Académique Documents

Professionnel Documents

Culture Documents

Mathcad - Pembebanan Pondasi Circuit Braker

Transféré par

andre novanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mathcad - Pembebanan Pondasi Circuit Braker

Transféré par

andre novanDroits d'auteur :

Formats disponibles

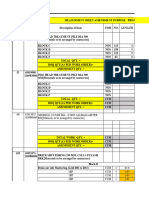

PT Harista Karsa Mandiri

VACUUM CIRCUIT BRAKER (VCB) FOUNDATION DESIGN

1. PILE CAP'S AND STUMP SELFWEIGHT :

COG

COG

COG

COG COG

COG

Stump CB-CT

Stump VCB

Stump DS Stump PI Stump DS

kN kN

Concrete unit weight : γbet 24 Steel Unit Weight : γbj 78.5

3 3

m m

Define Stump or Stub Dimension :

VCB Stump : Lstvcb 1.495m Bstvcb 1.145m Hstvcb 1.6m

DS Stump : Lstds 2m Bstds 0.9m Hstds 1.6m

CB-CT Stump : Lstcbct 1.495m Bstcbct 0.6m Hstcbct 1.6m

PI Stump : Lstpi 0.8m Bstpi 0.8m Hstpi 1.6m

3

Volume of the DS Stump : VSTDS Lstds Bstds Hstds 2.88 m

3

Volume of the PI Stump : VSTPI Lstpi Bstpi Hstpi 1.024 m

Pembebanan Travo Inalum Travo Inalum - 1

PT Harista Karsa Mandiri

3

Volume of the VCB Stump : VSTVCB Lstvcb Bstvcb Hstvcb 2.739 m

3

Volume of the CB-CT Stump : VSTCBCT Lstcbct Bstcbct Hstcbct 1.435 m

Weight of The Stump WSTDS VSTDS γbet 69.12 kN

DS :

Weight of The Stump WSTVCB VSTVCB γbet 65.732 kN

VCB :

Weight of The Stump WSTPI VSTPI γbet 24.576 kN

PI :

Weight of The Stump WSTCBCT VSTCBCT γbet 34.445 kN

CB-CT :

Define Pile Cap Dimension (Capping) :

Lenght of the Cap: Lcp 8.5m Width of the Cap : Bcp 3.5m

3

Thickness of the Cap : tcp 0.6m Volume of the Cap : Vcp Lcp Bcp tcp 17.85 m

Weight of The Cap : PCP Vcp γbet 428.4 kN

Define Center Of Gravity (COG) of The VCB and Capping :

VCB COG : x CGVCB 1.549m y CGVCB 0m zCGVCB 0.9m 2.6m 3.5 m

DS COG : x CGDSa 3.05m y CGDSa 0m zCGDSa 0.2m 2.2m

x CGDSb 3.05m y CGDSb 0m zCGDSb 0.2m 2.2m

PI COG : x CGPI 1.582 m y CGPI 0m zCGPI 0.4m 2.2m

CB-CT COG x CGCBCT 0.083 m y CGCBCT 0m zCGCBCT 0.4m 2.2m

:

Capping COG : x cp 0m y cp 0m zcp 0.45m

2. UPPER STRUCTURE STATIC LOAD :

2.1. Dead Load Parameter :

WVCB

VCB Weight : WVCB 4kN VCB Single Point Bearing : PVCB 1 kN

4

WCBCT

CB + CT WCBCT 1kN CBCT Single Point Bearing : PCBCT 0.5 kN

Weight : 2

WDS

DS Weight : WDS 8kN DS Single Point PDS 1 kN

Bearing : 8

WPI

PI Weight : WPI 3.2kN PI Single Point PPI 0.8 kN

Bearing : 4

Pembebanan Travo Inalum Travo Inalum - 2

PT Harista Karsa Mandiri

PDS PDS PDS PDS

PVCB PVCB

PPI PPI

PCBCT

WSTDS WSTPI WSTDS

WSTCBCT WSTVBC

Arm Forces of The Bearing Point Load in X Direction (Longitudinal) :

x VCB1 1.277m x VCB2 1.822m

x DS1 3.3m x DS2 2.8m x DS3 2.8m x DS4 3.3m

x CBCT 0.083 m

x PI1 1.753 m x PI2 1.413 m

Pembebanan Travo Inalum Travo Inalum - 3

PT Harista Karsa Mandiri

Arm Forces of The Bearing Point Load in Y Direction (Transversal) :

y VCB1 0.375 m y VCB2 0.375m

y DS1 0.725 m y DS2 0.485 m y DS3 0.485m y DS4 0.725m

y CBCT1 0.375 m y CBCT2 0.375m

y PI1 0.17m y PI2 0.17m

Define Point Bearing Load :

From DS Load :

PDS1 PDS 1 kN PDS2 PDS PDS3 PDS PDS4 PDS PDS5 PDS

PDS6 PDS PDS7 PDS PDS8 PDS PDS9 PDS PDS10 PDS

PDS11 PDS PDS12 PDS PDS13 PDS PDS14 PDS PDS15 PDS

PDS16 PDS

From VCB Load :

PVCB1 PVCB 1 kN PVCB2 PVCB PVCB3 PVCB PVCB4 PVCB

From PI Load :

PPI1 PPI 0.8 kN PPI2 PPI PPI3 PPI PPI4 PPI

From CBCT Load :

PCBCT1 PCBCT 0.5 kN PCBCT2 PCBCT

2.2. Live Load Parameter :

q LL 3kPa

Assume That Live Load exist During Construction Work :

Total Weight of the Live Load : PLL q LL Lcp Bcp 89.25 kN

Live Forces Working Line assume in same path with VCB COG ::

x LL x CGVCB 1.549 m y LL y CGVCB 0 m zLL zCGVCB 3.5 m

2.3. Wind Load Parameter :

m

Design wind velocity : v wind 25 90 kph

s

2

v wind kPa

Wind Pressure: Pw 0.391 kPa

16 2

m

100

2

s

Pembebanan Travo Inalum Travo Inalum - 4

PT Harista Karsa Mandiri

Compressive wind coefficien : cwc 0.9 Suction wind coefficien : cws 0.4

Contact Plane of the Transformer area subject to wind load (Equivalent with Transformer dimension plane) :

2

AWLL1 0.85m 0.6m 0.25m 0.8m 0.71 m (Longitudinal Due to VCB

Plane )

2

AWLL2 0.6m 0.4m 0.24 m (Longitudinal Due to DS

Plane )

2

AWLT1 0.75m 0.85m 3 0.25m 0.8m 1.238 m (Transversal Due to VCB

Plane)

2

AWLT2 0.7m 0.4m 0.28 m (Transversal Due to DS Plane)

Longitudinal Direction :

Compressive force :at front of wind contact plane : PWCL1 cwc AWLL1 Pw 0.25 kN (Due to VCB)

PWCL2 cwc AWLL2 Pw 0.084 kN (Due to

DS)

Suction force :at back of wind contact plane : PWSL1 cws AWLL1 Pw 0.111 kN (Due to VCB)

PWSL2 cws AWLL2 Pw 0.038 kN (Due to

DS)

Transversal Direction :

Compressive force :at front of wind contact plane : PWCT1 cwc AWLT1 Pw 0.435 kN (Due to

VCB)

PWCT2 cwc AWLT2 Pw 0.098 kN (Due to DS)

Suction force :at back of wind contact plane : PWST1 cws AWLT1 Pw 0.193 kN (Due to

VCB)

PWST2 cws AWLT2 Pw 0.044 kN (Due to DS)

Wind Forces Working Line assume in same path with VCB and DS COG ::

x WL1 x CGVCB 1.549 m y WL1 y CGVCB 0 m zWL1 zCGVCB 3.5 m

x WL2 x CGDSa 3.05 m y WL2 y CGDSa 0 m zWL2 zCGDSa 2.4 m

3. EARTHQUAKE LOAD :

3.1. VCB, DS, CB-CT, PI Earthquake Load :

Weight of the VCB, DS, CB-CT, PI :

Seismic Response Coefficient : Cg 0.55 (Medium Soil Zone)

Koefisien keutamaan : Ig 1

Seismic Response Modification Coefficien : Rg 3.5

Pembebanan Travo Inalum Travo Inalum - 5

PT Harista Karsa Mandiri

Cg Ig

Earthquake Base Shear : PBSVCB WVCB 0.629 kN

Rg

Cg Ig

PBSDS WDS 1.257 kN

Rg

Cg Ig

PBSCBCT WCBCT 0.157 kN

Rg

Cg Ig

PBSPI WPI 0.503 kN

Rg

PBSCBCT

PBSVCB

PBSPI

PBSDS PBSDS

PBSSTVCB

PBSSTCBCT

PBSSTDS PBSSTPI PBSSTDS

PBSC

3.2. STUMP VCB, DS, CB-CT, PI Earthquake Load :

Weight of the Stump VCB, DS, CB-CT, PI :

Seismic Response Coefficient : Cg 0.55 (Medium Soil Zone)

Koefisien keutamaan : Ig 1

Seismic Response Modification Coefficien : Rg 3.5

Cg Ig

Earthquake Base Shear : PBSSTVCB WSTVCB 10.329 kN

Rg

Pembebanan Travo Inalum Travo Inalum - 6

PT Harista Karsa Mandiri

Cg Ig

PBSSTDS WSTDS 10.862 kN

Rg

Cg Ig

PBSSTCBCT WSTCBCT 5.413 kN

Rg

Cg Ig

PBSSTPI WSTPI 3.862 kN

Rg

3.3. Capping Earthquake Load :

Weight of the Capping : PCP 428.4 kN

Seismic Response Coefficient : Cg 0.55 (Medium Soil Zone)

Koefisien keutamaan : Ig 1

Seismic Response Modification Coefficien : Rg 3.5

Cg Ig

Earthquake Base Shear : PBSC PCP 67.32 kN

Rg

4. LOAD COMBINATION FOR FOUNDATION DESIGN :

4.1. LOADING LIST

:

VCB Weight : WVCB 4 kN or

PVCB1 1 kN PVCB2 1 kN PVCB3 1 kN PVCB4 1 kN

DS Weight : WDS 8 kN or

PDS1 1 kN PDS2 1 kN PDS3 1 kN PDS4 1 kN

PDS5 1 kN PDS6 1 kN PDS7 1 kN PDS8 1 kN

PDS9 1 kN PDS10 1 kN PDS11 1 kN PDS12 1 kN

PDS13 1 kN PDS14 1 kN PDS15 1 kN PDS16 1 kN

PI Weight : WPI 3.2 kN or

PPI1 0.8 kN PPI2 0.8 kN PPI3 0.8 kN PPI4 0.8 kN

CB-CT Weight : WCBCT 1 kN or

PCBCT1 0.5 kN PCBCT2 0.5 kN

Stump DS Weight: WSTDS 69.12 kN

Stump VCB Weight: WSTVCB 65.732 kN

Pembebanan Travo Inalum Travo Inalum - 7

PT Harista Karsa Mandiri

Stump PI Weight: WSTPI 24.576 kN

Stump CB-CT Weight: WSTCBCT 34.445 kN

Capping Weight : PCP 428.4 kN

Live Load from construction Work : PLL 89.25 kN

Wind Load : PWCL1 0.25 kN PWSL1 0.111 kN

PWCL2 0.084 kN PWSL2 0.038 kN

PWCT1 0.435 kN PWST1 0.193 kN

PWCT2 0.098 kN PWST2 0.044 kN

Earthquake Load from PBSVCB 0.629 kN PBSDS 1.257 kN

VCB, PI, DS, CB-CT::

PBSPI 0.503 kN PBSCBCT 0.157 kN

Earthquake Load from PBSSTVCB 10.329 kN PBSSTDS 10.862 kN

Stump VCB, PI, DS,

CB-CT:: PBSSTPI 3.862 kN PBSSTCBCT 5.413 kN

Earthquake Load from Capping : PBSC 67.32 kN

Dead Load :

PDL WVCB 2WDS WCBCT WPI 2WSTDS WSTVCB WSTPI WSTCBCT 287.193 kN

4.2. AXIAL COMBINATION FOR ULS :

PULS1 1.4 PDL PCP 1001.83 kN PULS2 1.2 PDL PCP 1.6 PLL 1001.512 kN

PULS3 1.46 PDL PCP PLL 1134.016 kN PULS4 0.94 PDL PCP PLL 761.907 kN

PULS5 1.34 PDL PCP PLL 1048.145 kN PULS6 1.06 PDL PCP PLL 847.779 kN

PULS7 1.46 PDL PCP PLL 1134.016 kN PULS8 0.94 PDL PCP PLL 761.907 kN

PULS9 1.34 PDL PCP PLL 1048.145 kN PULS10 1.06 PDL PCP PLL 847.779 kN

PULS11 0.64 PDL PCP 457.979 kN PULS12 1.16 PDL PCP 830.088 kN

PULS13 1.04 PDL PCP 744.217 kN PULS14 0.76 PDL PCP 543.851 kN

PULS15 0.64 PDL PCP 457.979 kN PULS16 1.16 PDL PCP 830.088 kN

PULS17 1.04 PDL PCP 744.217 kN PULS18 0.76 PDL PCP 543.851 kN

Pembebanan Travo Inalum Travo Inalum - 8

PT Harista Karsa Mandiri

4.3. DEFINE MOMEN LOAD :

Momen Load at Y Axis :

VCB Momen Load :

M VCBY PVCB1 PVCB2 x VCB1 PVCB3 PVCB4 x VCB2 6.198 kN m

DS Momen Load :

M DSYa PDS1 PDS2 PDS3 PDS4 x DS1 PDS5 PDS6 PDS6 PDS8 x DS2 24.4 kN m

M DSYb PDS9 PDS10 PDS11 PDS12 x DS3 PDS13 PDS14 PDS15 PDS16 x DS4 24.4 kN m

M DSY M DSYa M DSYb 0 kN m

PI Momen Load :

M PIY PPI1 PPI2 x PI1 PPI2 PPI3 x PI2 5.066 kN m

CB-CT Momen Load :

M CBCTY PCBCT1 PCBCT2 x CBCT 0.083 kN m

Stump VCB Momen Load

:

M STVCBY WSTVCB x CGVCB 101.819 kN m

Stump DS Momen Load :

M STDSYa WSTDS x CGDSa 210.816 kN m

M STDSYb WSTDS x CGDSb 210.816 kN m

M STDSY M STDSYa M STDSYb 0 kN m

Stump PI Momen Load :

M STPIY WSTPI x CGPI 38.879 kN m

Stump CB-CT Momen Load :

M STCBCTY WSTCBCT x CGCBCT 2.859 kN m

Capping Momen Load : Live Load Momen Load :

M CPY PCP x cp 0 kN m M LLY PLL x LL 138.248 kN m

Wind Momen Load :

M WY PWCT1 zCGVCB PWST1 zCGVCB PWCT2 zCGDSa PWST2 zCGDSa PWCT2 zCGDSb PWST2 zCGDSb 2.882 k

Earthquake Momen Load :

M EQMY PBSVCB zCGVCB PBSC zcp PBSDS zCGDSa PBSDS zCGDSb PBSPI zCGPI PBSCBCT zCGCBCT 40.244 kN

Pembebanan Travo Inalum Travo Inalum - 9

PT Harista Karsa Mandiri

Earthquake Stump Momen Load :

Hstvcb Hstpi Hstds Hstcbct

M EQSTY PBSSTVCB PBSSTPI 2PBSSTDS PBSSTCBCT 33.062 kN m

2 2 2 2

Earthquake Total Momen Load :

M EQY M EQMY M EQSTY 73.306 kN m

Momen Load at X Axis :

VCB Momen Load :

M VCBX PVCB1 PVCB3 y VCB1 PVCB2 PVCB4 y VCB2 0 kN m

DS Momen Load :

M DSXa PDS1 PDS5 PDS9 PDS13 y DS1 PDS2 PDS6 PDS10 PDS14 y DS2 4.84 kN m

M DSXb PDS3 PDS7 PDS11 PDS15 y DS3 PDS4 PDS8 PDS12 PDS16 y DS4 4.84 kN m

M DSX M DSXa M DSXb 0 kN m

PI Momen Load :

M PIX PPI1 PPI3 y PI1 PPI2 PPI4 y PI2 0 kN m

CB-CT Momen Load :

M CBCTX PCBCT1 y CBCT1 PCBCT2 y CBCT2 0 kN m

Capping Momen Load : Live Load Momen Load :

M CPX PCP y cp 0 kN m M LLX PLL y LL 0 kN m

Wind Momen Load :

M WX PWCL1 zCGVCB PWSL1 zCGVCB PWCL2 zCGDSa PWSL2 zCGDSa PWCL2 zCGDSb PWSL2 zCGDSb 1.847 k

Earthquake Momen Load :

M EQMX PBSVCB zCGVCB PBSC zcp PBSDS zCGDSa PBSDS zCGDSb PBSPI zCGPI PBSCBCT zCGCBCT 40.244 kN

Earthquake Stump Momen Load :

Hstvcb Hstpi Hstds Hstcbct

M EQSTX PBSSTVCB PBSSTPI 2PBSSTDS PBSSTCBCT 33.062 kN m

2 2 2 2

Earthquake Total Momen

Load :

M EQX M EQMX M EQSTX 73.306 kN m

Total Momen Dead Load in Y Direction :

M DLy M VCBY M DSY M PIY M CBCTY M STVCBY M STDSY M STPIY M STCBCTY 61.13 kN m

Pembebanan Travo Inalum Travo Inalum - 10

PT Harista Karsa Mandiri

Total Momen Dead Load in X Direction :

M DLx M VCBX M DSX M PIX M CBCTX 0 kN m

4.4. MOMEN-Y COMBINATION FOR ULS :

M ULSY1 1.4 M DLy M CPY 85.583 m kN

M ULSY2 1.2 M DLy M CPY 1.6 M LLY 294.554 m kN

M ULSY3 1.46 M DLy M CPY M LLY M EQY 0.3 M EQX 322.797 m kN

M ULSY4 0.94 M DLy M CPY M LLY M EQY 0.3 M EQX 247.025 m kN

M ULSY5 1.34 M DLy M CPY M LLY M EQY 0.3 M EQX 168.849 m kN

M ULSY6 1.06 M DLy M CPY M LLY M EQY 0.3 M EQX 107.748 m kN

M ULSY7 1.46 M DLy M CPY M LLY 0.3M EQY M EQX 322.797 m kN

M ULSY8 0.94 M DLy M CPY M LLY 0.3M EQY M EQX 144.396 m kN

M ULSY9 1.34 M DLy M CPY M LLY 0.3M EQY M EQX 271.477 m kN

M ULSY10 1.06 M DLy M CPY M LLY 0.3M EQY M EQX 107.748 m kN

M ULSY11 0.64 M DLy M CPY M EQY 0.3 M EQX 134.422 m kN

M ULSY12 1.16 M DLy M CPY M EQY 0.3 M EQX 122.226 m kN

M ULSY13 1.04 M DLy M CPY M EQY 0.3 M EQX 12.261 m kN

M ULSY14 0.76 M DLy M CPY M EQY 0.3 M EQX 48.839 m kN

M ULSY15 0.64 M DLy M CPY 0.3M EQY M EQX 134.422 m kN

M ULSY16 1.16 M DLy M CPY 0.3M EQY M EQX 19.597 m kN

M ULSY17 1.04 M DLy M CPY 0.3M EQY M EQX 114.89 m kN

M ULSY18 0.76 M DLy M CPY 0.3M EQY M EQX 48.839 m kN

4.5. MOMEN-X COMBINATION FOR ULS

:

M ULSX1 1.4 M DLx M CPX 0 m kN

M ULSX2 1.2 M DLx M CPX 1.6 M LLX 0 m kN

M ULSX3 1.46 M DLx M CPX M LLX M EQX 0.3 M EQY 95.298 m kN

M ULSX4 0.94 M DLx M CPX M LLX M EQX 0.3 M EQY 51.314 m kN

M ULSX5 1.34 M DLx M CPX M LLX M EQX 0.3 M EQY 51.314 m kN

M ULSX6 1.06 M DLx M CPX M LLX M EQX 0.3 M EQY 95.298 m kN

Pembebanan Travo Inalum Travo Inalum - 11

PT Harista Karsa Mandiri

M ULSX7 1.46 M DLx M CPX M LLX 0.3M EQX M EQY 95.298 m kN

M ULSX8 0.94 M DLx M CPX M LLX 0.3M EQX M EQY 51.314 m kN

M ULSX9 1.34 M DLx M CPX M LLX 0.3M EQX M EQY 51.314 m kN

M ULSX10 1.06 M DLx M CPX M LLX 0.3M EQX M EQY 95.298 m kN

M ULSX11 0.64 M DLx M CPX M EQX 0.3 M EQY 95.298 m kN

M ULSX12 1.16 M DLx M CPX M EQX 0.3 M EQY 51.314 m kN

M ULSX13 1.04 M DLx M CPX M EQX 0.3 M EQY 51.314 m kN

M ULSX14 0.76 M DLx M CPX M EQX 0.3 M EQY 95.298 m kN

M ULSX15 0.64 M DLx M CPX 0.3M EQX M EQY 95.298 m kN

M ULSX16 1.16 M DLx M CPX 0.3M EQX M EQY 51.314 m kN

M ULSX17 1.04 M DLx M CPX 0.3M EQX M EQY 51.314 m kN

M ULSX18 0.76 M DLx M CPX 0.3M EQX M EQY 95.298 m kN

4.6. AXIAL COMBINATION FOR SLS :

PSLS1 1 PDL PCP 715.593 kN PSLS2 1 PDL PCP 1.6 PLL 858.393 kN

PSLS3 1 PDL PCP PLL 804.843 kN PSLS4 1 PDL PCP PLL 804.843 kN

PSLS5 1 PDL PCP PLL 804.843 kN PSLS6 1 PDL PCP PLL 804.843 kN

PSLS7 1 PDL PCP PLL 804.843 kN PSLS8 1 PDL PCP PLL 804.843 kN

PSLS9 1 PDL PCP PLL 804.843 kN PSLS10 1 PDL PCP PLL 804.843 kN

PSLS11 0.9 PDL PCP 644.034 kN PSLS12 0.9 PDL PCP 644.034 kN

PSLS13 0.9 PDL PCP 644.034 kN PSLS14 0.9 PDL PCP 644.034 kN

PSLS15 0.9 PDL PCP 644.034 kN PSLS16 0.9 PDL PCP 644.034 kN

PSLS17 0.9 PDL PCP 644.034 kN PSLS18 0.9 PDL PCP 644.034 kN

4.7. MOMEN-Y COMBINATION FOR SLS :

M SLSY1 1 M DLy M CPY 61.13 m kN

M SLSY2 1 M DLy M CPY 1 M LLY 199.379 m kN

Pembebanan Travo Inalum Travo Inalum - 12

PT Harista Karsa Mandiri

M SLSY3 1 M DLy M CPY M LLY M EQY 0.3 M EQX 294.677 m kN

M SLSY4 0.94 M DLy M CPY M LLY M EQY 0.3 M EQX 247.025 m kN

M SLSY5 1 M DLy M CPY M LLY M EQY 0.3 M EQX 148.064 m kN

M SLSY6 1 M DLy M CPY M LLY M EQY 0.3 M EQX 104.08 m kN

M SLSY7 1 M DLy M CPY M LLY 0.3M EQY M EQX 294.677 m kN

M SLSY8 0.94 M DLy M CPY M LLY 0.3M EQY M EQX 144.396 m kN

M SLSY9 1 M DLy M CPY M LLY 0.3M EQY M EQX 250.693 m kN

M SLSY10 1 M DLy M CPY M LLY 0.3M EQY M EQX 104.08 m kN

M SLSY11 0.9 M DLy M CPY M EQY 0.3 M EQX 150.315 m kN

M SLSY12 0.9 M DLy M CPY M EQY 0.3 M EQX 106.332 m kN

M SLSY13 0.9 M DLy M CPY M EQY 0.3 M EQX 3.703 m kN

M SLSY14 0.9 M DLy M CPY M EQY 0.3 M EQX 40.281 m kN

M SLSY15 0.9 M DLy M CPY 0.3M EQY M EQX 150.315 m kN

M SLSY16 0.9 M DLy M CPY 0.3M EQY M EQX 3.703 m kN

M SLSY17 0.9 M DLy M CPY 0.3M EQY M EQX 106.332 m kN

M SLSY18 0.9 M DLy M CPY 0.3M EQY M EQX 40.281 m kN

4.8. MOMEN-X COMBINATION FOR ULS

:

M SLSX1 1 M DLx M CPX 0 m kN

M SLSX2 1 M DLx M CPX 1 M LLX 0 m kN

M SLSX3 1 M DLx M CPX M LLX M EQX 0.3 M EQY 95.298 m kN

M SLSX4 0.94 M DLx M CPX M LLX M EQX 0.3 M EQY 51.314 m kN

M SLSX5 1 M DLx M CPX M LLX M EQX 0.3 M EQY 51.314 m kN

M SLSX6 1 M DLx M CPX M LLX M EQX 0.3 M EQY 95.298 m kN

M SLSX7 1 M DLx M CPX M LLX 0.3M EQX M EQY 95.298 m kN

M SLSX8 0.94 M DLx M CPX M LLX 0.3M EQX M EQY 51.314 m kN

M SLSX9 1 M DLx M CPX M LLX 0.3M EQX M EQY 51.314 m kN

M SLSX10 1 M DLx M CPX M LLX 0.3M EQX M EQY 95.298 m kN

M SLSX11 0.9 M DLx M CPX M EQX 0.3 M EQY 95.298 m kN

Pembebanan Travo Inalum Travo Inalum - 13

PT Harista Karsa Mandiri

M SLSX12 0.9 M DLx M CPX M EQX 0.3 M EQY 51.314 m kN

M SLSX13 0.9 M DLx M CPX M EQX 0.3 M EQY 51.314 m kN

M SLSX14 0.9 M DLx M CPX M EQX 0.3 M EQY 95.298 m kN

M SLSX15 0.9 M DLx M CPX 0.3M EQX M EQY 95.298 m kN

M SLSX16 0.9 M DLx M CPX 0.3M EQX M EQY 51.314 m kN

M SLSX17 0.9 M DLx M CPX 0.3M EQX M EQY 51.314 m kN

M SLSX18 0.9 M DLx M CPX 0.3M EQX M EQY 95.298 m kN

Maximum Design Forces at ULS :

PULSD PULS3 1134.016 kN M ULSXD M ULSX3 95.298 kN m M ULSYD M ULSY3 322.797 kN m

Maximum Design Forces at SLS :

PSLSD PSLS2 858.393 kN M SLSXD M SLSX3 95.298 kN m M SLSYD M SLSY3 294.677 kN m

PULSD PULSD

MULSXD

MULSYD

5. FOUNDATION DESIGN :

Assume this foundation use Footing As Shallow Foundation, Check Footing Stress Due

to Design Load :

Define Footing

Inertia :

1 3 4 1 3 4

Iyf Bcp Lcp 179.12 m Ixf Lcp Bcp 30.37 m

12 12

Calculate strees beneath base of the foot under Ultimate and Serviceability Load (ULS and

SLS) at X Direction :

Lcp Lcp

M SLSYD M SLSYD

PSLSD 2 PSLSD 2

q SLSYa 35.845 kPa q SLSYb 35.845 kPa

Bcp Lcp Iyf Bcp Lcp Iyf

Lcp

Lcp M SLSYD

M SLSYD PSLSD 2

PSLSD 2 q SLSYd 21.862 kPa

q SLSYc 21.862 kPa Bcp Lcp Iyf

Bcp Lcp Iyf

Pembebanan Travo Inalum Travo Inalum - 14

PT Harista Karsa Mandiri

qSLSYc

qSLSYa

Calculate strees beneath base of the foot under Ultimate and Serviceability Load (ULS and SLS) at Y Direction :

Bcp

M SLSXD

PSLSD 2

q SLSXa 23.362 kPa

Bcp Lcp Ixf

Bcp

M SLSXD

PSLSD 2

q SLSXb 34.345 kPa

Bcp Lcp Ixf

Bcp

M SLSXD

PSLSD 2

q SLSXc 23.362 kPa

Bcp Lcp Ixf

Bcp

M SLSXD

PSLSD 2

q SLSXd 34.345 kPa

Bcp Lcp Ixf

qSLSXc

qSLSXb

Pembebanan Travo Inalum Travo Inalum - 15

PT Harista Karsa Mandiri

Value of NSPT at Design Depht : N= 11 , Ultimate Bearing Capacity Nspt 10

calculate as :

2

Bcp 0.3m

q us 8 Nspt kPa 94.302 kPa

Bcp

q us

Safety Factor for Bearing SF BR 2.746 ...............OK!

Capacity : q SLSXb

6. CHECK CAPPING SHEAR CAPACITY :

Define Material

Parameter :

fc 20.75 MPa ( Concrete Compression Strenght )

fy 400 MPa ( Steel Yield Strees )

Ec 4700 fc MPa 21409.519 MPa (Concrete Elastic Modulus)

Ey 200000 MPa ( Steel Elastic Modulus )

d' 50 mm ( Concrete Cover at Top Fiber)

tp tcp 600 mm ( Capping Thickness )

d p tp d' 550 mm ( Capping Effective Thickness )

6.1. Check For One Way Shear :

6.1.1. One Way Shear Force in X

direction :

Shear Force :

Lcp

M SLSYD

PSLSD 2

q SLSYa 35.845 kPa

Bcp Lcp Iyf

PSLSD M SLSYD 4.05m

q SLSYe 35.516 kPa

Bcp Lcp Iyf

Pembebanan Travo Inalum Travo Inalum - 16

PT Harista Karsa Mandiri

q SLSYa q SLSYe

q avg11 35.681 kPa

2

Vu1X q avg11 ( 0.2m) Bcp 24.977 kN

Concrete One Way Shear Capacity :

1

ϕc 0.75 Vc1X fc MPa Bcp d p ϕc 1096.099 kN

6

Ratio about External forced with Concrete One Shear

Capacity :

Vu1X

R1X 0.023 1 ......... safe for one way shear failure, not require for shear reinforcement

Vc1X

6.1.2. One Way Shear Force in Y direction :

Shear Force :

Bcp

M SLSXD

PSLSD 2

q SLSXa 34.345 kPa

Bcp Lcp Ixf

PSLSD M SLSXD 1.55m

q SLSXf 33.717 kPa

Bcp Lcp Ixf

q SLSXa q SLSXf

q avg12 34.031 kPa

2

Vu1Y q avg12 ( 0.2m) Lcp 57.853 kN

Concrete One Way Shear

Capacity :

1

ϕc 0.75 Vc1Y fc MPa Lcp d p ϕc 2661.955 kN

6

Pembebanan Travo Inalum Travo Inalum - 17

PT Harista Karsa Mandiri

Ratio about External forced with Concrete One Shear Capacity :

Vu1Y

R1Y 0.022 1 ......... safe for one way shear failure, not require for shear reinforcement

Vc1Y

6.2. Check For Two Way (Punching) Shear :

6.2.1. Two Way (Punching) Shear Force in X direction :

Shear Force :

Lcp

M SLSYD

PSLSD 2

q SLSYa 35.845 kPa

Bcp Lcp Iyf

PSLSD M SLSYD 3.775 m

q SLSYg 35.064 kPa

Bcp Lcp Iyf

q SLSYa q SLSYg

q avg21 35.455 kPa

2

Lenght of Shear Plane : Lpons 7.55m Width of Shear Plane : Bpons 2.55m

b pons Lpons 2 Bpons 12.65 m

Area that affected streess beneath the slab to calculate two way shear :

2

Atws Lcp Bcp Lpons Bpons 10.498 m

Vu2X q avg21 Atws 372.185 kN

Concrete Two Way (Punching) Shear Capacity :

Equipment Column Stub dimension parameter : b leg 2m Lleg 7m

Lleg

βcp 3.5

b leg

Vc21 ϕc 2 fc MPa b pons d p 6225.395 kN

4

βcp

12

30dp fc MPa bpons dp

Vc22 ϕc 2 6545.277 kN

b pons 12

1

Vc23 ϕc fc MPa b pons d p 7923.23 kN

3

Vcpons min Vc21 Vc22 Vc23 6225.395 kN

Pembebanan Travo Inalum Travo Inalum - 18

PT Harista Karsa Mandiri

Ratio about External forced with Concrete Two Shear Capacity :

Vu2X

R2Y 0.06 1 ......... safe for Two way shear failure, not require for shear reinforcement

Vcpons

6.2.2. Two Way (Punching) Shear Force in Y direction :

Shear Force :

Bcp

M SLSXD

PSLSD 2

q SLSXa 34.345 kPa

Bcp Lcp Ixf

PSLSD M SLSXD 1.275 m

q SLSXh 32.854 kPa

Bcp Lcp Ixf

q SLSXa q SLSXh

q avg22 33.6 kPa

2

Lenght of Shear Lpons 7.55 m Width of Shear Bpons 2.55 m

Plane : Plane :

b pons 12.65 m

Area that affected streess beneath the slab to calculate

two way shear :

2

Atws Lcp Bcp Lpons Bpons 10.498 m

Vu2Y q avg22 Atws 352.712 kN

Concrete Two Way (Punching) Shear Capacity :

Equipment Column Stub dimension b leg 2 m Lleg 7 m

parameter :

Lleg

βcp 3.5

b leg

Vc21 ϕc 2

4 fc MPa b pons d p 6225.395 kN

βcp

12

Pembebanan Travo Inalum Travo Inalum - 19

PT Harista Karsa Mandiri

30dp fc MPa bpons dp

Vc22 ϕc 2 6545.277 kN

b pons 12

1

Vc23 ϕc fc MPa b pons d p 7923.23 kN

3

Vcpons min Vc21 Vc22 Vc23 6225.395 kN

Ratio about External forced with Concrete Two Shear Capacity :

Vu2Y

R2Y 0.057 1 ......... safe for Two way shear failure, not require for shear reinforcement

Vcpons

7. ANALYSIS FOR BASE SLAB FLEXURAL REINFORCEMENT :

7.1. Define Material Parameter :

fc 20.75 MPa ( Concrete Compression Strenght )

fy 400 MPa ( Steel Yield Strees )

Ec 21409.519 MPa (Concrete Elastic

Modulus)

Ey 200000 MPa ( Steel Elastic Modulus )

d' 50 mm ( Concrete Cover at Top

Fiber)

h tcp 600 mm ( Capping

Thickness )

d h d' 550 mm ( Capping Effective

Thickness )

b Bcp 3500 mm ( Capping

Width )

ϕf 0.8 ( Flexural reduction factor )

7.2. Define Flexural Moment in X Direction (Longitudinal):

Stress beneath slab that induce Flexure Momen :

q SLSYa 35.845 kPa

PSLSD M SLSYD 3.5m

q SLSYmy 34.612 kPa

Bcp Lcp Iyf

q SLSYa q SLSYmy

q avgmy 35.228 kPa

2

Arm of the forced that induce flexural : Lfx 0.375m

Flexural Moment in X Direction (Longitudinal) :

M fx

M fx q avgmy Bcp 0.75m Lfx 34.678 kN m Mn 43.348 kN m

ϕf

Pembebanan Travo Inalum Travo Inalum - 20

PT Harista Karsa Mandiri

q SLSYmy

q SLSYa

Lfx

Design Momen for Flexural

Reinforcement :

β 0.85 if fc 30MPa 0.85

0.65 if fc 55MPa

fc

MPa 30

0.85 0.05 if 30MPa fc 55MPa

7

Compression and Tension Reinforcement Ratio δ 0

'/ = :

Mn N

Rn Rn 0.041

2 2

b d mm

Quadratic Equation to Calculate reinforcement

ratio () :

2 2

fy ( 1 δ) δ

A B fy ( 1 δ) fy ( d d') C Rn

2 0.85 fc d

2

B B 4 A C

ρ1 ρ1 0

2 A

2

B B 4 A C

ρ2 ρ2 0.088

2 A

ρ' ρ1 δ ρ' 0

Demand Reinforcement

Area :

2

As ρ1 b d As 197.263 mm

2

A's ρ' b d A's 0 mm

Pembebanan Travo Inalum Travo Inalum - 21

PT Harista Karsa Mandiri

Value of Height of Compression

Stress Area :

ρ1 fy d ( 1 δ)

yc 1.504 mm

0.85 fc β

Check for Tension Reinforcement Strain Steel Yield Strain :

:

fy

d yc εy 0.002

εs 0.003 1.094 Ey

yc

Check for Compression Reinforcement

Strain :

yc d'

ε's 0.003 0.097

yc

Keterangan1 "Tension Reinforcement was yield!"

Keterangan2 "Trehe is no Compression Reinforcement"

Minimum Reinforcement

Ratio :

ρmin 0.002

Keterangan3 "Use Minimum Reinforcement Bos !"

Reinforcemnet Ratio At Balanced Single Reinforcement Maximum Ratio :

Condition :

fc

0.85 β

MPa 600 0.022

ρb ρmax 0.75 ρb 0.017

fy fy

600

MPa MPa

Keterangan4 "Foundation Slab was Ductile bos!"

Demand of Tension Reinforcement Area :

Asb ρmin b d if ρ1 ρmin

ρ1 b d otherwise

2

Asb 3850 mm ( Felxural tension reinforcement

Area )

Demand of Compression Reinforcement Area

Asc ρmin b d 3850 mm

2

Steel Bar That Used for Reinforcement :

Pembebanan Travo Inalum Travo Inalum - 22

PT Harista Karsa Mandiri

Tension Reinforcement (Bottom Side) :

2 2

Utilize size of Bar ϕtr 19mm Astultr 0.25 π ϕtr 283.529 mm

Dimension :

Asb

Quantity of Tension Bar n tr Ceil 1 14 bar

Reinforcement : Astultr

b

Space Sp 269.231 mm

: n tr 1

Use Bar Dimension -

200

Compression Reinforcement (Upper Side) :

2 2

Utilize size of Bar ϕtrc 19mm Astultrc 0.25 π ϕtrc 283.529 mm

Dimension :

Asc

Quantity of Compression Bar n trc Ceil 1 14 bar

Reinforcement : Astultrc

b

Space Spc 269.231 mm

: n trc 1

Use Bar Dimension -

150

8.3. Define Flexural Moment in Y Direction (Transversal):

Stress beneath slab that induce Flexure

Momen :

q SLSXa 34.345 kPa

PSLSD M SLSXD 0.748 m

q SLSXmx 31.201 kPa

Bcp Lcp Ixf

q SLSXa q SLSXmx

q avgmx 32.773 kPa

2

Arm of the forced that induce Lfy 0.5m

flexural :

qSLSmx qSLSXa

Pembebanan Travo Inalum Travo Inalum - 23

PT Harista Karsa Mandiri

Flexural Moment in X Direction

(Longitudinal) :

M fy q avgmx Lcp 1 m Lfx 104.463 kN m M fy

Mn 130.579 kN m

ϕf

Design Momen for Flexural

Reinforcement :

Width of Capping in Y Direction Flexural : b y Lcp 8500 mm

β 0.85 if fc 30MPa 0.85

0.65 if fc 55MPa

fc

MPa 30

0.85 0.05 if 30MPa fc 55MPa

7

Compression and Tension Reinforcement Ratio δ 0

'/ = :

Mn N

Rn Rn 0.051

2 2

b y d mm

Quadratic Equation to Calculate reinforcement

ratio () :

2 2

fy ( 1 δ) δ

A B fy ( 1 δ) fy ( d d') C Rn

2 0.85 fc d

2

B B 4 A C

ρ1 ρ1 0

2 A

2

B B 4 A C

ρ2 ρ2 0.088

2 A

ρ' ρ1 δ ρ' 0

Demand Reinforcement

Area :

2

As ρ1 b y d As 594.399 mm

2

A's ρ' b y d A's 0 mm

Value of Height of Compression

Stress Area :

ρ1 fy d ( 1 δ)

yc 1.866 mm

0.85 fc β

Check for Tension Reinforcement Strain Steel Yield Strain :

:

fy

d yc εy 0.002

εs 0.003 0.881 Ey

yc

Pembebanan Travo Inalum Travo Inalum - 24

PT Harista Karsa Mandiri

Check for Compression Reinforcement

Strain :

yc d'

ε's 0.003 0.077

yc

Keterangan1 "Tension Reinforcement was yield!"

Keterangan2 "There is no Compression Reinforcement"

Minimum Reinforcement

Ratio :

ρmin 0.002

Keterangan3 "Use Minimum Reinforcement Bos !"

Reinforcemnet Ratio At Balanced Single Reinforcement Maximum Ratio :

Condition :

fc

0.85 β

ρb

MPa 600 0.022 ρmax 0.75 ρb 0.017

fy fy

600 MPa

MPa

Keterangan4 "Capping was Ductile bos!"

Demand of Tension Reinforcement Area :

Asb ρmin b y d if ρ1 ρmin

ρ1 b y d otherwise

2

Asb 9350 mm ( Felxural tension reinforcement

Area )

Demand of Compression Reinforcement Area

Asc ρmin b y d 9350 mm

2

Steel Bar That Used for Reinforcement :

Tension Reinforcement (Bottom Side) :

2 2

Utilize size of Bar ϕtr 19mm Astultr 0.25 π ϕtr 283.529 mm

Dimension :

Asb

Quantity of Tension Bar n tr Ceil 1 33 bar

Reinforcement : Astultr

by

Space Sp 265.625 mm

: n tr 1

Use Bar Dimension -

200

Pembebanan Travo Inalum Travo Inalum - 25

PT Harista Karsa Mandiri

Compression Reinforcement (Upper Side) :

2 2

Utilize size of Bar ϕtrc 19mm Astultrc 0.25 π ϕtrc 283.529 mm

Dimension :

Asc

Quantity of Compression Bar n trc Ceil 1 33 bar

Reinforcement : Astultrc

by

Space Spc 265.625 mm

: n trc 1

Use Bar Dimension -

200

8. ANALYSIS FOR HORIZONTAL SLIDING STABILITY :

8.1. Define Design Parameter :

Cohessio cu 10kPa Internal Shear Φ s 30deg

n: Angle :

kN

Volume Weight of the soil : γu 16

3

m

2

Φs

Rankine Active Coefficient of the soil : Ka tan 45deg 0.333

2

Depth of the slab from top soil : h top 1.9m Depth of the Shear Key from top soil : h sky 2.5m

Stress at the base of the σslab γu h top Ka 10.133 kPa

slab :

Stress at the base of the Shear σsky γu h sky Ka 13.333 kPa

Key :

PBSPI PBSVCB

PBSDS PBSDS

PBSCBCT

PBSSTDS PBS STCBCT PBSSTDS

PBSSTVCB

PBSSTPI

Fpass1x

PBSC σ.slab

Fpass2x

σ.sky σ.sky

8.2. Sliding Stability in X Direction :

Passive Shear Forced Outer side ; Fpass1x 0.5 σsky h sky Bcp 58.333 kN

Passive Shear Forced Inner side ; Fpass2x 0.5 σsky σslab h sky h top Bcp 24.64 kN

Pembebanan Travo Inalum Travo Inalum - 26

PT Harista Karsa Mandiri

Resisting Forces

Combination :

Fres1x PSLSD tan Φ s cu Lcp Bcp 793.093 kN

Fres2x PSLSD tan Φ s cu Lcp Bcp Fpass1x Fpass2x 876.067 kN

Sliding Forces

Combination :

FSL1x PWCL1 PWCL2 PWSL1 PWSL2 0.482 kN

FSL2x PBSVCB PBSDS PBSPI PBSCBCT PBSC 69.866 kN

Safety Factor Sliding :

Fres1x Fres1x Fres1x

SF SL1x 1643.983 SF SL2x 1095.989 SF SL3x 11.352

FSL1x 1.5FSL1x FSL2x

Fres1x Fres2x Fres2x

SF SL4x 7.568 SF SL5x 1815.976 SF SL6x 1210.651

1.5FSL2x FSL1x 1.5FSL1x

Fres2x Fres2x

SF SL7x 12.539 SF SL8x 8.36

FSL2x 1.5FSL2x

8.2. Sliding Stability in Y Direction :

Passive Shear Forced Outer Fpass1y 0.5 σsky h sky Lcp 141.667 kN

side ;

Passive Shear Forced Inner Fpass2y 0.5 σsky σslab h sky h top Lcp 59.84 kN

side ;

Fpass1y

Fpass2y

Resisting Forces Combination :

Fres1y PSLSD tan Φ s cu Lcp Bcp 793.093 kN

Fres2y PSLSD tan Φ s cu Lcp Bcp Fpass1y Fpass2y 994.6 kN

Sliding Forces Combination :

FSL1y PWCT1 PWCT2 PWST1 PWST2 0.771 kN

Pembebanan Travo Inalum Travo Inalum - 27

PT Harista Karsa Mandiri

FSL2y PBSVCB PBSDS PBSPI PBSCBCT PBSC 69.866 kN

Safety Factor Sliding :

Fres1y Fres1y Fres1y

SF SL1y 1029.182 SF SL2y 686.121 SF SL3y 11.352

FSL1y 1.5FSL1y FSL2y

Fres1y Fres2y Fres2y

SF SL4y 7.568 SF SL5y 1290.674 SF SL6y 860.449

1.5FSL2y FSL1y 1.5FSL1y

Fres2y Fres2y

SF SL7y 14.236 SF SL8y 9.491

FSL2y 1.5FSL2y

9. ANALYSIS FOR SHEAR KEY FLEXURAL REINFORCEMENT :

9.1. Define Material Parameter :

fc 20.75 MPa ( Concrete Compression Strenght )

fy 400 MPa ( Steel Yield Strees )

Ec 21409.519 MPa (Concrete Elastic

Modulus)

Ey 200000 MPa ( Steel Elastic Modulus )

d' 50 mm ( Concrete Cover at Top

Fiber)

h sk 0.7m ( Shear Key Depth)

d sk h sk d' 650 mm ( Shear key Effective Depth )

b sk Bcp 3500 mm ( Shear key Width )

ϕf 0.8 ( Flexural reduction

factor )

9.2. Define Shear Key Flexural Moment i:

Passive Shear Forced Inner Fpass2x 0.5 σsky σslab h sky h top Bcp 24.64 kN

side ;

hsky htop

Arm of the forced that induce shear key Lfsk 0.3 m

flexural : 2

Flexural Moment for shear

key : M fsk

M fsk Fpass2x Lfsk 7.392 kN m M nsk 9.24 kN m

ϕf

Pembebanan Travo Inalum Travo Inalum - 28

PT Harista Karsa Mandiri

Lfsk=

Fpass2x

Design Momen for Flexural

Reinforcement :

β 0.85 if fc 30MPa 0.85

0.65 if fc 55MPa

fc

MPa 30

0.85 0.05 if 30MPa fc 55MPa

7

Compression and Tension Reinforcement Ratio δ 0

'/ = :

M nsk N

Rn Rn 0.006

2 2

b sk d sk mm

Quadratic Equation to Calculate reinforcement

ratio () :

2 2

fy ( 1 δ)

fy d sk d'

δ

A B fy ( 1 δ) C Rn

2 0.85 fc d sk

2

B B 4 A C

ρ1 ρ1 0

2 A

2

B B 4 A C

ρ2 ρ2 0.088

2 A

ρ' ρ1 δ ρ' 0

Demand Reinforcement

Area :

2

As ρ1 b sk d sk 35.545 mm

2

A's ρ' b sk d sk 0 mm

Value of Height of Compression

Stress Area :

ρ1 fy d sk ( 1 δ)

yc 0.271 mm

0.85 fc β

Pembebanan Travo Inalum Travo Inalum - 29

PT Harista Karsa Mandiri

Check for Tension Reinforcement Strain Steel Yield Strain :

:

fy

dsk yc εy 0.002

εs 0.003 7.194 Ey

yc

Check for Compression Reinforcement

Strain :

yc d'

ε's 0.003 0.551

yc

Keterangan1 "Tension Reinforcement was yield!"

Keterangan2 "Trehe is no Compression Reinforcement"

Minimum Reinforcement

Ratio :

ρmin 0.002

Keterangan3 "Use Minimum Reinforcement Bos !"

Reinforcemnet Ratio At Balanced Single Reinforcement Maximum Ratio :

Condition :

fc

0.85 β

MPa 600 0.022

ρb ρmax 0.75 ρb 0.017

fy fy

600

MPa MPa

Keterangan4 "Foundation Slab was Ductile bos!"

Demand of Tension Reinforcement Area :

Asb ρmin b sk d sk if ρ1 ρmin

ρ1 b sk d sk otherwise

2

Asb 4550 mm ( Felxural tension reinforcement

Area )

Demand of Compression

Reinforcement Area

Asc ρmin b sk d sk 4550 mm

2

Steel Bar That Used for Reinforcement :

Tension Reinforcement (Bottom Side) :

2 2

Utilize size of Bar ϕtr 19mm Astultr 0.25 π ϕtr 283.529 mm

Dimension :

Asb

Quantity of Tension Bar n tr Ceil 1 17 bar

Reinforcement : Astultr

b sk

Space Sp 218.75 mm

: n tr 1

Use Bar Dimension -

200

Pembebanan Travo Inalum Travo Inalum - 30

PT Harista Karsa Mandiri

Compression Reinforcement (Upper Side) :

2 2

Utilize size of Bar ϕtrc 19mm Astultrc 0.25 π ϕtrc 283.529 mm

Dimension :

Asc

Quantity of Compression Bar n trc Ceil 1 17 bar

Reinforcement : Astultrc

b

Space Spc 218.75 mm

: n trc 1

Use Bar Dimension -

200

10. DEFINE AXIAL, FLEXURE MOMEN AND SHEAR FOR STUMP/STUB COLUMN DESIGN :

10.1. Define Design Load for DS Stump :

PDSSTP 1.2 WDS WSTDS 1.6 q LL Lstds Bstds 101.184 kN

Hstds Hstds

M DSSTPx 1 PBSDS zCGDSa PBSSTDS 0.3 PBSDS zCGDSa PBSSTDS 15.218 kN m

2 2

HDSSTP PBSDS PBSSTDS 0.3 PBSDS PBSSTDS 15.755 kN

10.2. Define Design Load for PI Stump :

PPISTP 1.2 WPI WSTPI 1.6 q LL Lstpi Bstpi 36.403 kN

Hstpi Hstpi

M PISTPx 1 PBSPI zCGPI PBSSTPI 0.3 PBSPI zCGPI PBSSTPI 5.716 kN m

2 2

HPISTP PBSPI PBSSTPI 0.3 PBSPI PBSSTPI 5.674 kN

10.3. Define Design Load for VCB Stump

:

PVCBSTP 1.2 WVCB WSTVCB 1.6 q LL Lstvcb Bstvcb 91.895 kN

Hstvcb Hstvcb

M VCBSTPx 1 PBSVCB zCGVCB PBSSTVCB 0.3 PBSVCB zCGVCB PBSSTVCB 13.603 kN m

2 2

HVCBSTP PBSVCB PBSSTVCB 0.3 PBSVCB PBSSTVCB 14.245 kN

10.4. Define Design Load for CB-CT

Stump :

PCBCTSTP 1.2 WCBCT WSTCBCT 1.6 q LL Lstcbct Bstcbct 46.839 kN

Hstcbct Hstcbct

M CBCTSTPx 1 PBSCBCT zCGCBCT PBSSTCBCT 0.3 PBSCBCT zCGCBCT PBSSTCBCT 6.16 kN m

2 2

HCBCTSTP PBSCBCT PBSSTCBCT 0.3 PBSCBCT PBSSTCBCT 7.241 kN

Pembebanan Travo Inalum Travo Inalum - 31

PT Harista Karsa Mandiri

kN m

N m

Pembebanan Travo Inalum Travo Inalum - 32

PT Harista Karsa Mandiri

kN m

N m

Pembebanan Travo Inalum Travo Inalum - 33

PT Harista Karsa Mandiri

Pembebanan Travo Inalum Travo Inalum - 34

PT Harista Karsa Mandiri

Pembebanan Travo Inalum Travo Inalum - 35

PT Harista Karsa Mandiri

Keterangan1 "Tension Reinforcement was yield!" if ε s ε y

"Sorry, Tension Reinforcement not yield, Try Again bos !" otherwise

Keterangan2 "Tension Reinforcement was yield!" if ε's ε y

"Trehe is no Compression Reinforcement" if δ = 0

"Tension Reinforcement not yield !" otherwise

Keterangan3 "p > pmin Ok Bos !" if ρ1 ρmin

"Use Minimum Reinforcement Bos !" otherwise

Keterangan4 "Foundation Slab was brittle bos not ductile, repeat and Resize Plate Thickness !" if ρ1 ρmax

"Foundation Slab was Ductile bos!" otherwise

Pembebanan Travo Inalum Travo Inalum - 36

PT Harista Karsa Mandiri

Keterangan1 "Tension Reinforcement was yield!" if ε s ε y

"Sorry, Tension Reinforcement not yield, Try Again bos !" otherwise

Pembebanan Travo Inalum Travo Inalum - 37

PT Harista Karsa Mandiri

Keterangan2 "Tension Reinforcement was yield!" if ε's ε y

"There is no Compression Reinforcement" if δ = 0

"Tension Reinforcement not yield !" otherwise

Keterangan3 "p > pmin Ok Bos !" if ρ1 ρmin

"Use Minimum Reinforcement Bos !" otherwise

Keterangan4 "Capping was brittle bos not ductile, repeat and Resize Plate Thickness !" if ρ1 ρmax

"Capping was Ductile bos!" otherwise

Pembebanan Travo Inalum Travo Inalum - 38

PT Harista Karsa Mandiri

Keterangan1 "Tension Reinforcement was yield!" if ε s ε y

"Sorry, Tension Reinforcement not yield, Try Again bos !" otherwise

Keterangan2 "Tension Reinforcement was yield!" if ε's ε y

"Trehe is no Compression Reinforcement" if δ = 0

"Tension Reinforcement not yield !" otherwise

Keterangan3 "p > pmin Ok Bos !" if ρ1 ρmin

"Use Minimum Reinforcement Bos !" otherwise

Keterangan4 "Foundation Slab was brittle bos not ductile, repeat and Resize Plate Thickness !" if ρ1 ρmax

"Foundation Slab was Ductile bos!" otherwise

Pembebanan Travo Inalum Travo Inalum - 39

PT Harista Karsa Mandiri

Pembebanan Travo Inalum Travo Inalum - 40

PT Harista Karsa Mandiri

Pembebanan Travo Inalum Travo Inalum - 41

PT Harista Karsa Mandiri

Pembebanan Travo Inalum Travo Inalum - 42

Vous aimerez peut-être aussi

- Lc05-Flexural Design-Example 01Document5 pagesLc05-Flexural Design-Example 01Phearak PH NhemPas encore d'évaluation

- 10 Mathcad - SAMBUNGAN END PLATE CROSS BEAM KE JOINDocument10 pages10 Mathcad - SAMBUNGAN END PLATE CROSS BEAM KE JOINAndre NovanPas encore d'évaluation

- Base Plate Very EccentricityDocument2 pagesBase Plate Very EccentricityJetn SrisuthumPas encore d'évaluation

- Equilibrium Calculation - 4.0m X 250 HDPE PN10, W/ 2 X 90kg Ballast at 2.0 M SpacingDocument2 pagesEquilibrium Calculation - 4.0m X 250 HDPE PN10, W/ 2 X 90kg Ballast at 2.0 M SpacingtaddeoPas encore d'évaluation

- ZK-290-Jacket NGDL - FinalDocument4 pagesZK-290-Jacket NGDL - Finalchristi SPas encore d'évaluation

- JETTY 3000dwt: Title Document No.: Breasting Dolphin-Engineering Calculation Revision: Issued Date: CompanyDocument2 pagesJETTY 3000dwt: Title Document No.: Breasting Dolphin-Engineering Calculation Revision: Issued Date: CompanyAnonymous nXGOGxyePas encore d'évaluation

- Cowshed Rate AnalysisDocument8 pagesCowshed Rate AnalysisaniketPas encore d'évaluation

- Ejemplo Viga PretensadaDocument73 pagesEjemplo Viga PretensadaMarco Flores ZuñigaPas encore d'évaluation

- Foundation LoadingsDocument1 pageFoundation Loadingsmanish318Pas encore d'évaluation

- Mathcad - SENGKANG SLOOF S-01 GUDANG CMTFDocument4 pagesMathcad - SENGKANG SLOOF S-01 GUDANG CMTFAndre NovanPas encore d'évaluation

- Vibhutipura Charging Shed BOQ R00Document5 pagesVibhutipura Charging Shed BOQ R00newattelectricPas encore d'évaluation

- Embedded PostDocument6 pagesEmbedded PostMong is not herePas encore d'évaluation

- SidlDocument1 pageSidlRiddhiman bhowmikPas encore d'évaluation

- Gantry ExampleDocument4 pagesGantry ExamplechrisPas encore d'évaluation

- Plate No.3Document23 pagesPlate No.3Lyn ComendadorPas encore d'évaluation

- Stages of Anti-CollisionDocument1 pageStages of Anti-CollisiondxfPas encore d'évaluation

- 2023-01-13 - BP - Process Water Sleeper CalculationsDocument27 pages2023-01-13 - BP - Process Water Sleeper CalculationsPruthviraj JuniPas encore d'évaluation

- Isolated Footing: BY: Albaytar, Mark Joseph A. Billones, Joyce Anne CDocument2 pagesIsolated Footing: BY: Albaytar, Mark Joseph A. Billones, Joyce Anne CMark JosephPas encore d'évaluation

- Test Load Calculation For Load - Deflection Test On 30.5 M Non Standard (7 Leaf) Composite Girder BridgeDocument1 pageTest Load Calculation For Load - Deflection Test On 30.5 M Non Standard (7 Leaf) Composite Girder BridgeRiddhiman bhowmikPas encore d'évaluation

- DATEM Bridge Calculation-SignedDocument3 pagesDATEM Bridge Calculation-SignedJohn Paul UmaliPas encore d'évaluation

- Bending Moment Calculation - Anticreep Center, One Cantilever, Tangent TrackDocument7 pagesBending Moment Calculation - Anticreep Center, One Cantilever, Tangent TrackAnkit AgarwalPas encore d'évaluation

- BW Tokyo Gasform CDocument8 pagesBW Tokyo Gasform CAndi IrfanPas encore d'évaluation

- MH Analysis SampleDocument83 pagesMH Analysis Sampleenhuipp8168Pas encore d'évaluation

- Specified Condition - Assignment: Key Point Type Freeboard MDocument2 pagesSpecified Condition - Assignment: Key Point Type Freeboard MFida MashfihaPas encore d'évaluation

- Calculation Report For PHC Pile: I. Input Data For Pile's Material I.1. Effective Presstress: ValueDocument3 pagesCalculation Report For PHC Pile: I. Input Data For Pile's Material I.1. Effective Presstress: ValuehuhumaluPas encore d'évaluation

- Portal Frame UdlDocument2 pagesPortal Frame UdlAkhtar BahramPas encore d'évaluation

- Mathcad - Sengkang Sloof GudangDocument4 pagesMathcad - Sengkang Sloof Gudangandre novanPas encore d'évaluation

- Mathcad - Sengkang Sloof GudangDocument4 pagesMathcad - Sengkang Sloof Gudangandre novanPas encore d'évaluation

- Mathcad - Sengkang Sloof GudangDocument4 pagesMathcad - Sengkang Sloof Gudangandre novanPas encore d'évaluation

- Proposed 3-Storey Residence With Lower GroundDocument93 pagesProposed 3-Storey Residence With Lower Groundfrancis sebastian lagamayoPas encore d'évaluation

- Column DesignDocument23 pagesColumn Designjonilyn florentinoPas encore d'évaluation

- Boq Amendment QntyDocument10 pagesBoq Amendment Qntyalmamunmolla96Pas encore d'évaluation

- Faster Than Speed of LightDocument64 pagesFaster Than Speed of Lightandre villanuevaPas encore d'évaluation

- Prestressed BeamDocument15 pagesPrestressed BeamMohamed Abbassy100% (1)

- RCC Footing DesignDocument21 pagesRCC Footing Designnitin chaudharyPas encore d'évaluation

- Axial Capacity of Bored Pile Type End Bearing Base On SPT Data InvestigationDocument3 pagesAxial Capacity of Bored Pile Type End Bearing Base On SPT Data Investigationandre novanPas encore d'évaluation

- FrameDocument48 pagesFrameMuhammad HafizPas encore d'évaluation

- 5 Tishchenko Method 4Document32 pages5 Tishchenko Method 4Deepak Paul TirkeyPas encore d'évaluation

- Specified Condition: Full Load DepartureDocument43 pagesSpecified Condition: Full Load DepartureFida MashfihaPas encore d'évaluation

- Tension Pile Analysis and Design - 04-06Document10 pagesTension Pile Analysis and Design - 04-06KalpanaPas encore d'évaluation

- Design of RC Beam (GB) : GeometryDocument5 pagesDesign of RC Beam (GB) : GeometryJake CortezPas encore d'évaluation

- BP - Process Water Sleeper CalculationsDocument13 pagesBP - Process Water Sleeper CalculationsPruthviraj JuniPas encore d'évaluation

- Base Plate Very EccentricityDocument7 pagesBase Plate Very Eccentricityอัชวิน เจริญสินPas encore d'évaluation

- Reinforced Concrete Square Spread Footing Analysis Design ACI318 14 PDFDocument17 pagesReinforced Concrete Square Spread Footing Analysis Design ACI318 14 PDFravi kumar B v APas encore d'évaluation

- No 07 Oct 2006 AnswersDocument4 pagesNo 07 Oct 2006 AnswersAditya VermaPas encore d'évaluation

- Perhitungan Pondasi Chimney Dengan Program AFES PDFDocument52 pagesPerhitungan Pondasi Chimney Dengan Program AFES PDFd'Hell CaesarPas encore d'évaluation

- Slab Support Walls DesignDocument1 pageSlab Support Walls DesignWesly CenterwallPas encore d'évaluation

- Column and Footing DesignDocument41 pagesColumn and Footing Designnia.eaa.karlPas encore d'évaluation

- Northwoods Software: Red Important NoteDocument10 pagesNorthwoods Software: Red Important Notegv Sathishkumar KumarPas encore d'évaluation

- Figure 1: Forces Acting On Thrust Block-Plan View: Calculati OnsDocument22 pagesFigure 1: Forces Acting On Thrust Block-Plan View: Calculati OnsCloradoJuniorPas encore d'évaluation

- Approach SlabDocument4 pagesApproach SlabjamesPas encore d'évaluation

- Live Loads TrussDocument1 pageLive Loads TrussKea CuizonPas encore d'évaluation

- Pile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesDocument4 pagesPile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesRuemu Godwin InikoriPas encore d'évaluation

- Gulf of PariaDocument37 pagesGulf of Pariacaptjas9886Pas encore d'évaluation

- Krupal Ldhund-PagesDocument1 pageKrupal Ldhund-PagesKrupal ksPas encore d'évaluation

- Design of Rectangular Footing - 1Document4 pagesDesign of Rectangular Footing - 1Roiven Dela Rosa TrinidadPas encore d'évaluation

- BOLT PLATE ReportDocument17 pagesBOLT PLATE ReportmaheshbandhamPas encore d'évaluation

- 2850-1992 KN S (Type - A1) Span P 51 Anti Uplift ArrangementDocument9 pages2850-1992 KN S (Type - A1) Span P 51 Anti Uplift ArrangementGaurav PatilPas encore d'évaluation

- Bollard Capacity Calculation (REV1)Document5 pagesBollard Capacity Calculation (REV1)Dito NarendraPas encore d'évaluation

- Cast Iron: Physical and Engineering PropertiesD'EverandCast Iron: Physical and Engineering PropertiesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Mathcad - Sengkang Sloof GudangDocument4 pagesMathcad - Sengkang Sloof Gudangandre novanPas encore d'évaluation

- Mathcad - Sengkang Sloof GudangDocument4 pagesMathcad - Sengkang Sloof Gudangandre novanPas encore d'évaluation

- Mathcad - Sengkang Sloof GudangDocument4 pagesMathcad - Sengkang Sloof Gudangandre novanPas encore d'évaluation

- 擜̩ - - CEK KAPASITAS GELAGAR RAPP 20 JAN 2020Document36 pages擜̩ - - CEK KAPASITAS GELAGAR RAPP 20 JAN 2020andre novanPas encore d'évaluation

- Mathcad - ANALISA KAP SLOOF GUDANGDocument13 pagesMathcad - ANALISA KAP SLOOF GUDANGandre novanPas encore d'évaluation

- 厐ջ儸ջ써 - Tulpoer Abutment RappDocument9 pages厐ջ儸ջ써 - Tulpoer Abutment Rappandre novanPas encore d'évaluation

- 厐ջ儸ջ써 - Tulpoer Pier-rappDocument9 pages厐ջ儸ջ써 - Tulpoer Pier-rappandre novanPas encore d'évaluation

- 㤰洭牡㈭〰7 - COMP BTG MAKELAR D75Document4 pages㤰洭牡㈭〰7 - COMP BTG MAKELAR D75andre novanPas encore d'évaluation

- False - TUL WING WALL ABT TAMPUNIKDocument9 pagesFalse - TUL WING WALL ABT TAMPUNIKandre novanPas encore d'évaluation

- 厐ջ儸ջ써 - Tul Wing Wall Abt RappDocument9 pages厐ջ儸ջ써 - Tul Wing Wall Abt Rappandre novanPas encore d'évaluation

- Mathcad - Tul Pondasi Tapak p1100x100Document4 pagesMathcad - Tul Pondasi Tapak p1100x100andre novanPas encore d'évaluation

- Mathcad - B1X 5.5 MDocument12 pagesMathcad - B1X 5.5 Mandre novanPas encore d'évaluation

- Axial Capacity of Bored Pile Type End Bearing Base On SPT Data InvestigationDocument3 pagesAxial Capacity of Bored Pile Type End Bearing Base On SPT Data Investigationandre novanPas encore d'évaluation

- SAE J403 Grade 1055: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDocument4 pagesSAE J403 Grade 1055: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearALEX MURPHYPas encore d'évaluation

- Concrete ClothDocument20 pagesConcrete ClothShrinivasPas encore d'évaluation

- WACS Villaba, LeyteDocument11 pagesWACS Villaba, Leyteroderick biazonPas encore d'évaluation

- Recycled Glass Utilization in Highway Construction Isaac Finkle, GRA, EITDocument25 pagesRecycled Glass Utilization in Highway Construction Isaac Finkle, GRA, EITUsama HeneashPas encore d'évaluation

- Adsorption Modeling With The Esd Equation of State: Aaron D. Soule, Cassandra A. Smith, Xiaoning Yang Carl T. LiraDocument38 pagesAdsorption Modeling With The Esd Equation of State: Aaron D. Soule, Cassandra A. Smith, Xiaoning Yang Carl T. LiraSanjeeva YedavalliPas encore d'évaluation

- Conventional Manufacturing Process 20ME33: Class 05Document5 pagesConventional Manufacturing Process 20ME33: Class 05Vinayaka G PPas encore d'évaluation

- FT (Remazol BR Yellow 3GL)Document3 pagesFT (Remazol BR Yellow 3GL)Orlando Yerén ValenciaPas encore d'évaluation

- Geochemical CycleDocument8 pagesGeochemical CycleJacinta Mediana EspelaPas encore d'évaluation

- Digital PrintingDocument24 pagesDigital PrintingPreethi ArunPas encore d'évaluation

- Pif 00 Forms Final ListDocument8 pagesPif 00 Forms Final Listkaty leePas encore d'évaluation

- Analytical ChemistryDocument5 pagesAnalytical ChemistryChristian FloresPas encore d'évaluation

- Cobalt: Definition, Mineralogy and DepositsDocument19 pagesCobalt: Definition, Mineralogy and DepositsJesusSalamancaPas encore d'évaluation

- Method Statement of Static Tension Load Test PLTU Suralaya Jawa 9 & 10 - Page 9 Rev PDFDocument12 pagesMethod Statement of Static Tension Load Test PLTU Suralaya Jawa 9 & 10 - Page 9 Rev PDFFendi Rang TigorPas encore d'évaluation

- Anchor Cage DocumentsDocument13 pagesAnchor Cage DocumentsDan BitcaPas encore d'évaluation

- KALORIMETERDocument8 pagesKALORIMETERSeliyaPas encore d'évaluation

- Elevation 01 Elevation 04: C03 C01 C02 D01 D02 D03 D04 D05 D06 D07Document1 pageElevation 01 Elevation 04: C03 C01 C02 D01 D02 D03 D04 D05 D06 D07Abid AyubPas encore d'évaluation

- Qa/Qc Department: ICOM QC Inspector Client QC Inspector Name Signature DateDocument2 pagesQa/Qc Department: ICOM QC Inspector Client QC Inspector Name Signature Dategopi krishnaPas encore d'évaluation

- Rates For Rate Analysis Excel FormatDocument23 pagesRates For Rate Analysis Excel FormatIswers GuptaPas encore d'évaluation

- Aimer Bathroom CatalogDocument12 pagesAimer Bathroom CatalogmdnajmiePas encore d'évaluation

- Anaerobic Digestion of Wastewater Sludge: (Nazaroff & Alvarez-Cohen, Section 6.E.3)Document7 pagesAnaerobic Digestion of Wastewater Sludge: (Nazaroff & Alvarez-Cohen, Section 6.E.3)syafiqzainordinPas encore d'évaluation

- Uniform Mechanical Code - 2009 Chapter 5Document34 pagesUniform Mechanical Code - 2009 Chapter 5memosplumbingPas encore d'évaluation

- Design of Pipe Sleeper and Raised Pipe Sleeper On Steel FrameDocument22 pagesDesign of Pipe Sleeper and Raised Pipe Sleeper On Steel FrameAmmarPas encore d'évaluation

- EN 10204/3.1 1546708 Pag. /: Mill Test Certificate DOC - CREDIT N. M04091506NU00250Document4 pagesEN 10204/3.1 1546708 Pag. /: Mill Test Certificate DOC - CREDIT N. M04091506NU00250Paviter SinghPas encore d'évaluation

- Assignment 1Document32 pagesAssignment 1sharifah atiqahPas encore d'évaluation

- Determination of In-Situ Unit Weight of Soil: Experiment No 2 & 3 Soil Mechanics Laboratory CE PC 594Document30 pagesDetermination of In-Situ Unit Weight of Soil: Experiment No 2 & 3 Soil Mechanics Laboratory CE PC 594SumanHaldar100% (1)

- Metodo XenosepDocument12 pagesMetodo XenosepJenny Chavez AlarconPas encore d'évaluation

- Makrolon Solid Flame Retardant Polycarbonate Sheet: Your BenefitsDocument2 pagesMakrolon Solid Flame Retardant Polycarbonate Sheet: Your BenefitsAbdelmajid HmPas encore d'évaluation

- Pengaruh Lingkungan Minyak Mentah Terhadap Laju Korosi Pada Pipa Baja Karbon Dan Pipa GalvanisDocument4 pagesPengaruh Lingkungan Minyak Mentah Terhadap Laju Korosi Pada Pipa Baja Karbon Dan Pipa GalvanisafifahPas encore d'évaluation

- Licensed To Arun Kumar Das: Ceramic Unglazed Vitreous Acid Resisting Tiles - Specification (Second Revision)Document24 pagesLicensed To Arun Kumar Das: Ceramic Unglazed Vitreous Acid Resisting Tiles - Specification (Second Revision)Indira BanerjeePas encore d'évaluation