Académique Documents

Professionnel Documents

Culture Documents

Garlock Bolt Torque Values for Rubber Gaskets in B16.5 and ASTM A193 Flanges

Transféré par

Pedro Viru BernaolaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Garlock Bolt Torque Values for Rubber Gaskets in B16.5 and ASTM A193 Flanges

Transféré par

Pedro Viru BernaolaDroits d'auteur :

Formats disponibles

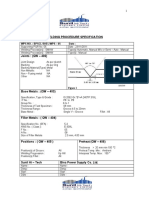

Garlock Bolt Torque Values for Full Face Homogeneous Rubber Gaskets in

B16.5 and 16.47 Series A 150# Flat Face Flanges and ASTM A193 B7 & B7M bolts

<70 durometer Shore A >70 durometer Shore A

Nominal Gasket Flange Bolt Hole Number Size of Max. Gasket Min. Rec'd Min. Rec'd Max. Rec'd/Avail. Preferred Max. Rec'd/Avail. Preferred

Pipe Size Contact I.D. O.D. Diameter Of Bolts Stress Avail. Gasket Stress Torque/Bolt Gasket Stress Torque/Bolt Gasket Stress Torque/Bolt

(in) (in) (in) (in) Bolts (in) (psi) (psi) (ft.lbs.) (psi) (ft.lbs.) (psi) (ft.lbs.)

0.5 0.84 3.50 0.63 4 0.50 3857 600 9 900 14 1200 19

0.75 1.06 3.88 0.63 4 0.50 3113 600 12 900 17 1200 23

1 1.31 4.25 0.63 4 0.50 2604 600 14 900 21 1200 28

1.25 1.66 4.63 0.63 4 0.50 2255 600 16 900 24 1200 32

1.5 1.91 5.00 0.63 4 0.50 1946 600 19 900 28 1200 37

2 2.38 6.00 0.75 4 0.63 2198 600 33 900 49 1200 66

2.5 2.88 7.00 0.75 4 0.63 1605 600 45 900 67 1200 90

3 3.50 7.50 0.75 4 0.63 1478 600 49 900 73 1200 97

3.5 4.00 8.50 0.75 8 0.63 2386 600 30 900 45 1200 60

4 4.50 9.00 0.75 8 0.63 2195 600 33 900 49 1200 66

5 5.56 10.00 0.88 8 0.75 2931 600 41 900 61 1200 82

6 6.62 11.00 0.88 8 0.75 2598 600 46 900 69 1200 92

8 8.62 13.50 0.88 8 0.75 1813 600 66 900 99 1200 132

10 10.75 16.00 1.00 12 0.88 2991 600 64 900 96 1200 128

12 12.75 19.00 1.00 12 0.88 2060 600 93 900 140 1200 186

14 14.00 21.00 1.13 12 1.00 2198 600 134 900 201 1200 268

16 16.00 23.50 1.13 16 1.00 2440 600 120 900 181 1200 241

18 18.00 25.00 1.25 16 1.13 3224 600 132 900 198 1200 264

20 20.00 27.50 1.25 20 1.13 3422 600 124 900 187 1200 249

24 24.00 32.00 1.38 20 1.25 3460 600 173 900 260 1200 347

26 26.00 34.25 1.38 24 1.25 3774 900 238 900 238 1200 318

28 28.00 36.50 1.38 28 1.25 4015 900 224 900 224 1200 299

30 30.00 38.75 1.38 28 1.25 3622 900 248 900 248 1200 331

32 32.00 41.75 1.62 28 1.50 4655 900 309 900 309 1200 412

34 34.00 43.75 1.62 32 1.50 5095 900 283 900 283 1200 377

36 36.00 46.00 1.62 32 1.50 4667 900 309 900 309 1200 411

38 38.00 48.75 1.62 32 1.50 4048 900 356 900 356 1200 474

40 40.00 50.75 1.62 36 1.50 4386 900 328 900 328 1200 438

42 42.00 53.00 1.62 36 1.50 4065 900 354 900 354 1200 472

44 44.00 55.25 1.62 40 1.50 4244 900 339 900 339 1200 452

46 46.00 57.25 1.62 40 1.50 4063 900 354 900 354 1200 473

48 48.00 59.50 1.62 44 1.50 4214 900 342 900 342 1200 456

50 50.00 61.75 1.88 44 1.75 5750 900 470 900 470 1200 626

52 52.00 64.00 1.88 44 1.75 5383 900 502 900 502 1200 669

54 54.00 66.25 1.88 44 1.75 5051 900 535 900 535 1200 713

56 56.00 68.75 1.88 48 1.75 5110 900 528 900 528 1200 705

58 58.00 71.00 1.88 48 1.75 4817 900 561 900 561 1200 747

60 60.00 73.00 1.88 52 1.75 5090 900 530 900 530 1200 707

*NOTE 1: This torque table applies for 1/16" and 1/8" thick homogeneous elastomeric gaskets. The pressure rating of the material may vary depending on the grade.

*NOTE 2: The above mentioned torque values are based on a maximum bolt stress of 60,000 psi. Bolt yield should be at least 80,000 psi.

NOTE 3: This table does not take flange strength into consideration. We recommend consulting the flange manufacturer to confirm the suitability of the above-mentioned values.

NOTE 4: Apply torque in increments. When the gasket extends past the OD of the flange by 1/4" to 3/8", stop tightening.

Page 1

Vous aimerez peut-être aussi

- Anvil Fig137 U-Bolt PDFDocument1 pageAnvil Fig137 U-Bolt PDFAin AzmiPas encore d'évaluation

- COMPARISON OF MATERIAL STANDARDS FOR TUBESDocument1 pageCOMPARISON OF MATERIAL STANDARDS FOR TUBESRaja HonePas encore d'évaluation

- Bolt and Nut StandardDocument1 pageBolt and Nut Standardcrys suryo prayogoPas encore d'évaluation

- HB D KomplettDocument181 pagesHB D KomplettGabriel BourguignonPas encore d'évaluation

- BS en 12334-2001Document14 pagesBS en 12334-2001Udit Kumar SarkarPas encore d'évaluation

- Asme Flange RatingsDocument4 pagesAsme Flange RatingsvaliullahPas encore d'évaluation

- Assignment No. 1 Design Basis Report G+5 BuildingDocument34 pagesAssignment No. 1 Design Basis Report G+5 BuildingMerijanPas encore d'évaluation

- API 5l x42 Pipe Specification Data SheetDocument1 pageAPI 5l x42 Pipe Specification Data SheetIván López PavezPas encore d'évaluation

- HYDRO Control Katalog PDFDocument174 pagesHYDRO Control Katalog PDFPedro Viru BernaolaPas encore d'évaluation

- 012.0 - Cat-6060 - Central Greasing System - AttachmentDocument50 pages012.0 - Cat-6060 - Central Greasing System - AttachmentJorby Cuadros100% (2)

- Acceptance Criteria for Welds Visual and Radiographic ExaminationDocument3 pagesAcceptance Criteria for Welds Visual and Radiographic ExaminationerboalPas encore d'évaluation

- Bevel ExplanationDocument4 pagesBevel ExplanationVarun VaidyaPas encore d'évaluation

- Pipe Fitting Weight ChartDocument1 pagePipe Fitting Weight Chartab5918590Pas encore d'évaluation

- Physics Question Bank Kvpy PDFDocument97 pagesPhysics Question Bank Kvpy PDFaswin sivakumarPas encore d'évaluation

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument38 pagesSTD 1104 - Welding of Pipelines and Related FacilitiesGishnu SunilPas encore d'évaluation

- Astm A106 Ts EnglDocument4 pagesAstm A106 Ts EnglxaviereduardoPas encore d'évaluation

- Crown ToolsDocument20 pagesCrown ToolsLuis Alberto Rivas GarciaPas encore d'évaluation

- Kirloskar Valves Technical Specification CatalogueDocument24 pagesKirloskar Valves Technical Specification CatalogueAbhinay SuratkarPas encore d'évaluation

- ASME B16 Welding EndsDocument2 pagesASME B16 Welding Endsf_risePas encore d'évaluation

- GB 3087Document14 pagesGB 3087QUYEN TRANPas encore d'évaluation

- 6 Gases PDFDocument70 pages6 Gases PDFRogerine RoyPas encore d'évaluation

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanPas encore d'évaluation

- Catalogo Motor Parker TC, TB, TE, TJ, TF, TG, TH, TLDocument56 pagesCatalogo Motor Parker TC, TB, TE, TJ, TF, TG, TH, TLg alves100% (1)

- Costs of Individual Equipment ExplainedPacked towers:C, = 1.7C, + Nf&fC, + CDocument7 pagesCosts of Individual Equipment ExplainedPacked towers:C, = 1.7C, + Nf&fC, + CNishithPas encore d'évaluation

- 150#FFCNA With B7 - Tabla de TorqueDocument2 pages150#FFCNA With B7 - Tabla de TorqueCoquin AntPas encore d'évaluation

- 20G Boiler Steel Pipe Resource GuideDocument5 pages20G Boiler Steel Pipe Resource GuideHeza FirdausPas encore d'évaluation

- Asme CCase 1987-2Document2 pagesAsme CCase 1987-2ADAMJSRAOPas encore d'évaluation

- Torque values for ICP flange insulation gasketsDocument2 pagesTorque values for ICP flange insulation gasketsYasser MahmoudPas encore d'évaluation

- Stud Bolt LengthDocument1 pageStud Bolt LengthSanthosh100% (1)

- Torque Values B7 Studs PDFDocument1 pageTorque Values B7 Studs PDFipsthethiPas encore d'évaluation

- 2.1 WPS - PipingDocument13 pages2.1 WPS - PipingSheri DiĺlPas encore d'évaluation

- Instrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard RatingDocument5 pagesInstrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard Ratinggohjh80Pas encore d'évaluation

- 1.torque Tables For Spiral Wound Gaskets (ASME B16.5) and For Insulating GasketsDocument2 pages1.torque Tables For Spiral Wound Gaskets (ASME B16.5) and For Insulating GasketsDusko ArsenovskiPas encore d'évaluation

- Metal Chemical CompositionDocument1 pageMetal Chemical CompositionprathmeshPas encore d'évaluation

- Welding Electrode Selection Table - Piping StudyDocument1 pageWelding Electrode Selection Table - Piping StudySujay AsukarPas encore d'évaluation

- SS WPSDocument1 pageSS WPSMOHAMEDABBASPas encore d'évaluation

- WPS API1104 A516 GR 70Document1 pageWPS API1104 A516 GR 70Erick HoganPas encore d'évaluation

- Acsr SPLN 41-7 PDFDocument2 pagesAcsr SPLN 41-7 PDFDharta Wira100% (1)

- API Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksDocument12 pagesAPI Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksEC BaloncestoPas encore d'évaluation

- Mild Steel Welding ElectrodeDocument12 pagesMild Steel Welding ElectrodeVĩnh NguyễnPas encore d'évaluation

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniPas encore d'évaluation

- Welding Rod For c5 & f5 - Er 80s-b6Document1 pageWelding Rod For c5 & f5 - Er 80s-b6SatyamEngPas encore d'évaluation

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamPas encore d'évaluation

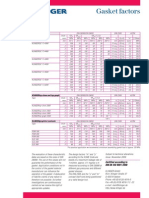

- Klinger - Gasket FactorsDocument4 pagesKlinger - Gasket FactorsFelip PrietoPas encore d'évaluation

- Hidden Defects in FittingsDocument3 pagesHidden Defects in FittingsFerlie IndrapatiPas encore d'évaluation

- Fire Test Certificate SummaryDocument1 pageFire Test Certificate SummaryjajakaPas encore d'évaluation

- Bolt Torque Chart: ASTM A307Document5 pagesBolt Torque Chart: ASTM A307Leonardo Díaz Cerna100% (1)

- NB-T 47003.1-2009 钢制焊接常压容器Document92 pagesNB-T 47003.1-2009 钢制焊接常压容器Yu Chen100% (1)

- Astm A105Document1 pageAstm A105Isaac SamuelPas encore d'évaluation

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaPas encore d'évaluation

- Nickel Alloy Based Filler MetalDocument1 pageNickel Alloy Based Filler MetaljoehodohPas encore d'évaluation

- Nominal Pipe Size ChartDocument1 pageNominal Pipe Size ChartvijayachiduPas encore d'évaluation

- Asme Ix - Welder Id Rev.2Document5 pagesAsme Ix - Welder Id Rev.2Joseph Peter100% (1)

- Shell Joint SpecificationsDocument37 pagesShell Joint SpecificationsKiran NikatePas encore d'évaluation

- Virgo Trunnion Ball ValveDocument16 pagesVirgo Trunnion Ball ValveKamalPas encore d'évaluation

- BPVC Viii-1 Udr-2Document2 pagesBPVC Viii-1 Udr-2asniff08Pas encore d'évaluation

- Stub EndDocument4 pagesStub EndFranciscoplazaPas encore d'évaluation

- ASTM A283 Grade C: General Product DescriptionDocument1 pageASTM A283 Grade C: General Product DescriptionPratyas SarahPas encore d'évaluation

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminPas encore d'évaluation

- AV GasketsDocument2 pagesAV GasketsAliPas encore d'évaluation

- Insulating Flange Kits DatasheetDocument4 pagesInsulating Flange Kits DatasheetKykyRizkyPas encore d'évaluation

- Material Comparisons For Astm and JisDocument2 pagesMaterial Comparisons For Astm and JisNitesh GargPas encore d'évaluation

- AIL REVISED P-LiST MAY 2012 Audco Ball ValveDocument2 pagesAIL REVISED P-LiST MAY 2012 Audco Ball ValveGopi KrishnanPas encore d'évaluation

- Table UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3Document7 pagesTable UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3MechanicalPas encore d'évaluation

- Esab Buddy TIG400iDocument2 pagesEsab Buddy TIG400iJeganeswaranPas encore d'évaluation

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaPas encore d'évaluation

- En 13920-2015Document8 pagesEn 13920-2015mihaiPas encore d'évaluation

- 7 classes of dissimilar steel filler metalsDocument1 page7 classes of dissimilar steel filler metals911targa100% (1)

- IMI Remosa ValvesDocument4 pagesIMI Remosa ValvesDhananjay B KPas encore d'évaluation

- Torque Vs Angle of Twist: Cast IronDocument4 pagesTorque Vs Angle of Twist: Cast IronPrateek K srivastavaPas encore d'évaluation

- La Integracion de Los Niveles Estrategico TacticoDocument9 pagesLa Integracion de Los Niveles Estrategico TacticoPedro Viru BernaolaPas encore d'évaluation

- Libro 4Document3 pagesLibro 4Pedro Viru BernaolaPas encore d'évaluation

- Manual Ford 7200eDocument27 pagesManual Ford 7200ePedro Viru BernaolaPas encore d'évaluation

- Inventario de Caja 1 (12-19)Document1 pageInventario de Caja 1 (12-19)Pedro Viru BernaolaPas encore d'évaluation

- Volvo Penta Marine CatalogDocument52 pagesVolvo Penta Marine CatalogairtupasPas encore d'évaluation

- TorqueDocument5 pagesTorqueguillemirPas encore d'évaluation

- Pres. 14 (1hr) Blighs TheoryDocument10 pagesPres. 14 (1hr) Blighs TheoryJahanzeb AliPas encore d'évaluation

- Durapac-Cylinder-Single Acting High Tonnage Locking CollarDocument4 pagesDurapac-Cylinder-Single Acting High Tonnage Locking CollarBùi Văn HợpPas encore d'évaluation

- Drying solids fundamentals and equipment selectionDocument30 pagesDrying solids fundamentals and equipment selectionArfel Marie FuentesPas encore d'évaluation

- Gerstle1989 PDFDocument8 pagesGerstle1989 PDFJorge HenriquePas encore d'évaluation

- PAES 303-2000roller Chains and Sprockets For Agricultural Machines - SpecificDocument30 pagesPAES 303-2000roller Chains and Sprockets For Agricultural Machines - SpecificYanYan CustodioPas encore d'évaluation

- Getting A Good Fit: Selecting The Right Shaft and Housing ToleranceDocument2 pagesGetting A Good Fit: Selecting The Right Shaft and Housing Toleranceeng13Pas encore d'évaluation

- Asme 314Document2 pagesAsme 314JoelHernandezGonzalezPas encore d'évaluation

- Design of crane runway girdersDocument4 pagesDesign of crane runway girdersHamdi AslanPas encore d'évaluation

- Bagatelle Showroom Structural AnalysisDocument15 pagesBagatelle Showroom Structural AnalysisDhiraj BeechooPas encore d'évaluation

- Technical Data Sheet: Ft041En - A - 0313 - 160atjDocument2 pagesTechnical Data Sheet: Ft041En - A - 0313 - 160atjElaine Malazzab PublikoPas encore d'évaluation

- Esr-1990 Fis emDocument18 pagesEsr-1990 Fis emEduardo Antonio Duran SepulvedaPas encore d'évaluation

- Racor Oil Filtration Hydraulic Filter Cart 7768Document2 pagesRacor Oil Filtration Hydraulic Filter Cart 7768sinter-musicPas encore d'évaluation

- AS 1056.1-1991 Storage Water Heaters - General RequirementsDocument43 pagesAS 1056.1-1991 Storage Water Heaters - General RequirementsChetan ChopraPas encore d'évaluation

- Mechanical Sensors 25augustDocument74 pagesMechanical Sensors 25augustSasikumar SukumaranPas encore d'évaluation

- Salford Journal of Bridge Engineering Jan-18Document24 pagesSalford Journal of Bridge Engineering Jan-18Swaminathan VivekananthamPas encore d'évaluation

- Rock Anchoring and Bolt Systems: - Rod Series - Anchors - Equipment - InstallationDocument40 pagesRock Anchoring and Bolt Systems: - Rod Series - Anchors - Equipment - InstallationTarekPas encore d'évaluation

- Threads Unc, Unf, UnefDocument3 pagesThreads Unc, Unf, UnefIlya FuksmanPas encore d'évaluation

- Shock Wave Standoff Distance of Near Space Hypersonic VehiclesDocument9 pagesShock Wave Standoff Distance of Near Space Hypersonic VehiclesudhayPas encore d'évaluation

- SN043a-EN-EU Design of Fixed Column Base JointsDocument23 pagesSN043a-EN-EU Design of Fixed Column Base JointsCenascenascenascenasPas encore d'évaluation

- Electric Power System Components (Robert Stein)Document487 pagesElectric Power System Components (Robert Stein)Jorge Pérez100% (1)