Académique Documents

Professionnel Documents

Culture Documents

New 3 Story Building Logistics Plan

Transféré par

MuhammadMursaleenDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

New 3 Story Building Logistics Plan

Transféré par

MuhammadMursaleenDroits d'auteur :

Formats disponibles

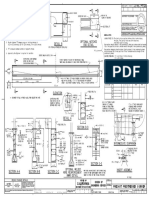

KEY PLAN DOT LOGISTICS PLAN:

NEW 3 STORY BUILDING

AT 104-19

NOTE: ROOSEVELT AVENUE

FOR DRILL RIG INFORMATION SEE QUEENS, NY 11368

ATTACHED MANUFACTURER'S

FEED STROKE 4750-10200 SINGLE HEAD

SPECIFICATION SHEET DOB# BLOCK: STORIES:

FEED STROKE 3450 DOUBLE HEAD

4206636641 30'-0" 3

BIN: LOT: HEIGHT

9'-0" 4618371 1776 63

Safety Zone

Notes: CB# ZONE: MAP:

304 #6-8 108

8390-13840

1) All construction equipment activities will be in the

40'

T.O.B

presence of the Transit Authority Inspector.

PROPERTY LINE

55'-0"

2) Movement of crawler to be supervised by Transit OWNER

MAKE THE ROAD NEW YORK

SOUTH PROPERTY LINE

Authority Inspector 104-19 ROOSEVELT AVENUE

ROOF FLOOR 3) Pre-huddle / coordination meeting with MTA QUEENS, NY 11368

39'-5"

CONTACT: JAVIER H VALDES

representatives and all contractors onsite prior to PHONE: 718-418-7690

8'-0"

operations involving concrete pump truck & pile driving

3RD FLOOR

27'-0"

truck. SAFETY DESIGNER

STEEL SUPPORT BEAM MENOTTI ENTERPRISE, LLC

2370

1695 EASTCHESTER ROAD, SUITE L3

No Swing BRONX, NY 10461

Zone

2ND FLOOR CONTACT: MICHAEL MENOTTI

13'-6"

1ST FLOOR MEZZ PHONE: 646-494-5383

20'-3"

10'-6"

PILE RIG OPERATIONS ON GRADE/MAT-PONTOON 16'-4" 47'-4 21 " 2960

WHERE REQUIRED 500 500

SIDEWALK 7180 2500

18-4" CURB

ROOSEVELT AVENUE ROADWAY GROUND FLOOR

SAFETY MANAGEMENT

0'-0" MENOTTI ENTERPRISE, LLC

7'-8"

FILL 7

1695 EASTCHESTER ROAD, SUITE L3

FUTURE CONSTRUCTION

N=21

BRONX, NY 10461

3'-0"

7'-6"

4'-8"

BOTTOM OF TA PILE CAP

SM, 3b -10'-0" CONTACT: MICHAEL MENOTTI

PHONE: 646-494-5383

BOTTOM OF EXCAVATION

N=9

-15'-7" SSM: JAMES T. HARRIS

-15''-7"

-14''-8" Potenza Motore LICENCE NO: 001601

1'-11"

-19''-4" -17''-10" -19''-4"

-15''-7"

Engine Power 147-168-197-225 KW HP 147-168-197-225

1

19'-4" 37'-6 1

4" 13'-10" 5'-9 4" 8'-4" SM, 3a

Livello Emissioni

1'-11"

Emission Level

Step 3A/ Tier3- Step4/Tier4f [HT Line] - Step 3A/ Tier3- Step4/Tier4f [HT Line] CONTRACTOR

FILL 7

N = 31 Livello Emissioni KBE NY

PILE TIP

3.450-10.200-11.3-33.5 mm ft 5.800-5.900-19.0-19.4

-33'-3"

Emission Level 205 EAST 42ND STREET

SM, 3b

Forza di Spinta NEW YORK, NY 10017

Feed Force 8.000 17.984 daN lbs 8.000 17.984

CLAYEY

SILT

N = 28

CONTACT: JESSE WEINBERG

GRAVEL/ Forza di Tiro OFFICE: 212-235-1523

COBBLE N = 47 8.000 17.984 daN lbs 8.000 17.984

Retract Force

SM, 3b

Coppia Rotary 1.300-3.100 9.588- 22.864 daNm lb-ft 1.300-3.100 9.588- 22.864

N = 26

Rotary Tarque Range

SM, 3a Giri Rotary 70-350 rpm 70-350 NO. REVISION: DATE:

PILE TIP

N = 42

-60'-0" Rotary Speed Range

Serraggio Morse

45-520 1.8-20.5 mm in 45-360 1.8-14.2

Clamp Range

Peso

22.000-24.000 48.000- 52.900 kg lbs 24.000-25.000 52.900- 55.100

Weight

PROPERTY LINE

2 SECTION VIEW

1/8" = 1'-0"

400 PSI GROUT FILL

INTERIOR SIDE

DRAWING TITLE

1

4" TYP

Bauer BG24/ Comacchio M22 Or Similar

SOIL SIDE

TIMBER LAGGING 3" x 10"

PL 3X1/2 TYP WILLIAMS MTA PILE PLAN

HSS 11.250X0.50 THREADED BAR

OR EQUIVALENT

#14 W/75KSI WITH TRUCK

SOLDIER PILE INSTALLATION PROCEDURE DOB APPROVAL SEAL

SHORING SCHEDULE

DRAWING LIST: 1.SET UP RIG ON PROPER LOCATION AND PLUMB MAST. 1.INSTALL ALL SOLDIER PILES.

2.INSTALL FIRST PIECE OF CASING WITH CARBIDE CUTTING TEETH ATTACHED. 2.EXCAVATE SITE DOWN TO EXISTING WATER ELEVATION DEPTH WHILE

3.DRILL CASING DOWN AND MAINTAIN POSITIVE FLUID HEAD AT ALL TIMES. PLACING LAGGING BETWEEN SOLDIER PILES.

4.DRILLING TO BE PERFORMED USING INTERNAL FLUSH METHOD 3.INSTALL WALER AS INDICATED IN THE DRAWING.

NOTE: OUTSIDE CASING SHALL REMAIN AHEAD OF THE INTERNAL FLUSHING BY 4.CONTINUE EXCAVATION END LAGGING INSTALLTION AT THE RAKER

A MINIMUM OF 2. FEET. IF OBSTRUCTIONS ARE ENCOUNTERED OR IF THE LOCATION.

OUTSIDE CASING GETS STUCK ADVANCE THE INNER CASING THROUGH 5.EXCAVATE ONE RAKER LOCATION AT THE TIME SLOPE EXCAVATION AS

OBSTRUCTION OR UNTIL OUTER CASING CAN REVOLVE, AND THEN RESUME

Excavation/Foundation SOE Only

REQUIRED.

STANDARD PROCEDURE OF 2 FEET LEAD OF THE OUTSIDE CASING IF EXISTING 6.INSTALL 18” X 18” X 2” PLATE WITH 1/2" ANCHOR BOLTS EMBEDDED MIN 12″.

CONCRETE IS DISCOVERED DURING DRILLING PROCESS FOLLOW NYCT

GENERAL NOTE IS PERTAINING TO THE USE OF DOWN THE HOLE-HAMMER. 7.DIG PITS FOR THE 5″ × 5″ × 5″ DEADMANS AND POUR WITH 4000 PS

CONCRETE.

5.FOLLOW UP WITH ADDITIONAL CASING TO ELEVATION SHOWN ON THESE

DRAWINGS. 8.INSTALL W12 × 45 RAKERS AND ANCHOR TO DEADMAN ALL CONNECTING TO PHASE 1

BE WELDED WITH AYESHA WELDS.

6.REMOVE INNER CASING.

9.CONTINUE EXCAVATING NEXT SECTION G.

7.FLUSH INSIDE OF CASING CLEAN OF SPOILS.

10.REPEAT THE ABOVE AT THE NEXT RAKER LOCATION.

8.INSERT THE SOLDIER PILE INTO THE CASING.

SEAL AND SIGNATURE DATE: 01-30-2019

9.FILL THE VOIDS WITHIN THE CASING USING ONE BAG SAND/CEMENT MIX FOR

THE SOCKET PROJECT No.: 05-62

PORTION OF THE PILE. DRAWN BY: AA

10.START PULLING THE CASING AS THE CASING IS FULLED.CONTINUE TO FILL CHECK BY: CC

THE CASING WITH ONE BAG SAND/CEMENT.MIX AS TO MAINTAIN AT LEAST 10 DRAWING No.:

FEET OF HEAD ABOVE TIP OF CASING.CONTINUE THIS PROCESS UNTIL THE MTA-004.00

CASING IS COMPLETELY PULLED FROM THE HOLE.

PAGE No.: 04 05

Refer to MTA SOE Approved Drawings SOE-001.01, SOE-002.01, SOE-100.01, SOE-300-01, SOE-301.01

Vous aimerez peut-être aussi

- Design Review For Albraj QuartierDocument5 pagesDesign Review For Albraj QuartierklynchellePas encore d'évaluation

- Flow SheetDocument1 pageFlow SheetJimmy EfraimPas encore d'évaluation

- 293-1-Spc-002 Specification For Grouting, Rev. ADocument10 pages293-1-Spc-002 Specification For Grouting, Rev. ABasitPas encore d'évaluation

- Splice Plate Details Rock Bolt Sections Elevations PlansDocument1 pageSplice Plate Details Rock Bolt Sections Elevations PlansRohit BandagalePas encore d'évaluation

- Excavation Induced Building DamageDocument5 pagesExcavation Induced Building DamageMarco Dos Santos NevesPas encore d'évaluation

- Slope StabilityDocument44 pagesSlope StabilitySUNDEEP KUMAR.BPas encore d'évaluation

- Plan - Soldier Pile Wall Without P. G. A.: Timber Lagging SizesDocument1 pagePlan - Soldier Pile Wall Without P. G. A.: Timber Lagging SizesgmkmalPas encore d'évaluation

- FAB-3021117-01-SK10-ER-001_REV-0 SK-10Document26 pagesFAB-3021117-01-SK10-ER-001_REV-0 SK-10juuzousama1Pas encore d'évaluation

- Front Elevation: Department of Architecture, CHDDocument7 pagesFront Elevation: Department of Architecture, CHDSunil Tandan100% (1)

- Case & Uzun: Mount Pisgah Christian School New Upper School BuildingDocument20 pagesCase & Uzun: Mount Pisgah Christian School New Upper School Buildingervikas34Pas encore d'évaluation

- Sheet Size and Sewage Rising Main DetailsDocument1 pageSheet Size and Sewage Rising Main DetailsmohdnazirPas encore d'évaluation

- JJ Cruz + Associates S-02: Standard HooksDocument1 pageJJ Cruz + Associates S-02: Standard HooksCarlo GarciaPas encore d'évaluation

- STR 106 Details of Rafter2 ModelDocument1 pageSTR 106 Details of Rafter2 ModelUDayPas encore d'évaluation

- 9479 0801 12.10.2015 Madan Mohan Malviya Tech. University GorakhpurDocument17 pages9479 0801 12.10.2015 Madan Mohan Malviya Tech. University GorakhpurAnoopPas encore d'évaluation

- Soil & Rock Types Reference GuideDocument7 pagesSoil & Rock Types Reference Guidechen zhaoPas encore d'évaluation

- New Fulcrum Canopies - Structural Drawings - PermitDocument6 pagesNew Fulcrum Canopies - Structural Drawings - PermitJorge Alnerto Perez SanchezPas encore d'évaluation

- M P02453 23 B01 Co#00 ApdDocument21 pagesM P02453 23 B01 Co#00 ApdThinh LuongPas encore d'évaluation

- 313 WEST 117th STREET New York, NyDocument17 pages313 WEST 117th STREET New York, NyGalo Delgado100% (1)

- Infill-Wall CalculationDocument10 pagesInfill-Wall CalculationPrakash Singh RawalPas encore d'évaluation

- California: Engineering Services Division ofDocument1 pageCalifornia: Engineering Services Division ofsilvereyes18Pas encore d'évaluation

- Site Construction Matter: No Critical Issues and Action Plan Required Status Action by Target Remark Required ActualDocument30 pagesSite Construction Matter: No Critical Issues and Action Plan Required Status Action by Target Remark Required ActualPembaca SenyapPas encore d'évaluation

- Kingpost RemovalDocument22 pagesKingpost RemovalcczzPas encore d'évaluation

- Rafter Detail: Roofing InsulationDocument1 pageRafter Detail: Roofing InsulationRODEAN HOPE LACSIPas encore d'évaluation

- Shell Canopy Standard (Toll Type - 8.2M Span) : Rowena M. Garcia Christopher S. ValdezDocument4 pagesShell Canopy Standard (Toll Type - 8.2M Span) : Rowena M. Garcia Christopher S. ValdezRobert RiveraPas encore d'évaluation

- TH-50-BLOCK 5 - STR - Drawings-01 PDFDocument16 pagesTH-50-BLOCK 5 - STR - Drawings-01 PDFSales ConstructionPas encore d'évaluation

- CALCULATION SHEETPILE Intake v.2Document68 pagesCALCULATION SHEETPILE Intake v.2Dica Rasyid MaulidhaniPas encore d'évaluation

- 2013 07 27 Manapakkam House Vamsi WD 03 04 Terrace Floor PlanDocument1 page2013 07 27 Manapakkam House Vamsi WD 03 04 Terrace Floor PlanJuly RaviPas encore d'évaluation

- 17 Priebe 1998 Vibro Replacement To Prevent LiquefactionDocument4 pages17 Priebe 1998 Vibro Replacement To Prevent LiquefactionGerman RodriguezPas encore d'évaluation

- Detailed Design ReportDocument74 pagesDetailed Design ReportAmos Mutoro100% (1)

- Mapeplan Gb5-2016 LowDocument46 pagesMapeplan Gb5-2016 LowMohamed Ismail ShehabPas encore d'évaluation

- Rectangular Column CalculationsDocument1 pageRectangular Column CalculationsSharif UddinPas encore d'évaluation

- Notes: Traffic Direction MP238Document1 pageNotes: Traffic Direction MP238alvaroPas encore d'évaluation

- Tender Drawings Merged and Numbered - Final - 153 PagesDocument153 pagesTender Drawings Merged and Numbered - Final - 153 PagesTamilkumar D (Tamil)Pas encore d'évaluation

- Lecture23 Retaining WallsDocument76 pagesLecture23 Retaining WallsMayMSTPas encore d'évaluation

- Structural Bracket Design for D-WallDocument4 pagesStructural Bracket Design for D-WalldsureshcivilPas encore d'évaluation

- Notes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationDocument6 pagesNotes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationAquiles MartinezPas encore d'évaluation

- 3 Detail-1: Reference Drawings / NotesDocument2 pages3 Detail-1: Reference Drawings / NotesTarun MauryaPas encore d'évaluation

- Soil nails & cutting slopes design to EC7 & BS 8006-2Document33 pagesSoil nails & cutting slopes design to EC7 & BS 8006-2RoshanRSVPas encore d'évaluation

- Geosynthetics Product Brochure 2Document32 pagesGeosynthetics Product Brochure 2Mulsa KTGPas encore d'évaluation

- Georgetown K-8 Hvac and Fire Alarm Replacement ProjectDocument43 pagesGeorgetown K-8 Hvac and Fire Alarm Replacement ProjectayyappagosuPas encore d'évaluation

- Wind Load Analysis by Edward Albert M. BañagaDocument4 pagesWind Load Analysis by Edward Albert M. BañagaEDWARD ALBERT M. BAÑAGAPas encore d'évaluation

- Design Consultant For The :ork Under The Project Construction of Lebukhali-Rampur-Mirzagonj Link RoadDocument5 pagesDesign Consultant For The :ork Under The Project Construction of Lebukhali-Rampur-Mirzagonj Link RoadCEG Bangladesh100% (1)

- 1.wind Guide 1Document32 pages1.wind Guide 1quaisarPas encore d'évaluation

- How To Set Up Dewatering Plan For ExcavationsDocument5 pagesHow To Set Up Dewatering Plan For ExcavationsNaveen BansalPas encore d'évaluation

- Strutting systems for deep excavations technical challengesDocument10 pagesStrutting systems for deep excavations technical challengesratneshtripathi1412Pas encore d'évaluation

- Boussinesq's Equation - Assumptions, Derivation & Solved ExampleDocument9 pagesBoussinesq's Equation - Assumptions, Derivation & Solved ExampleSushant MallickPas encore d'évaluation

- Lifting Proposal SuaDocument2 pagesLifting Proposal Suajasekan.dcPas encore d'évaluation

- Retaining Wall DrawingDocument1 pageRetaining Wall DrawingManupriya KapleshPas encore d'évaluation

- Kanaba Overpass GADDocument1 pageKanaba Overpass GADSandipan DharPas encore d'évaluation

- Pile Reinforcement - DPL Ver 0.6Document8 pagesPile Reinforcement - DPL Ver 0.6Antony GodwinPas encore d'évaluation

- DN Nagar Mandala: Viaduct Layout Plan For Pier No. P1 To P18Document1 pageDN Nagar Mandala: Viaduct Layout Plan For Pier No. P1 To P18naba1577Pas encore d'évaluation

- Design Calculation Report For CCT Tank: TitleDocument15 pagesDesign Calculation Report For CCT Tank: TitleghansaPas encore d'évaluation

- P 2Document1 pageP 2AZTRID PEREZPas encore d'évaluation

- FHS Valve Chamber Platform SE CTJ CVAL D 986NLXX 67765Document1 pageFHS Valve Chamber Platform SE CTJ CVAL D 986NLXX 67765varadarajPas encore d'évaluation

- Box CulvertDocument4 pagesBox CulvertDen OghangsombanPas encore d'évaluation

- Residential Building Structural DrawingsDocument29 pagesResidential Building Structural DrawingsWin Thant AungPas encore d'évaluation

- Sewerage Drainage Floor Plans Shopdrawing02-03-Dr-102bDocument1 pageSewerage Drainage Floor Plans Shopdrawing02-03-Dr-102ba.azeemPas encore d'évaluation

- Site Plan PRTDocument1 pageSite Plan PRTAmarnathPas encore d'évaluation

- Boundary Wall ProjectDocument1 pageBoundary Wall ProjectMuhammad Wazim AkramPas encore d'évaluation

- Siteplan - PT Platinum Persada-SiteplanDocument1 pageSiteplan - PT Platinum Persada-SiteplansugengwidiharsoPas encore d'évaluation

- KB Op-1Document1 pageKB Op-1MuhammadMursaleenPas encore d'évaluation

- Entry Test 2020 Guidelines For Propspective CandidatesDocument2 pagesEntry Test 2020 Guidelines For Propspective CandidatesMuhammadMursaleenPas encore d'évaluation

- KB Op-2Document1 pageKB Op-2MuhammadMursaleenPas encore d'évaluation

- PART 1: MATHEMATICS (30 Questions)Document11 pagesPART 1: MATHEMATICS (30 Questions)Ayesha awanPas encore d'évaluation

- Advt No 9 2020 PDFDocument2 pagesAdvt No 9 2020 PDFAbdur RehmanPas encore d'évaluation

- Dawn Word List PDFDocument48 pagesDawn Word List PDFyaar1220Pas encore d'évaluation

- Admission InformationDocument5 pagesAdmission InformationMuhammadMursaleenPas encore d'évaluation

- Determination of Merit: 1. Examinations Considered For Merit PurposeDocument4 pagesDetermination of Merit: 1. Examinations Considered For Merit PurposeMuhammadMursaleenPas encore d'évaluation

- Undergraduate Admission Process Tentative Schedule 2020Document1 pageUndergraduate Admission Process Tentative Schedule 2020MuhammadMursaleenPas encore d'évaluation

- Undergraduate Admissions 2020: Main CampusDocument2 pagesUndergraduate Admissions 2020: Main Campusayan aliPas encore d'évaluation

- 3 PDFDocument2 pages3 PDFMuhammadMursaleenPas encore d'évaluation

- The FIDIC Suite of ContractsDocument9 pagesThe FIDIC Suite of ContractsRaluca CazanescuPas encore d'évaluation

- Nust Sample Test 01 For Management SciencesDocument16 pagesNust Sample Test 01 For Management ScienceskaleemcomsianPas encore d'évaluation

- Advt No.16-2020 06-07-2020 FinalDocument3 pagesAdvt No.16-2020 06-07-2020 FinalMuhammadMursaleenPas encore d'évaluation

- AnalogiesDocument121 pagesAnalogiesMichael Pasok100% (3)

- Advt No 10 2020 PDFDocument3 pagesAdvt No 10 2020 PDFFaisal NaeemPas encore d'évaluation

- House floor plan dimensionsDocument1 pageHouse floor plan dimensionsMuhammadMursaleenPas encore d'évaluation

- Mta-001 20Document1 pageMta-001 20MuhammadMursaleenPas encore d'évaluation

- Horizontal CurvesDocument27 pagesHorizontal CurvesJR ZunigaPas encore d'évaluation

- Refer To The Drawing MTA 002.00 For Placement of Pump Truck: 40Z-MeterDocument1 pageRefer To The Drawing MTA 002.00 For Placement of Pump Truck: 40Z-MeterMuhammadMursaleenPas encore d'évaluation

- Project Folder Hierarchy: Standard Project Filing PlanDocument7 pagesProject Folder Hierarchy: Standard Project Filing PlanMuhammadMursaleenPas encore d'évaluation

- Code of EthicsDocument28 pagesCode of EthicsShahid Javaid100% (1)

- TS06G Kilinc Baybura 5563Document14 pagesTS06G Kilinc Baybura 5563Sahyadree ShahPas encore d'évaluation

- Horizontal CurvesDocument27 pagesHorizontal CurvesJR ZunigaPas encore d'évaluation

- Fidic 1999 Red BookDocument9 pagesFidic 1999 Red BookAden Banks0% (1)

- EJO2&EJ06 291120-Model KantaflexDocument1 pageEJO2&EJ06 291120-Model KantaflexVarunn VelPas encore d'évaluation

- DETAILED DESIGN REPORT OF RCC PORTAL T1-P2Document13 pagesDETAILED DESIGN REPORT OF RCC PORTAL T1-P2RanjithPas encore d'évaluation

- LHS-DI-MAR-MEP-042 - Duct and Pipe Support - Diamond - R0 PDFDocument2 pagesLHS-DI-MAR-MEP-042 - Duct and Pipe Support - Diamond - R0 PDFMelvin Angelo LopenarioPas encore d'évaluation

- Stabilized Mud Blocks: An Affordable Eco-Friendly Building MaterialDocument8 pagesStabilized Mud Blocks: An Affordable Eco-Friendly Building MaterialAravind BobbiliPas encore d'évaluation

- DISEÑO de Cerchas de Acero TallerDocument25 pagesDISEÑO de Cerchas de Acero TallerJose SierraPas encore d'évaluation

- Poarr C20Document18 pagesPoarr C20slohariPas encore d'évaluation

- TEC-131100 - MET-DoR-001 (Method Statement For Swimming Pool & Jacuzzi) (K)Document16 pagesTEC-131100 - MET-DoR-001 (Method Statement For Swimming Pool & Jacuzzi) (K)Hoằng Phạm ĐứcPas encore d'évaluation

- Usjr Temfacil Balance of Work Schedule Aug 25, 2022Document5 pagesUsjr Temfacil Balance of Work Schedule Aug 25, 2022Maribeth PalumarPas encore d'évaluation

- Optimizing the Design of Injected Plastic PartsDocument77 pagesOptimizing the Design of Injected Plastic PartsSilviu StinigutaPas encore d'évaluation

- Rigid Pavement Course IIT Bombay April 2020 PDFDocument2 pagesRigid Pavement Course IIT Bombay April 2020 PDFManoj DasPas encore d'évaluation

- SSE Stability Check-Sheet v1.05Document1 pageSSE Stability Check-Sheet v1.05Sophea PhanPas encore d'évaluation

- Teknik Penambangan BatubaraDocument21 pagesTeknik Penambangan BatubaraInda LamersPas encore d'évaluation

- Inspection Checklist (Icl) : Fill Placement & Compaction Inspection CivilDocument1 pageInspection Checklist (Icl) : Fill Placement & Compaction Inspection Civilasif aziz khan100% (1)

- CEN-TC250-SC7 - N1326 - prEN - 1997-3 - Geotechnical Design - Geotechnical Structures (Final PTs Draft, 2019-10) PDFDocument291 pagesCEN-TC250-SC7 - N1326 - prEN - 1997-3 - Geotechnical Design - Geotechnical Structures (Final PTs Draft, 2019-10) PDFzhiyiseowPas encore d'évaluation

- Project Quality Plan for Alumina and Coke SilosDocument32 pagesProject Quality Plan for Alumina and Coke SilosSagar AliasjackeyPas encore d'évaluation

- 8.15 Stress-Calculations-For-Wood-Structural-Panels PDFDocument10 pages8.15 Stress-Calculations-For-Wood-Structural-Panels PDFnickPas encore d'évaluation

- Correl DesignDocument14 pagesCorrel DesignClashing CouchPas encore d'évaluation

- Oowin WPC: Commercial Residential ..Document12 pagesOowin WPC: Commercial Residential ..rajeshPas encore d'évaluation

- RCD Chaptetr 5Document9 pagesRCD Chaptetr 5jereck loquisoPas encore d'évaluation

- BS en 640-1995Document19 pagesBS en 640-1995SpakkGroup SrlPas encore d'évaluation

- 4 - Shallow FoundationsDocument2 pages4 - Shallow FoundationspeterPas encore d'évaluation

- Group 5 - Assignment 2 Green BuildingDocument5 pagesGroup 5 - Assignment 2 Green BuildingDesigan PillayPas encore d'évaluation

- Logbook Filing Guide-GomezDocument20 pagesLogbook Filing Guide-GomezMercy GomezPas encore d'évaluation

- Tds Isover TPDocument1 pageTds Isover TPBulent KABADAYIPas encore d'évaluation

- Types of Pile Construction MethodsDocument3 pagesTypes of Pile Construction MethodsVivian KallouPas encore d'évaluation

- Ancient Roman ArchitectureDocument15 pagesAncient Roman ArchitectureAzrudin AnsariPas encore d'évaluation

- Firewall: High Performance Fire-Resistant Wall SystemDocument8 pagesFirewall: High Performance Fire-Resistant Wall SystemRamkumar KumaresanPas encore d'évaluation

- Selection Chart For Welding and Brazing Rods - Weldclass - 2021.08Document2 pagesSelection Chart For Welding and Brazing Rods - Weldclass - 2021.08velan73Pas encore d'évaluation

- Standards For Old Bridges 1961-1965 Vol. 4 PDFDocument91 pagesStandards For Old Bridges 1961-1965 Vol. 4 PDFaapennsylvaniaPas encore d'évaluation

- Comparison of Deck Sheet Profiles-2Document1 pageComparison of Deck Sheet Profiles-2KPas encore d'évaluation