Académique Documents

Professionnel Documents

Culture Documents

CBIHLJN Full en Us A4

Transféré par

Emiliano ManriqueTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CBIHLJN Full en Us A4

Transféré par

Emiliano ManriqueDroits d'auteur :

Formats disponibles

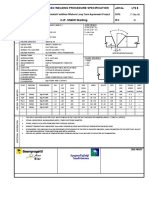

MODEL 10:1 pilot ratio, standard capacity counterbalance valve

CBIH SERIES 4 / CAPACITY: 120 gpm / CAVITY: T-19A

snhy.com/CBIH

3-Port Non-vented

Counterbalance valves with pilot assist are meant to control an overrunning load. The check valve allows free flow

CONFIGURATION from the directional valve (port 2) to the load (port 1) while a direct-acting, pilot-assisted relief valve controls flow

from port 1 to port 2. Pilot assist at port 3 lowers the effective setting of the relief valve at a rate determined by the

pilot ratio.

L Control Standard Screw Adjustment

J Functional 2000 - 5000 psi w/25 psi Other names for this valve include motion control valve and over-center valve.

Setting Range Check (140 - 350 bar w/ 1,7

bar Check), 3000 psi (210 bar)

Standard Setting

TECHNICAL DATA NOTE: DATA MAY VARY BY CONFIGURATION. SEE CONFIGURATION SECTION.

N Seal Material Buna-N Cavity T-19A

(none) Material/Coating Standard Material/Coating Series 4

Capacity 120 gpm

Pilot Ratio 10:1

Maximum Recommended Load Pressure at Maximum Setting 3850 psi

Maximum Setting 5000 psi

Factory Pressure Settings Established at 2 in³/min.

Maximum Valve Leakage at Reseat 5 drops/min.

Adjustment - No. of CCW Turns from Min. to Max. Setting 3.75

Operating Characteristic Standard

Reseat >85% of setting

Valve Hex Size 1 5/8 in.

Valve Installation Torque 350 - 375 lbf ft

Adjustment Screw Internal Hex Size 7/32 in.

Locknut Hex Size 3/4 in.

Locknut Torque 25 - 30 lbf ft

Seal kit - Cartridge Buna: 990019007

Seal kit - Cartridge EPDM: 990019014

Seal kit - Cartridge Polyurethane: 990019002

Seal kit - Cartridge Viton: 990019006

Model Weight 2.99 lb.

CONFIGURATION OPTIONS Model Code Example: CBIHLJN

CONTROL (L) FUNCTIONAL SETTING RANGE (J) SEAL MATERIAL (N) MATERIAL/COATING

L Standard Screw Adjustment J 2000 - 5000 psi w/25 psi Check (140 - N Buna-N Standard Material/Coating

C Tamper Resistant - Factory Set 350 bar w/ 1,7 bar Check), 3000 psi E EPDM /AP Stainless Steel, Passivated

(210 bar) Standard Setting V Viton /LH Mild Steel, Zinc-Nickel

C 2000 - 5000 psi w/4 psi Check (140 -

350 bar w/ 0,3 bar Check), 3000 psi

(210 bar) Standard Setting

D 1000 - 2500 psi w/4 psi Check (70 -

175 bar w/ 0,3 bar Check), 2000 psi

(140 bar) Standard Setting

K 1000 - 2500 psi w/25 psi Check (70 -

175 bar w/ 1,7 bar Check), 2000 psi

(140 bar) Standard Setting

c 2019 Sun Hydraulics

1 of 2

TECHNICAL FEATURES

Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

Turn adjustment clockwise to decrease setting and release load.

Full clockwise setting is less than 200 psi (14 bar).

Backpressure at port 2 adds to the effective relief setting at a ratio of 1 plus the pilot ratio times the backpressure.

Reseat exceeds 85% of set pressure when the valve is standard set. Settings lower than the standard set pressure may result in lower reseat percentages.

Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage

the seals.

Sun counterbalance cartridges can be installed directly into a cavity machined in an actuator housing for added protection and improved stiffness in the circuit.

Two check valve cracking pressures are available. Use the 25 psi (1,7 bar) check unless actuator cavitation is a concern.

This valve has positive seals between all ports.

All 3-port counterbalance, load control, and pilot-to-open check cartridges are physically interchangeable (i.e. same flow path, same cavity for a given frame size).

Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge

machining variations.

PERFORMANCE CURVES

c 2019 Sun Hydraulics

2 of 2

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- DCS Portal Frame MethodDocument13 pagesDCS Portal Frame MethodDipankar NathPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Embr 1 PDFDocument32 pagesEmbr 1 PDFKamod RanjanPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Ferrock: A Carbon Negative Sustainable Concrete: Presented by Abil Chandra BJK18CE001 Guided by Mrs. Jisha B SDocument39 pagesFerrock: A Carbon Negative Sustainable Concrete: Presented by Abil Chandra BJK18CE001 Guided by Mrs. Jisha B SMovie ManiaczzPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Asme2a Sa-36Document7 pagesAsme2a Sa-36asjkhjshdjkashdashPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Behaviour of Ductile and Brittle Material On Different Loading Conditions (Recovered)Document7 pagesThe Behaviour of Ductile and Brittle Material On Different Loading Conditions (Recovered)NishaThakuriPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Case Study On Underwater Construction: AbstractDocument5 pagesA Case Study On Underwater Construction: AbstractKB GovardhanPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grupsa Clean SystemDocument4 pagesGrupsa Clean Systemsalman nazeerdzPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- DAFZ RegulationsDocument41 pagesDAFZ RegulationsRoger SchulpPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Muller (MCC & MCF)Document12 pagesMuller (MCC & MCF)Muhammad Nur Shidiq100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Rugasol F C - Pds enDocument2 pagesRugasol F C - Pds enbonongx100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- 2016 ICJ Sunitha MPhi PDFDocument12 pages2016 ICJ Sunitha MPhi PDFMiguel SalasPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Platecoil Data ManualDocument106 pagesPlatecoil Data ManualDoug LambPas encore d'évaluation

- Paseo Curtain Wall Strutural CalculationDocument79 pagesPaseo Curtain Wall Strutural CalculationVictor Dlreyes100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Introduction To Turbulent FlowsDocument8 pagesIntroduction To Turbulent FlowsDoddy CarvalloPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Building Construction and Building Services IntegrationDocument46 pagesBuilding Construction and Building Services IntegrationGaurika Grover100% (2)

- Subroutine For Cohesive ElementDocument41 pagesSubroutine For Cohesive ElementBhushanRaj100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Thickness Determination For Spray-Applied Fire Protection MaterialsDocument6 pagesThickness Determination For Spray-Applied Fire Protection MaterialsAntonPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1091)

- Selected New Provisions of ASCE 7-05Document93 pagesSelected New Provisions of ASCE 7-05me-elormPas encore d'évaluation

- Mci Catálogo Hofflights Fixtures Novelties by Grupo MciDocument72 pagesMci Catálogo Hofflights Fixtures Novelties by Grupo MciVEMATELPas encore d'évaluation

- Post - Tensioned Concrete SlabsDocument18 pagesPost - Tensioned Concrete SlabsAakash MohanPas encore d'évaluation

- Choy K. Chemical Vapour Deposition (CVD) - Advances, Tech and App 2019Document417 pagesChoy K. Chemical Vapour Deposition (CVD) - Advances, Tech and App 2019Ketan VekariyaPas encore d'évaluation

- Brosur ADVA Cast 512Document2 pagesBrosur ADVA Cast 512Kartika Setia RiniPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Gruvlok CatalogDocument260 pagesGruvlok CatalogMichael LopesPas encore d'évaluation

- Technical - DOAS-01 - DA1-0710Document4 pagesTechnical - DOAS-01 - DA1-0710Sicologo CimePas encore d'évaluation

- ASME B31.3 InterpretatioNo.23Document9 pagesASME B31.3 InterpretatioNo.23Syed AbudhakirPas encore d'évaluation

- ITP-FW For Civil & Building WorksDocument17 pagesITP-FW For Civil & Building WorksRizki KresnaPas encore d'évaluation

- FS-04 - EXL Iloilo - FM 200 Miscellaneous Details 2Document1 pageFS-04 - EXL Iloilo - FM 200 Miscellaneous Details 2MEZ-OBO Visayas ITPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Phase Transition and Dielectric Properties of Batio3 Ceramics Containing10 Mol% Bageo3Document17 pagesPhase Transition and Dielectric Properties of Batio3 Ceramics Containing10 Mol% Bageo3Jeff SalesPas encore d'évaluation

- Evaluation of 7050 TAF ConditionsDocument9 pagesEvaluation of 7050 TAF ConditionsAndré LopesPas encore d'évaluation

- Wps SmawDocument1 pageWps SmawFedericoC67% (3)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)