Académique Documents

Professionnel Documents

Culture Documents

Delphi Injector Test Plans

Transféré par

Zauron Kent TouchitCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Delphi Injector Test Plans

Transféré par

Zauron Kent TouchitDroits d'auteur :

Formats disponibles

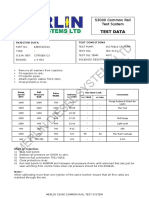

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJDR01101D Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:-

Test Oil Temperature- 40 C

EM

Engine:-

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 95-105 Max Fuel

1500 1200 1200 65-70

S

1500 800 600 27-32 Mid Range

IE

1500 400 600 10.5-11.5 Light Load

400 250 700 13.0-14.0 Idle

D

1500 1350 900 55 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-180BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJBR01401z Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- RENAULT

Test Oil Temperature- 40 C

EM

Engine:- K9K

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 65-70 Max Fuel

1500 1200 1200 43-48

S

1500 800 600 17.0-20.0 Mid Range

IE

1500 400 600 12.0-13.0 Light Load

400 250 700 10.0-11.0 Idle

D

1500 1350 900 50 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-170BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJBR01701Z Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- RENAULT

Test Oil Temperature- 40 C

EM

Engine:- K9K

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 65-70 Max Fuel

1500 1200 1200 43-48

S

1500 800 600 17.0-20.0 Mid Range

IE

1500 400 600 12.0-13.0 Light Load

400 250 700 10.0-11.0 Idle

D

1500 1350 900 50 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-170BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJBR02101Z Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- RENAULT

Test Oil Temperature- 40 C

EM

Engine:- K9K

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 65-70 Max Fuel

1500 1200 1200 43-48

S

1500 800 600 17.0-20.0 Mid Range

IE

1500 400 600 12.0-13.0 Light Load

400 250 700 10.0-11.0 Idle

D

1500 1350 900 50 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-170BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJBR02201Z Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- FORD

Test Oil Temperature- 40 C

EM

Engine:- DURATORQ 1.8 TDCI

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 87-90 Max Fuel

1500 1200 1200 55-60

S

1500 800 600 32-37 Mid Range

IE

1500 400 600 16.0-18.0 Light Load

400 250 700 12.0-13.5 Idle

D

1500 1350 900 55 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-170BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJBR02601Z Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- SSANGYONG

Test Oil Temperature- 40 C

EM

Engine:- D27DT

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 97-102 Max Fuel

1500 800 600 35-40 Mid Range

S

400 250 700 12.0-14.0 Idle

IE

1500 1350 900 55 Max Back leakage

Start of Injection

D

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

N

from nozzle holes. Rail pressure should be 140-180BAR.

LI

Note:-

When calibrating more than one injector of the same number ensure that all flow

ER

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJBR02801D Testing Prerequisites

(WAS EJBR02301Z) Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- KIA/HYUNDAI

Test Oil Temperature- 40 C

EM

Engine:- 2.9

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 112-117 Max Fuel

1500 1200 1200 75-80

S

1500 800 600 35-40 Mid Range

IE

1500 400 600 17-20 Light Load

400 250 700 11.0-14.0 Idle

D

1500 1350 900 55 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-180BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJBR03101D Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- Daimler Benz

Test Oil Temperature- 40 C

EM

Engine:- E-Class OM646

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 65-70 Max Fuel

1500 1200 1200 45-50

S

1500 800 600 22-26 Mid Range

IE

1500 400 600 10-11 Light Load

400 250 700 6.5-7.5 Idle

1500 1350 900 55 Max Back leakage

D

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-170BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJBR04001D Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- RENAULT

Test Oil Temperature- 40 C

EM

Engine:- K9K

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 65-70 Max Fuel

1500 1200 1200 40-44

S

1500 800 600 20-24 Mid Range

IE

1500 400 600 7.0-9.0 Light Load

400 250 700 9.0-10.0 Idle

D

1500 1350 900 50 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-170BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJBR04101D Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- RENAULT

Test Oil Temperature- 40 C

EM

Engine:- K9K

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 65-70 Max Fuel

1500 1200 1200 43-48

S

1500 800 600 17.0-20.0 Mid Range

IE

1500 400 600 12.0-13.0 Light Load

400 250 700 10.0-11.0 Idle

D

1500 1350 900 50 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-170BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJBR04201D Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- Daimler Benz

Test Oil Temperature- 40 C

EM

Engine:- E-Class OM646

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 100-110 Max Fuel

1500 1200 1200 70-75

S

1500 800 600 28-33 Mid Range

IE

1500 400 600 11-12 Light Load

400 250 700 4.5-5.5 Idle

D

1500 1350 900 55 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 160-190BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJBR05101D Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- RENAULT

Test Oil Temperature- 40 C

EM

Engine:- MEGANE 2 1.5DCI

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 60-65 Max Fuel

1500 1200 1200 40-45

S

1500 800 600 17-22 Mid Range

IE

1500 400 600 8.0-12.0 Light Load

400 250 700 7.0-10.0 Idle

D

1500 1350 900 55 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-180BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJBR05102D Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- RENAULT

Test Oil Temperature- 40 C

EM

Engine:- MEGANE 2 1.5DCI

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 60-65 Max Fuel

1500 1200 1200 40-45

S

1500 800 600 17-22 Mid Range

IE

1500 400 600 8.0-12.0 Light Load

400 250 700 7.0-10.0 Idle

D

1500 1350 900 55 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 140-180BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJDR00301Z Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- FORD

Test Oil Temperature- 40 C

EM

Engine:- DURATORQ 2.0 TDCi

Solenoid Resistance @ 20°C - 4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 80-85 Max Fuel

1500 1200 1200 52-57

S

1500 800 600 25-30 Mid Range

IE

1500 400 600 15.0-18.0 Light Load

400 250 700 9.0-11.0 Idle

D

1500 1350 900 55 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJDR00401Z Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- FORD

Test Oil Temperature- 40 C

EM

Engine:- DURATORQ 2.0 TDCi

Solenoid Resistance @ 20°C - 4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 80-85 Max Fuel

1500 1200 1200 52-57

S

1500 800 600 25-30 Mid Range

IE

1500 400 600 15.0-18.0 Light Load

400 250 700 9.0-11.0 Idle

D

1500 1350 900 55 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJDR00402Z Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- FORD

Test Oil Temperature- 40 C

EM

Engine:- DURATORQ 2.0 TDCi

Solenoid Resistance @ 20°C - 4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 78.0-82.0 Max Fuel

1500 1200 1200 -

S

1500 800 600 - Mid Range

IE

1500 400 600 - Light Load

400 250 700 9.0-11.0 Idle

D

1500 1350 900 55 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

D

PART No: EJDR00501Z TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

LT

O.E.M. REF: JAGUAR TEST OIL TEMP: 40°C

ENGINE: 2.0L, 130 BHP, X404 SOLENOID RESISTANCE @ 20°C – 0.4

S

EM

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipes.

Attach injector cables T031-3401.

Close protective cover.

ST

SY

Pump Rail Max Back Leak

Pulse

Speed Pressure Delivery Comments

Width

RPM BAR cc/1000 cc/1000 cc/min

EL

Purge System & Check for

1000 1000 700 N/A

- - Leaks

1500 1600 1600 80-85 - - Max Fuel

S

1500 1200 1200 55-60 - -

IE

1500 800 600 22-27 - - Mid Range

D

1500 400 600 15-20 - - Light Load

400 250 700 9-13 - - Idle

N

1500 1350 900 N/A 55 82 Max Back Leakage

LI

400 150-250 700 N/A - - S.O.I

ER

Start of Injection

1) Stop test bench.

M

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJDR00502Z Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:-

Test Oil Temperature- 40 C

EM

Engine:-

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors (Remove White Spacer fit seal only). Close protective

cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

EL

1000 1000 1200 Purge System

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 75-80 Max Fuel

S

1500 1200 1200 50-55

1500 800 600 21-25 Mid Range

IE

1500 400 600 15.5-17.5 Light Load

400 250 700 10.0-12.0 Idle

D

1500 1350 900 55 Max Back leakage

N

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

LI

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

ER

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

M

rates are matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJDR00504Z Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- FORD

Test Oil Temperature- 40 C

EM

Engine:- DURATORQ 2.0 TDCi 125HP

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 80-85 Max Fuel

1500 1200 1200 57-62

S

1500 800 600 30-32 Mid Range

IE

1500 400 600 13.5-14.5 Light Load

400 250 700 6.5-8.0 Idle

D

1500 1350 900 55 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJDR00701D Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- JAGUAR X TYPE

Test Oil Temperature- 40 C

EM

Engine:- 2.2L 155PS PUMA (EURO 4)

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 95-100 Max Fuel

1500 1200 1200 65-70

S

1500 800 600 28-32 Mid Range

IE

1500 400 600 12-14 Light Load

400 250 700 6.5-8.0 Idle

D

1500 1350 900 55 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- EJDR00801D Testing Prerequisites

Mount Suitable Test Pump

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- FORD

Test Oil Temperature- 40 C

EM

Engine:- MONDEO 2.0 TDCi

Solenoid Resistance @ 20°C - 0.4

ST

Remove all washers. Fit Injectors to Injector rack. Attach cables T031-3401 and

metering pipes to injectors. Close protective cover.

SY

Pump Speed Rail Pressure Pulse Width Delivery Comments

RPM BAR cc/1000

1000 1000 1200 Purge System

EL

2000 1500 1200 N/A Check for Leaks

1500 1600 1600 80-85 Max Fuel

1500 1200 1200 57-62

S

1500 800 600 28-32 Mid Range

IE

1500 400 600 11.5-12.5 Light Load

400 250 700 6.2-6.6 Idle

D

1500 1350 900 55 Max Back leakage

Start of Injection

N

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

LI

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

ER

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

Vous aimerez peut-être aussi

- Denso Procedure For Servicing 2 Nozzles InjectorsDocument41 pagesDenso Procedure For Servicing 2 Nozzles InjectorsCostas Ponehundred75% (4)

- Spare Parts Denso Common Rail InjectorsDocument10 pagesSpare Parts Denso Common Rail Injectorserdemsecen100% (5)

- YD 25 Engines IssuesDocument4 pagesYD 25 Engines IssuesZauron Kent TouchitPas encore d'évaluation

- Denso Common Rail Injector Test Data PDFDocument28 pagesDenso Common Rail Injector Test Data PDFصلاح طه السيد0% (1)

- 096000-352# Pump Test Specification (Plano de Teste Denso)Document4 pages096000-352# Pump Test Specification (Plano de Teste Denso)Junior IungPas encore d'évaluation

- Leasing Consultant HandbookDocument18 pagesLeasing Consultant Handbookapi-301906787Pas encore d'évaluation

- CRI Injector Shim RefDocument5 pagesCRI Injector Shim RefGuler Rahim100% (3)

- Boschinjectortestplans 29 WEBDocument156 pagesBoschinjectortestplans 29 WEBedward06Pas encore d'évaluation

- Bosch Pump Test Plans 4 Web 3232Document146 pagesBosch Pump Test Plans 4 Web 3232Eduardo Alvarez HuizaPas encore d'évaluation

- Common Rail Injector Repair Tool Sets Instruction ManualDocument17 pagesCommon Rail Injector Repair Tool Sets Instruction ManualAnonymous 5tkF5bFwO100% (1)

- Denso Cri Repair Guide v4Document22 pagesDenso Cri Repair Guide v4Misuka Misi97% (38)

- Denso Common Rail Injector Test Data PDFDocument28 pagesDenso Common Rail Injector Test Data PDFFernando SanchezPas encore d'évaluation

- Tabel Test CR I by MerlinDocument126 pagesTabel Test CR I by MerlinLucas Man100% (2)

- DENSO X2 InstructionDocument13 pagesDENSO X2 InstructionAnonymous 5tkF5bFwO100% (3)

- EPS 205 Frequently Asked Questions 2 8.28 PDFDocument32 pagesEPS 205 Frequently Asked Questions 2 8.28 PDFDarshan Diesel100% (2)

- 62 Bosch Crin Repair Instructions enDocument38 pages62 Bosch Crin Repair Instructions enBoris100% (29)

- Piezo ElectricmeteringDocument7 pagesPiezo Electricmeteringeko sulistyo utomo100% (1)

- Sanitary Report AshenfiDocument10 pagesSanitary Report AshenfiJaspergroup 15Pas encore d'évaluation

- Siemens Injector Test Data New6 PDFDocument20 pagesSiemens Injector Test Data New6 PDFJose HasinPas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Manuale Injectors Delphi 15-23-2 Ediz IngDocument7 pagesManuale Injectors Delphi 15-23-2 Ediz IngKary Shito100% (2)

- Denso InjectorDocument20 pagesDenso Injectoraddelyn_robescu8794100% (7)

- The Care of Surgical Instruments PDFDocument38 pagesThe Care of Surgical Instruments PDFMarvin BautistaPas encore d'évaluation

- BoschEUI EUPRepairInstructionsDocument56 pagesBoschEUI EUPRepairInstructionsYeltsin Ore100% (8)

- Test Manual EEN00015-00Document21 pagesTest Manual EEN00015-00Alex Bravo100% (2)

- Motor CleaningMethods Bishop 0620Document21 pagesMotor CleaningMethods Bishop 0620Rolando LoayzaPas encore d'évaluation

- Delphi Pump Test Plans 4 WebDocument54 pagesDelphi Pump Test Plans 4 WebAspro Brazil Se Iglesias100% (4)

- Denso Injector Catalogue: Update 05/2020Document23 pagesDenso Injector Catalogue: Update 05/2020davide100% (1)

- S5000-1-Test-Data Ui Up Bosch, DelphiDocument29 pagesS5000-1-Test-Data Ui Up Bosch, DelphiEdinson Ariel Chavarro Quintero100% (1)

- Common Rail Spare Parts ListDocument57 pagesCommon Rail Spare Parts Listbuztedcgycom67% (3)

- MANUAL - Bosch CRIN 2.0 and 3.0 Common Rail InjectorsDocument24 pagesMANUAL - Bosch CRIN 2.0 and 3.0 Common Rail InjectorsLUIS SAENZ100% (4)

- Denso Common Rail Injector Test DataDocument28 pagesDenso Common Rail Injector Test DataInkanata Sac94% (16)

- Denso Control Valve & Rod 2016Document4 pagesDenso Control Valve & Rod 2016Екатерина КалашниковаPas encore d'évaluation

- Marks On Bosch Common Rail InjectorsDocument25 pagesMarks On Bosch Common Rail InjectorsBarkat HussainPas encore d'évaluation

- Reviewer Laundry AttendantDocument15 pagesReviewer Laundry AttendantkimpoiikPas encore d'évaluation

- Bk2q-9k546-Ag 20190701 112041 PDFDocument2 pagesBk2q-9k546-Ag 20190701 112041 PDFคุณชายธวัชชัย เจริญสุขPas encore d'évaluation

- InyectorDocument20 pagesInyectorDaen50% (2)

- Denso Type CR Injector ShimsDocument11 pagesDenso Type CR Injector ShimsCostinDodenech100% (2)

- Denso-Injector PDFDocument20 pagesDenso-Injector PDFZauron Kent TouchitPas encore d'évaluation

- Denso-Injector PDFDocument20 pagesDenso-Injector PDFZauron Kent TouchitPas encore d'évaluation

- Siemens Injector Test Data New6Document20 pagesSiemens Injector Test Data New6cartronix2010100% (2)

- Bosch Injector CaracteristicsDocument14 pagesBosch Injector CaracteristicsNelson Augusto97% (31)

- Bosch CR Pumps Test Data PDFDocument146 pagesBosch CR Pumps Test Data PDFInyectronix Vyh100% (2)

- Delphi Electronic Unit Injectors CatalogDocument20 pagesDelphi Electronic Unit Injectors CatalogStroia Constantin Marius100% (4)

- Siemens Pump Test Plans 4Document10 pagesSiemens Pump Test Plans 4DJAMel LPas encore d'évaluation

- Denso PDFDocument36 pagesDenso PDFGiovaniBalzani95% (22)

- Illidio SerraDocument24 pagesIllidio SerraVictor GarciaPas encore d'évaluation

- Siemens Injector Test Data New6 PDFDocument20 pagesSiemens Injector Test Data New6 PDFJuan David Cepeda GonzalesPas encore d'évaluation

- CRI CRIN - Defect CatalogDocument57 pagesCRI CRIN - Defect CatalogMassahiro Filho100% (2)

- Zanussi Lindo 100 ZWF 71-63w enDocument18 pagesZanussi Lindo 100 ZWF 71-63w enbianca06bofPas encore d'évaluation

- VDO Diesel IAM Roadmap Q3 2018 ENDocument13 pagesVDO Diesel IAM Roadmap Q3 2018 ENLuis Miranda100% (2)

- Calibracion Doble ResorteDocument60 pagesCalibracion Doble ResorteHector Jamaica100% (6)

- 8 Operation Instruction: 8.1. Before StartDocument10 pages8 Operation Instruction: 8.1. Before StartJRC DIESELPas encore d'évaluation

- Inj. Pump Calibration Data: 1. Test ConditionsDocument4 pagesInj. Pump Calibration Data: 1. Test ConditionsEdinson Ariel Chavarro Quintero100% (2)

- Common Rail Spare Parts ListDocument52 pagesCommon Rail Spare Parts Listcartronix2010100% (3)

- Rotary ScrubberDocument2 pagesRotary ScrubberTamal Tanu RoyPas encore d'évaluation

- B L Theraja Volume 1Document8 pagesB L Theraja Volume 1Umar MajeedPas encore d'évaluation

- Test Plan Common Rail InjectorsDocument76 pagesTest Plan Common Rail Injectorslennon r100% (2)

- Atos Fuel SDocument133 pagesAtos Fuel Singenieriaelectronic100% (1)

- Delphi Injector Test Plans 9 WebDocument26 pagesDelphi Injector Test Plans 9 WebAdrian MacayaPas encore d'évaluation

- Ford 5R55S Partes BDocument4 pagesFord 5R55S Partes BJose Mejia CaveroPas encore d'évaluation

- Delphiinjectortestplans 12WEBDocument30 pagesDelphiinjectortestplans 12WEBkampee100% (1)

- Chicken ProcessingDocument28 pagesChicken ProcessingBlack BirdPas encore d'évaluation

- Asia-Pacific Institute of Management: Prof Mr. Kuldeep SharmaDocument51 pagesAsia-Pacific Institute of Management: Prof Mr. Kuldeep SharmaVikas Singh67% (3)

- Inyectores Delphi Tabla ValoresDocument30 pagesInyectores Delphi Tabla Valoresbruttus139Pas encore d'évaluation

- TCM300 (Nta855 G1B) TCM300CDocument5 pagesTCM300 (Nta855 G1B) TCM300CHASSAN NADEEMPas encore d'évaluation

- Imo Pump - E4 - 1104.02 - GBDocument8 pagesImo Pump - E4 - 1104.02 - GBDijana Zojceska - SmokvarskaPas encore d'évaluation

- Pressure Reducing, Pilot Operated Spool Type: Common Cavity, Size 10Document2 pagesPressure Reducing, Pilot Operated Spool Type: Common Cavity, Size 10tecnicomanelPas encore d'évaluation

- 26 2000 Pressure Reducing RegulatorDocument4 pages26 2000 Pressure Reducing RegulatorMFERRPas encore d'évaluation

- TCM250 TCM250CDocument5 pagesTCM250 TCM250CAung MhPas encore d'évaluation

- Dokumentation Energoutil 2015-35370 - enDocument37 pagesDokumentation Energoutil 2015-35370 - enbrctlnPas encore d'évaluation

- Circulators For Heating and Air Conditioning Systems: ApplicationsDocument18 pagesCirculators For Heating and Air Conditioning Systems: Applicationsresistance-bandsPas encore d'évaluation

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaPas encore d'évaluation

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN TESTE2021Pas encore d'évaluation

- Pistons Weight ToleranceDocument1 pagePistons Weight ToleranceZauron Kent TouchitPas encore d'évaluation

- Performance Testing of An Electrically Assisted Turbocharger On A Heavy Duty Diesel EngineDocument23 pagesPerformance Testing of An Electrically Assisted Turbocharger On A Heavy Duty Diesel EngineZauron Kent TouchitPas encore d'évaluation

- 4-5 Rotrex Vanddampkompressor Anders KolstrupDocument17 pages4-5 Rotrex Vanddampkompressor Anders KolstrupZauron Kent TouchitPas encore d'évaluation

- User Manual: UDB100xS Seriers DDS Signal GeneratorDocument6 pagesUser Manual: UDB100xS Seriers DDS Signal GeneratorZauron Kent TouchitPas encore d'évaluation

- Service Manual: PN-2714B-ADocument33 pagesService Manual: PN-2714B-AZauron Kent TouchitPas encore d'évaluation

- Haier HW-E Service ManualDocument28 pagesHaier HW-E Service ManualDoru RazvanPas encore d'évaluation

- Opl LgwashdrybroDocument6 pagesOpl LgwashdrybrodelgadotcortPas encore d'évaluation

- Miele Dishwasher Manual PDFDocument96 pagesMiele Dishwasher Manual PDFfornizaPas encore d'évaluation

- Parts Manual: MODEL: 4215HTDocument586 pagesParts Manual: MODEL: 4215HTMessi EmetievPas encore d'évaluation

- Alpm 802848Document82 pagesAlpm 802848masterlove07Pas encore d'évaluation

- Primus Operation FS6 To FS23Document50 pagesPrimus Operation FS6 To FS23Arun George50% (2)

- EXCELAM PLUS, MICRO Series 2012.5.7Document14 pagesEXCELAM PLUS, MICRO Series 2012.5.7Vance IbzPas encore d'évaluation

- Tunnel Washers: Sustainability in Commercial Laundering ProcessesDocument43 pagesTunnel Washers: Sustainability in Commercial Laundering ProcessesSanjay SinhaPas encore d'évaluation

- Whirlpool Awo D 43115 1 WPDocument14 pagesWhirlpool Awo D 43115 1 WPkumkatPas encore d'évaluation

- HTM 01 01 PartDDocument108 pagesHTM 01 01 PartDwaseem kausarPas encore d'évaluation

- tm130 Soil ResistanceDocument19 pagestm130 Soil ResistanceNisreen MohamedPas encore d'évaluation

- Manual de Utilizare Uscator Samsung PremiumDocument56 pagesManual de Utilizare Uscator Samsung PremiumPerfectreviewPas encore d'évaluation

- Graco 247551 Hydra Clean Pressure WasherDocument2 pagesGraco 247551 Hydra Clean Pressure WasherMROstop.comPas encore d'évaluation

- (Ebook) - Free Energy - Energy - Efficient Water HeatingDocument6 pages(Ebook) - Free Energy - Energy - Efficient Water Heatingdumitrescu viorelPas encore d'évaluation

- Washing Machine: User ManualDocument72 pagesWashing Machine: User ManualOlvan SuazoPas encore d'évaluation

- Pulverizador Honda PDFDocument46 pagesPulverizador Honda PDFAbel RodriguezPas encore d'évaluation

- Haier Washing Machine Price in Pakistan - Updated Feb 2021 Price ListDocument1 pageHaier Washing Machine Price in Pakistan - Updated Feb 2021 Price ListOrim AzizPas encore d'évaluation

- Electrolux Front Load Installation Instructions Washer A04615101BDocument44 pagesElectrolux Front Load Installation Instructions Washer A04615101BAlbertiPas encore d'évaluation