Académique Documents

Professionnel Documents

Culture Documents

SP-1246-1 Specification For Painting and Coating of Oil and Gas Production Facilities - Part 1 Technical Requirements

Transféré par

muthuvelaaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SP-1246-1 Specification For Painting and Coating of Oil and Gas Production Facilities - Part 1 Technical Requirements

Transféré par

muthuvelaaDroits d'auteur :

Formats disponibles

Specification for Painting and Coating of Oil and Gas Production Facilities–Part - 1 Version 2

3.2.63.2.5 VOC Requirements Formatted: Bullets and Numbering

There are no statutory requirements in Oman for control of Volatile Organic Compound (VOC) and PDO uses

the American Conference of Governmental Industrial Hygienists (ACGIH) publication which covers the

current USA statutory regulations for controlling the exposure levels to paint solvents (VOCs). This publication

lists the maximum exposure limits and occupational exposure standards.

The levels of VOCs that can be admitted to the atmosphere through both the manufacture and application of

paints and associated products shall be in accordance with the above.

Paints and other coatings, specified in this Specification, shall not contain any components that are carcinogenic

or possess high toxicity (eg. isocyanates) which can be released during application, in service or during removal.

3.63.3 Finish Colour and Colour Coding Schedule Formatted: Bullets and Numbering

3.6.13.3.1 Overall Top Coat Colours

The final coat of a coating system shall be of a colour in accordance with PDO colour scheme for equipment and

process facilities shown in Table 1 below.

Table 1 Recommended Colours for Oil and Gas Installations

Facility Description Colour BS 4800 RAL

Oil and gas installations in the Interior and Government Gas White 00 E 55 9010

installations on the Coast, including above-ground tanks,

vessels, piping and structural steel. See also SP-1166

Bottom strake of oil and water storage tanks Black 00 E 53 9005

Oil installations in Mina al Fahal including above-ground tanks, Camouflage 1019

vessels, piping and structural steel.

Stacks and heat transfer equipment Aluminium 00 A 05 9006

Electrical equipment Light Grey 7036

Instrument panels Silver Grey 18 B 21 7032

Safety markings including handrails Yellow 08 E 51 1021

Pipeline isolating joints Red 3000

Offshore mooring buoys topside steelwork Yellow 08 E 51 1021

3.6.23.3.2 Colour Identification for Plant Pipework and Pipelines Formatted: Bullets and Numbering

Colour coding shall be in accordance with SP-1166 the technical specification for Identification of On-plot

Piping

3.73.4 Metallic Coatings Formatted: Bullets and Numbering

3.7.13.4.1 Hot Dip Galvanising

All carbon steel gratings, ladders, handrails, fences, stairways, walkways, cable trays, and other items as

specified by the Project Technical Information shall be hot dip galvanised in accordance with BS EN ISO 1461:

covering hot dip galvanised coatings on iron and steel articles. The minimum coating weight shall comply with

the values laid down in Table 1 of BS EN ISO 1461: and shall not be less than 610 g/m2.

All sealed tubes must have a small weep-hole to allow hydrogen gas to escape.

Small areas of galvanised coating, damaged by cutting, welding, drilling or any preparation during fabrication,

erection, transportation or installation, shall be repaired in accordance with Part 3.

Painting systems for galvanised items that are to be painted are detailed in Sections 5 of Part 2 and Part 3 of this

Specification, for new construction and maintenance painting respectively.

SP-1246 9 April 2010

Vous aimerez peut-être aussi

- TL - 260 - en 2015Document11 pagesTL - 260 - en 2015hand42100% (1)

- Job Specification Shop & Field PaintingDocument47 pagesJob Specification Shop & Field PaintingVikash TiwariPas encore d'évaluation

- Fabrication ProcedureDocument16 pagesFabrication ProcedureAryo WicaksonoPas encore d'évaluation

- Painting Scheme StructureDocument10 pagesPainting Scheme StructureVeerapandianPas encore d'évaluation

- Surface Finish StandardDocument3 pagesSurface Finish StandardvinodmysorePas encore d'évaluation

- All-in-One Manual of Industrial Piping Practice and MaintenanceD'EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceÉvaluation : 5 sur 5 étoiles5/5 (1)

- Shear Modulus at Room Temperature: Standard Test Method ForDocument5 pagesShear Modulus at Room Temperature: Standard Test Method ForROHITPas encore d'évaluation

- Painting SpecDocument54 pagesPainting Specashim_scribd100% (4)

- 6744-0642-PT-C06 Rev 0 PDFDocument44 pages6744-0642-PT-C06 Rev 0 PDFVineet SinghPas encore d'évaluation

- Section 21 List of Specification and British Standard (BS) NumbersDocument3 pagesSection 21 List of Specification and British Standard (BS) NumbersOmar DhiebPas encore d'évaluation

- Arch-2.2-Protective Treatments For MetalsDocument2 pagesArch-2.2-Protective Treatments For MetalsSherazPas encore d'évaluation

- Specification For Plant Access Platforms, Stairs and Ladders Materials and FabricationDocument41 pagesSpecification For Plant Access Platforms, Stairs and Ladders Materials and FabricationRajveer SinghPas encore d'évaluation

- Division 05 - Metals Section 05500 - Metal FabricationDocument20 pagesDivision 05 - Metals Section 05500 - Metal FabricationMohamed taha ahmedPas encore d'évaluation

- Eil Painting Tech Spec Vol IIDocument44 pagesEil Painting Tech Spec Vol IIMl Jain82% (11)

- VolDocument67 pagesVolapi-3698996100% (1)

- 50-Applicable Codes and StandardsDocument48 pages50-Applicable Codes and StandardsmohsenPas encore d'évaluation

- Protective Coating Specification for Elgin/Franklin Wellhead TopsidesDocument46 pagesProtective Coating Specification for Elgin/Franklin Wellhead TopsidesmatmarcantonioPas encore d'évaluation

- Koc MP 016Document18 pagesKoc MP 016Ravi MahetoPas encore d'évaluation

- Anodized Coatings Spec for Aluminum AlloysDocument20 pagesAnodized Coatings Spec for Aluminum Alloysnoman888Pas encore d'évaluation

- Cs Welded Pipes - 1Document7 pagesCs Welded Pipes - 1albejo_r9Pas encore d'évaluation

- GB5237.2-2017 英文Document16 pagesGB5237.2-2017 英文TheAnh TranPas encore d'évaluation

- 10080-1-SS-PP-042Document16 pages10080-1-SS-PP-042SURAJ PRSADPas encore d'évaluation

- Consulting Engineering Group Metalwork SpecificationDocument1 pageConsulting Engineering Group Metalwork SpecificationSherazPas encore d'évaluation

- A3-40 External MetalworkDocument17 pagesA3-40 External Metalworklwin_oo2435Pas encore d'évaluation

- A2 40 SkylightsDocument16 pagesA2 40 SkylightsJacky TiongPas encore d'évaluation

- Annex 14 - Piping SpecDocument18 pagesAnnex 14 - Piping SpecbisworupmPas encore d'évaluation

- Structural SteelworkDocument24 pagesStructural SteelworkJohnson SunderPas encore d'évaluation

- A1-40 Metal CladdingDocument16 pagesA1-40 Metal Claddinglwin_oo2435Pas encore d'évaluation

- 1-0september 1993Document20 pages1-0september 1993Bryan MartinezPas encore d'évaluation

- HDG TirantiDocument17 pagesHDG TirantiGMSPas encore d'évaluation

- TANK PAINT SPECDocument25 pagesTANK PAINT SPECandri yanto100% (1)

- VW TL 217 2016Document8 pagesVW TL 217 2016Bartek HajaPas encore d'évaluation

- INS-000-SPE-0002 Rev.3 Specification For Painting and Coating, Structural Steel of Marine FacilitiesDocument25 pagesINS-000-SPE-0002 Rev.3 Specification For Painting and Coating, Structural Steel of Marine FacilitiesenriquePas encore d'évaluation

- Design of SHSDocument56 pagesDesign of SHSRobertBayley100% (1)

- Piping Material Specification 2010014 00 l0 Gs 001Document215 pagesPiping Material Specification 2010014 00 l0 Gs 001Wilson Xavier Orbea Bracho100% (1)

- Painting SpecificationDocument40 pagesPainting SpecificationIkram Syed100% (4)

- ASME and AWS Welding Codes and Standards GuideDocument14 pagesASME and AWS Welding Codes and Standards Guiderusf123100% (1)

- ST Structural Steel FramingDocument45 pagesST Structural Steel Framingwookie1977100% (1)

- Arc Welding Requirments: General: 1.1 PurposeDocument47 pagesArc Welding Requirments: General: 1.1 PurposeAriel FerrerPas encore d'évaluation

- Painting Process Equipment and PipingDocument17 pagesPainting Process Equipment and PipingJoseph Darwin ZionPas encore d'évaluation

- En 10028 2 P265GH - Boiler Plate Steel - ProductsDocument2 pagesEn 10028 2 P265GH - Boiler Plate Steel - ProductsShankey JAlanPas encore d'évaluation

- Astm B633 19Document4 pagesAstm B633 19Satish JadhavPas encore d'évaluation

- Section 09960 Protective CoatingsDocument17 pagesSection 09960 Protective CoatingsMØhãmmed ØwięsPas encore d'évaluation

- West Qurna 1 Building Upgrades & Facilities WorkDocument19 pagesWest Qurna 1 Building Upgrades & Facilities WorkNoor A QasimPas encore d'évaluation

- Subject: Fire ProtectionDocument3 pagesSubject: Fire ProtectionAlexis Moya ManzorPas encore d'évaluation

- Welding CodeDocument14 pagesWelding CodeKureiPas encore d'évaluation

- Standards & RegulationsDocument12 pagesStandards & RegulationsdantranzPas encore d'évaluation

- M4 For Steel StackDocument25 pagesM4 For Steel Stackksshashidhar100% (1)

- INS-000-SPE-0002 Rev.1 Specification For Painting and Coating%2c Structural Steel of Marine FacilitiesDocument18 pagesINS-000-SPE-0002 Rev.1 Specification For Painting and Coating%2c Structural Steel of Marine FacilitiesCristhian Joel VIPas encore d'évaluation

- RG6-S-00-1360-083 - 0001 - 4 Specification For Forged Valves Non-CryogenicDocument8 pagesRG6-S-00-1360-083 - 0001 - 4 Specification For Forged Valves Non-CryogenicShivashankar Durga MedisettiPas encore d'évaluation

- Painting Standard ListDocument15 pagesPainting Standard Listvikas dahiyaPas encore d'évaluation

- WeldComm Stair SpecDocument16 pagesWeldComm Stair Specsks_242Pas encore d'évaluation

- Plant InspectionDocument9 pagesPlant InspectionSyed SulaimanPas encore d'évaluation

- TL 244 EnglischDocument9 pagesTL 244 Englisch'Lampa'Pas encore d'évaluation

- Peel Test Degree & ValueDocument129 pagesPeel Test Degree & ValueZainudin0% (1)

- ES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Document23 pagesES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Nikki RobertsPas encore d'évaluation

- MP HALL - Speci-EDocument15 pagesMP HALL - Speci-EAbdul RahumanPas encore d'évaluation

- Astm B 908 - 03Document2 pagesAstm B 908 - 03kaminaljuyu100% (1)

- ODISHA POWER TRANSMISSION CORPORATION RATE CONTRACTDocument25 pagesODISHA POWER TRANSMISSION CORPORATION RATE CONTRACTVenkatPas encore d'évaluation

- AVK Fire Hydrant Technical SpecificationsDocument2 pagesAVK Fire Hydrant Technical SpecificationsmuthuvelaaPas encore d'évaluation

- TQ 0121 - 00Document8 pagesTQ 0121 - 00muthuvelaaPas encore d'évaluation

- ARAMCO SAUDI NOTESDocument1 pageARAMCO SAUDI NOTESmuthuvelaaPas encore d'évaluation

- Refer To Drawing No.: 620620 SH-002 Refer To Drawing No.: 620620 SH-003Document1 pageRefer To Drawing No.: 620620 SH-002 Refer To Drawing No.: 620620 SH-003muthuvelaaPas encore d'évaluation

- MF RCPDocument1 pageMF RCPmuthuvelaaPas encore d'évaluation

- ARAMCO Saudi consent notesDocument1 pageARAMCO Saudi consent notesmuthuvelaaPas encore d'évaluation

- Ground Floor: B RA-620717 001 B 961 G203Document1 pageGround Floor: B RA-620717 001 B 961 G203muthuvelaaPas encore d'évaluation

- Emergency Exit FloorplanDocument1 pageEmergency Exit FloorplanmuthuvelaaPas encore d'évaluation

- Catalogues and Manufacturing Data Sheet For Detection SystemDocument52 pagesCatalogues and Manufacturing Data Sheet For Detection SystemmuthuvelaaPas encore d'évaluation

- C410 963 A RA-635784 001 D: LegendsDocument1 pageC410 963 A RA-635784 001 D: LegendsmuthuvelaaPas encore d'évaluation

- Refer To Drawing No.: 620356 SH-002 Refer To Drawing No.: 620356 SH-003Document1 pageRefer To Drawing No.: 620356 SH-002 Refer To Drawing No.: 620356 SH-003muthuvelaaPas encore d'évaluation

- B RA-620356 002 B 963 C204: NotesDocument1 pageB RA-620356 002 B 963 C204: NotesmuthuvelaaPas encore d'évaluation

- Ra-616190-001 (D-1) PDFDocument1 pageRa-616190-001 (D-1) PDFmuthuvelaaPas encore d'évaluation

- C RA-620208 002 B 961 A310: Ground Floor Firefighting Part Plan 1Document1 pageC RA-620208 002 B 961 A310: Ground Floor Firefighting Part Plan 1muthuvelaaPas encore d'évaluation

- AVK Hydrant Kite Mark Certificate KM53897Document2 pagesAVK Hydrant Kite Mark Certificate KM53897muthuvelaa100% (1)

- Ra-616190-001 (D-1) PDFDocument1 pageRa-616190-001 (D-1) PDFmuthuvelaaPas encore d'évaluation

- Business Email - Functional Language Reference Sheets PDFDocument21 pagesBusiness Email - Functional Language Reference Sheets PDFsarwarrosunPas encore d'évaluation

- General Notes: Legends: Abbreviations:: Reference DrawingsDocument1 pageGeneral Notes: Legends: Abbreviations:: Reference DrawingsmuthuvelaaPas encore d'évaluation

- Ra-620575-001 (A-1)Document1 pageRa-620575-001 (A-1)muthuvelaaPas encore d'évaluation

- Business Email - Functional Language Reference Sheets PDFDocument21 pagesBusiness Email - Functional Language Reference Sheets PDFsarwarrosunPas encore d'évaluation

- Material Part Description Part No. QTY: Inch MetricDocument1 pageMaterial Part Description Part No. QTY: Inch MetricmuthuvelaaPas encore d'évaluation

- Drawing Is Controlled ONLY When Viewed in R & D Electronic Print Library. NON - CONTROLLED When Saved, Printed, or EmailedDocument1 pageDrawing Is Controlled ONLY When Viewed in R & D Electronic Print Library. NON - CONTROLLED When Saved, Printed, or EmailedmuthuvelaaPas encore d'évaluation

- Spec LIna123Document72 pagesSpec LIna123muthuvelaaPas encore d'évaluation

- 4 Inch Mono Strainer (Inner Basket) PDFDocument1 page4 Inch Mono Strainer (Inner Basket) PDFmuthuvelaaPas encore d'évaluation

- Firemiks 180 3 PP MDocument2 pagesFiremiks 180 3 PP MmuthuvelaaPas encore d'évaluation

- 3 Painting and Coating Selection Schedules: 3.1 New Construction WorksDocument2 pages3 Painting and Coating Selection Schedules: 3.1 New Construction WorksmuthuvelaaPas encore d'évaluation

- Boq For A'sharqiyah UniversityDocument10 pagesBoq For A'sharqiyah UniversitymuthuvelaaPas encore d'évaluation

- 3 Painting and Coating Selection Schedules: 3.1 New Construction WorksDocument2 pages3 Painting and Coating Selection Schedules: 3.1 New Construction WorksmuthuvelaaPas encore d'évaluation

- 3 Painting and Coating Selection Schedules: 3.1 New Construction WorksDocument2 pages3 Painting and Coating Selection Schedules: 3.1 New Construction WorksmuthuvelaaPas encore d'évaluation

- Control Valve CV Calculation ManualDocument86 pagesControl Valve CV Calculation ManualDuong NguyenPas encore d'évaluation

- Pacemaker Electric: Efficiency PlusDocument2 pagesPacemaker Electric: Efficiency PlusJijo J JosePas encore d'évaluation

- Barrier Performance of Common Plastic FilmDocument1 pageBarrier Performance of Common Plastic FilmAriane Victoria DantesPas encore d'évaluation

- INFX8000C Ceailing HightDocument2 pagesINFX8000C Ceailing HightKhan KakaPas encore d'évaluation

- RFP-EAH-2016-008 - Section V - Annex C - Technical SpecificationsDocument147 pagesRFP-EAH-2016-008 - Section V - Annex C - Technical SpecificationsKhlif NadaPas encore d'évaluation

- REINFORCEMENT SCHEDULEDocument30 pagesREINFORCEMENT SCHEDULEMiko AbiPas encore d'évaluation

- Technozen Quiz MaterialDocument35 pagesTechnozen Quiz MaterialKarthi100% (1)

- Electrical legend and layout for bedroomDocument1 pageElectrical legend and layout for bedroomPardhan Lakshay PareekPas encore d'évaluation

- Descriptive Analysis of Advantages and Disadvantages of Expanded Polystyrene Monolytic Panels - EPSDocument11 pagesDescriptive Analysis of Advantages and Disadvantages of Expanded Polystyrene Monolytic Panels - EPSWilson Bryan RegaladoPas encore d'évaluation

- Installation Instructions BWC Waterline Shower ChannelDocument4 pagesInstallation Instructions BWC Waterline Shower ChannelBLUCHERPas encore d'évaluation

- ACI 350 CalculationDocument3 pagesACI 350 CalculationBoris GalindoPas encore d'évaluation

- Sm-Etabs GuideDocument5 pagesSm-Etabs GuidetaroPas encore d'évaluation

- Decking (Composite & 2 Layers Reinf)Document41 pagesDecking (Composite & 2 Layers Reinf)Than Than SoePas encore d'évaluation

- Truss Design DocumentationDocument2 pagesTruss Design DocumentationNiroj MaharjanPas encore d'évaluation

- Fluid Mechanics PDFDocument48 pagesFluid Mechanics PDFrakib hasanPas encore d'évaluation

- 12.0 Moment and Shear Coefficient For Solid Slab: L Effective Span F Total Ultimate Load 1.35gDocument1 page12.0 Moment and Shear Coefficient For Solid Slab: L Effective Span F Total Ultimate Load 1.35gKumaresvaranPas encore d'évaluation

- Pile CalculationDocument1 pagePile Calculationepe civil1Pas encore d'évaluation

- Price List 2020 Fy 2077 078 Wef July 2020Document3 pagesPrice List 2020 Fy 2077 078 Wef July 2020Roshan KejariwalPas encore d'évaluation

- C-31 - Defence Colony - Terrace Garden ProposalDocument7 pagesC-31 - Defence Colony - Terrace Garden ProposalDevangie Shrivastava100% (1)

- Ebara 3M IE3 UKDocument19 pagesEbara 3M IE3 UKAfraz ShaikhPas encore d'évaluation

- En GRP Vs PE CSDocument19 pagesEn GRP Vs PE CSbehzad sahandpourPas encore d'évaluation

- 1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00Document107 pages1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00vhpatel67Pas encore d'évaluation

- Hot Isostatic Pressing CeramicsDocument4 pagesHot Isostatic Pressing CeramicsamirsuryahidayahPas encore d'évaluation

- In-Line Pulsation Dampeners For Bredel 25-100, APEX 28 and APEX 35 PumpsDocument2 pagesIn-Line Pulsation Dampeners For Bredel 25-100, APEX 28 and APEX 35 PumpsVruno Velasquez LPas encore d'évaluation

- Adfreezing and Frost Heaving of FoundationsDocument9 pagesAdfreezing and Frost Heaving of FoundationsAhmed AbdelazizPas encore d'évaluation

- Enau Polyla (FDM Filament) : Problem StatementDocument1 pageEnau Polyla (FDM Filament) : Problem Statementhakim nasirPas encore d'évaluation

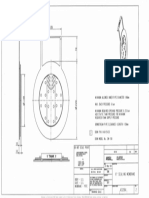

- Brake Disk AnalysisDocument20 pagesBrake Disk AnalysisashwaniPas encore d'évaluation

- 1) Design A Large Building WITHOUT Expansion JointDocument7 pages1) Design A Large Building WITHOUT Expansion JointSubinDesarPas encore d'évaluation

- Low Cost Housing Report 3 GateDocument71 pagesLow Cost Housing Report 3 GateS.K. Recruiting100% (1)