Académique Documents

Professionnel Documents

Culture Documents

Series 560 & 570: Pressure Safety Valves ASME Section I (560) & VIII (570) NB Certified For Air, Gas and Steam

Transféré par

Edbaac BADescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Series 560 & 570: Pressure Safety Valves ASME Section I (560) & VIII (570) NB Certified For Air, Gas and Steam

Transféré par

Edbaac BADroits d'auteur :

Formats disponibles

Catalog 547C

Series 560 & 570

Pressure Safety Valves

ASME Section I (560) & VIII (570)

NB Certified for Air, Gas and Steam

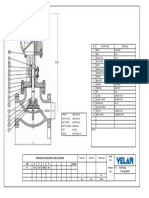

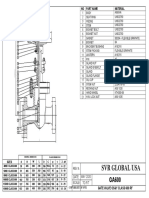

APPLICATIONS INCLUDE: PARTS IDENTIFICATION & MATERIALS

Steam Boilers, Air Compressors, Dryers, Receivers, Pressure ITEM PART NAME MATERIAL ASTM

Vessels, Piping Systems, Accumulators, Reducing Stations, Tanks, 1 HOOD CAST BRASS

Inter/After Coolers, Cooking Equipment, Autoclaves, Sterilizers 2 COTTER PIN

3 LIFT LEVER PIN BRASS

or wherever higher capacity pressure protection or relief may 4 LIFTER NUT BRASS B-16

be required. 5 PRESSURE SCREW BRASS B-16

6 LOCK NUT BRASS B-16

1 12 7 HOOD SCREW BRASS

4 SIZES FROM 1/2” TO 2 1/2” 8 LIFT LEVER CAST BRASS

3 NB RATED TO 250 PSIG 9 SPRING PLATE BRASS B-16

2

5 TEMPERATURES TO 406O F 10 SPRING STAINLESS STEEL

6

MAX TEMP BRASS BRONZE 406 O F 11 NAMEPLATE ALUMINUM

12 SPRING POST BRASS B-16

8 7

BRASS B-16

13 BODY

9 CAST BRASS B-61, 62

14 BONNET CAST BRASS B-61, 62

10 15 UPPER RING CAST BRASS

14 9 16 LOWER RING CAST BRASS

12 17 DISC NUT BRASS B-16

18 DISC BRASS B-16

17 A SEATING OPTIONS

19 REGULATOR SCREW BRASS B-16

18 20 BALL BEARING STAINLESS STEEL

20

SEATING / TRIM OPTIONS

19

METAL TO METAL 560 BRASS/BRONZE 570 BRASS BRONZE

15

561 TEFLON 571 TEFLON

19

562 O-RING 572 O-RING

B

16 564 SPECIAL 574 SPECIAL

O-RING

13

SERIES 560/570 DIMENSIONS • AIR/GAS/STEAM

SERIES NO. ORIFICE ORIFICE SIZE INLET OUTLET SIZE ----------DIMENSIONS---------- WEIGHT

I.D. (Sq. Ins.) (Sq. Ins.) (Sq. Ins.) I.D. A B C (lbs)

560 D 0.125 1/2 3/4 A 7.312 2.468 1.5 1.9

560 D 0.125 3/4 3/4 B 7.312 2.468 1.5 2.2

560 E 0.221 3/4 1 C 7.625 2.5 1.625 2.8

560 E 0.221 1 1 D 7.625 2.5 1.625 3.0

560 F 0.342 1 1 1/4 E 8.625 2.75 1.75 4.0

560 F 0.342 1 1/4 1 1/4 F 8.625 2.75 1.75 4.2

560 G 0.478 1 1/4 1 1/2 G 9.25 3.218 2.25 6.7

560 G 0.478 1 1/2 1 1/2 H 9.25 3.218 2.25 6.9

560 H 0.899 1 1/2 2 J 10.875 3.625 2.5 11.4

560 H 0.899 2 2 K 10.875 3.625 2.5 11.6

560 J 1.463 2 2 1/2 L 12.062 3.937 3.125 15.6

560 J 1.463 2 1/2 2 1/2 M 12.062 3.937 3.125 16.3

Metric Equivalents: Centimeters = Inches x 2.540 Kg = Lbs x .4536

Capacity ratings based on pounds

per hour of saturated steam at

3% over pressure. NB certified at

90% of accumulated flow.

SERIES 560 CAPACITIES • STEAM • ASME SECTION I Section I (V)-National Board Certified

ORIFICE D ORIFICE E ORIFICE F ORIFICE G ORIFICE H ORIFICE J

SET PRESSURE PSIG .125 (Sq. Ins.) .221 (Sq. Ins.) .352 (Sq. Ins.) .567 (Sq. Ins.) .899 (Sq. Ins.) 1.463 (Sq. Ins.)

5* 120 211 337 542 860 1400

10* 147 260 414 667 1058 1722

15 175 309 492 792 1256 2044

20 213 377 601 967 1534 2496

25 230 406 647 1042 1653 2689

30 257 455 725 1167 1851 3012

35 285 504 802 1292 2049 3334

40 312 552 880 1417 2247 3657

45 340 601 957 1542 2445 3979

50 368 650 1035 1667 2643 4302

55 395 699 1113 1792 2842 4624

60 423 747 1190 1917 3040 4947

65 450 796 1268 2042 3238 5269

70 478 846 1347 2170 3440 5598

75 506 895 1426 2297 3642 5927

80 535 946 1507 2427 3848 6262

85 563 996 1586 2555 4050 6591

90 592 1046 1667 2685 4256 6927

95 620 1096 1746 2812 4459 7256

100 649 1147 1826 2942 4665 7591

110 705 1247 1986 3199 5073 8255

120 762 1347 2146 3457 5481 8920

130 819 1448 2306 3714 5889 9584

140 876 1548 2466 3972 6297 10248

150 932 1648 2626 4229 6706 10913

160 989 1749 2785 4487 7114 11577

170 1046 1849 2945 4744 7522 12241

180 1103 1949 3105 5002 7930 12905

190 1159 2050 3265 5259 8338 13570

200 1216 2150 3425 5517 8747 14234

210 1273 2251 3585 5774 9155 14898

220 1330 2351 3744 6031 9563 15563

230 1386 2451 3904 6289 9971 16227

240 1443 2552 4064 6546 10379 16891

250 1500 2652 4224 6804 10788 17556

260* 1557 2752 4384 7061 11196 18220

270* 1613 2853 4544 7319 11604 18884

280* 1670 2953 4703 7576 12012 19548

290* 1727 3053 4863 7834 12421 20213

300* 1784 3154 5023 8091 12829 20877

BAR = PSI x .06895 Kilograms = PPH x .4536

*Not ASME/NB over 250 PSI.

Capacity ratings based on SCFM

(standard cubic feet per minute)

of Air at 10% over pressure. NB

certified at 90% of measured flow.

SERIES 570 CAPACITIES • AIR/GAS • ASME SECTION VIII Section VIII (UV)-National Board Certified

ORIFICE D ORIFICE E ORIFICE F ORIFICE G ORIFICE H ORIFICE J

SET PRESSURE PSIG .125 (Sq. Ins.) .221 (Sq. Ins.) .352 (Sq. Ins.) .567 (Sq. Ins.) .899 (Sq. Ins.) 1.463 (Sq. Ins.)

5 45 79 125 202 320 521

10 54 96 153 246 391 636

15 64 113 181 291 461 751

20 74 131 208 335 532 865

25 84 148 236 380 602 980

30 94 165 263 424 673 1095

35 104 184 294 473 750 1221

40 115 204 324 522 828 1348

45 126 223 355 571 906 1474

50 137 242 385 620 983 1600

55 147 261 415 669 1061 1726

60 158 280 446 718 1138 1853

65 169 299 476 767 1216 1979

70 180 318 506 816 1294 2105

75 191 337 537 865 1371 2231

80 201 356 567 914 1449 2358

85 212 375 598 963 1526 2484

90 223 394 628 1012 1604 2610

95 234 413 658 1061 1681 2736

100 245 432 689 1109 1759 2863

110 266 471 750 1207 1914 3115

120 288 509 810 1305 2069 3368

130 309 547 871 1403 2225 3620

140 331 585 932 1501 2380 3873

150 352 623 993 1599 2535 4125

160 374 661 1053 1697 2690 4378

170 396 699 1114 1795 2845 4630

180 417 738 1175 1892 3000 4883

190 439 776 1236 1990 3156 5135

200 460 814 1296 2088 3311 5388

210 482 852 1357 2186 3466 5640

220 503 890 1418 2284 3621 5893

230 525 928 1479 2382 3776 6145

240 547 966 1539 2480 3931 6398

250 568 1005 1600 2577 4087 6650

260* 590 1043 1661 2675 4242 6903

270* 611 1081 1722 2773 4397 7156

280* 633 1119 1782 2871 4552 7408

290* 655 1157 1843 2969 4707 7661

300* 676 1195 1904 3067 4863 7913

BAR = PSI x .06895 SM3/MIN = SCFM x 0.028

*Not ASME/NB over 250 PSI.

SERIES SERIES SERIES

570 570 570

Capacity ratings based on pounds

per hour of saturated steam at

10% over pressure. NB certified

at 90% of accumulated flow.

SERIES 570 CAPACITIES • STEAM • ASME SECTION VIII Section VIII (UV)-National Board Certified

ORIFICE D ORIFICE E ORIFICE F ORIFICE G ORIFICE H ORIFICE J

SET PRESSURE PSIG .125 (Sq. Ins.) .221 (Sq. Ins.) .352 (Sq. Ins.) .567 (Sq. Ins.) .899 (Sq. Ins.) 1.463 (Sq. Ins.)

5* 125 221 352 567 900 1464

10* 153 270 430 692 1098 1787

15 180 319 507 817 1296 2109

20 208 367 585 942 1494 2431

25 235 416 663 1067 1692 2754

30 263 465 740 1192 1890 3076

35 293 518 826 1330 2108 3431

40 323 572 911 1467 2326 3786

45 354 625 996 1605 2544 4141

50 384 679 1082 1742 2762 4495

55 414 733 1167 1880 2980 4850

60 445 786 1252 2017 3198 5205

65 475 840 1338 2155 3416 5559

70 505 893 1423 2292 3634 5914

75 536 947 1508 2430 3852 6269

80 566 1001 1594 2567 4070 6624

85 596 1054 1679 2705 4288 6978

90 627 1108 1764 2842 4506 7333

95 657 1161 1850 2979 4724 7688

100 687 1215 1935 3117 4942 8043

110 748 1322 2106 3392 5378 8752

120 808 1429 2276 3667 5814 9461

130 869 1536 2447 3942 6250 10171

140 930 1644 2618 4217 6686 10880

150 990 1751 2789 4492 7122 11590

160 1051 1858 2959 4767 7558 12299

170 1111 1965 3130 5042 7994 13009

180 1172 2072 3301 5317 8430 13718

190 1233 2179 3471 5592 8866 14428

200 1293 2287 3642 5866 9302 15137

210 1354 2394 3813 6141 9737 15846

220 1415 2501 3983 6416 10173 16556

230 1475 2608 4154 6691 10609 17265

240 1536 2715 4325 6966 11045 17975

250 1596 2822 4495 7241 11481 18684

260* 1657 2930 4666 7516 11917 19394

270* 1718 3037 4837 7791 12353 20103

280* 1778 3144 5008 8066 12789 20813

290* 1839 3251 5178 8341 13225 21522

300* 1899 3358 5349 8616 13661 22231

BAR = PSI x .06895 Kilograms = PPH x .4536 *Not ASME/NB over 250 PSI.

Farris Engineering

division of Curtiss-Wright Flow Control Corporation

10195 Brecksville Road, Brecksville, OH 44141 USA • Telephone: 440-838-7690 • Fax: 440-838-7699 • www. farrisengineering.com

Facilities: Brecksville, OH USA; Brantford, Ontario; Edmonton, Alberta, Canada; Kettering, Northants, UK; Delhi, India; Tianjin, China

Offices: worldwide. For a listing of our global sales network, visit our website at www.farrisengineering.com

While this information is presented in good faith and believed to be accurate, Farris Engineering, division of Curtiss-Wright Flow Control Corporation, does not guarantee

satisfactory results from reliance on such information. Nothing contained herein is to be construed as a warranty or guarantee, expressed or implied, regarding the performance,

merchantability, fitness or any other matter with respect to the products, nor as a recommendation to use any product or process in conflict with any patent. Farris Engineering,

division of Curtiss-Wright Flow Control Corporation, reserves the right, without notice, to alter or improve the designs or specifications of the products described herein. Printed in USA 10/08-5M-R1

Vous aimerez peut-être aussi

- Dimensions in Millimetres and Kilograms: Prepered by Checked by Costomer Appd Drawn DateDocument1 pageDimensions in Millimetres and Kilograms: Prepered by Checked by Costomer Appd Drawn DateAnggi SujiwoPas encore d'évaluation

- Bronze Safety Relief Valves-Models SV5601 SV5708-Technical InformationDocument5 pagesBronze Safety Relief Valves-Models SV5601 SV5708-Technical InformationMarco ChablaPas encore d'évaluation

- ITEM 2-5 - TBV-150LB-2in To 4in-WCB-SS316-RF-LeverDocument1 pageITEM 2-5 - TBV-150LB-2in To 4in-WCB-SS316-RF-LeversatphoenixPas encore d'évaluation

- 00A Single Cylinder Horizontal Steam Engine General Arrangement & Parts ListDocument1 page00A Single Cylinder Horizontal Steam Engine General Arrangement & Parts ListJorge Luis Villegas ValdiviaPas encore d'évaluation

- Forged Steel Gate Valve 800 15NB To 50NBDocument1 pageForged Steel Gate Valve 800 15NB To 50NBArsag Tech PharmaPas encore d'évaluation

- LT Ci Web PDFDocument6 pagesLT Ci Web PDFjaihindPas encore d'évaluation

- Equipment 326675 Catalog 4d55f4f7Document2 pagesEquipment 326675 Catalog 4d55f4f7Nour Mohamed MohamedPas encore d'évaluation

- AQUATROL Series-69-51-55 VAL SEGURIDADDocument4 pagesAQUATROL Series-69-51-55 VAL SEGURIDADGregorio Mata MartínezPas encore d'évaluation

- Safety ValvesDocument1 pageSafety Valvesrenzo condePas encore d'évaluation

- Forged Steel Gate Valve 800 15NB To 50NBDocument1 pageForged Steel Gate Valve 800 15NB To 50NBArsag Tech PharmaPas encore d'évaluation

- RTBNDocument1 pageRTBNAjay PrajapatiPas encore d'évaluation

- Globe Valve Flanged End 150 25NB To 250NBDocument1 pageGlobe Valve Flanged End 150 25NB To 250NBpriyanka GPas encore d'évaluation

- VB 537 Ag BR: FiguraDocument1 pageVB 537 Ag BR: FiguraMaffone NumerounoPas encore d'évaluation

- Bronze Safety Relief Valve: SV-B27 SVP-B27 SV-B29 SVP-B29Document1 pageBronze Safety Relief Valve: SV-B27 SVP-B27 SV-B29 SVP-B29Shishan Ahmad100% (1)

- Forged Steel Globe Valve 800 15NB To 50NBDocument1 pageForged Steel Globe Valve 800 15NB To 50NBpriyanka GPas encore d'évaluation

- GA150 CAST STEEL GA Specs 15-200Document1 pageGA150 CAST STEEL GA Specs 15-200Priyanka rajpurohitPas encore d'évaluation

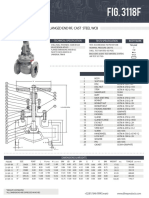

- 3118F 3318F 3618F-SeriesDocument6 pages3118F 3318F 3618F-SeriesDavid CandoPas encore d'évaluation

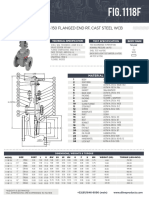

- 1118F 1318F 1618F SeriesDocument4 pages1118F 1318F 1618F SeriesĐức Thiện HuỳnhPas encore d'évaluation

- GL600 - CAST - STEEL - GL - Specs Uns TrimDocument1 pageGL600 - CAST - STEEL - GL - Specs Uns TrimPriyanka rajpurohitPas encore d'évaluation

- Foam Outlet Solution Inlet Water: Vertical Bladder Tank CAPACITY - 1700 LtrsDocument1 pageFoam Outlet Solution Inlet Water: Vertical Bladder Tank CAPACITY - 1700 LtrsAdhya RazanPas encore d'évaluation

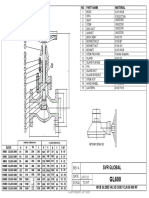

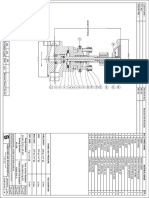

- SVR Global Usa: Technical RequirementsDocument1 pageSVR Global Usa: Technical RequirementsPriyanka rajpurohitPas encore d'évaluation

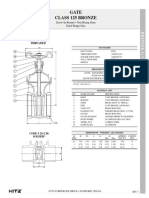

- Powell Gate C-125Document2 pagesPowell Gate C-125JOSE GABRIELPas encore d'évaluation

- 1BAF S6R 0.5to6 ACHECHDocument1 page1BAF S6R 0.5to6 ACHECHGlobal MeteringPas encore d'évaluation

- Layout PLN 1Document2 pagesLayout PLN 1EwindalimunthePas encore d'évaluation

- Gate Class 125 Bronze: CODE # 27 (AKH) ThreadedDocument1 pageGate Class 125 Bronze: CODE # 27 (AKH) Threadedthilina lakhithaPas encore d'évaluation

- E - TBV-600LB-6in To 12in-WCB-SS316-RF-GearDocument1 pageE - TBV-600LB-6in To 12in-WCB-SS316-RF-Gearrashid kPas encore d'évaluation

- Angle Valve Figure B-222T Class 150 - Union Bonnet - PTFE Disc - Threaded EndsDocument1 pageAngle Valve Figure B-222T Class 150 - Union Bonnet - PTFE Disc - Threaded Endsmax_powerPas encore d'évaluation

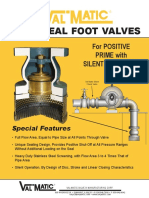

- Valmatic - Sure Seal Foot ValvesDocument2 pagesValmatic - Sure Seal Foot ValvesKayrol AmryPas encore d'évaluation

- Gad 4Document1 pageGad 4Himanshu PatilPas encore d'évaluation

- OUTLINE DRAWING DRAWING 500kVA YNyn6Document1 pageOUTLINE DRAWING DRAWING 500kVA YNyn6SetiawanBudiPas encore d'évaluation

- Technical Data Sheet and Ga of Condenser Water Pumps (Ac System)Document15 pagesTechnical Data Sheet and Ga of Condenser Water Pumps (Ac System)Ashok reddyPas encore d'évaluation

- Pf20xxx XXXX SF 10 InstDocument1 pagePf20xxx XXXX SF 10 InstFelipe SalvatierraPas encore d'évaluation

- Dimensional Standard For Pipes Fittings & ValvesDocument1 pageDimensional Standard For Pipes Fittings & ValvesPetrokens FamilyPas encore d'évaluation

- Air Governor TrucksDocument4 pagesAir Governor TrucksMaldwin MenorcaPas encore d'évaluation

- Fig No.:WARREN-1155-8: Materials ListDocument2 pagesFig No.:WARREN-1155-8: Materials ListJavier FernandezPas encore d'évaluation

- FJP R1Document4 pagesFJP R1Amr ATTIAPas encore d'évaluation

- Token C18CADocument1 pageToken C18CANick BoldingPas encore d'évaluation

- GA800 BB NPT SW GA Specs SW-f55Document1 pageGA800 BB NPT SW GA Specs SW-f55Priyanka rajpurohitPas encore d'évaluation

- Products SolutionsDocument57 pagesProducts SolutionsSandro AraújoPas encore d'évaluation

- 1600 GalDocument1 page1600 GalZK KTPas encore d'évaluation

- Piping 1685957422Document1 pagePiping 1685957422Doğuhan DenizgezPas encore d'évaluation

- Gondola Unoshelf Shelving Assembly Instructions 2Document7 pagesGondola Unoshelf Shelving Assembly Instructions 2Arturo Gutiérrez100% (1)

- GL300 CAST STEEL GL SpecsDocument1 pageGL300 CAST STEEL GL SpecsPriyanka rajpurohitPas encore d'évaluation

- Kamat - Pressure Relief Valve-AssemblyDocument9 pagesKamat - Pressure Relief Valve-Assemblyarmin heidariPas encore d'évaluation

- Datasheet PSV PDPDEDocument8 pagesDatasheet PSV PDPDERicardo NapitupuluPas encore d'évaluation

- Jyoti Pump Cross SectionalDocument3 pagesJyoti Pump Cross SectionalRan TandiaPas encore d'évaluation

- Oo-15 Inventory List (Hull Outfitting Part)Document13 pagesOo-15 Inventory List (Hull Outfitting Part)Celal BozdoganPas encore d'évaluation

- Maeda Vietnam Co., LTD.: Construction Schedule (Monthly) /july.2016Document2 pagesMaeda Vietnam Co., LTD.: Construction Schedule (Monthly) /july.2016Nguyễn Sinh PhúcPas encore d'évaluation

- Blowout PreventerDocument6 pagesBlowout PreventerMoataz NazeemPas encore d'évaluation

- Installation Instructions: 2018 Harley-Davidson Softail Stainless Hi-Output 2-1 PART# 27631/47631Document11 pagesInstallation Instructions: 2018 Harley-Davidson Softail Stainless Hi-Output 2-1 PART# 27631/47631Kurt LeadbeaterPas encore d'évaluation

- 200.000 Ton/Year Fractional Destillation Zone in Indonesia (Div.2)Document3 pages200.000 Ton/Year Fractional Destillation Zone in Indonesia (Div.2)Idil FitriPas encore d'évaluation

- Governor D-2 Service ManualDocument4 pagesGovernor D-2 Service ManualLuis Eduardo Albarracin Rugeles100% (1)

- Fig No.:WARREN-1155-5N: Materials ListDocument2 pagesFig No.:WARREN-1155-5N: Materials ListDiego OrtegaPas encore d'évaluation

- Thermodynamic DC50 A105 PDFDocument2 pagesThermodynamic DC50 A105 PDFRoo FaPas encore d'évaluation

- Gate Class 125 Cast Iron: CODE # 73 (125FCLS)Document1 pageGate Class 125 Cast Iron: CODE # 73 (125FCLS)thilina lakhithaPas encore d'évaluation

- Valve Materials DetailsDocument15 pagesValve Materials DetailsKasthuri Rangan KPas encore d'évaluation

- DrawingDocument1 pageDrawingade oilPas encore d'évaluation

- 6 Nos Ø13 Holes On 155 PCD Equispaced.: Bore CapacityDocument1 page6 Nos Ø13 Holes On 155 PCD Equispaced.: Bore CapacityShyam J VyasPas encore d'évaluation

- ITT CONTROLS Barton Chart Recorders 202e User Manual 1Document52 pagesITT CONTROLS Barton Chart Recorders 202e User Manual 1Edbaac BAPas encore d'évaluation

- ITT CONTROLS Barton Chart Recorders 202e User Manual 1Document52 pagesITT CONTROLS Barton Chart Recorders 202e User Manual 1Edbaac BAPas encore d'évaluation

- Series 1001, 1001A and 1001XL Level Controllers: Proven PerformersDocument16 pagesSeries 1001, 1001A and 1001XL Level Controllers: Proven PerformersEdbaac BAPas encore d'évaluation

- NUFLO MC-II Flow Analyzer: SpecificationsDocument2 pagesNUFLO MC-II Flow Analyzer: SpecificationsEdbaac BAPas encore d'évaluation

- PSE72-600-70 Softstarter: Product-DetailsDocument4 pagesPSE72-600-70 Softstarter: Product-DetailsEdbaac BAPas encore d'évaluation

- Sello Jhon craneTD-4600 - SeriesDocument10 pagesSello Jhon craneTD-4600 - SeriesEdbaac BAPas encore d'évaluation

- KTM50S1 50Hz SS304 MergedDocument7 pagesKTM50S1 50Hz SS304 MergedEdbaac BAPas encore d'évaluation

- Cameron T41 IOMDocument8 pagesCameron T41 IOMEdbaac BAPas encore d'évaluation

- KTM50S1 50Hz SS304 MergedDocument7 pagesKTM50S1 50Hz SS304 MergedEdbaac BAPas encore d'évaluation

- Caudalimetro Ultrasonico de Bajo Coste Portatil - A1tds PDFDocument11 pagesCaudalimetro Ultrasonico de Bajo Coste Portatil - A1tds PDFEdbaac BAPas encore d'évaluation

- Prosonic Flow 93 E+HDocument134 pagesProsonic Flow 93 E+HEdbaac BAPas encore d'évaluation

- 22 Thành NG Quen Thu C Trên Ielts - FirefighterDocument2 pages22 Thành NG Quen Thu C Trên Ielts - FirefighterNinh NguyễnPas encore d'évaluation

- Handbook On National Spectrum Management 2015Document333 pagesHandbook On National Spectrum Management 2015Marisela AlvarezPas encore d'évaluation

- Combinational Logic-Part-2 PDFDocument25 pagesCombinational Logic-Part-2 PDFSAKSHI PALIWALPas encore d'évaluation

- Evidence MODULE 1 Evidence DefinitionDocument8 pagesEvidence MODULE 1 Evidence Definitiondave BarretoPas encore d'évaluation

- DA-I Question Bank From Module 1-3 of PHY1701 Course, Winter Semester 2020-21Document6 pagesDA-I Question Bank From Module 1-3 of PHY1701 Course, Winter Semester 2020-21Likith MallipeddiPas encore d'évaluation

- (Word 365-2019) Mos Word MocktestDocument4 pages(Word 365-2019) Mos Word MocktestQuỳnh Anh Nguyễn TháiPas encore d'évaluation

- A Presentation On-: E-Paper TechnologyDocument19 pagesA Presentation On-: E-Paper TechnologyRevanth Kumar TalluruPas encore d'évaluation

- 1.2 The Basic Features of Employee's Welfare Measures Are As FollowsDocument51 pages1.2 The Basic Features of Employee's Welfare Measures Are As FollowsUddipta Bharali100% (1)

- Biosynthesis and Characterization of Silica Nanoparticles From RiceDocument10 pagesBiosynthesis and Characterization of Silica Nanoparticles From Riceanon_432216275Pas encore d'évaluation

- Reviewer in PE&H 1st Quarter 18-19Document7 pagesReviewer in PE&H 1st Quarter 18-19rhex minasPas encore d'évaluation

- Formulae HandbookDocument60 pagesFormulae Handbookmgvpalma100% (1)

- OB Case Study Care by Volvo UK 2020Document1 pageOB Case Study Care by Volvo UK 2020Anima AgarwalPas encore d'évaluation

- AMiT Products Solutions 2022 1 En-SmallDocument60 pagesAMiT Products Solutions 2022 1 En-SmallMikhailPas encore d'évaluation

- HAFOMA Presentation 2022 ENGDocument9 pagesHAFOMA Presentation 2022 ENGVeljko MilicevicPas encore d'évaluation

- Classical Theories of Economic GrowthDocument16 pagesClassical Theories of Economic GrowthLearner8494% (32)

- WSI - Catalogue of O-Ring PDFDocument37 pagesWSI - Catalogue of O-Ring PDFyearetg100% (1)

- Medrano, Rene LynnDocument2 pagesMedrano, Rene LynnRene Lynn Labing-isa Malik-MedranoPas encore d'évaluation

- Chapter 3 - Methods of Circuit Analysis and Circuit TheoremsDocument125 pagesChapter 3 - Methods of Circuit Analysis and Circuit TheoremsNaim NizamPas encore d'évaluation

- Empowerment Technology Lesson 4 PDFDocument18 pagesEmpowerment Technology Lesson 4 PDFqueenless eightyonePas encore d'évaluation

- Plastic Hinge Length and Depth For Piles in Marine Oil Terminals Including Nonlinear Soil PropertiesDocument10 pagesPlastic Hinge Length and Depth For Piles in Marine Oil Terminals Including Nonlinear Soil PropertiesGopu RPas encore d'évaluation

- Dpb6013 HRM - Chapter 3 HRM Planning w1Document24 pagesDpb6013 HRM - Chapter 3 HRM Planning w1Renese LeePas encore d'évaluation

- Swenson 1 Dan Swenson Printing Press: Part One (Timeline)Document6 pagesSwenson 1 Dan Swenson Printing Press: Part One (Timeline)Dan SwensonPas encore d'évaluation

- HP Scanjet Pro 2500 F1 Flatbed Scanner: Boost Productivity With Fast, Versatile ScanningDocument2 pagesHP Scanjet Pro 2500 F1 Flatbed Scanner: Boost Productivity With Fast, Versatile ScanningParesh BabariaPas encore d'évaluation

- InterviewDocument8 pagesInterviewswapnadip kumbharPas encore d'évaluation

- Turbine Start-Up SOPDocument17 pagesTurbine Start-Up SOPCo-gen ManagerPas encore d'évaluation

- 61annual Report 2010-11 EngDocument237 pages61annual Report 2010-11 Engsoap_bendPas encore d'évaluation

- Cimo Guide 2014 en I 3Document36 pagesCimo Guide 2014 en I 3lakisPas encore d'évaluation

- Brp-Rotax Chassis Approval FormDocument3 pagesBrp-Rotax Chassis Approval Formdelta compPas encore d'évaluation

- Unit 1 - Plant & Eqpt. Safety Apprisal & Control Techq.Document147 pagesUnit 1 - Plant & Eqpt. Safety Apprisal & Control Techq.Madhan MPas encore d'évaluation

- Teachers Guide Lower Secondary Science PDFDocument141 pagesTeachers Guide Lower Secondary Science PDFNuzhat IbrahimPas encore d'évaluation