Académique Documents

Professionnel Documents

Culture Documents

Motor Starting Exercises 3 To 6: ETAP Workshop Notes Page 1 of 7

Transféré par

Royer CcosiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Motor Starting Exercises 3 To 6: ETAP Workshop Notes Page 1 of 7

Transféré par

Royer CcosiDroits d'auteur :

Formats disponibles

Motor Starting Exercises 3 to 6

3. Exercise 3

The purpose of this exercise is to identify and solve the starting problems by utilizing the Starting

Device element available in motor editor

3.1. Open the project file name MSExample3.oti

3.2. Select Library to be MtrStart.lib in MSExample3 folder

3.3. Se the following:

Configuration: Tie-Open,

Study Case: MSCase-1B

Revision: Base

Run Dynamic Motor Starting and open the Alert View.

Check bus voltage for starting motors. (Bus8 for Mtr1 V < 80%)

Drag the motor starting time slider around t=5s and observe the Bus8 turns to red.

Verify the reason and compare bus voltage drop with Study case Alert settings.

How can you solve the problem? (Re-sequencing, start at reduced load, using starter?)

3.4. Try Using Starting Device

What type of starting device to use?

Try current control soft starter and Capacitor bank at motor terminal. Is it a good way of

solving problem?

Starting Device

Current Control Capacitor at Bus/Terminal

Speed Setting Type Speed Setting Type

(%ωs) (%ωs)

0 400% Fixed 0 1000 kvar Fixed

2 200 or 250% Ramp 95 Remove

95 400% Fixed

95 Remove

3.5.Try voltage control soft starter.

ETAP Workshop Notes ©2015 - 2017 ETAP/Operation Technology, Inc. Page 1 of 7

Motor Starting Exercises 3 to 6

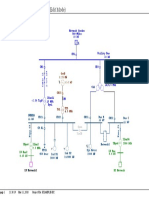

4. Exercise 4: MOV Starting

4.1. Set up MOV data

Both MOVs have Hammer Blow.

Both MOVs do not have Micro Switch.

Both MOVs have %Voltage Limit = 80 for all three stages (check “Start Cat” page).

T = 0.5 second for Start, Full Speed, Seating/unseating, and Stall periods.

5 seconds for Travel period.

4.2. Set up Study Case MSCase-2 and MSCase-3

Using Design Load, No load diversity factor.

Run simulation for 15 Seconds.

Include XFMR LTC in Pre-starting Load Flow, not during simulation.

Acceleration motor model based on Mechanical Load.

Use default settings on Adjustment and Alert Pages. Check all alert options with minimum

violation span = 0.2 second.

Use Normal configuration.

Action sequence:

Study Case: MSCase-2

Time Parameter Setting

0.2 second Start all motors in the system belongs to Backup Category

Switch on static load Load 1, Design category

3 second Start OpenMOV and ClosedMOV

Study Case: MSCase-3

Time Parameter Setting

3 second Start OpenMOV and ClosedMOV

5 second Start all motors in the system belongs to Backup Category

Switch on static load Load 1, Design category

4.3. Run Dynamic Motor Starting with MSCase-2

Check results from OLV display, plot and report.

Check MOV starting process.

4.4. Run Dynamic Motor Starting with MSCase-3

Check results from OLV display, plot and report.

Check MOV starting process.

ETAP Workshop Notes ©2015 - 2017 ETAP/Operation Technology, Inc. Page 2 of 7

Motor Starting Exercises 3 to 6

5. Exercise 5: Load Transition

5.1. Set up Load data

Mtr 1: Design -- 100%, Normal – 80%, Winter – 0%.

Mtr 2 & 3: Design -- 100%, Normal – 0%, Winter – 90%.

All Other Motors: Design -- 100%, Normal – 90%, Winter -- 75.

All Static Load: Design -- 100%, Normal – 80%, Winter -- 90.

5.2. Set up Study Case MSCase-4

Using Design Load, No load diversity factor.

Run simulation for 10 Seconds.

Include XFMR LTC in Pre-starting Load Flow, not during simulation.

Acceleration motor model based on Mechanical Load.

Use default settings on Adjustment and Alert Pages. Check all alert options

Use Normal configuration.

Action sequence:

Study Case: MSCase-4

Time Parameter Setting

0.2 second Switch to Normal Load Category

Exclude MV loads >= 5000 kVA

3 second Switch to Winter Load Category

Exclude MV loads >= 1200 kVA

Exclude MV loads >= 1000 kVA

5.3. Run Dynamic Motor Starting with MSCase-4

Check results from OLV display, plot and report.

Check bus load change.

Check if any motors are started or stopped.

ETAP Workshop Notes ©2015 - 2017 ETAP/Operation Technology, Inc. Page 3 of 7

Motor Starting Exercises 3 to 6

6. Exercise 6: Apply the motor load characteristic curve:

Go to Library from top toolbar.

Go to Motor Load Model and select the Curve option, click Add

Read the few suggested points from the following load Torque curve and enter to library.

ETAP Workshop Notes ©2015 - 2017 ETAP/Operation Technology, Inc. Page 4 of 7

Motor Starting Exercises 3 to 6

Save the Library file and open Mtr1 motor editor.

Go to Load page and select the Curve option and pickup the load model have added to library.

Run Dynamic Motor Starting and check the Load Torque output plot for Mtr1.

ETAP Workshop Notes ©2015 - 2017 ETAP/Operation Technology, Inc. Page 5 of 7

Motor Starting Exercises 3 to 6

Inertia:

Dynamic Motor Starting is sensitive to total inertia of the machine. This exercise shows increasing the

load inertia makes the acceleration time longer.

Open Mtr1 and go to Inertia page.

Set H = 1 for the Load. (Total H = 1.4)

Run Dynamic starting and observe the current output plot for Mtr1.

ETAP Workshop Notes ©2015 - 2017 ETAP/Operation Technology, Inc. Page 6 of 7

Motor Starting Exercises 3 to 6

Compare the plots using MS Excel:

Here are the steps to compare two plots and overlap on each other:

Open Plot 1 and double-click on the curve to open the following “Plot Parameters” window:

Click on Data to see the list of points (X, and Y values)

Click on Copy

Open a new XLS file and paste the points

Repeat the same steps for plot2. And in XLS file paste them next to plot1 points.

Select all the columns and go to Insert > Scatter as shown below:

ETAP Workshop Notes ©2015 - 2017 ETAP/Operation Technology, Inc. Page 7 of 7

Vous aimerez peut-être aussi

- 08a Motor StartingDocument36 pages08a Motor StartingAhmed Abd El WahabPas encore d'évaluation

- Arc Flash Rev 02 STL Power SolutionDocument47 pagesArc Flash Rev 02 STL Power Solutionalf sunflowerPas encore d'évaluation

- Impact of Source Impedance On ANSI 2W Transformer Damage Curve PDFDocument4 pagesImpact of Source Impedance On ANSI 2W Transformer Damage Curve PDFgilbertomjcPas encore d'évaluation

- Transformer Details ReportDocument1 pageTransformer Details Reportwaseem kausarPas encore d'évaluation

- Principles of MV SWG Testing 02: Functional TestsDocument6 pagesPrinciples of MV SWG Testing 02: Functional TestsAhmed Mohsen HandoussaPas encore d'évaluation

- Load Flow Analysis of 66 KV Substation Using ETAP SoftwareDocument4 pagesLoad Flow Analysis of 66 KV Substation Using ETAP SoftwareAnonymous CUPykm6DZ100% (1)

- Arc Flash Exercise 1: Purpose & DescriptionDocument5 pagesArc Flash Exercise 1: Purpose & DescriptionFrancisco AndradePas encore d'évaluation

- Overcurrent Coordination Basics CapacitorsDocument4 pagesOvercurrent Coordination Basics CapacitorsrobertoseniorPas encore d'évaluation

- For Transformer DifferentialDocument2 pagesFor Transformer DifferentialVishnu ShankerPas encore d'évaluation

- Protection Relay SettingsDocument3 pagesProtection Relay SettingssmsbondPas encore d'évaluation

- Load Flow Analysis: ETAP Workshop Notes © 1996-2010 Operation Technology, IncDocument94 pagesLoad Flow Analysis: ETAP Workshop Notes © 1996-2010 Operation Technology, IncAnonymous uZ8NCbCBPas encore d'évaluation

- One-Line Diagram - DHAHRAN - 2017 ... LOOP 6 (Short-Circuit Analysis)Document7 pagesOne-Line Diagram - DHAHRAN - 2017 ... LOOP 6 (Short-Circuit Analysis)dhananjay_gvit2207Pas encore d'évaluation

- Generator PresentationDocument20 pagesGenerator PresentationAbhishek SinhaPas encore d'évaluation

- One-Line Diagram - DHAHRAN - 2017 SUBSTATION-18 (Load Flow Analysis)Document5 pagesOne-Line Diagram - DHAHRAN - 2017 SUBSTATION-18 (Load Flow Analysis)dhananjay_gvit2207Pas encore d'évaluation

- Power System PDFDocument31 pagesPower System PDFFaiza FofaPas encore d'évaluation

- 04 - Transformer SizingDocument19 pages04 - Transformer Sizingashraf-84Pas encore d'évaluation

- Technical Specifications of 300/132/11 Oh SubstaionsDocument342 pagesTechnical Specifications of 300/132/11 Oh SubstaionsAnonymous ziKTLimPas encore d'évaluation

- 110 KV VSIP2 Nhat ThuDocument1 page110 KV VSIP2 Nhat Thutrần vũPas encore d'évaluation

- Calculation of Non Linear Resistor (Al Hassa Housing 115Kv/13.8Kv S/S)Document7 pagesCalculation of Non Linear Resistor (Al Hassa Housing 115Kv/13.8Kv S/S)vthiyagainPas encore d'évaluation

- Short-Circuit Analysis IEC StandardDocument47 pagesShort-Circuit Analysis IEC StandardAlex Aima ChacoPas encore d'évaluation

- 11KV VCBDocument3 pages11KV VCBeagles1109Pas encore d'évaluation

- Motor ProtectionDocument7 pagesMotor ProtectionAbhijit KumarPas encore d'évaluation

- Ms MP Manual 2012Document8 pagesMs MP Manual 2012Arun KumarPas encore d'évaluation

- Cable HV Report PDFDocument8 pagesCable HV Report PDFJayson PatrickPas encore d'évaluation

- Technical Guide No 7Document20 pagesTechnical Guide No 7peloduro1010Pas encore d'évaluation

- Load Flow Analysis PDFDocument33 pagesLoad Flow Analysis PDFRakshitha VPas encore d'évaluation

- ETAP PS 7 Arc Flash Calculation MethodologyDocument29 pagesETAP PS 7 Arc Flash Calculation MethodologyhenriquezrsPas encore d'évaluation

- Overcurrent Coordination Basics ConductorsDocument7 pagesOvercurrent Coordination Basics ConductorsrobertoseniorPas encore d'évaluation

- One-Line Diagram - Study View (Edit Mode) : Network Feeder 500 Mvasc 33 KV Network Feeder 500 Mvasc 33 KVDocument1 pageOne-Line Diagram - Study View (Edit Mode) : Network Feeder 500 Mvasc 33 KV Network Feeder 500 Mvasc 33 KVBhavik PrajapatiPas encore d'évaluation

- Case Studies On Paralleling of TransformersDocument7 pagesCase Studies On Paralleling of Transformersmuaz_aminu1422Pas encore d'évaluation

- 2.unit GSUT Tap OptimizationDocument9 pages2.unit GSUT Tap OptimizationKrishnan KrishPas encore d'évaluation

- NS222 Major Substation Earthing Layout DesignDocument37 pagesNS222 Major Substation Earthing Layout DesignJose ValdiviesoPas encore d'évaluation

- 11 KV Bay EquipmentDocument22 pages11 KV Bay EquipmentSudhir ShindePas encore d'évaluation

- ! Over Current Coordination StudyDocument25 pages! Over Current Coordination Studybacuoc.nguyen356100% (1)

- Design Analysis of 220132 KV Substation Using ETAP PDFDocument5 pagesDesign Analysis of 220132 KV Substation Using ETAP PDFRUBIOPas encore d'évaluation

- DecisionERCCaseNo2012 128RC PDFDocument24 pagesDecisionERCCaseNo2012 128RC PDFFranz Xyrlo Ibarra TobiasPas encore d'évaluation

- UPS SpecificationDocument15 pagesUPS Specificationpreetam100% (1)

- Circuit Breaker Tripping Setting - Fuse For Motor Protection (1.1.19)Document4 pagesCircuit Breaker Tripping Setting - Fuse For Motor Protection (1.1.19)Krisna Bayu AriyantoPas encore d'évaluation

- 3.2 Multi Gen Load Sharing PDFDocument5 pages3.2 Multi Gen Load Sharing PDFhussainPas encore d'évaluation

- 67 Directional Phase Over Current RelayDocument12 pages67 Directional Phase Over Current RelayYPV TECHNICAL SERVICESPas encore d'évaluation

- 110V DC Station Battery and Charger Calculations: 1 Input DataDocument2 pages110V DC Station Battery and Charger Calculations: 1 Input DataDEADMAN100% (1)

- One-Line Diagram - DHAHRAN - 2017 SUBSTATION-18 (Load Flow Analysis)Document5 pagesOne-Line Diagram - DHAHRAN - 2017 SUBSTATION-18 (Load Flow Analysis)dhananjay_gvit2207Pas encore d'évaluation

- TS 110V 150AH Batterry Charger Battery DCDBDocument24 pagesTS 110V 150AH Batterry Charger Battery DCDBkajale.shrikantPas encore d'évaluation

- Fault Current Calculations and Relay SettingDocument94 pagesFault Current Calculations and Relay Settingதுரைராஜ் இலட்சுமணன்Pas encore d'évaluation

- 7UM6 Gen Prot-Schemes EDocument10 pages7UM6 Gen Prot-Schemes EruslaninstPas encore d'évaluation

- Manav Energy Rca PDFDocument9 pagesManav Energy Rca PDFp m yadavPas encore d'évaluation

- Arc Flash Software - Arc Flash Analysis - Arc Flash Calculation - Arc Flash PDFDocument13 pagesArc Flash Software - Arc Flash Analysis - Arc Flash Calculation - Arc Flash PDFBintESabirPas encore d'évaluation

- Overcurrent Coordination Basics GeneratorsDocument4 pagesOvercurrent Coordination Basics GeneratorsrobertoseniorPas encore d'évaluation

- 6Document23 pages6api-3854942100% (1)

- 221661A - QGX-CLP - Relay Coordination-Rev1Document78 pages221661A - QGX-CLP - Relay Coordination-Rev1HassenL100% (1)

- Sizing A MV Generator Circuit Breake1Document25 pagesSizing A MV Generator Circuit Breake1Afifah Zuhroh0% (1)

- Indian Standard: Application Guide For Electrical Relays For Ac SystemsDocument16 pagesIndian Standard: Application Guide For Electrical Relays For Ac SystemsvenkateshbitraPas encore d'évaluation

- Protection Coordination in MV Distribution System of Sri Lanka PDFDocument120 pagesProtection Coordination in MV Distribution System of Sri Lanka PDFJulioPas encore d'évaluation

- Cable Etap 01 18 2IN1 PDFDocument77 pagesCable Etap 01 18 2IN1 PDFMichael BesaPas encore d'évaluation

- MS Exercise 3Document8 pagesMS Exercise 3Samir AlzekriPas encore d'évaluation

- Motor Starting Study Exercise ETAP PDFDocument5 pagesMotor Starting Study Exercise ETAP PDFLoretta KimPas encore d'évaluation

- Motor Starting Study Exercise ETAPDocument5 pagesMotor Starting Study Exercise ETAPFebriyanto Saja0% (1)

- Motor Starting Study Exercise ETAP PDFDocument5 pagesMotor Starting Study Exercise ETAP PDFGilberto Mejía100% (1)

- LF Exercise WorkshopDocument7 pagesLF Exercise WorkshopIlham LuthfiPas encore d'évaluation

- Adv Trans NuclearDocument33 pagesAdv Trans NuclearJose Alberto RodriguezPas encore d'évaluation

- I PartsDocument18 pagesI PartsAnilkumar KrPas encore d'évaluation

- Asset Failure Detention Codes (ICMS - PAM - ZN - SECR 312)Document5 pagesAsset Failure Detention Codes (ICMS - PAM - ZN - SECR 312)mukesh lachhwani100% (1)

- Money ComponentsDocument10 pagesMoney ComponentsArifa AkterPas encore d'évaluation

- ScriptHookDotNet ReadmeDocument8 pagesScriptHookDotNet ReadmeFajar Hari MuliaPas encore d'évaluation

- Kitar FosforusDocument4 pagesKitar FosforusMohd Hakimi MD Setapa100% (1)

- Chemistry Note Form 5Document9 pagesChemistry Note Form 5SofiyyahOpiePas encore d'évaluation

- Mechanics of Structure IIDocument3 pagesMechanics of Structure IIvenkata369Pas encore d'évaluation

- Bituminus Material PDFDocument196 pagesBituminus Material PDFSubramanian BalakrishnanPas encore d'évaluation

- Acoustical Materials 2.0Document16 pagesAcoustical Materials 2.0anuragPas encore d'évaluation

- Construction Cost EstimatesDocument25 pagesConstruction Cost EstimatesAnonymous zwnFXURJPas encore d'évaluation

- Stars and Galaxies 9th Edition Seeds Test BankDocument20 pagesStars and Galaxies 9th Edition Seeds Test Bankngocalmai0236h100% (32)

- Compressor Anti-Surge ValveDocument2 pagesCompressor Anti-Surge ValveMoralba SeijasPas encore d'évaluation

- An Ecient Uniform-Cost Normalized Edit Distance AlgorithmDocument12 pagesAn Ecient Uniform-Cost Normalized Edit Distance Algorithmanon-75650Pas encore d'évaluation

- Atomic Structure ActivityDocument4 pagesAtomic Structure ActivityClarisse BonaobraPas encore d'évaluation

- Cisco Ccna Icnd PPT 2.0 OspfDocument15 pagesCisco Ccna Icnd PPT 2.0 OspfAMIT RAJ KAUSHIKPas encore d'évaluation

- Properties of Solutions: Electrolytes and Non-Electrolytes by Dan HolmquistDocument4 pagesProperties of Solutions: Electrolytes and Non-Electrolytes by Dan HolmquistPaul Schumann50% (2)

- Quid 2005Document85 pagesQuid 2005mayan73Pas encore d'évaluation

- Genetic Variability and Correlation Studies in Okra (Abelmuschus Esculentus (L) Moench)Document67 pagesGenetic Variability and Correlation Studies in Okra (Abelmuschus Esculentus (L) Moench)rajsign5100% (3)

- CP IMarEst Mitigation of Corrosion by Cathodic ProtectionDocument25 pagesCP IMarEst Mitigation of Corrosion by Cathodic Protectionjose yoyPas encore d'évaluation

- Unit 7: Brittel Coating MethodsDocument12 pagesUnit 7: Brittel Coating Methodsmaya singhPas encore d'évaluation

- C1 Questions Part 4Document34 pagesC1 Questions Part 4Mohammad KhanPas encore d'évaluation

- Slide 1: No-Churn TelecomDocument11 pagesSlide 1: No-Churn Telecomleongladxton100% (1)

- TELEMETRY TEMPERATURE MONITOR (Project)Document34 pagesTELEMETRY TEMPERATURE MONITOR (Project)Judpraise AkumsPas encore d'évaluation

- PLCC-28: FeaturesDocument5 pagesPLCC-28: Features肖磊Pas encore d'évaluation

- Chapter 6: Fatigue Failure: Introduction, Basic ConceptsDocument21 pagesChapter 6: Fatigue Failure: Introduction, Basic ConceptsNick MezaPas encore d'évaluation

- CG Mod 3Document51 pagesCG Mod 3Misba nausheenPas encore d'évaluation

- Truefire Guitar Chord Cookbook PDFDocument101 pagesTruefire Guitar Chord Cookbook PDFeuripides7794% (17)

- 1575 Tania SultanaDocument10 pages1575 Tania SultanaTania SultanaPas encore d'évaluation

- Buffer SolutionDocument6 pagesBuffer SolutionAdrija MandalPas encore d'évaluation

- Clayton, R., Chen, S., & Lefort, G. (2005) - New Bit Design, Cutter Technology Extend PDC Applications To Hard Rock Drilling PDFDocument9 pagesClayton, R., Chen, S., & Lefort, G. (2005) - New Bit Design, Cutter Technology Extend PDC Applications To Hard Rock Drilling PDFadeelsnPas encore d'évaluation