Académique Documents

Professionnel Documents

Culture Documents

Q1 Lot Number: 15888757: Certificate of Conformance

Transféré par

DesdeAquiHastaAlla0 évaluation0% ont trouvé ce document utile (0 vote)

67 vues2 pagescertificados

Titre original

Q1-15888757

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentcertificados

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

67 vues2 pagesQ1 Lot Number: 15888757: Certificate of Conformance

Transféré par

DesdeAquiHastaAllacertificados

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

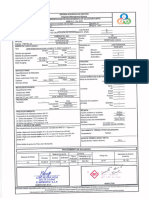

The Lincoln Electric Company

22801 St. Clair Avenue CERTIFICATE OF CONFORMANCE

Cleveland, Ohio 44117-1199

Q1 Lot Number: 15888757

Product: Innershield® NR®-203MP

Classification: E71T-8-JH8

E71T8-A4-CS3-H8

Specification: AWS A5.20:2005, ASME SFA-5.20

AWS A5.36:2016, ASME SFA-5.36

Date August 14, 2018

This is to certify that the product named above is of the same classification(s) and design as the material used for the tests reported herein. The material was tested according to the

specification(s) indicated and met all requirements. It was manufactured and supplied according to a Quality System Program that meets the requirements of ISO9001 among others as

documented on The Lincoln Electric web page (http://www.lincolnelectric.com/en-us/company/Pages/certifications.aspx).

E71T8-A4-CS3-H8 E71T-8-JH8

Operating Settings Requirements Requirements RESULTS

Required Size for Classification 781

Not Specified 780

Not Specified 1 mm)

.068" (1.7 2 mm)

5/64" (2.0

Current Type/Polarity DC- DC- DC- DC-

Wire Feed Speed, cm/min (in/min) 279 (110) 229 (90)

Nominal Voltage, V 20 19

Nominal Current, A 220 240

Average Heat Input, kJ/mm (kJ/in) (35 - 65) (35 - 65) 1.7 (42) 1.6 (41)

Travel Speed, cm/min (in/min) 16 (6.39) 17 (6.68)

Contact Tip to Work Distance, mm (in) 25 (1) 25 (1)

Pass/Layers 16/8 16/8

Preheat Temperature, °C (°F) (60 min.) (60 min.) 20 (71) 20 (70)

Interpass Temperature, °C (°F) (325 max.) (325 max.) 135 (275) 135 (275)

Postweld Heat Treatment As-welded As-welded As-welded As-welded

Mechanical Properties of Weld Metal

Tensile Strength, MPa (ksi) (70 - 95) (70 - 95) 570 (82) 550 (80)

Yield Strength, 0.2% Offset, MPa (ksi) (58 min.) (58 min.) 460 (67) 440 (64)

Elongation % 22 min. 22 min. 28 28

Average Impact Energy (20 min.) (20 min.) 153 (113) 115 (85)

Joules @ -40 °C (ft-lbs @ -40 °F) 131,164,165 (97,121,122) 96,105,144 (71,77,106)

Average Hardness, HRB Info. Only Info. Only 88 88

Chemical Composition of Weld Metal (weight %)

C 0.30 max. 0.30 max. 0.07 0.07

Mn 1.75 max. 1.75 max. 1.47 1.43

Si 0.60 max. 0.60 max. 0.26 0.22

P 0.030 max. 0.03 max. 0.010 0.01

S 0.030 max. 0.03 max. <0.003 <0.003

Al 1.8 max. 1.8 max. 0.8 0.8

Diffusible Hydrogen (per AWS A4.3) E71T8-A4-CS3-H8 E71T-8-JH8

Requirements Requirements RESULTS

Required Size for Classification 781 780 1 .068" (1.7 mm) 2 5/64" (2.0 mm)

Current Type/Polarity DC- DC-

Nominal Voltage, V 21 21

Nominal Current, A 224 244

Diffusible Hydrogen, mL/100g 8 max. 8.0 max. 6.8 5.9

Abs. Humidity (gr moisture/lb dry air) 65 65

Page 1 of 2 Cert. No. 22029

The Lincoln Electric Company

22801 St. Clair Avenue CERTIFICATE OF CONFORMANCE

Cleveland, Ohio 44117-1199

Q1 Lot Number: 15888757

Product: Innershield® NR®-203MP

Classification: E71T-8-JH8

E71T8-A4-CS3-H8

Specification: AWS A5.20:2005, ASME SFA-5.20

AWS A5.36:2016, ASME SFA-5.36

Date August 14, 2018

1. This document meets the requirements of AWS A5.01M/A5.01 Schedule G. When a specific lot number is referenced it

also meets the requirements of EN10204, type 2.2. It does not meet the requirements of type 3.1. August 14, 2018

2. The size(s) of electrode tested is determined by the requirements for this classification. All other sizes manufactured will

also meet these requirements. Toronto Cunningham, Certification Supervisor Date

3. Fillet Weld Test (positions as required): Met requirements.

4. Radiographic Inspection: Met requirements. August 15, 2018

5. The strength and elongation properties reported here were obtained from tensile specimens artificially aged at 105°C Jon Ogborn, Manager, Consumable Compliance Date

(220°F) for 48 hours.

6. Strength values in SI units are reported to the nearest 10 MPa converted from actual data. Preheat and interpass

temperature values in SI units are reported to the nearest 5 degrees.

Page 2 of 2 Cert. No. 22029

Vous aimerez peut-être aussi

- Q1Display 15843280Document3 pagesQ1Display 15843280Oscar BasantesPas encore d'évaluation

- CertMaterialTestReport E6010 Fletweld SP 1-8Document1 pageCertMaterialTestReport E6010 Fletweld SP 1-8gerosuca800Pas encore d'évaluation

- Certificate of Conformance: Q1 Lot Number: 15163483Document1 pageCertificate of Conformance: Q1 Lot Number: 15163483interx00Pas encore d'évaluation

- Excalibur 11018M MR CertDocument2 pagesExcalibur 11018M MR CertAminPas encore d'évaluation

- Pipeliner® NR®-208-XP: (Applies Only To U.S. Products)Document2 pagesPipeliner® NR®-208-XP: (Applies Only To U.S. Products)Pablo PazPas encore d'évaluation

- Q1 Lot Number: 14997588: Certificate of ConformanceDocument3 pagesQ1 Lot Number: 14997588: Certificate of ConformanceOscar BasantesPas encore d'évaluation

- Lincoln (Data Sheet) Murex E7024Document2 pagesLincoln (Data Sheet) Murex E7024PubcrawlPas encore d'évaluation

- Certificate of ConformanceDocument1 pageCertificate of ConformanceedwinPas encore d'évaluation

- .072" (1.8 MM) AWS D1.8:2016 March 01, 2022: Innershield® NR®-232Document1 page.072" (1.8 MM) AWS D1.8:2016 March 01, 2022: Innershield® NR®-232yousab creator2Pas encore d'évaluation

- L-50 Lincolnweld 980Document1 pageL-50 Lincolnweld 980geloram66Pas encore d'évaluation

- Lincolnweld 888 & LA-85Document2 pagesLincolnweld 888 & LA-85Pablo PazPas encore d'évaluation

- Certificado Lote Er70s-6Document1 pageCertificado Lote Er70s-6willariasPas encore d'évaluation

- 1 - Primacore LW71 1.2 E208038900Document1 page1 - Primacore LW71 1.2 E208038900Suli HartoPas encore d'évaluation

- Q1 DisplayDocument1 pageQ1 DisplayOscar BasantesPas encore d'évaluation

- Data - Sheet 2H Grade 50Document3 pagesData - Sheet 2H Grade 50sagitrosePas encore d'évaluation

- TroubleshootingDocument6 pagesTroubleshootingKolo BenduPas encore d'évaluation

- Data Sheet API 2W Grade 50Document3 pagesData Sheet API 2W Grade 50sagitrosePas encore d'évaluation

- Catalogue - 71-T8 (Rev06)Document7 pagesCatalogue - 71-T8 (Rev06)Suntech Testing Limited STLPas encore d'évaluation

- Datasheet Sandvik 2283l en v2018!07!24 14 - 12 Version 1Document3 pagesDatasheet Sandvik 2283l en v2018!07!24 14 - 12 Version 1bhuvandesignPas encore d'évaluation

- Surface-Mount Fuses: 2410 Very Fast-Acting Chip FusesDocument4 pagesSurface-Mount Fuses: 2410 Very Fast-Acting Chip Fusesreza yousefiPas encore d'évaluation

- F-Cem-021 - Cptch-012-19a-Fcaw - Aws D1.1 - Plana-HorizontalDocument7 pagesF-Cem-021 - Cptch-012-19a-Fcaw - Aws D1.1 - Plana-Horizontalenrique.chavezPas encore d'évaluation

- GBU10A GBU10K Data SheetDocument2 pagesGBU10A GBU10K Data Sheetmarcelo giussaniPas encore d'évaluation

- Qmot Qsh6018 ManualDocument14 pagesQmot Qsh6018 ManualleftoverchopsPas encore d'évaluation

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data SheetNaveen HlPas encore d'évaluation

- Data Sheet: Applications Designation Chemical CompositionDocument2 pagesData Sheet: Applications Designation Chemical CompositionManankPas encore d'évaluation

- Certificado Pipeliner 6P+Document2 pagesCertificado Pipeliner 6P+Eric RamirezPas encore d'évaluation

- Capacitor ELEDocument2 pagesCapacitor ELEJhoscky L. DuttiPas encore d'évaluation

- Diagrama de Ignitor BVS-006-ADocument1 pageDiagrama de Ignitor BVS-006-AHector Luis PalomoPas encore d'évaluation

- Grinnell Mechanical Products Mechanical Outlet Coupling General Description Technical Data Installation / AssemblyDocument4 pagesGrinnell Mechanical Products Mechanical Outlet Coupling General Description Technical Data Installation / AssemblyСергей КолесниковPas encore d'évaluation

- RPEL2-06: 4/2 and 4/3 Directional Control Valve, Solenoid Operated, LightlineDocument4 pagesRPEL2-06: 4/2 and 4/3 Directional Control Valve, Solenoid Operated, LightlineVito LaudicinaPas encore d'évaluation

- 180 Series Servo Motors: Dimension: Unit MMDocument1 page180 Series Servo Motors: Dimension: Unit MMMax QuintanillaPas encore d'évaluation

- 20 MN VS6Document2 pages20 MN VS6billPas encore d'évaluation

- SF-71 en EngDocument2 pagesSF-71 en EngbvbarcPas encore d'évaluation

- Data Sheet: Three Phase Induction Motor - Squirrel CageDocument10 pagesData Sheet: Three Phase Induction Motor - Squirrel CageSergeiPas encore d'évaluation

- GTB v6Document7 pagesGTB v6Chan Shiaw SyanPas encore d'évaluation

- VRLA Rechargeable Battery: Application FeaturesDocument1 pageVRLA Rechargeable Battery: Application FeaturesbrobataPas encore d'évaluation

- V90D6412Document1 pageV90D6412ardalanxoshnawPas encore d'évaluation

- RDamper CatalogDocument12 pagesRDamper CatalogEvandro MoreiraPas encore d'évaluation

- Weidmuller PROmax Datasheet PDFDocument2 pagesWeidmuller PROmax Datasheet PDFM. Andri Ludfi FananiPas encore d'évaluation

- Mot-An-S en 20160403Document9 pagesMot-An-S en 20160403DARIOPas encore d'évaluation

- WEG 132kW 315frame 2pole B5Document23 pagesWEG 132kW 315frame 2pole B5A aaa AaaPas encore d'évaluation

- Lower Unit (85A Models) : Maintenance SpecificationDocument1 pageLower Unit (85A Models) : Maintenance SpecificationPHUONG NGUYENPas encore d'évaluation

- Pipeliner 7P+: Conformances Key FeaturesDocument2 pagesPipeliner 7P+: Conformances Key FeaturesAnand GPas encore d'évaluation

- Datasheet Nema23Document1 pageDatasheet Nema23Juan De La TorrePas encore d'évaluation

- LGK Air Plasma Cutter: 1. Technology ParameterDocument1 pageLGK Air Plasma Cutter: 1. Technology ParameterMiguel DuranPas encore d'évaluation

- Lower Unit (55D, 75A Models) : SpecificationDocument1 pageLower Unit (55D, 75A Models) : SpecificationPHUONG NGUYENPas encore d'évaluation

- Jacketed Tubing (MS-02-188) R1Document6 pagesJacketed Tubing (MS-02-188) R1herysyam1980Pas encore d'évaluation

- Test Object - Device SettingsDocument32 pagesTest Object - Device SettingsEngr Fahimuddin QureshiPas encore d'évaluation

- DatasheetDocument2 pagesDatasheetStuxnetPas encore d'évaluation

- Catalogo Servo Motor AC Driver Policomp ComponentesDocument12 pagesCatalogo Servo Motor AC Driver Policomp ComponentesHI TEC SERVICE BAURUPas encore d'évaluation

- Properties of Commercially Pure Titanium and Titanium AlloysDocument27 pagesProperties of Commercially Pure Titanium and Titanium AlloysZhu DanielPas encore d'évaluation

- 107 - WELDOX - 700 - UK - Data SheetDocument2 pages107 - WELDOX - 700 - UK - Data SheetLuis AguilarPas encore d'évaluation

- Datasheet Sandvik 199l enDocument3 pagesDatasheet Sandvik 199l enpedro rojasPas encore d'évaluation

- Physical: .100" and .100" × .100" Straight, Solder Tails 929 SeriesDocument3 pagesPhysical: .100" and .100" × .100" Straight, Solder Tails 929 Seriesyamaha640Pas encore d'évaluation

- PT5460 01 - en GBDocument3 pagesPT5460 01 - en GBreza mohammadianPas encore d'évaluation

- Pamphlet MG-51T PDFDocument2 pagesPamphlet MG-51T PDFImmalatulhusnaPas encore d'évaluation

- Manual de Operacion DGW310MC 220Document11 pagesManual de Operacion DGW310MC 220Uma A. UchePas encore d'évaluation

- Energi Hasil Pengujian Energi Hasil Perhitungan: Suhu Spesimen Selisih (ºC) (J) (J)Document4 pagesEnergi Hasil Pengujian Energi Hasil Perhitungan: Suhu Spesimen Selisih (ºC) (J) (J)Milka PutriPas encore d'évaluation

- Data Sheet - Núcleo - 00K6527E060Document1 pageData Sheet - Núcleo - 00K6527E060pauloPas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Vector Calculus+ShawDocument336 pagesVector Calculus+Shawrichardfisica100% (1)

- All India Aakash Test Series For JEE (Advanced) - 2022 TEST - 4A (Paper-2) - Code-FDocument8 pagesAll India Aakash Test Series For JEE (Advanced) - 2022 TEST - 4A (Paper-2) - Code-FNITIN NBNB100% (1)

- Savonius Turbin5Document14 pagesSavonius Turbin5Maha D NugrohoPas encore d'évaluation

- A Seminar On MetaphysicsDocument26 pagesA Seminar On MetaphysicsMark Anthony DacelaPas encore d'évaluation

- ZL - 209Document2 pagesZL - 209Fraz AhmadPas encore d'évaluation

- Limit SwitchDocument3 pagesLimit SwitchrofelsmPas encore d'évaluation

- Servolectric E 09Document18 pagesServolectric E 09Fahrurrazi HaronPas encore d'évaluation

- ASTM D 3682-01 Major and Minor Elements in Combustion Residues FromDocument6 pagesASTM D 3682-01 Major and Minor Elements in Combustion Residues FromBalas43Pas encore d'évaluation

- Experiment 6'SDocument12 pagesExperiment 6'SShennyKoh67% (3)

- TCA - Project GuideDocument64 pagesTCA - Project GuideDamnit Dan100% (2)

- Comparison of Marshall and Superpave Asp PDFDocument7 pagesComparison of Marshall and Superpave Asp PDFwillypraviantoPas encore d'évaluation

- 5th Grade Math ChecklistDocument4 pages5th Grade Math ChecklistCheryl Dick100% (2)

- Investigation of Chloro Pentaammine Cobalt (III) Chloride - Polyvinyl Alcohol CompositesDocument5 pagesInvestigation of Chloro Pentaammine Cobalt (III) Chloride - Polyvinyl Alcohol CompositesAlexander DeckerPas encore d'évaluation

- Forces & Motion, IGCSEDocument4 pagesForces & Motion, IGCSEsapiniPas encore d'évaluation

- HW 07Document8 pagesHW 07Aeyrul KhairulPas encore d'évaluation

- Spectacle Lens OptionsDocument11 pagesSpectacle Lens OptionsJitander Dudee100% (1)

- D7097-Determination of Mederately High Temperature Piston Deposis by Thermooxidation Engine Oil Simulation Test TEOST MHTDocument14 pagesD7097-Determination of Mederately High Temperature Piston Deposis by Thermooxidation Engine Oil Simulation Test TEOST MHTengrsurifPas encore d'évaluation

- M Tech Thermal and Fluids EngineeringDocument26 pagesM Tech Thermal and Fluids EngineeringSumanPas encore d'évaluation

- Gossen Metrawatt A2000 HandleidingDocument3 pagesGossen Metrawatt A2000 HandleidingDavidPas encore d'évaluation

- Lecture3 (RockTestingTechnique)Document50 pagesLecture3 (RockTestingTechnique)chouszeszePas encore d'évaluation

- L298 Dual H-Bridge Motor Driver DatasheetDocument3 pagesL298 Dual H-Bridge Motor Driver DatasheetSuresh LPas encore d'évaluation

- Solution3 HIT Optical FiberDocument10 pagesSolution3 HIT Optical FiberMichael NaymarkPas encore d'évaluation

- 30 07 2022 JR.C IPL (Incoming) Jee Main WTM 04 Q.paperDocument12 pages30 07 2022 JR.C IPL (Incoming) Jee Main WTM 04 Q.paperMurari MarupuPas encore d'évaluation

- E.C.G Machine: by Er.U.Karthik Premkumar, H.O.D - Biomedical Engineering DepartmentDocument36 pagesE.C.G Machine: by Er.U.Karthik Premkumar, H.O.D - Biomedical Engineering DepartmentAch ThungPas encore d'évaluation

- Great Ideas of Classical PhysicsDocument108 pagesGreat Ideas of Classical Physicsamaan8buttPas encore d'évaluation

- Practice Test 4Document14 pagesPractice Test 4shreyshreyPas encore d'évaluation

- Viscosimetro OfiteDocument20 pagesViscosimetro OfitejomarlucaPas encore d'évaluation

- StructuralMechanicsModuleUsersGuide PDFDocument420 pagesStructuralMechanicsModuleUsersGuide PDFFrancisco RibeiroPas encore d'évaluation

- Van Eekelen Et Al 2011 BS8006 FinalDocument15 pagesVan Eekelen Et Al 2011 BS8006 FinalRaden Budi HermawanPas encore d'évaluation