Asco - Solenoide Ef8017g1 Red HatDocument4 pagesAsco - Solenoide Ef8017g1 Red HatMariano DomenechPas encore d'évaluation

- Data Sheet: How To Select Your RS SolenoidDocument3 pagesData Sheet: How To Select Your RS SolenoidsaccaroPas encore d'évaluation

- How To Select Your BLP Solenoid: SolenoidsDocument4 pagesHow To Select Your BLP Solenoid: SolenoidshjgajjarPas encore d'évaluation

- Clean and repair diesel starter motor solenoid to fix tapping issueDocument2 pagesClean and repair diesel starter motor solenoid to fix tapping issueronald allan liviocoPas encore d'évaluation

- Relays and Solenoids: Understanding ElectromagnetsDocument2 pagesRelays and Solenoids: Understanding ElectromagnetsTowfiqPas encore d'évaluation

- How Zener Diodes Regulate VoltageDocument22 pagesHow Zener Diodes Regulate VoltageRafath UmaimathPas encore d'évaluation

- Relays N SolenoidsDocument2 pagesRelays N SolenoidsDavison ThomasPas encore d'évaluation

- 056-092 Best Practices For Wiring Resistive SensorsDocument4 pages056-092 Best Practices For Wiring Resistive SensorsManuel Estrela Brito Junior100% (2)

- How To Make Solenoid at Home?: InstructablesDocument4 pagesHow To Make Solenoid at Home?: InstructablesClóvis MorPas encore d'évaluation

- Zener DiodeDocument7 pagesZener DiodeMuhammad AsgharPas encore d'évaluation

- Basic Electronics - Junction DiodesDocument5 pagesBasic Electronics - Junction DiodesMansour MashaeiPas encore d'évaluation

- Solenoid Engine ExplainedDocument12 pagesSolenoid Engine Explainedseema lakraPas encore d'évaluation

- DOL Motor StarterDocument6 pagesDOL Motor StartermshahidshaukatPas encore d'évaluation

- ZenerDocument14 pagesZeneraravindh rhssPas encore d'évaluation

- The Solenoid PDFDocument8 pagesThe Solenoid PDFweldsaidiPas encore d'évaluation

- General Description and Operation (See FIGURE 1. Through FIGURE 3.)Document8 pagesGeneral Description and Operation (See FIGURE 1. Through FIGURE 3.)weldsaidiPas encore d'évaluation

- Project Report 2k19Document23 pagesProject Report 2k19Deepak VishwakarmaPas encore d'évaluation

- I Therefore Conclude That The Zener Volt-Ampere Characteristics For A Typical Zener DiodeDocument2 pagesI Therefore Conclude That The Zener Volt-Ampere Characteristics For A Typical Zener DiodeEllenMaeMalikStylesPas encore d'évaluation

- Transmission Power Shift: Voltage and Electrical Power RequirementsDocument11 pagesTransmission Power Shift: Voltage and Electrical Power RequirementsJesus Carhuamaca PascualPas encore d'évaluation

- SSR-05 IngDocument1 pageSSR-05 IngHafez AymanPas encore d'évaluation

- Battery Desulphator: John Drake Services, IncDocument3 pagesBattery Desulphator: John Drake Services, IncBoulos NassarPas encore d'évaluation

- Slide No. Slide Content Voice Over: ( (VIDEO:13018) ) + P.15.3.2Document4 pagesSlide No. Slide Content Voice Over: ( (VIDEO:13018) ) + P.15.3.2Gaurav JainPas encore d'évaluation

- Integrated CircuitsDocument38 pagesIntegrated CircuitsShashank SharmaPas encore d'évaluation

- Soumyadip Kalsa, Roll - 33, Sub - BiologyDocument13 pagesSoumyadip Kalsa, Roll - 33, Sub - BiologySMOKER GAMINGPas encore d'évaluation

- ZenerDocument5 pagesZeneraravindh rhssPas encore d'évaluation

- Zener DiodeDocument3 pagesZener Diodekanak-825262Pas encore d'évaluation

- Valvula Solenoide S6NDocument4 pagesValvula Solenoide S6NRamon BriceñoPas encore d'évaluation

- Personal Studio: Owner's ManualDocument1 pagePersonal Studio: Owner's ManualFlavioDpfOliveiraPas encore d'évaluation

- Dyna S Electronic Ignition Instructions: InstallationDocument5 pagesDyna S Electronic Ignition Instructions: InstallationAlejandro CardozoPas encore d'évaluation

- Relays in AutomobilesDocument8 pagesRelays in AutomobilesTesfahun TegegnePas encore d'évaluation

- How Solar Cells WorkDocument2 pagesHow Solar Cells WorkSurya KotamrajaPas encore d'évaluation

- Travel Mobile Charger AbstractDocument3 pagesTravel Mobile Charger AbstractVishalKashyap100% (1)

- A4 LDDocument1 pageA4 LDOmar Molina100% (1)

- Controller MotorDocument7 pagesController MotorArdityo SatrianiPas encore d'évaluation

- MS 4T60E: Master Solenoid KitDocument1 pageMS 4T60E: Master Solenoid KitGuilherme ZoboliPas encore d'évaluation

- Soumyadip Kalsa, Roll - 33, Sub - BiologyDocument13 pagesSoumyadip Kalsa, Roll - 33, Sub - BiologySMOKER GAMINGPas encore d'évaluation

- Zener DiodeDocument3 pagesZener DiodeInnocentOvickPas encore d'évaluation

- Presentation On Zener Diode: Submitted byDocument10 pagesPresentation On Zener Diode: Submitted bytej26121994Pas encore d'évaluation

- EE 3105 AssignmentDocument2 pagesEE 3105 AssignmentKarlo Miranda MacadangdangPas encore d'évaluation

- Zener Diode - WikipediaDocument29 pagesZener Diode - WikipediaLupu DanielPas encore d'évaluation

- HDLS Series Switches: Installation Instructions For TheDocument4 pagesHDLS Series Switches: Installation Instructions For Theflasher_for_nokiaPas encore d'évaluation

- Zener DiodeDocument15 pagesZener DiodeEEE M.AASTHIKAPas encore d'évaluation

- Edu Expansion Presentation (Circuits)Document16 pagesEdu Expansion Presentation (Circuits)nandinigupta613Pas encore d'évaluation

- AUTO 131 - Week 03 Worksheet: InstructionsDocument5 pagesAUTO 131 - Week 03 Worksheet: InstructionsRAUL DE JESUS VILLENA AMEZQUITAPas encore d'évaluation

- Diagrama Hidraulico Tren de PotenciaDocument12 pagesDiagrama Hidraulico Tren de Potenciahenotharenas100% (1)

- Codigos de OBD 2Document48 pagesCodigos de OBD 2Rommel VacaPas encore d'évaluation

- 48900Document22 pages48900Jeff RobertPas encore d'évaluation

- Relay Working PrincipleDocument8 pagesRelay Working PrinciplePoornachandar7Pas encore d'évaluation

- Checkballbook: Import Volume IIIDocument10 pagesCheckballbook: Import Volume IIIFS TRANSMISSÕESPas encore d'évaluation

- Flowmaster Rotary Driven Hydraulic Pump Models: 85480, 85481, 85482, 85483, Series B Models: 85247, 85610, 85586 Series ADocument11 pagesFlowmaster Rotary Driven Hydraulic Pump Models: 85480, 85481, 85482, 85483, Series B Models: 85247, 85610, 85586 Series ASIDI ahmedou yahyaPas encore d'évaluation

- 793F Plano HidraulicoDocument10 pages793F Plano HidraulicoSam B VladPas encore d'évaluation

- ARO Valve CatalogDocument80 pagesARO Valve Catalogعبدالله عمرPas encore d'évaluation

- DuplomatikDocument4 pagesDuplomatikado_22Pas encore d'évaluation

- Hand Clutch For Handicapped Person ReportDocument56 pagesHand Clutch For Handicapped Person ReportSesha Thri0% (1)

- Electrovalvula Norgren V52Document4 pagesElectrovalvula Norgren V52Base SistemasPas encore d'évaluation

- Pneumatic JackDocument35 pagesPneumatic JackVignesh viki100% (1)

- Magnetic Effects of Electric Current I: Activity 12.1 Activity 12.1 Activity 12.1 Activity 12.1 Activity 12.1Document13 pagesMagnetic Effects of Electric Current I: Activity 12.1 Activity 12.1 Activity 12.1 Activity 12.1 Activity 12.1shouvik palPas encore d'évaluation

- 27.multipurpose Sheet Metal Cutting and Bending MachineDocument5 pages27.multipurpose Sheet Metal Cutting and Bending MachineMaruthi JacsPas encore d'évaluation

- FIZ102E SuggestedProblemsDocument26 pagesFIZ102E SuggestedProblemsSelin PınarPas encore d'évaluation

- Simulating a Solenoid Actuator in SimulinkDocument1 pageSimulating a Solenoid Actuator in SimulinkDio Izqhaq Risky SasongkoPas encore d'évaluation

- Pneumatic ComponentsDocument2 pagesPneumatic ComponentsDonny ClintonPas encore d'évaluation

- 12769HG-1Manual117 GrifosDocument12 pages12769HG-1Manual117 GrifosrodrigoarrepolPas encore d'évaluation