Académique Documents

Professionnel Documents

Culture Documents

LMC Flotation Project Compressor Building Ventilation Fans Equipment Data Sheet

Transféré par

alimoya13Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

LMC Flotation Project Compressor Building Ventilation Fans Equipment Data Sheet

Transféré par

alimoya13Droits d'auteur :

Formats disponibles

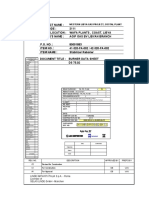

LMC Flotation Project Equipment Data Sheet Prepared By Aker Kvaerner Pty Limited

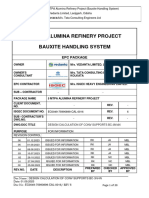

EQUIPMENT DATA SHEET

Rev

AXIAL FANS

DATA SHEET No: 11069-1550-M-FA1560

PROJECT TITLE: FLOTATION PROJECT

CLIENT: LIHIR MANAGEMENT COMPANY

PURCHASE REQ. No: 11069-00-13003

PURCHASE REQ. TITLE: VENTILATION FANS

PURCHASE ORDER No:

VENDOR / CONTRACTOR : Flakt Woods Fans (Australia) Pty Ltd 0

EQUIPMENT TAG NUMBER(S) 1550-FA1560, 1561

EQUIPMENT NAME(S) Compressor Building Ventilation Fans

EQUIPMENT CRITICALITY RATING: 3

PLANT AREA Air Liquide Oxygen Plant

MANUFACTURER Flakt Woods Fans (Australia) Pty Ltd 0

MODEL / DESCRIPTION AF-1250-200-12-980-rpm

PROJECT SPECIFICATION No. 11069-00-M0730

UPGRADED EXISTING OR NEW EQUIPMENT New equipment

1.00 NOTES

1.01 1. Fields marked with a ? will be completed by Aker Kvaerner.

1.02 2. Fields marked with an * shall be completed by the Seller at quotation stage.

1.03 3. Fields marked with an # shall be completed by the Seller post award.

1.04 4. Seller shall supply all nuts, bolts and gaskets necessary for assembly.

1.05 5. Seller shall supply full details of static and dynamic loading of support structure at quotation stage.

1.06 6. Seller to provide a dimensioned sketch of noise test arrangement.

1.07 7. Octave band Analysis to be completed only if sound level exceeds 75 dB(A) re 2μPa.

1.08 8. If it is not practicable to meet the "Acceptable Maximum Level", the Seller shall offer the most practical solution.

1.09 9. For all entries in "Unsilenced" column, the Seller shall provide Octave Band Analysis for each fans alone (installation conditions and silencer not considered)

1.10 10. For all entries in "Silenced" column, the Seller shall indicate noise control methods used to achieve this level and shall indicate separately the costs of achieving

1.11 this level. In this particular case, for fans1550-FA1560, 1561, the silenced value shall be that which pertains within 1 m from the fans and discharge silencers, external

1.12 to the compressor building, taking into account the noise generated by the compressor.

1.13 11. Fans to include suction inlet duct (min 3mm stiffened PL, Lihir Spec S135 System CS1 surface protection) and pop-up damper as configured on layout sketch. P2

1.14

Rev Date By Chk. Appr. Auth. Revision Description

P1 09-Jan-06 FAK JSH JSH MJC Issued for Tender

P2 20-Feb-06 FAK JSH JSH MJC Re-issued for Tender

0 23-Mar-06 FAK JSH JSH MJC Issued for Purchase

11069-1550-FA1560_0 Compressor Building Vent Fans.xls Page 1 of 8

LMC Flotation Project Equipment Data Sheet Prepared by Aker Kvaerner Pty Limited

EQUIPMENT TAG NUMBER(S) 1550-FA1560, 1561

Rev

EQUIPMENT NAME(S) Compressor Building Ventilation Fans

2.00 PROCESS INFORMATION

2.01 KEY PFD / P&ID 11069-130-F0620

2.02 PLANT DESIGN LIFE (y) 20

2.03 EARTHQUAKE AND WIND LOADING DESIGN CRITERIA Refer to Specification 11069-00-C0716: Seismic and Wind Loads on Equipment

2.04 SUCTION CONDITIONS

2.05 MATERIAL HANDLED Ambient Air

3

2.06 DENSITY Normal kg/m 1.2

3

2.07 Design kg/m 1.2

2.08 MOLECULAR WEIGHT Normal 29

2.09 Design 29

2.10 TOXITY DUE TO None - Ambient Air

2.11 CORROSIVE/EROSIVE DUE TO None - Ambient Air

2.12 FLAMMABLE/EXPLSIVE DUE TO None - Ambient Air

Oxygen Plant Compressor Building, cooling air to dissipate heat rejected to atmosphere by the

2.13 MODE OF OPERATION

compressor package.

2.14 INLET LOUVRES - PRESSURE LOSS AT 50 m³/SEC LESS THAN 100 Pa

2.15 OPERATING CONDITIONS

2.16 MASS FLOW Normal t/h 108

2.17 Design t/h 108

2.18 Rated t/h *

2.19 PRESSURE Normal Pag -100 Pa - Loss through acoustic Louvre at 2m/s face velocity

2.20 Design Pag -100 Pa - Loss through acoustic Louvre at 2m/s face velocity

2.21 Rated Pag Refer Curve 0

o

2.22 TEMPERATURE Normal C 30

o

2.23 Design C 40

o

2.24 Rated C *

2.25 RELATIVELY HUMIDITY Normal % Range 75 - 92

2.26 Design % 92

2.27 Rated % *

2.28 GAS COMPRSS'TY FACTOR Z Normal 1.00

2.29 Design 1.00

2.30 Rated *

3

2.31 VOLUME FLOW Normal Sm /h 87,030

3

2.32 Design Sm /h 84,249

2.33 Rated Sm3/h Refer Curve 0

2.34 SPECIFIC HEAT RATIO Cp/Cv Normal 1.41

2.35 Design 1.41

2.36 Rated *

2.37 DENSITY Normal kg/m3 1.16

3

2.38 Design kg/m 1.12

2.39 DISCHARGE CONDITIONS

2.40 STATE (V or L) Normal V

2.41 Design V

2.42 COMPOSITION Normal Air

2.43 Design Air

2.44 MASS FLOW Normal t/h 42

2.45 Design t/h 42

2.46 Rated t/h *

2.47 VOLUME FLOW Normal Am3/h 90,000

2.48 Design Am3/h 90,000

2.49 Rated Am3/h Refer Curve 0

2.50 PRESSURE Normal Pag Discharge to atmosphere (through discharge silencer)

2.51 Design Pag SELLER TO ADVISE

2.52 Rated Pag Refer Curve 0

2.53 PRESSURE DIFFERENTIAL Normal Pag

2.54 Design Pag

2.55 Rated Pag

o

2.56 TEMPERATURE Normal C *

o

2.57 Design C *

o

2.58 Rated C *

11069-1550-FA1560_0 Compressor Building Vent Fans.xls Page 2 of 8

LMC Flotation Project Equipment Data Sheet Prepared by Aker Kvaerner Pty Limited

EQUIPMENT TAG NUMBER(S) 1550-FA1560, 1561

Rev

EQUIPMENT NAME(S) Compressor Building Ventilation Fans

2.59 GAS COMPRSS'TY FACTOR Z Normal 1.41

2.60 Design 1.41

2.61 Rated *

3

2.62 DENSITY Normal kg/m 1.16

2.63 Design kg/m3 1.12

2.64 MAXIMUM ALLOWABLE Normal Oil free

2.65 OIL CONTENT Design Oil free

2.66 Rated Oil free

2.67 FAN LOCATION Indoors

2.68 FAN DUTY Continuous 24/7

3.00 SPECIFIC NOISE PERFORMANCE DATA

3.01 INSTALLATION REFER SKETCH 11069-00-MSK6014

3.02 COMPRESSOR BUILDING DIMENSIONS 3 BAYS OF 2.5 m x 9.1 m X ~10 m HIGH

3.03 MAX SOUND PRESSURE LEVEL TO BE ACHIEVED 85 dB(A) EXTERNAL TO COMPRESSOR BUILDING

3.04 BUILDING SHEETING SPANDEK (ACHIEVES LESS THAN 85dB(A) OUTSIDE THE BUILDING)

3.05 COMPRESSOR NOISE EMISSION DATA

11069-1550-FA1560_0 Compressor Building Vent Fans.xls Page 3 of 8

LMC Flotation Project Equipment Data Sheet Prepared by Aker Kvaerner Pty Limited

EQUIPMENT TAG NUMBER(S) 1550-FA1560, 1561

Rev

EQUIPMENT NAME(S) Compressor Building Ventilation Fans

4.00 MECHANICAL INFORMATION

4.01 AXIAL FAN

4.02 MANUFACTUER Flakt Woods Fans (Australia) Pty Ltd 0

4.03 MODEL TYPE AND NUMBER *AF-1250-200-12-980-rpm 0

4.04 PROPOSED FAN CURVE NUMBER *AF-1250-200-12-980-rpm 0

4.05 FAN DIAMETER mm 1,250 0

4.06 FAN CASING DIAMETER mm *

4.07 FAN DRIVE TYPE In-line Axial 0

4.08 DRIVE ARRANGEMENT (Direct/V Belt) Direct 0

4.09 HUB DIAMETER mm *

4.10 NUMBER OF FAN BLADES 12 0

4.11 FAN BLADE PITCH Deg / mm *

4.12 BLADE PITCH ADJUSTABLE (Y/N) *

4.13 BLADE PITCH ADJ. RANGE Maximum Deg / mm *

4.14 Minimum Deg / mm *

4.15 FAN CASING LENGTH mm *

o

4.16 MAXIMUM OPERATING TEMPERATURE C *

4.17 FAN EFFICIENCY % *

4.18 FAN SPEED r/min 980 0

4.19 FAN SOLIDITY *

4.20 MAX. DIFF'L PRESSURE @ RATED CONDITIONS Pa Refer Curve 0

4.21 VELOCITY Ducted Inlet m/sec *

4.22 Ducted Discharge m/sec *

4.23 TOTAL EFFICIENCY % *

4.24 POWER ABSORBED @ RATED CONDITIONS kW 15.6 0

4.25 CRITICAL TIP SPEED r/min *

4.26 FILTER Not required 0

4.27 Model No

4.28 Type

4.29 Size mm X mm

4.30 Length mm

4.31 SILENCERS

4.32 GAS INLET SIDE Model No Not required

4.33 Type Not required

4.34 Size mm X mm Not required

4.35 Length mm Not required

4.36 GAS PRESSURE SIDE Model No *

4.37 Type *

4.38 Size mm X mm *

4.39 Length mm *

5.00 ELECTRICAL INFORMATION

5.01 DRIVE MOTORS

5.02 OPERATING CONDITIONS

5.03 SUPPLY VOLTAGE 415

5.04 PHASE 3

5.05 FREQUENCY 50

5.06 EARTHING Solidly Earthed

5.07 MOTOR ENVIRONMENT Outdoors, dusty corrosive, coastal

5.08 HAZARDOUS AREA Non-hazardous

5.09 ZONE N/A

5.10 GAS GROUP N/A

5.11 TEMPERATURE CLASS N/A

5.12 DRIVEN MACHINE DETAILS

5.13 LOAD TYPE *

5.14 ABSORBED POWER (kW) *

5.15 DRIVEN SPEED (r/min) 980 0

5.16 STARTING TORQUE REQUIRED (Nm) *

5.17 MAXIMUM ALLOWABLE TORQUE (Nm) *

11069-1550-FA1560_0 Compressor Building Vent Fans.xls Page 4 of 8

LMC Flotation Project Equipment Data Sheet Prepared by Aker Kvaerner Pty Limited

EQUIPMENT TAG NUMBER(S) 1550-FA1560, 1561

Rev

EQUIPMENT NAME(S) Compressor Building Ventilation Fans

5.18 LOAD INERTIA (kgm2) *

5.19 DRIVE TYPE *

5.20 DUTY DETAILS *

5.21 STARTS/HOUR *

5.22 RUN UP TIME - MAX (sec) *

5.23 RUN UP TIME - MIN (sec) *

5.24 LOADING - AXIAL N *

5.25 LOADING - RADIAL N *

5.26 MOTOR DETAILS

5.27 POWER (kW) 18.5 0

5.28 VOLTAGE (V) 415

5.29 POLES 6 0

5.30 FRAME SIZE *

5.31 DUTY TYPE *

5.32 ENCLOSURE *

5.33 COOLING TYPE *

5.34 TYPE OF MOTOR *

5.35 MOUNTING *

5.36 ORIENTATION *

5.37 INSULATION CLASS F / Tropicalised

5.38 TEMPERATURE RISE B

5.39 SERVICE FACTOR

5.40 STARTER *

5.41 NOISE - SOUND PRESSURE LIMIT (dBA @ 1m) 85

5.42 PAINTING To Manufacturers Standard

5.43 HAZARDOUS AREA REQUIREMENTS

5.44 ENCLOSURE TYPE N/A

5.45 CERTIFICATING AUTHORITY N/A

5.46 CERTIFICATE No N/A

5.47 SHAFT

5.48 NUMBER OFF 1

5.49 DIAMETER (STANDARD / mm) *

5.50 LENGTH (STANDARD / mm) *

5.51 BEARINGS

5.52 DRIVE END TYPE *

5.53 DRIVE END SIZE *

5.54 NON-DRIVE END TYPE *

5.55 NON-DRIVE END SIZE *

5.56 BEARING LUBRICATION *

5.57 TEMPERATURE DETECTORS *

5.58 ANTI CONDENSATE HEATER

5.59 REQUIRED Yes (55 kW and above)

5.60 VOLTAGE (V AC) 240

5.61 EARTHING STUDS

5.62 NUMBER INTERNAL 1

5.63 NUMBER EXTERNAL 1

5.64 VIBRATION SENSORS (Shock pulse meter pad/stu *

5.65 NAMEPLATE Stainless Steel

5.66 MOUNTING (slide rails / base plate / sole plate) *

5.67 ROTATION (viewed from ND end) CW o*

5.68 JUNCTION BOX (viewed from ND end) LHS LHS

5.69 TERMINAL BOXES

5.70 POWER

5.71 ENCLOSURE IP66

5.72 ENTRY SIZE (mm) *

5.73 ANTI-CONDENSATE HEATER

5.74 ENCLOSURE IP66

5.75 ENTRY SIZE (mm) 20

5.76 THERMISTOR/RTD

11069-1550-FA1560_0 Compressor Building Vent Fans.xls Page 5 of 8

LMC Flotation Project Equipment Data Sheet Prepared by Aker Kvaerner Pty Limited

EQUIPMENT TAG NUMBER(S) 1550-FA1560, 1561

Rev

EQUIPMENT NAME(S) Compressor Building Ventilation Fans

5.77 ENCLOSURE IP66

5.78 ENTRY SIZE (mm) 20

5.79 MOTOR MANUFACTURER'S DATA

5.80 MANUFACTURER Teco

5.81 MODEL No. *

5.82 SERIAL No *

5.83 DRAWING No *

5.84 WEIGHT (kg) *

5.85 FULL LOAD SPEED (rpm) *

5.86 BUILT TO STANDARD *

5.87 CURRENT (A)

5.88 STARTING (x FLC) *

5.89 50% LOAD *

5.90 75% LOAD *

5.91 100% LOAD *

5.92 TORQUE (Nm)

5.93 STARTING (x FLT) *

5.94 50% LOAD *

5.95 75% LOAD *

5.96 100% LOAD *

5.97 EFFICIENCY (%)

5.98 STARTING *

5.99 50% LOAD *

6.00 75% LOAD *

6.01 100% LOAD *

6.02 POWER FACTOR

6.03 STARTING *

6.04 50% LOAD *

6.05 75% LOAD *

6.06 100% LOAD *

6.07 CALCULATED RUN UP TIME (sec) *

6.08 te TIME FOR Ex e MOTORS N/A

6.09 FIELD JUNCTION BOXES

6.10 ENCLOSURE IP66

6.11 JUNCTION BOX MoC 316 Stainless Steel

7.00 PAINTING AND SURFACE PROTECTION

7.01 SPECIFICATION(S) Lihir Spec S135 Rev 2 Steel Surface Protection - System CS2 0

7.02 MACHINED SURFACES Suitable Anti Corrosion Coating

7.03 STRUCTURAL STEELWORK

7.04 FRAMES / SUPPORTS / BRIDGE ASSEMBLY *

7.05 VESSELS

7.06 TANKS NA

7.07 LAUNDERS N/A

7.08 PIPING

7.09 SLURRY N/A

7.10 PUMPS / COMPRESSORS AND DRIVERS

7.11 MECHANICAL EQUIPMENT *

7.12 DRIVE GUARDS *

8.00 NOISE - FAN DISCHARGE

8.01 DRIVE TYPE *

8.02 DRIVER POWER (kW) kW *

8.03 DRIVER SPEED (r/min) r/min *

8.04 NOISE DATA INCLUDES DRIVER (Y/N) *

8.05 AUXILIARIES INCLUDED (Y/N) *

8.06 DESCRIPTION OF AUXILIARIES Inlet elbow, Discharge silencer, Pop-up Damper plus windband 0

8.07 NOISE DATA OBTAINED BY Calculation / Measurement / On Site / Workshop Test

11069-1550-FA1560_0 Compressor Building Vent Fans.xls Page 6 of 8

LMC Flotation Project Equipment Data Sheet Prepared by Aker Kvaerner Pty Limited

EQUIPMENT TAG NUMBER(S) 1550-FA1560, 1561

Rev

EQUIPMENT NAME(S) Compressor Building Ventilation Fans

8.08 MEASURED IN ACCORDANCE WITH *

8.09 TYPICAL SOUND LEVEL at 1m dB(A) *

8.10 EQUIPMENT MAJOR DIMENSIONS Length mm *

8.11 Width mm *

8.12 Height mm *

8.13 OCTAVE BAND ANALYSIS - METER TO BE SET AT LINEAR CHARACTERISTIC

8.14 UNITS Sound Pressure Level (SPL) at 1m in dB re 20μPa Yes/No

-12

8.15 Sound Power Level (PWL) in dB re 10 Watts No/Yes

8.16 OCTAVE BAND CENTRE FREQUENCY Hz

8.17 63 Acceptable Maximum Level

8.18 Impulsive Correction

8.19 Tonal Correction

8.20 Unsilenced *

8.21 Silenced *

8.22 125 Acceptable Maximum Level

8.23 Impulsive Correction

8.24 Tonal Correction

8.25 Unsilenced *

8.26 Silenced *

8.27 250 Acceptable Maximum Level

8.28 Impulsive Correction

8.29 Tonal Correction

8.30 Unsilenced *

8.31 Silenced *

8.32 500 Acceptable Maximum Level

8.33 Impulsive Correction

8.34 Tonal Correction

8.35 Unsilenced *

8.36 Silenced *

8.37 1k Acceptable Maximum Level

8.38 Impulsive Correction

8.39 Tonal Correction

8.40 Unsilenced *

8.41 Silenced *

8.42 2k Acceptable Maximum Level

8.43 Impulsive Correction

8.44 Tonal Correction

8.45 Unsilenced *

8.46 Silenced *

8.47 4k Acceptable Maximum Level

8.48 Impulsive Correction

8.49 Tonal Correction

8.50 Unsilenced *

8.51 Silenced *

8.52 8k Acceptable Maximum Level

8.53 Impulsive Correction

8.54 Tonal Correction

8.55 Unsilenced *

8.56 Silenced *

8.57 DOES THE EQUIPMENT EMIT ANY AUDIBLE PURE TONES *

8.58 IS THE EQUIPMENT NOISE IMPULSIVE IN CHARACTER *

8.59 IS ENCLOSURE USED TO ATTENUATE EQUIPMENT NOISE *

8.60 NOISE - DISCHARGE SILENCERS

8.61 ACOUSTIC INSERTION LOSS PROVIDED dB (LINEAR)

8.62 OCTAVE BAND FREQUENCY

8.63 63 *

8.64 125 *

8.65 250 *

8.66 500 *

11069-1550-FA1560_0 Compressor Building Vent Fans.xls Page 7 of 8

LMC Flotation Project Equipment Data Sheet Prepared by Aker Kvaerner Pty Limited

EQUIPMENT TAG NUMBER(S) 1550-FA1560, 1561

Rev

EQUIPMENT NAME(S) Compressor Building Ventilation Fans

8.67 1000 *

8.68 2000 *

8.69 4000 *

8.70 8000 *

8.71 NOISE - PERFORMANCE GENERAL

8.72 FAN/ SILENCER COMBINATION

8.73 ACHIEVES MAX 85 dB(A) EXTERNALLY YES/NO

8.74 FAN REQUIRES SEPARATE EXTERNAL INSULATION YES/NO

11.00 WEIGHTS AND SHIPPING SIZES

11.01 SHIPPING MASSES / VOLUMES (t) / (m x m x m) (Refer to Schedule of Cargo and Freight)

11.02 FAN (EACH) */*

11.03 SILENCER (EACH) */*

11.04 ADAPTOR (EACH - IF REQUIRED) */*

11.05 MISCELLANEOUS (DEFINE) */*

11.06 MISCELLANEOUS (DEFINE) */*

11.07 TOTAL */*

11069-1550-FA1560_0 Compressor Building Vent Fans.xls Page 8 of 8

Vous aimerez peut-être aussi

- TBA - TE-1910-0318 REV 0cDocument9 pagesTBA - TE-1910-0318 REV 0cAnaPas encore d'évaluation

- For Approval: Refractory Installation ProcedureDocument16 pagesFor Approval: Refractory Installation ProcedureLuis EscobedoPas encore d'évaluation

- Preliminary Datasheets For Analysers: PT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaDocument43 pagesPreliminary Datasheets For Analysers: PT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaJan Richardo GultomPas encore d'évaluation

- Ns2-Yt01-p0gcf-120002-Ab (Water Treatment Plant) - Motor Data SheetDocument196 pagesNs2-Yt01-p0gcf-120002-Ab (Water Treatment Plant) - Motor Data Sheettrong ngoc PhanPas encore d'évaluation

- 501abcde 016Document30 pages501abcde 016husen123 alhusadaPas encore d'évaluation

- Tba - Te-1910-0318 Rev 0Document9 pagesTba - Te-1910-0318 Rev 0AnaPas encore d'évaluation

- R2 - RevADocument12 pagesR2 - RevAChirag ShahPas encore d'évaluation

- N2 - Rev ADocument13 pagesN2 - Rev AChirag ShahPas encore d'évaluation

- Erbil Refinery Diesel Filling Pump Data SheetDocument5 pagesErbil Refinery Diesel Filling Pump Data SheetSardar PerdawoodPas encore d'évaluation

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodPas encore d'évaluation

- Datahseet For Strainer With Air EliminatorDocument4 pagesDatahseet For Strainer With Air Eliminatorvinoj chandranPas encore d'évaluation

- EC0049-75990899-CAL-0016Document204 pagesEC0049-75990899-CAL-0016akash824876Pas encore d'évaluation

- 02-1 Tecnical SpecDocument22 pages02-1 Tecnical SpechamzehPas encore d'évaluation

- J910-Yt01-P0ana-145411 Datasheet For Cable, Conduit and Accessories (Lighting System), Rev.2 (Afc)Document29 pagesJ910-Yt01-P0ana-145411 Datasheet For Cable, Conduit and Accessories (Lighting System), Rev.2 (Afc)niaPas encore d'évaluation

- TBA - TE-1910-0318 REV 0aDocument8 pagesTBA - TE-1910-0318 REV 0aAnaPas encore d'évaluation

- MQ SP M 4010 PDFDocument16 pagesMQ SP M 4010 PDFjaseelPas encore d'évaluation

- MQ SP M 4033 PDFDocument16 pagesMQ SP M 4033 PDFjaseelPas encore d'évaluation

- Chapter 12 - Servicing (Lubrications)Document148 pagesChapter 12 - Servicing (Lubrications)reginaldo11Pas encore d'évaluation

- Job Procedure For Earthing SystemDocument7 pagesJob Procedure For Earthing SystemNisith SahooPas encore d'évaluation

- Tfu 92.00.00.007 6 PDFDocument2 pagesTfu 92.00.00.007 6 PDFPHI nguyễnPas encore d'évaluation

- Capex+ +opex Caso+1Document20 pagesCapex+ +opex Caso+1Karen Selene Manrique RetoPas encore d'évaluation

- DS 7502Document4 pagesDS 7502ThirukkumaranBalasubramanianPas encore d'évaluation

- K229-0c-Mr-4300-401-A0104-0001 - 4X (Equip List)Document2 pagesK229-0c-Mr-4300-401-A0104-0001 - 4X (Equip List)Mohamed SamirPas encore d'évaluation

- MQ SP M 4035 PDFDocument9 pagesMQ SP M 4035 PDFjaseelPas encore d'évaluation

- 05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSDocument5 pages05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSSelim SelimPas encore d'évaluation

- DOAS Sizing Summary for BedroomDocument105 pagesDOAS Sizing Summary for BedroomSaahil KhaanPas encore d'évaluation

- RDJ GM 620 047 - (En)Document14 pagesRDJ GM 620 047 - (En)fouad kerkarPas encore d'évaluation

- 26071-100-VSC-CV5-00009 - Method Statment of Sheet Pile 00ADocument13 pages26071-100-VSC-CV5-00009 - Method Statment of Sheet Pile 00ARezky BaskoroPas encore d'évaluation

- M-32 Emergency Shut-Off ValveDocument19 pagesM-32 Emergency Shut-Off Valveramdayal bhairaPas encore d'évaluation

- Voltage Drop & Power Cable Sizing CalculationDocument46 pagesVoltage Drop & Power Cable Sizing CalculationAnujGargPas encore d'évaluation

- Ds-Me-0018 - Mechanical Data Sheet For Overfill Prevention Valve (Rev.0)Document2 pagesDs-Me-0018 - Mechanical Data Sheet For Overfill Prevention Valve (Rev.0)Panisa BanimaPas encore d'évaluation

- PS Valve Service PDFDocument40 pagesPS Valve Service PDFJuanManuelPerillaPas encore d'évaluation

- Specification For Approval: DC FanDocument13 pagesSpecification For Approval: DC FanElias CoelhoPas encore d'évaluation

- MQ SP M 4003 PDFDocument18 pagesMQ SP M 4003 PDFjaseelPas encore d'évaluation

- Flipkart, Kolkata-Concept Note On Hvac System-Rev p0Document24 pagesFlipkart, Kolkata-Concept Note On Hvac System-Rev p0SajeshKumarPas encore d'évaluation

- 1900 MTPD Ammonia Plant Venturi Flow Element Data SheetDocument40 pages1900 MTPD Ammonia Plant Venturi Flow Element Data SheetJan Richardo GultomPas encore d'évaluation

- A320-214 - Yom 2014 (Sale)Document6 pagesA320-214 - Yom 2014 (Sale)Francisco SoFuentesPas encore d'évaluation

- EGPM-10-DAS-MOV-ISO-01 - Datasheet For MOV IsolatorDocument4 pagesEGPM-10-DAS-MOV-ISO-01 - Datasheet For MOV IsolatordrkongalaPas encore d'évaluation

- L01-6400-Eprc-Ds-0001 - 00 - Inlet Separator Filter-Em&rDocument19 pagesL01-6400-Eprc-Ds-0001 - 00 - Inlet Separator Filter-Em&rVU ingenieriaPas encore d'évaluation

- Contractor instrument pressure piping hook-up documentDocument35 pagesContractor instrument pressure piping hook-up documentTahir100% (1)

- (6648-0200-5-PS-DS-0026) 200-C-51 - Rev.FDocument15 pages(6648-0200-5-PS-DS-0026) 200-C-51 - Rev.FMohamed OuichaouiPas encore d'évaluation

- Offshore Air-Cooled Heat Exchanger Functional SpecDocument19 pagesOffshore Air-Cooled Heat Exchanger Functional Specsumit kumarPas encore d'évaluation

- Technical Specs for 36,000 CFM Floor Mounted Fan UnitDocument3 pagesTechnical Specs for 36,000 CFM Floor Mounted Fan UnitSuraj KhopePas encore d'évaluation

- Atlasco ManualDocument248 pagesAtlasco ManualAyoade Lanre BexPas encore d'évaluation

- Purchase Order Requisition R-1910-0318 Rev 0Document27 pagesPurchase Order Requisition R-1910-0318 Rev 0AnaPas encore d'évaluation

- Plant TS PVB El Evd LPF 001 00Document18 pagesPlant TS PVB El Evd LPF 001 00rahul rPas encore d'évaluation

- AK2 - RevADocument13 pagesAK2 - RevAChirag ShahPas encore d'évaluation

- Actuated Quarter Turn IPF Valves SpecificationDocument117 pagesActuated Quarter Turn IPF Valves Specificationviperjet67% (3)

- Air Handling Unit Schedule: Attachment 1Document15 pagesAir Handling Unit Schedule: Attachment 1charadeg100Pas encore d'évaluation

- uplot-25509-100-3PS-EKL0-F0001 Substation PDFDocument17 pagesuplot-25509-100-3PS-EKL0-F0001 Substation PDFAnonymous FHkX0APas encore d'évaluation

- PDFDocument17 pagesPDFDelovan CheikhoPas encore d'évaluation

- BOP DL 13-5.8_5K 2245081-03Document15 pagesBOP DL 13-5.8_5K 2245081-03a.solvevPas encore d'évaluation

- C22-YS20-S-7960 - 1 - Cooling Tower Layout - PS2 PDFDocument3 pagesC22-YS20-S-7960 - 1 - Cooling Tower Layout - PS2 PDFsartajPas encore d'évaluation

- Epcc-2 Package (RFCC Unit) ) For Petrochemical and Lube Integration Project "Lupech" (J-18)Document8 pagesEpcc-2 Package (RFCC Unit) ) For Petrochemical and Lube Integration Project "Lupech" (J-18)phanikrishnabPas encore d'évaluation

- 21 4033 Central Region Library - 2023.08.11Document1 305 pages21 4033 Central Region Library - 2023.08.11zhungjian586Pas encore d'évaluation

- Additional Development OF Luhais & Subba Oil Field ProjectsDocument12 pagesAdditional Development OF Luhais & Subba Oil Field ProjectsMohamedHussein MohamedHusseinPas encore d'évaluation

- HvacDocument22 pagesHvacMudassar Idris Raut100% (1)

- 5 SS Data Sheet TurboDocument34 pages5 SS Data Sheet TurboYhony Gamarra VargasPas encore d'évaluation

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsD'EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Marine Electrical Practice: Marine Engineering SeriesD'EverandMarine Electrical Practice: Marine Engineering SeriesÉvaluation : 4 sur 5 étoiles4/5 (8)

- Mission Planning Guidelines: 1. Has The Method Statement Been Made?Document2 pagesMission Planning Guidelines: 1. Has The Method Statement Been Made?alimoya13Pas encore d'évaluation

- Mission Difficulty Assessment Card v7Document1 pageMission Difficulty Assessment Card v7alimoya13Pas encore d'évaluation

- ClapperDocument2 pagesClapperalimoya13Pas encore d'évaluation

- HTTPDocument1 pageHTTPalimoya13Pas encore d'évaluation

- Physics 115 Lab Manual GuideDocument45 pagesPhysics 115 Lab Manual Guidealimoya13Pas encore d'évaluation

- Model 4 5 0 0 ADocument2 pagesModel 4 5 0 0 Aalimoya13Pas encore d'évaluation

- CuttingCmpd PDFDocument5 pagesCuttingCmpd PDFalimoya13Pas encore d'évaluation

- Original Installed Unit (IFC 090)Document1 pageOriginal Installed Unit (IFC 090)alimoya13Pas encore d'évaluation

- Safety Data Sheet: Section 1: Identification of The Substance/mixture and of The Company/undertakingDocument5 pagesSafety Data Sheet: Section 1: Identification of The Substance/mixture and of The Company/undertakingalimoya13Pas encore d'évaluation

- Original Installed Unit (IFC 090)Document1 pageOriginal Installed Unit (IFC 090)alimoya13Pas encore d'évaluation

- Yoke Design For FabricationDocument1 pageYoke Design For Fabricationalimoya13Pas encore d'évaluation

- Kammer Actuators P2, P3, P4, P5Document6 pagesKammer Actuators P2, P3, P4, P5alimoya130% (1)

- CX-Programmer Tutorial PDFDocument13 pagesCX-Programmer Tutorial PDFEga NuregaPas encore d'évaluation

- Data Sheet: Squirrel Cage Induction Electric MotorDocument1 pageData Sheet: Squirrel Cage Induction Electric Motoralimoya13Pas encore d'évaluation

- No Life Without Diversity!: Biodiversity Photo: Miguel Schmitter/Julia HamacherDocument1 pageNo Life Without Diversity!: Biodiversity Photo: Miguel Schmitter/Julia Hamacheralimoya13Pas encore d'évaluation

- SC0501 01 - en UsDocument3 pagesSC0501 01 - en Usalimoya13Pas encore d'évaluation

- One SayDocument1 pageOne Sayalimoya13Pas encore d'évaluation

- Datasheet Monarch Cast Iron Frame Tefc To 500KwDocument1 pageDatasheet Monarch Cast Iron Frame Tefc To 500Kwalimoya13Pas encore d'évaluation

- Electrical Memo - Electrical Wiring Colour CodeDocument1 pageElectrical Memo - Electrical Wiring Colour Codealimoya13Pas encore d'évaluation

- Alarm Display - Tips & Tricks 1 PDFDocument15 pagesAlarm Display - Tips & Tricks 1 PDFalimoya13Pas encore d'évaluation

- Boot UsbDocument3 pagesBoot Usbalimoya13Pas encore d'évaluation

- Temp Relay For Regen HeaterDocument2 pagesTemp Relay For Regen Heateralimoya13Pas encore d'évaluation

- PLC Comparison Chart 2007 v5Document3 pagesPLC Comparison Chart 2007 v5yaronstPas encore d'évaluation

- BPG Floor-Marking (Floor)Document20 pagesBPG Floor-Marking (Floor)alimoya13Pas encore d'évaluation

- Low Voltage 3-Phase Induction Motors 0.55kW To 500kW: RangeDocument12 pagesLow Voltage 3-Phase Induction Motors 0.55kW To 500kW: Rangealimoya13Pas encore d'évaluation

- Old Motor FA1561Document1 pageOld Motor FA1561alimoya13Pas encore d'évaluation

- Industrial Ethernet: A Control Engineer's Guide: White PaperDocument19 pagesIndustrial Ethernet: A Control Engineer's Guide: White PaperHamidreza Moaddeli100% (1)

- UE BOOM 2 TAP CONTROLSDocument11 pagesUE BOOM 2 TAP CONTROLSalimoya13Pas encore d'évaluation

- Dynalco SST-2000A.data SheetDocument2 pagesDynalco SST-2000A.data Sheetalimoya13Pas encore d'évaluation

- Semiconductor: 1 PropertiesDocument9 pagesSemiconductor: 1 PropertiesGilberto ManhattanPas encore d'évaluation

- Qa TableDocument9 pagesQa Tableapi-299403846Pas encore d'évaluation

- En010 104 Engineering MechanicsDocument1 pageEn010 104 Engineering MechanicsArun SaiPas encore d'évaluation

- Photo ResistorDocument3 pagesPhoto ResistorHarish PrakashPas encore d'évaluation

- Corrosion Resistance of Surface Treated 42crmo4 Steel: D. Kusmič, V. Hrubý, L. BachárováDocument6 pagesCorrosion Resistance of Surface Treated 42crmo4 Steel: D. Kusmič, V. Hrubý, L. BachárovárachidradouaniPas encore d'évaluation

- Bagh Bon BondukDocument105 pagesBagh Bon BondukAdnan RahmanPas encore d'évaluation

- CE 437/537 Retaining Wall Design ExampleDocument8 pagesCE 437/537 Retaining Wall Design ExampleJefferson Nobleza67% (3)

- Shell Horizontal Butt-Weld Minimum RequirementsDocument16 pagesShell Horizontal Butt-Weld Minimum RequirementsBTEPas encore d'évaluation

- Circuit BreakerDocument70 pagesCircuit BreakerBADAL CHOUDHARYPas encore d'évaluation

- Armfield F1 Fluid Mechanics Series Brochure V2a Download 1Document30 pagesArmfield F1 Fluid Mechanics Series Brochure V2a Download 1paul contrerasPas encore d'évaluation

- All Ceramic Material SelectionDocument6 pagesAll Ceramic Material SelectionERIKA BLANQUETPas encore d'évaluation

- Romax 4000 PDFDocument2 pagesRomax 4000 PDFALEKSANDARPas encore d'évaluation

- Linear Programming: Presented by - Meenakshi TripathiDocument13 pagesLinear Programming: Presented by - Meenakshi TripathiRajendra PansarePas encore d'évaluation

- Grade 12 English Test Review: Key Terms, Grammar, Reading ComprehensionDocument5 pagesGrade 12 English Test Review: Key Terms, Grammar, Reading ComprehensionLinh HuongPas encore d'évaluation

- GSK980TDDocument406 pagesGSK980TDgiantepepinPas encore d'évaluation

- Siniloan Integrated National High SchoolDocument4 pagesSiniloan Integrated National High SchoolKimberlyn VelascoPas encore d'évaluation

- S7-1200 SM 1231 8 X Analog Input - SpecDocument3 pagesS7-1200 SM 1231 8 X Analog Input - Specpryzinha_evPas encore d'évaluation

- Za Sans 5011 2005 PDFDocument18 pagesZa Sans 5011 2005 PDFJan-Louis ReyndersPas encore d'évaluation

- Astm 1784Document4 pagesAstm 1784arifin rizalPas encore d'évaluation

- FFT window and transform lengthsDocument5 pagesFFT window and transform lengthsNguyen Quoc DoanPas encore d'évaluation

- Topic 5 - Criticality of Homogeneous ReactorsDocument53 pagesTopic 5 - Criticality of Homogeneous ReactorsSit LucasPas encore d'évaluation

- Programming ExercisesDocument2 pagesProgramming ExercisesDaryl Ivan Empuerto HisolaPas encore d'évaluation

- Chap3 (D) MillDocument22 pagesChap3 (D) MilljojoPas encore d'évaluation

- Radiation Physics and Chemistry: Traian Zaharescu, Maria Râp Ă, Eduard-Marius Lungulescu, Nicoleta Butoi TDocument10 pagesRadiation Physics and Chemistry: Traian Zaharescu, Maria Râp Ă, Eduard-Marius Lungulescu, Nicoleta Butoi TMIGUEL ANGEL GARCIA BONPas encore d'évaluation

- Blade Profile Optimization of Kaplan Turbine Using CFD AnalysisDocument16 pagesBlade Profile Optimization of Kaplan Turbine Using CFD Analysiscbaraj100% (1)

- Astm B 265 - 03Document8 pagesAstm B 265 - 03kaminaljuyuPas encore d'évaluation

- 1 BelzonaDocument41 pages1 BelzonashakeelahmadjsrPas encore d'évaluation

- Computer Numerical Control CNC: Ken Youssefi Mechanical Engineering DepartmentDocument43 pagesComputer Numerical Control CNC: Ken Youssefi Mechanical Engineering DepartmentSreedhar PugalendhiPas encore d'évaluation

- Company Profile: BIS CML No.: 7200050893 An Iso 9001:2015 Certified CompanyDocument4 pagesCompany Profile: BIS CML No.: 7200050893 An Iso 9001:2015 Certified CompanyPowerlitePas encore d'évaluation

- d270 PDFDocument8 pagesd270 PDFศิวาเวช อบมาPas encore d'évaluation