Académique Documents

Professionnel Documents

Culture Documents

Beam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)

Transféré par

Yisrael AshkenazimTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Beam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)

Transféré par

Yisrael AshkenazimDroits d'auteur :

Formats disponibles

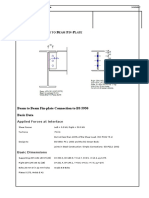

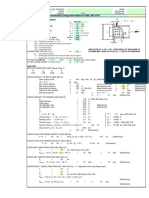

Beam Connection of Conventional Configuration Based on AISC Manual 13th Edition (AISC 360-05)

INPUT DATA & DESIGN SUMMARY

WF BEAM SECTION = > W12X22

GRAVITY SERVICE LOAD P = 22.21 kips

LATERAL TENSION LOAD, ASD T = 11.352 kips

PLATE THICKNESS t = 0.5 in

PLATE STEEL YIELD STRESS Fy = 36 ksi

TRIAL WELD SIZE w= 0.5 in ( 1/2 in)

BOLT DIAMETER f = 0.75 in ( 1 in)

BOLT MATERIAL (A307, A325, A490) ASTM = A325

HOLE TYPE (STD, NSL, OVS, SSL, LSL) => STD

STD = Standard round holes ( d + 1/16 " )

NSL = Long or short-slotted hole normal to load direction

OVS = Oversize round holes

SSL = Short-slotted holes

LSL = Long-slotted holes USE PLATE 9.5" x 4.0" x 3/4" WITH WELD 1/2" EACH SIDE TO

CONNECTION TYPE (SC, N, X) => N COLUMN AND 1 ROW OF TOTAL (3) - 1" BOLTS AT BEAM END.

SC = Slip critical connection

N = Bearing-type connection with threads included in the shear plane

X = Bearing-type connection with threads excluded from the shear plane

TRY BOLT NUMBERS 1 row & 3 bolts per row, (total 3 bolts.)

IS TOP FLANGE COPED ? (1=Yes, 0=No,) => 0 No

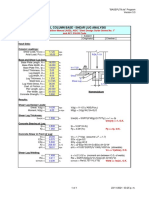

ANALYSIS

SECTION PROPERTIES (AISC 13th Table 1)

d tw tf k

20.8 0.38 0.535 1.04

CHECK CAPACITY OF BOLTS (AISC 360-05 J3)

Allow shear per bolt = 18.8 kips / bolt, (Rn / Wv, AISC 13th Table 7)

(P2 + T2 )0.5 = 49 kips

No. of bolts required = 2.6 Number of bolts used = 3 bolts [Satisfactory]

Bolt spacing required = 3.00 in Bolt spacing used = 3.00 in [Satisfactory]

Edge spacing required = 1.75 in, (Tab J3.4) Edge spacing used = 1.75 in [Satisfactory]

Number of rows required = 1 rows Number of rows used = 1 rows [Satisfactory]

Bolt group capacity = 57 kips > (P2 + T2 )0.5 = 49 kips

> P = 47 kips [Satisfactory]

CHECK CAPACITY OF WELDING (AISC 360-05 J2)

e = 2.25 in, (AISC 360-05, Table J3.4)

Plate thickness = 0.75 in

Weld size,w = 0.50 in

Min allowable weld = 0.25 in [Satisfactory]

Max allowable weld = 0.69 in [Satisfactory]

te = 0.35 in

D = 9.5 in

I = 2 ( te D3 / 12 ) = 50.5 in4

Vertical shear = P / Aw = P / 2 D te = 7.0 ksi

Bending stress = 0.5 P e D / I = 9.9 ksi

Tension stress = T / Aw = T / 2 D t e = 2.2 ksi

2 2 0.5

Resultant Stress = [ (P/Aw) + (0.5 P e D / I + T/Aw) ] = 14.0 ksi

Allow shear Fw / W = (0.6 x 70 ksi) / 2.0 = = 21.0 ksi > 14.0 ksi [Satisfactory]

CHECK PLATE FOR SHEAR CAPACITY (AISC 365-05 G2)

P/A = 6.6 ksi < 0.6 Fy Cv / Wv = 0.6 Fy 1.0 / 1.5 = 14.4 ksi [Satisfactory]

CHECK PLATE FOR TENSION CAPACITY (AISC 365-05 D)

T/A= 2.1 ksi < Fy / Wt = Fy / 1.67 = 21.56 ksi [Satisfactory]

CHECK NET SHEAR FRACTURE (AISC 360-05 J4.2)

Fu = 58 ksi ( AISC Manual 13th Edition, Pg. 2-39)

Pallow = 0.6 Fu / W [ D - n (ds + 1/8 ) ] t = 80 kips > 47 kips [Satisfactory]

CHECK NET TENSION FRACTURE (AISC 360-05 J4.1)

Fu = 58 ksi

Tallow = Fu / W [ D - n (ds + 1/8 ) ] t = 133 kips > 15 kips [Satisfactory]

CHECK BLOCK SHEAR ( WEB TEAR-OUT, AISC 360-05 J4) <== Applicable only for top flange coped.

lh = 1.3 in

lv = 5.3 in

Fu = 65 ksi ( for WF, AISC Manual 13th Edition, Pg. 2-39)

Rbs,P = 0.6 Av Fu / W + At Fu / W = (0.3 lv + 0.5 lh) tw Fu

[Satisfactory]

Rbs,T = (0.5 lv + 2 x 0.3 lh) tw Fu = 83 > T= 15 kips

[Satisfactory]

Vous aimerez peut-être aussi

- UB 254 146 31 B B F - P: X X EAM TO EAM IN LateDocument7 pagesUB 254 146 31 B B F - P: X X EAM TO EAM IN LateihpeterPas encore d'évaluation

- Det-1 Ub457x191x67Document4 pagesDet-1 Ub457x191x67ihpeterPas encore d'évaluation

- Angle SupportDocument1 pageAngle SupportSharyn PolleyPas encore d'évaluation

- Design of Pinned Base Plate BP11Document15 pagesDesign of Pinned Base Plate BP11vivekPas encore d'évaluation

- Gusset Plate Connection DesignDocument3 pagesGusset Plate Connection DesignMin Khant KyawPas encore d'évaluation

- 05 Erection ChecklistDocument8 pages05 Erection ChecklistAnonymous cG5MyHMPas encore d'évaluation

- Base PLT For IT CentreDocument13 pagesBase PLT For IT CentreUday UdmalePas encore d'évaluation

- Column Base PlateDocument4 pagesColumn Base PlateYHK3001Pas encore d'évaluation

- Staad-Technical Reference 2007 Complete PDFDocument782 pagesStaad-Technical Reference 2007 Complete PDFdesikudi9000Pas encore d'évaluation

- PINNED BASE DESIGN CALCULATIONDocument4 pagesPINNED BASE DESIGN CALCULATIONTuanQuachPas encore d'évaluation

- Analysis and Concrete Design of Structure With STAADDocument18 pagesAnalysis and Concrete Design of Structure With STAADGautam PaulPas encore d'évaluation

- All Type Pile Cap DesignDocument2 pagesAll Type Pile Cap DesignJohn BandaPas encore d'évaluation

- Bolted Splice ConnectionDocument6 pagesBolted Splice ConnectionSeetharam Mahanthi100% (1)

- LIFTING PADEYE STRESS ANALYSISDocument16 pagesLIFTING PADEYE STRESS ANALYSISCHEPas encore d'évaluation

- MC ASD Prying Ref 0Document2 pagesMC ASD Prying Ref 0Roberto Ramirez AlcantarPas encore d'évaluation

- Eccentric Footing Design Based On ACI 318-05: Input Data Design SummaryDocument3 pagesEccentric Footing Design Based On ACI 318-05: Input Data Design SummaryWillian Delgado MendozaPas encore d'évaluation

- Basic Data:: Calculation of Gust Effect FactorDocument1 pageBasic Data:: Calculation of Gust Effect FactorYaser ShabasyPas encore d'évaluation

- Civil Structural Calculations for Essar Oil Refinery ProjectDocument70 pagesCivil Structural Calculations for Essar Oil Refinery ProjectthakrarhitsPas encore d'évaluation

- Ocbf IbcDocument3 pagesOcbf IbcNikki RobertsPas encore d'évaluation

- AISC 13ed - LRFD Bolted Moment Connections Post r4Document613 pagesAISC 13ed - LRFD Bolted Moment Connections Post r4jh50000Pas encore d'évaluation

- Brace Frame Connection ECBFDocument48 pagesBrace Frame Connection ECBFleonid48Pas encore d'évaluation

- Calculations of HEB260 beam splice connectionsDocument23 pagesCalculations of HEB260 beam splice connectionsLudovicoVicoPas encore d'évaluation

- Calculation of Beam/Column Splice: HB-300x300x10x15Document5 pagesCalculation of Beam/Column Splice: HB-300x300x10x15amachmouchiPas encore d'évaluation

- Anchor bolt design calculation for piperack foundationDocument10 pagesAnchor bolt design calculation for piperack foundationArivoli JayaramanPas encore d'évaluation

- Norma Aisc-Asd89 Sap2000Document29 pagesNorma Aisc-Asd89 Sap2000IVAN SAAVEDRA TPas encore d'évaluation

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2மாறன் செங்கேணிPas encore d'évaluation

- Portal Method: For Transversal/Longitudinal SectionDocument70 pagesPortal Method: For Transversal/Longitudinal SectionJoseph Tan LantoPas encore d'évaluation

- Calculation of end plate beam connection designDocument1 pageCalculation of end plate beam connection designFortunata Citraningrum SukmonoPas encore d'évaluation

- Jindal ProfilesDocument15 pagesJindal ProfilesJane NishaPas encore d'évaluation

- UB406X178X85Document5 pagesUB406X178X85Uday UdmalePas encore d'évaluation

- HILTI RE-500 Rebar ConnectionDocument7 pagesHILTI RE-500 Rebar ConnectionAlma M. LaraPas encore d'évaluation

- Footing Design DimensionsDocument3 pagesFooting Design DimensionsMesfinPas encore d'évaluation

- 2b. Shear Connection - BTOB (M Project) - 0618Document210 pages2b. Shear Connection - BTOB (M Project) - 0618Omprakash Khodke100% (1)

- Steel Column Base - Shear Lug AnalysisDocument1 pageSteel Column Base - Shear Lug AnalysisVega DesPas encore d'évaluation

- Manual For Detailing Reinforced Concrete Structures To Ec2Document1 pageManual For Detailing Reinforced Concrete Structures To Ec2MahmoudRadiPas encore d'évaluation

- Spreadsheets To BS 8110Document11 pagesSpreadsheets To BS 8110NitinShepurPas encore d'évaluation

- Built - Up Column Design ("Effectiveness of Various Built-Up Columns") Section PropertiesDocument2 pagesBuilt - Up Column Design ("Effectiveness of Various Built-Up Columns") Section PropertiesAnandPas encore d'évaluation

- Quikjoint - Eaves Haunch Calculations PDFDocument9 pagesQuikjoint - Eaves Haunch Calculations PDFvtalexPas encore d'évaluation

- FLECHA (Moment-Curvature Wall - Cali08)Document1 pageFLECHA (Moment-Curvature Wall - Cali08)Niranjan GodagePas encore d'évaluation

- Steel ConnectionsDocument83 pagesSteel ConnectionsMEPPas encore d'évaluation

- Base PlateDocument2 pagesBase PlateEosPas encore d'évaluation

- Doseme Egilme ACI (2 Sira-EN)Document1 pageDoseme Egilme ACI (2 Sira-EN)OktayPas encore d'évaluation

- Design of Fin Plate Connection - (Beam To Column) : DT12007-SS-C8831 DT12007Document3 pagesDesign of Fin Plate Connection - (Beam To Column) : DT12007-SS-C8831 DT12007sundarPas encore d'évaluation

- Base Plate Design (Pin) Asd For CompressionDocument54 pagesBase Plate Design (Pin) Asd For CompressionEmdadul HuqPas encore d'évaluation

- Tubular Sections-Hazira Project (Available)Document3 pagesTubular Sections-Hazira Project (Available)Ouseppachan AmbookenPas encore d'évaluation

- Design of PurlinDocument2 pagesDesign of PurlinRAVI PRAKASH SAINIPas encore d'évaluation

- Zapatas Con Viga de Amarre-DSA-OSHPDDocument11 pagesZapatas Con Viga de Amarre-DSA-OSHPDWillian Delgado MendozaPas encore d'évaluation

- Design Calculation For Hexadecagonal Pole: L W W T FDocument3 pagesDesign Calculation For Hexadecagonal Pole: L W W T FsaravqwertyPas encore d'évaluation

- Anchor Design for 219mm Pole SupportDocument1 pageAnchor Design for 219mm Pole SupportS A K ClostrePas encore d'évaluation

- British Verification Problem 2Document7 pagesBritish Verification Problem 2elixnzPas encore d'évaluation

- Base Plate & Anchor BoltDocument40 pagesBase Plate & Anchor BoltSiva baalanPas encore d'évaluation

- Hunch Splice-10bolts-2 Row PatternDocument5 pagesHunch Splice-10bolts-2 Row PatternSrikanth SikhaPas encore d'évaluation

- Isolated Footing 73Document21 pagesIsolated Footing 73Ritz Anne Chan TanPas encore d'évaluation

- Beam ConnectionDocument3 pagesBeam ConnectionMalik awanPas encore d'évaluation

- Beam ConnectionDocument3 pagesBeam ConnectionLeonardo PimentelPas encore d'évaluation

- Beam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)Document64 pagesBeam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)christian abogadoPas encore d'évaluation

- Beam connection design summaryDocument1 pageBeam connection design summaryKaren Esther Acuña VelasquezPas encore d'évaluation

- Beam Connection Design SummaryDocument4 pagesBeam Connection Design SummaryAlpha100% (2)

- Moment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16Document4 pagesMoment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16gyanwapiPas encore d'évaluation

- BeamConnection Calculo SoldaduraDocument30 pagesBeamConnection Calculo SoldaduraMaría TejedaPas encore d'évaluation

- WF Base Plate Design Based On AISC Manual 13th Edition (AISC 360-05)Document1 pageWF Base Plate Design Based On AISC Manual 13th Edition (AISC 360-05)Yisrael AshkenazimPas encore d'évaluation

- Caranay Column 2Document1 pageCaranay Column 2Yisrael AshkenazimPas encore d'évaluation

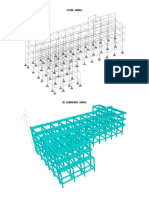

- Staad ResultsDocument12 pagesStaad ResultsYisrael AshkenazimPas encore d'évaluation

- Earthquake Load ParametersDocument2 pagesEarthquake Load ParametersYisrael AshkenazimPas encore d'évaluation

- Wind Load CalculationDocument4 pagesWind Load CalculationYisrael AshkenazimPas encore d'évaluation

- Staad ModelDocument2 pagesStaad ModelYisrael AshkenazimPas encore d'évaluation

- Staad ModelDocument2 pagesStaad ModelYisrael AshkenazimPas encore d'évaluation

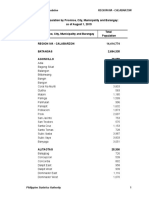

- Bacolod To IloiloDocument14 pagesBacolod To IloiloYisrael AshkenazimPas encore d'évaluation

- Structural Model Using StaadDocument9 pagesStructural Model Using StaadYisrael AshkenazimPas encore d'évaluation

- Pile Cap Design ProblemDocument1 pagePile Cap Design ProblemYisrael AshkenazimPas encore d'évaluation

- Staad 3d RenderDocument1 pageStaad 3d RenderYisrael AshkenazimPas encore d'évaluation

- LPTRP FlowchartDocument1 pageLPTRP FlowchartYisrael Ashkenazim0% (1)

- R04ADocument5 pagesR04AstumbagahanPas encore d'évaluation

- HW1 TheoryDocument11 pagesHW1 TheoryYisrael AshkenazimPas encore d'évaluation

- Korea Visa Requirements and Guidelines Updated 03012019Document2 pagesKorea Visa Requirements and Guidelines Updated 03012019Yisrael AshkenazimPas encore d'évaluation

- Elevator PlansDocument1 pageElevator PlansYisrael AshkenazimPas encore d'évaluation

- Isolated footing design for load case 1Document3 pagesIsolated footing design for load case 1Yisrael AshkenazimPas encore d'évaluation

- Jezreel S. Benliro 2016-61147: Concrete 0Document2 pagesJezreel S. Benliro 2016-61147: Concrete 0Yisrael AshkenazimPas encore d'évaluation

- Pile Cap Design 1Document3 pagesPile Cap Design 1Yisrael AshkenazimPas encore d'évaluation

- Design Reaction - Continuous FootingDocument1 pageDesign Reaction - Continuous FootingYisrael AshkenazimPas encore d'évaluation

- Continuous Footing Design MomentsDocument5 pagesContinuous Footing Design MomentsYisrael AshkenazimPas encore d'évaluation

- Mat Foundation Design: Soil Data MaterialsDocument2 pagesMat Foundation Design: Soil Data MaterialsYisrael AshkenazimPas encore d'évaluation

- HW1 TheoryDocument11 pagesHW1 TheoryYisrael AshkenazimPas encore d'évaluation

- Assignment ShellsDocument1 pageAssignment ShellsYisrael AshkenazimPas encore d'évaluation

- College of Pharmacy ProjectDocument1 pageCollege of Pharmacy ProjectYisrael AshkenazimPas encore d'évaluation

- Purlin and Roof DesignDocument4 pagesPurlin and Roof DesignAnilkumar Cm100% (2)

- Frame 2 Portal MethodDocument1 pageFrame 2 Portal MethodYisrael AshkenazimPas encore d'évaluation

- Frame 1 Portal MethodDocument1 pageFrame 1 Portal MethodYisrael AshkenazimPas encore d'évaluation

- Para Sayo Chords by Juan Karlos Labajo Tabs at Ultimate Guitar ArchiveDocument3 pagesPara Sayo Chords by Juan Karlos Labajo Tabs at Ultimate Guitar ArchiveYisrael AshkenazimPas encore d'évaluation

- IP46 - Guide To Use BAPCO WPS & Welding ProceduresDocument4 pagesIP46 - Guide To Use BAPCO WPS & Welding ProceduressajiPas encore d'évaluation

- Digital and Analog SignalsDocument10 pagesDigital and Analog SignalsSrishti GargPas encore d'évaluation

- Hospital Managemen T System: Oose LAB FileDocument62 pagesHospital Managemen T System: Oose LAB FileAASHPas encore d'évaluation

- Chapter 1Document11 pagesChapter 1bekemaPas encore d'évaluation

- Sensitive Albuminuria Analysis Using Dye-Binding Based Test StripsDocument24 pagesSensitive Albuminuria Analysis Using Dye-Binding Based Test StripsВалерия БедоеваPas encore d'évaluation

- Open Hole Logs Introduction GR SP CALDocument21 pagesOpen Hole Logs Introduction GR SP CALmagedPas encore d'évaluation

- ISO 11957 1996 en PreviewDocument5 pagesISO 11957 1996 en PreviewHoang TraPas encore d'évaluation

- TM View Software User - S ManualDocument190 pagesTM View Software User - S ManualLuis SánchezPas encore d'évaluation

- Class 9 Sample Paper 2020-21Document3 pagesClass 9 Sample Paper 2020-21sasta jiPas encore d'évaluation

- Brake SystemDocument19 pagesBrake SystemSudarshan NepalPas encore d'évaluation

- Measurement of SubstructureDocument24 pagesMeasurement of SubstructureAamaniVeeranam80% (10)

- The Big Bang Never HappenedDocument3 pagesThe Big Bang Never HappenedIvan Vule Fridman100% (1)

- 12.6 Perform An Activity - Measuring The Critical Angle For Various MediaDocument2 pages12.6 Perform An Activity - Measuring The Critical Angle For Various MediaRajeshri SoniPas encore d'évaluation

- Essay For Villa Savoye AbstractDocument1 pageEssay For Villa Savoye AbstractFrancis PohPas encore d'évaluation

- Impact of GIC On Power TransformersDocument141 pagesImpact of GIC On Power TransformersAkash Verma100% (1)

- SQL SlidesDocument65 pagesSQL SlidescopsamostoPas encore d'évaluation

- 006 PVC & CPVC Schedule 80 Fittings, Unions Tank Adapters, Expansion Joints & Saddles PDFDocument92 pages006 PVC & CPVC Schedule 80 Fittings, Unions Tank Adapters, Expansion Joints & Saddles PDFnicacio_89507470Pas encore d'évaluation

- Active Heating and CoolingDocument16 pagesActive Heating and Coolinga_j_sanyal2590% (1)

- Prepare and Interpret Technical DrawingDocument5 pagesPrepare and Interpret Technical DrawingDwin Rosco75% (4)

- Mechanical Engineering Conference ProgramDocument40 pagesMechanical Engineering Conference Programirinuca12Pas encore d'évaluation

- Basic Hydraulic SystemsDocument128 pagesBasic Hydraulic Systemsbeau04297% (35)

- Eee f111 Electrical Sciences1Document3 pagesEee f111 Electrical Sciences1aryan mittalPas encore d'évaluation

- Richard A. Nyquist and Ronald O. Kagel (Auth.) - Handbook of Infrared and Raman Spectra of Inorganic Compounds and Organic Salts. Infrared Spectra of Inorganic Compounds-Academic Press (1971)Document499 pagesRichard A. Nyquist and Ronald O. Kagel (Auth.) - Handbook of Infrared and Raman Spectra of Inorganic Compounds and Organic Salts. Infrared Spectra of Inorganic Compounds-Academic Press (1971)Patrícia Bodanese PratesPas encore d'évaluation

- The I AM 22 Chakra ChartDocument8 pagesThe I AM 22 Chakra ChartMarina G. Giamalidi100% (22)

- Molecular Cell Biology Lodish 7th Edition Solutions ManualDocument8 pagesMolecular Cell Biology Lodish 7th Edition Solutions ManualmarisorbornewwssPas encore d'évaluation

- Plasma CuttingDocument12 pagesPlasma Cuttingpavi32Pas encore d'évaluation

- LAB REPORT-Rock Pore Volume and Porosity Measurement by Vacuum Saturation-GROUP - 5-PETE-2202Document13 pagesLAB REPORT-Rock Pore Volume and Porosity Measurement by Vacuum Saturation-GROUP - 5-PETE-2202Jeremy MacalaladPas encore d'évaluation

- 01238-00-AD TY96 Installation ManualDocument42 pages01238-00-AD TY96 Installation ManualJohan SwanepoelPas encore d'évaluation

- Speedrunfile 1Document26 pagesSpeedrunfile 1Adrian AquinoPas encore d'évaluation

- Lectures Accompanying The Book - Solid State Physics - An (PDFDrive)Document148 pagesLectures Accompanying The Book - Solid State Physics - An (PDFDrive)Raza Ali RazaPas encore d'évaluation