Académique Documents

Professionnel Documents

Culture Documents

Model Name - Flashd Flash Drum Flash Drum (Function) : Vapor Phase Product Liquid Phase Feed 3 Vapor Phase Feed

Transféré par

amlhrdsDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Model Name - Flashd Flash Drum Flash Drum (Function) : Vapor Phase Product Liquid Phase Feed 3 Vapor Phase Feed

Transféré par

amlhrdsDroits d'auteur :

Formats disponibles

7.1.

1(1)

Model

Flash drum Flash drum _FLASHD

name

[Function]

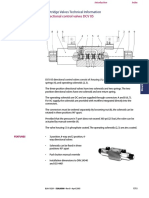

• General-purpose flash tank model. Vapor phase product

• This model can be used as a vapor-liquid separating 1 Liquid phase feed

Vapor phase feed

vessel, or a sealed liquid tank.

3 2

• The mass transfer rate between vapor and liquid is

taken into account to represent the non-equilibrium

between vapor and liquid. Main feed

• The component/heat holdup is taken into account 1

for both the liquid and vapor phases.

• The temperature in the tank is identical to the liquid

and vapor phase temperatures. The heat capacity of

the tank vessel is also taken into account, and the

liquid phase temperature is calculated from the sum q

of the liquid phase and tank wall heat holdups.

• Heat transfer between the vapor phase and the liquid

phase (including the tank wall) is taken into account. Liquid phase product 2

• The driving force for the mass transfer between

vapor and liquid phases is the difference between

the liquid phase equilibrium partial pressure and the

vapor-phase holdup partial pressure.

• The vessel type may be specified as a vertical or horizontal cylindrical tank, or as a spherical tank. Also,

the volume of piping for connection can be included in the vapor phase volume.

• The model can be started empty (without liquid), and the tank can also be emptied from its liquid content.

• The standard function of this model is to calculate pressure by inputting a flow rate, since it is a model for

which vapor and liquid phase holdups and mass transfer between vapor and liquid phases are taken into

account.

• Each nozzle should be connected with pressure drop units (valve, piping, etc.) and flow rate specifying

units.

• It is possible to specify the height of each stream nozzle.

[Flow and phases]

• By defining a liquid phase in the vapor product nozzle, liquid outflow can occur when the vessel is full of

liquid. Note that regardless of its position relative to the liquid level, nozzle p1 continues to output vapor

until the vessel is full.

• By defining a vapor phase in the liquid product nozzle, vapor outflow can occur when the liquid level is

low.

• A reverse flow may occur. All stream nozzles support reverse flow definitions.

[Component system]

• There are no restrictions regarding components.

• The component system should be specified.

[Malfunctions]

• None

[Block : flashd] V9-12

7.1.1(2)

Model

Flash drum Flash drum _FLASHD

name

[Nozzles]

Item Symbol Type Connection Normal flow phases Reverse flow phases

Main feed f1 Feed Required V, L, VL -, V, L, VL

Liquid phase feed f2 Feed Optional L, VL -, L, VL

Vapor phase feed f3 Feed Optional V, VL -, V, VL

Vapor phase product p1 Prod Required V, VL -, V, VL

Liquid phase product p2 Prod Required L, VL -, L, VL

External heat load to liquid phase [MJ/h] q Set Optional - -

Note: When NZLHGT=0, nozzle p2 is automatically located at the bottom of the vessel, and all the other

nozzles at the top of the vessel unless a liquid phase reverse flow is defined for the main feed line, in

which case nozzle f1 is also located at the bottom of the vessel.

[Generation Parameters]

Item Symbol Type Contents Value

Specify Nozzle Heights NZLHGT Parm [-] 0: No, 1:Yes (0)

[Parameters (PRIMARY)]

Item Symbol Type Description Value

Liquid Phase Mol Composition x() Calc [mol/mol] Each component. -

Vapor Phase Mol Composition y() Calc [mol/mol] Each component. -

The initial value should be specified.

Liquid Phase Temperature Temp Calc [°C] The initial value should be specified. (25)

Vapor Phase Temperature Tv Calc [°C] -

Vapor Phase Pressure Pres Calc [kPa] The initial value should be specified. (101.32)

{F} SPECifiable in steady state calculation

Liquid Level Level Calc [m] -

{F} SPECifiable in steady state calculation

Vessel Type DTYPE Const [-] 1: Vertical cylinder (1)

2: Horizontal cylinder

3: Spherical

Diameter DD Const [m] *

Length LD Const [m] *

Volume VD Calc [m3] -

Feed f1 Height Hghtf1 Const [m] (Created when NZLHGT=1) *

Feed f2 Height Hghtf2 Const [m] (Created when NZLHGT=1) *

Feed f3 Height Hghtf3 Const [m] (Created when NZLHGT=1) *

Product p1 Height Hghtp1 Const [m] (Created when NZLHGT=1) *

Product p2 Height Hghtp2 Const [m] (Created when NZLHGT=1) *

Vessel Weight Gw Const [kg] *

Vapor Phase Heat Transfer Coefficient Uv Const [W/m2k] (40)

Mass Transfer Rate Coefficient kG Const [kmol/m2kPah] (0.1)

Evaporation Rate fevap() Calc [kmol/h] Each component. -

Negative for condensation.

System No. s1 Const [-] *

V9-12 [Block : flashd]

7.1.1(3)

Model

Flash drum Flash drum _FLASHD

name

Level : For steady state calculations, it is always necessary to specify the liquid level “Level” by moving a

SPEC from a valve on the liquid discharge side. The set value must be greater than the minimum

liquid level Lmin.

kG : This is a coefficient to determine the rate to reach the vapor-liquid equilibrium state. The bigger this

value the faster the vapor-liquid equilibrium state is reached, but if it is too big, an important change

in the liquid phase holdup will result in unstable calculations (particularly when a component having

a large K value exists in a trace liquid phase). Therefore, the kG value must be decided considering

the attainment of vapor-liquid equilibrium and the stability of calculations. Since this model

employs a method which allows a stable calculation of mass transfer (cf. model equation 4.(1)),

more emphasis may be put on the attainment of vapor-liquid equilibrium.

[Block : flashd] V9-12

7.1.1(4)

Model

Flash drum Flash drum _FLASHD

name

[Parameters (DETAIL)]

Item Symbol Type Description Value

Liquid Phase Holdup zl() Calc [kmol] Each component. (0)

The initial value should be specified.

Vapor Phase Holdup zv() Calc [kmol] Each component. -

Liquid Phase Holdup Zl Calc [kmol] -

Liquid Phase Heat Holdup Hl Calc [MJ] -

Vapor Phase Holdup Zv Calc [kmol] -

Vapor Phase Heat Holdup Hv Calc [MJ] -

Vessel Specific Heat Cpw Const [kJ/kgK] (0.46)

Heat Trans. Area of H. Loss Aatm Const [m2] (0)

Heat Trans. Coef. of H. Loss Uatm Const [W/m2k] (6)

Heat Release Qair Calc [MJ/h] -

Heat Transfer from Vapor Phase to Qv Calc [MJ/h] -

Wall Liquid

Heating and Cooling from Outside Qe Calc [MJ/h] -

3

Attached Line Volume Vv0 Const [m ] (0)

Volume Ratio Limit for Phase Rdis Const [-] (0.05)

Disappearance

Vapor-Liquid Volume Ratio Rvol Calc [-] -

Min. Vapor Volume Vvmin Calc [m3] Vvmin = VD*Rdis -

Min. Liquid Level to Discharge Lmin Const [m] (0)

Full Liquid Flag k_full Calc [-] 0: Vapor-liquid separation, -

1: Almost full liquid 2: Full liquid

-1: Almost no liquid -2: No liquid

Vvmin, Rvol, Rdis: Vvmin is related to the vapor phase holdup calculation. If this value is too small, the

vapor phase holdup calculation near the full liquid conditions can become unstable. Therefore, it is

preferable in some cases to set this value above the default value.

If the vapor phase volume of the vessel goes below Vvmin (i.e., when Rvol < Rdis), calculation of

mass transfer and heat transfer between the vapor and liquid phases is not performed. In addition:

(1) If there is no vapor entering the vessel, it is considered to be full of liquid, and vapor is no longer

discharged from the vapor phase outlet p1. Liquid is discharged from outlet p1 if the connected

stream has a mixed phase definition.

(2) If there is vapor entering the vessel, vapor will still be discharged from the vapor phase outlet p1. If

the stream connected to this outlet has a mixed phase definition, liquid is also discharged and the

vapor ratio linearly decreases as the vapor volume decreases.

Similarly, if the liquid phase volume becomes smaller than Vvmin (i.e., when 1.0-Rvol < Rdis), and

the stream connected to the liquid phase outlet p2 has a mixed phase definition, vapor is also

discharged and the liquid ratio linearly decreases as the liquid volume decreases.

V9-12 [Block : flashd]

7.1.1(5)

Model

Flash drum Flash drum _FLASHD

name

[Parameters (STEADY STATE)]

Item Symbol Type Description Value

Start Value of Pressure PreSt Const [kPa] This value is set to Pres and to the p1 stream (101.325)

{u} pressure.

Start Value of Liquid Level LevelSt Const [m] This value is set to Level. (0.5)

Start Value of Temperature TempSt Const [°C] This value is set to Temp, Tv and to the p1 and (25)

{u} p2 stream temperatures.

Start Value of Vapor Phase Outlet ySt Const [mol/mol] This value is set to the p1 stream *(0)

Composition composition.

Start Value of Liquid Phase Outlet xSt Const [mol/mol] This value is set to the p2 stream *(0)

Composition composition.

[Parameters (PRIVATE)]

Item Symbol Type Description Value

Flow Rate Calculation Index ind(5) Calc [-] Each stream -

Flow Rate Regulation Capacity eta(5) Calc [kPa/(kmol/h)] Each stream -

Flow Constraints Fcons Const 1:Yes 0:No (1)

Nozzle p2 Liquid Phase Ratio RLp2 Calc [mol/mol] -

Nozzle p1 Vapor Phase Ratio RVp1 Calc [mol/mol] -

Calculation Parameter uparm(10) Const (1) Lower limit of vapor phase pressure [kPa] (0.1)

(2) (Obsolete) For old unit version (0.1)

(3) Omit handling for water separation calculation

0: No 1:Yes (0)

S Factor S Calc [-] For steady state calculations -

Split Flow Ratio 1 rp1 Calc [-] For steady state calculations -

S Factor Correction by Feed 1 fldS Calc [-] For steady state calculations -

S Factor Correction by Feed 2 f2dS Calc [-] For steady state calculations -

S Factor Correction by Feed 3 f3dS Calc [-] For steady state calculations -

G Factor G Calc [-] For steady state calculations -

G Factor Correction by Feed 1 fldG Calc [-] For steady state calculations -

G Factor Correction by Feed 2 f2dG Calc [-] For steady state calculations -

G Factor Correction by Feed 3 f3dG Calc [-] For steady state calculations -

Temperature Correction by Feed 1 fldT Calc [-] For steady state calculations -

Latent Heat Correction by Feed 1 flddh Calc [-] For steady state calculations -

Temperature Correction by Feed 2 f2dT Calc [-] For steady state calculations -

Latent Heat Correction by Feed 2 f2ddh Calc [-] For steady state calculations -

Temperature Correction by Feed 3 f3dT Calc [-] For steady state calculations -

Latent Heat Correction by Feed 3 f3ddh Calc [-] For steady state calculations -

Fcons: If set to 0, removes the flow rate constraints that prevent the fluid volume to exceed the volume of

the vessel from the pressure-flow balance calculation. The constraints that prevent holdup from

becoming negative, however, are always maintained.

[Block : flashd] V9-12

7.1.1(6)

Model

Flash drum Flash drum _FLASHD

name

[[Model equations]

1. Model outline

Vapor phase product

Vapor phase product Fp1, y, Tv

Vapor phase feed Liquid phase feed

Vapor phase feed Fp1 Ff3 Ff2

Ff3 rvf3

Vapor phase Pres

Heat transfer Zv zv y

rvf1 Temp Tv Hv Vapor phase

Vapor-liquid Qv

Vapor-liquid

mixed phase feed Mass transfer mixed phase feed

fevap=ftre-ftrc Mass transfer

Ff1 Ff1 fevap=ftre-ftrc

rlf3 Liquid phase

rlf1 feed

Liquid phase

Zl zl x

Ff2 Liquid phase

Temp Hl

Fp2

Fp2, x, Temp

Liquid phase product Liquid phase product

Normally this unit is used to perform a two phase vapor-liquid flash calculation by specifying a vapor-

liquid mixed phase for the feed stream.

2. Liquid phase

(1) Liquid phase component mass balance equation

dzl i dt = Ff1 rlf1 lxf1 i + Ff2 rlf1 xf2 i + Ff3 rlf3 lxf3 i

(1)

– Fp1 rlp1 lxp1 i – Fp2 rlp2 lxp2 i – ftre i + ftrc i

Zl = zl i (2)

x i = zl i Zl (3)

zl : Liquid phase component holdup [kmol]

Zl : Phase holdup [kmol]

Ff1 : f1 feed flow rate [kmol/h]

Ff2 : f2 feed liquid flow rate [kmol/h]

Ff3 : f3 feed flow rate [kmol/h]

Fp1 : p1 product liquid flow rate [kmol/h]

Fp2 : p2 product liquid flow rate [kmol/h]

rlf1 : f1 feed liquid phase ratio [mol/mol]

rlf2 : f2 feed liquid phase ratio [mol/mol]

rlf3 : f3 feed liquid phase ratio [mol/mol]

rlp1 : p1 product liquid phase ratio [mol/mol]

rlp2 : p2 product liquid phase ratio [mol/mol]

lxf1 : f1 feed liquid composition [mol/mol]

lxf2 : f2 feed liquid composition [mol/mol]

lxf3 : f3 feed liquid composition [mol/mol]

lxp1 : p1 product liquid composition [mol/mol]

V9-12 [Block : flashd]

7.1.1(7)

Model

Flash drum Flash drum _FLASHD

name

lxp2 : p2 product liquid composition [mol/mol]

ftre : Transfer volume of evaporated component [kmol/h]

ftrc : Transfer volume of condensed component [kmol/h]

x : Liquid phase holdup composition [mol/mol]

(2) Liquid phase heat balance

Liquid phase heat holdup (including vessel wall)

d Hl + Hw dt = Ff1 rlf1 hlf1 + Ff2 rlf2 hlf2 + Ff3 rlf3 hlf3

– Fp1 rlp1 hlp1 – Fp2 rlp2 hlp2 (4)

– Ftre hle + Ftrc hvc + Qv + Qin – Qloss

hl = Hl Zl (5)

Hw = C 1 Gw Cpw Temp (6)

Liquid phase temperature

Temp = f hl x Pres (7)

Temp : Liquid phase (including vessel wall) temperature [°C]

Hl : Liquid phase heat holdup [MJ]

hl : Liquid phase molar enthalpy [kJ/mol]

Gw : Vessel wall weight [kg]

Cpw : Vessel specific heat [kJ/kgK]

Qv : Heat transfer rate from vapor phase to liquid phase [MJ/h]

Qin : Energy input from the outside to the liquid phase [MJ/h]

Qloss : Heat loss [MJ/h]

Ftre : Evaporation [kmol/h]= SUM( ftre(i) )

Ftrc : Condensate [kmol/h]= SUM( ftrc(i) )

hlf1, hlf2, hlf3, hlp1, hlp2 :

Molar enthalpy of f1, f2, f3, or p1, p2 liquid [kJ/mol]

hle : Molar enthalpy of evaporation liquid at the liquid phase temperature [kJ/mol]

hvc : Molar enthalpy of condensed vapor at vapor phase temperature [kJ/mol]

C1 : Conversion coefficient (=1.0e-3)

(3) Liquid phase volume, level

Vl = Zl dl (8)

Level = f Vl DD LD (9)

Vl : Liquid phase volume [m3]

dl : Liquid density [kmol/m3]

[Block : flashd] V9-12

7.1.1(8)

Model

Flash drum Flash drum _FLASHD

name

Level : Liquid Level [m]

The liquid level is obtained from the vessel type and liquid phase volume.

The vessel type may be specified as cylindrical (vertical or horizontal) or spherical.

V9-12 [Block : flashd]

7.1.1(9)

Model

Flash drum Flash drum _FLASHD

name

3. Vapor phase

(1) Vapor phase component mass balance equation

dzv i dt = Ff1 rvf1 vyf1 i + Ff2 rvf2 vyf2 i + Ff3 rvf3 vyf3 i

(10)

– Fp1 rvp1 vyp1 i – Fp2 rvp2 vyp2 i + ftre i – ftrc i

Zv = zv i (11)

yv i = zv i Zv (12)

zv : Vapor phase component holdup [kmol]

Zv : Vapor phase holdup [kmol]

rvf1 : f1 feed vapor phase ratio [-]

rvf2 : f2 feed vapor phase ratio [-]

rvf3 : f3 feed vapor phase ratio [-]

vyf1 : f1 feed vapor phase composition [mol/mol]

vyf2 : f2 feed vapor phase composition [mol/mol]

vyf3 : f3 feed vapor phase composition [mol/mol]

vyp1 : p1 product vapor phase composition [mol/mol]

vyp2 : p2 product vapor phase composition [mol/mol]

y : Vapor phase holdup composition [mol/mol]

(2) Vapor phase heat balance

Vapor phase heat holdup

dHv dt = Ff1 rvf1 hvf1 + Ff2 rvf2 hvf2 + Ff3 rvf3 hvf3

(13)

– Fp1 rvp1 hvp1 – Fp2 rvp2 hvp2 + Ftre hve – Ftrc hvc – Qv

Vapor phase temperature

hv = Hv Zv (14)

Tv = f hv yv Pres (15)

Hv : Vapor phase heat holdup [MJ]

hv : Vapor phase molar enthalpy [kJ/mol]

hvf1, hvf2, hvf3, hvp1, hvp2 :

f1, f2, f3 feed and p1, p2 product vapor phase molar enthalpy [kJ/mol]

hve : Evaporation component vapor phase molar enthalpy at the liquid phase

temperature Temp [kJ/mol]

hvc : Condensed component vapor phase molar enthalpy at the vapor phase

temperature Tv [kJ/mol]

Tv : Vapor phase temperature [K]

[Block : flashd] V9-12

7.1.1(10)

Model

Flash drum Flash drum _FLASHD

name

(3) Vapor phase volume

VV = Vv + Vv0 (16)

Vv = VD – Vl (17)

VV : Vapor phase volume [m3]

Vv : Vapor phase volume of vessel [m3]

Vv0 : Volume of piping connected to the vessel [m3]

VD : Vessel volume [m3]

(4) Vapor phase pressure

Zv = VV dv (18)

dv = f y Tv Pres (19)

Pres : Vapor phase pressure [kPa]

dv : Vapor phase density [kmol/m3]

The vapor phase pressure Pres is obtained by convergence calculation so that the equations (16) and (17)

can be calculated simultaneously.

V9-12 [Block : flashd]

7.1.1(11)

Model

Flash drum Flash drum _FLASHD

name

4. Mass transfer between vapor and liquid phases

(1) Mass transfer rate (evaporation and condensation rate)

The mass transfer between the vapor and liquid phases is assumed to be proportional to the difference

between equilibrium partial pressure and vapor phase partial pressure in the vessel, and calculated for each

component i from the following equation.

fevap i = kG As ps i – Pres y i (20)

ps i = Pres kval i x i (21)

fevap : Component mass transfer rate [kmol/h]

As : Interfacial area of vapor and liquid [m2]

kG : Mass transfer rate coefficient [kmol/m2kPah]

ps : Equilibrium partial pressure [kPa]

kval : K value [-] (values at Temp and Pres)

When fevapi is positive, it is evaporation (ftrei) and when negative, condensation (ftrci).

(2) Heat transfer accompanied by mass transfer between vapor and liquid phases

Evaporation heat and condensation heat are assumed to be handled by the liquid phase and sensible heat is

assumed to be handled by the destination phase.

Evaporation heat Qle and condensation heat Qlc are calculated from the following equations.

Qle = Ftre hv Temp xe – hl Temp xe (22)

Qlc = Ftrc hv Tv xc – hl Tv xc (23)

xe : Evaporation composition [mol/mol] ( = ftrei /Ftre)

xc : Condensation composition [mol/mol] ( = ftrci /Ftrc)

hv(Temp, xe) : Evaporation component vapor phase molar enthalpy at the liquid phase

temperature Temp [kJ/mol]

hl(Temp, xe) : Evaporation component liquid phase molar enthalpy at the liquid phase

temperature Temp [kJ/mol]

hv(Tv, xc) : Condensation component vapor phase molar enthalpy at the vapor phase temperature

Tv [kJ/mol]

hl(Tv, xc) : Condensation component liquid phase mol entahlpy at the vapor phase temperature

Tv [kJ/mol]

[Block : flashd] V9-12

7.1.1(12)

Model

Flash drum Flash drum _FLASHD

name

5. Heat transfer equation

(1) Heat transfer rate Qv from the vapor phase to the (liquid phase + vessel wall)

Qv = 3.6e – 3 Aw Uv Tv – Temp (24)

Aw : Heat transfer area [m2] ((Surface area of vessel + Surface area of liquid phase) which

contacts the vapor phase.)

Uv : Vapor phase heat transfer coefficient [W/m2k]

(2) Heat loss rate Qloss from the outer vessel surface

Qloss = 3.6e – 3 Aatm Uatm Temp – Tatm (25)

Aatm : Heat loss area [m2]

Uatm : Transfer heat coefficient of heat loss [W/m2k]

Tatm : Atmospheric temperature [°C]

6. Steady state calculation model

The model for steady state calculations is basically the same as that for dynamic calculations, and uses

equations obtained by setting the time derivative terms such as holdup fluctuation to zero.

However, the following special operating states are excluded from steady state calculations.

• Empty state (no liquid)

It is always necessary that there be a liquid level and that the liquid may be discharged normally from the

liquid outlet nozzle p2.

• Full liquid state (no vapor).

• Reverse flow in any of the nozzle streams.

• Vapor blow-by to the liquid product line (p2)

[Revision record]

V7 : Made it possible to change the lower limit of the vapor phase pressure with calculation parameter

uparm.

V8 : Added parameters VD, Rdis and Rvol. Made Vvmin a calculated value.

Replaced parameter Zl0 with Lmin. Removed parameters dv_full and useS.

Improved to give flow rate constraints due to holdup from the unit to the pressure-flow calculation.

Improved liquid phase enthlapy and temperature calculation.

V9 : Made it possible to specify nozzle heights.

Increased the number of allowable reverse flow phase definitions.

V9-12 [Block : flashd]

Vous aimerez peut-être aussi

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGD'EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGPas encore d'évaluation

- Binary Distillation (2) Binary Distillation (2) : (CH 7) (CH 7) (Ch. 7) (Ch. 7)Document12 pagesBinary Distillation (2) Binary Distillation (2) : (CH 7) (CH 7) (Ch. 7) (Ch. 7)wahab aliPas encore d'évaluation

- Chapter 12: Proportional Directional Control: ObjectivesDocument12 pagesChapter 12: Proportional Directional Control: ObjectivesSangmin KimPas encore d'évaluation

- Che821 - Lecture FiveDocument109 pagesChe821 - Lecture Fiveprof.kess.unibenPas encore d'évaluation

- A Device To Generate Plentiful, Cheap An Multi-Purpose Source To Satisfy Extra-Somatic NeedsDocument60 pagesA Device To Generate Plentiful, Cheap An Multi-Purpose Source To Satisfy Extra-Somatic NeedsSrotriya TripathiPas encore d'évaluation

- CHEE 321 - Chemical Reaction Engineering - BonneDocument46 pagesCHEE 321 - Chemical Reaction Engineering - BonneDha OstrIxPas encore d'évaluation

- Advance Fluid Lab ManualDocument55 pagesAdvance Fluid Lab ManualchristianPas encore d'évaluation

- DCD1 Lecture PDFDocument43 pagesDCD1 Lecture PDFChristopher RileyPas encore d'évaluation

- Experiment No: - 4 Study of A Buck-Boost DC-DC Converter Under Real-Time Using Typhoon HilDocument4 pagesExperiment No: - 4 Study of A Buck-Boost DC-DC Converter Under Real-Time Using Typhoon HilShwet PrasoonPas encore d'évaluation

- 2,4 Pipes&PumpsDocument226 pages2,4 Pipes&PumpskotiramaPas encore d'évaluation

- 2 OLGA Basic UpdDocument56 pages2 OLGA Basic Updi786zzyPas encore d'évaluation

- CKRD-MS-03 (2020)Document51 pagesCKRD-MS-03 (2020)Shakoor MalikPas encore d'évaluation

- Section17 - D05 Directional Control ValvesDocument12 pagesSection17 - D05 Directional Control ValvesHENRY LLOFREL CORREA LOPEZPas encore d'évaluation

- Reciprocating CompressorDocument10 pagesReciprocating CompressorSanket PatilPas encore d'évaluation

- Analysis of Axial & Centrifugal Compressors: To Be Selected As Per Specific Speed of ApplicationsDocument31 pagesAnalysis of Axial & Centrifugal Compressors: To Be Selected As Per Specific Speed of ApplicationsSiraj MohammedPas encore d'évaluation

- Brno Flyback Design Rev1 PDFDocument103 pagesBrno Flyback Design Rev1 PDFela81Pas encore d'évaluation

- Analysis of Axial & Centrifugal Compressors: To Be Selected As Per Specific Speed of ApplicationsDocument31 pagesAnalysis of Axial & Centrifugal Compressors: To Be Selected As Per Specific Speed of ApplicationsAvi ChPas encore d'évaluation

- 4modelingandcontrolofdistillationcolumninapetroleumprocess 140320113744 Phpapp01 PDFDocument14 pages4modelingandcontrolofdistillationcolumninapetroleumprocess 140320113744 Phpapp01 PDFMohamed GuenounePas encore d'évaluation

- Basics of Petroleum Engineering For WellDocument90 pagesBasics of Petroleum Engineering For WellEnockPas encore d'évaluation

- Pumps Chapter 11Document87 pagesPumps Chapter 11Muhammad UsamaPas encore d'évaluation

- Lecture 04A - Homologous Units and Affinity LawsDocument32 pagesLecture 04A - Homologous Units and Affinity LawsVũ ThanhPas encore d'évaluation

- Analysis of Axial & Centrifugal Compressors: To Be Selected As Per Specific Speed of ApplicationsDocument31 pagesAnalysis of Axial & Centrifugal Compressors: To Be Selected As Per Specific Speed of ApplicationsArockia FenilPas encore d'évaluation

- Analysis of Axial & Centrifugal Compressors: To Be Selected As Per Specific Speed of ApplicationsDocument31 pagesAnalysis of Axial & Centrifugal Compressors: To Be Selected As Per Specific Speed of ApplicationsNitish KumarPas encore d'évaluation

- Analysis of Axial & Centrifugal Compressors: To Be Selected As Per Specific Speed of ApplicationsDocument31 pagesAnalysis of Axial & Centrifugal Compressors: To Be Selected As Per Specific Speed of ApplicationsAbdullah IyadPas encore d'évaluation

- Tips OlgaDocument15 pagesTips OlgaArlen ZapataPas encore d'évaluation

- Experiment No 7 Objective: - Measurement of Coefficient of Discharge of Valve As Function of Valve LiftDocument5 pagesExperiment No 7 Objective: - Measurement of Coefficient of Discharge of Valve As Function of Valve LiftMuket AgmasPas encore d'évaluation

- Mel346 42Document31 pagesMel346 42Gaurav VirdiPas encore d'évaluation

- Lecture 3 Multiphase Flow 1 PDFDocument46 pagesLecture 3 Multiphase Flow 1 PDFmsdPas encore d'évaluation

- Separation Processes I: Topic 2: Vapour-Liquid EquilibriumDocument24 pagesSeparation Processes I: Topic 2: Vapour-Liquid EquilibriumPatrice PierrePas encore d'évaluation

- PLT InterpretationDocument71 pagesPLT Interpretationdhiaa100% (2)

- Refinery and Petrochemical Equipment: Distillation ColumnDocument48 pagesRefinery and Petrochemical Equipment: Distillation ColumnFikrie MuhdPas encore d'évaluation

- Reactor DesignDocument181 pagesReactor DesignRam0% (1)

- Equilibrium Staged Operations: A1 SlotDocument21 pagesEquilibrium Staged Operations: A1 SlotSAI P HARIHARAN 19BCM0030Pas encore d'évaluation

- PC Task 1 by Rizwan - AnausDocument5 pagesPC Task 1 by Rizwan - AnausmoinPas encore d'évaluation

- 2.adcatrol Control Valves - KV GeneralDocument10 pages2.adcatrol Control Valves - KV GenerallemvanPas encore d'évaluation

- Reservoir and Tubing Performance SlidesDocument50 pagesReservoir and Tubing Performance SlidesAliPas encore d'évaluation

- Chapter 2Document37 pagesChapter 2Abdullah Ibn MasudPas encore d'évaluation

- C Module-5 Reciprocating Air Compressors. Reciprocating Compressors - Construction - WorkingDocument48 pagesC Module-5 Reciprocating Air Compressors. Reciprocating Compressors - Construction - WorkingJasraj Gill100% (1)

- Transformer DesignDocument15 pagesTransformer DesignTeklu AnbesePas encore d'évaluation

- Chemical Engineering: ReactionDocument58 pagesChemical Engineering: ReactionziaPas encore d'évaluation

- Transformer DesignDocument15 pagesTransformer DesignTeklu AnbesePas encore d'évaluation

- Chapter (5) Conservation Laws of Fluid FlowDocument35 pagesChapter (5) Conservation Laws of Fluid FlowZiad ElnagarPas encore d'évaluation

- 5 - Distillation ColumnsDocument18 pages5 - Distillation ColumnsAzizah Azizah100% (1)

- Liu Gong Hydraulic System PDFDocument86 pagesLiu Gong Hydraulic System PDFYadi100% (3)

- Water Conveyance With Syphons: September, 2000 (Rev 2009)Document19 pagesWater Conveyance With Syphons: September, 2000 (Rev 2009)Sameer ShrivastavaPas encore d'évaluation

- Lecture Notes On SIZINGDocument27 pagesLecture Notes On SIZINGsara95Pas encore d'évaluation

- Advanced Fluid Mechanics Vl-300 1 Lab Manual: FALL 2022Document67 pagesAdvanced Fluid Mechanics Vl-300 1 Lab Manual: FALL 2022FahadImranXhiekhPas encore d'évaluation

- Distillation 2Document20 pagesDistillation 2arslanadeelPas encore d'évaluation

- Packinox Multistream ServiceDocument2 pagesPackinox Multistream ServiceCorneliuPopaPas encore d'évaluation

- ML T ML T ML T ML T ML T R L T MT: Separation Columns (Distillation, Absorption and Extraction)Document4 pagesML T ML T ML T ML T ML T R L T MT: Separation Columns (Distillation, Absorption and Extraction)Sami WhitePas encore d'évaluation

- Ce423b RRLDocument7 pagesCe423b RRLZanne RosePas encore d'évaluation

- Advanced Well TestingDocument91 pagesAdvanced Well TestingBendali MehdiPas encore d'évaluation

- Form 410-5 7-2013Document15 pagesForm 410-5 7-2013Ali MoazamiPas encore d'évaluation

- PVG 100 Customer PresentationDocument24 pagesPVG 100 Customer PresentationbrunosamaeianPas encore d'évaluation

- Equilibrium Staged Operations: A1 SlotDocument18 pagesEquilibrium Staged Operations: A1 SlotErmias NigussiePas encore d'évaluation

- Is Now Part ofDocument15 pagesIs Now Part ofjohn.monroyPas encore d'évaluation

- Distillation Control TheoryDocument12 pagesDistillation Control Theoryinstrutech0% (1)

- Working Guide to Reservoir Rock Properties and Fluid FlowD'EverandWorking Guide to Reservoir Rock Properties and Fluid FlowÉvaluation : 3 sur 5 étoiles3/5 (1)

- Reboiler Case StudyDocument6 pagesReboiler Case StudyamlhrdsPas encore d'évaluation

- LearnThermo Workbook 2017Document583 pagesLearnThermo Workbook 2017Fernando Pratama0% (1)

- Crude Column Design Example PDFDocument13 pagesCrude Column Design Example PDFamlhrdsPas encore d'évaluation

- Evaluation of Corrosion in Different Parts of An Oil Refinery Using Corrosion Coupons PDFDocument83 pagesEvaluation of Corrosion in Different Parts of An Oil Refinery Using Corrosion Coupons PDFDavid RodriguesPas encore d'évaluation

- Crude Tower Simulation-HYSYS v10Document72 pagesCrude Tower Simulation-HYSYS v10ppcprPas encore d'évaluation

- AspenHYSYSDynModelV7 3 RefDocument224 pagesAspenHYSYSDynModelV7 3 RefThanh-Dat NguyenPas encore d'évaluation

- InstrumentationDocument112 pagesInstrumentationShivshankar GhugePas encore d'évaluation

- HYSYS Tutorial 2014Document36 pagesHYSYS Tutorial 2014ridhajamelPas encore d'évaluation

- 4 Girish ChitnisDocument22 pages4 Girish ChitnisridanormaPas encore d'évaluation

- FPSO Digi TwinDocument18 pagesFPSO Digi TwinamlhrdsPas encore d'évaluation

- P 475188Document33 pagesP 475188Parth PatelPas encore d'évaluation

- Refinery Processes-Kirk OthmerDocument49 pagesRefinery Processes-Kirk OthmeramlhrdsPas encore d'évaluation

- Petroleum Fraction at Ion OverviewDocument35 pagesPetroleum Fraction at Ion Overviewphobos2000Pas encore d'évaluation

- Presentations Oil Refinery ProcessesDocument36 pagesPresentations Oil Refinery ProcessesGururaj SreepatharaoPas encore d'évaluation

- CAPE® Chemistry Free ResourcesDocument4 pagesCAPE® Chemistry Free Resourcesabbey4623Pas encore d'évaluation

- Waterproofing and Weatherproofing MaterialsDocument37 pagesWaterproofing and Weatherproofing MaterialsSanjay Areyoukiddingme Somnath50% (2)

- Cavitation and Pipe DetailsDocument34 pagesCavitation and Pipe DetailsSANDIP ROYPas encore d'évaluation

- Grade Twelve Biology Model QuestionsDocument9 pagesGrade Twelve Biology Model Questionsmmree yyttPas encore d'évaluation

- PPG Cs 743: PPG CS 743 Is A Copolymer Polyol Especially Designed For The Production ofDocument2 pagesPPG Cs 743: PPG CS 743 Is A Copolymer Polyol Especially Designed For The Production ofVaittianathan MahavapillaiPas encore d'évaluation

- Brazing Road SP PDFDocument32 pagesBrazing Road SP PDFFAYAZPas encore d'évaluation

- Grade 7 Heat End of Unit TestDocument6 pagesGrade 7 Heat End of Unit TestJayPas encore d'évaluation

- Lab Report - Tensile TestingDocument19 pagesLab Report - Tensile Testingapi-404653452100% (1)

- 1100-Data Sheets PDFDocument3 pages1100-Data Sheets PDFPaturu VijayPas encore d'évaluation

- Science G9 Ext Educator-14.1.2020 WebDocument355 pagesScience G9 Ext Educator-14.1.2020 WebNadya AnggrainiPas encore d'évaluation

- UL PresentationDocument18 pagesUL Presentationsethhcohen11Pas encore d'évaluation

- What Is Concrete Curing Compound?Document17 pagesWhat Is Concrete Curing Compound?SHAIK ASIMUDDIN100% (2)

- 2280-Article Text-2915-1-10-20180123 PDFDocument7 pages2280-Article Text-2915-1-10-20180123 PDFBela RamdhaniPas encore d'évaluation

- F.4 Acids and Exercise)Document69 pagesF.4 Acids and Exercise)arielshy100% (5)

- AlSi12Fe MS, Props Under VacuumDocument14 pagesAlSi12Fe MS, Props Under VacuumRishabh MenonPas encore d'évaluation

- Material Safety Data Sheet - NITRIC ACID PDFDocument9 pagesMaterial Safety Data Sheet - NITRIC ACID PDFJunaid AhmadPas encore d'évaluation

- Chemistry Viva QuestionsDocument3 pagesChemistry Viva QuestionsShivamPas encore d'évaluation

- Beta-Cyclodextrin Solid DispersionDocument30 pagesBeta-Cyclodextrin Solid Dispersiondarkarva84100% (1)

- Friction Welding Usage TodayDocument15 pagesFriction Welding Usage Todaycule93Pas encore d'évaluation

- Eco-Friendly Polymer Composites For Green Packaging Future Vision PDFDocument10 pagesEco-Friendly Polymer Composites For Green Packaging Future Vision PDFAncuţa-IonelaPartinPas encore d'évaluation

- Corrosion-Resistant-Pumps - Ib116-C - Bom InoxDocument9 pagesCorrosion-Resistant-Pumps - Ib116-C - Bom InoxKhang TrầnPas encore d'évaluation

- Astm A514 1977Document6 pagesAstm A514 1977Elumalai Srinivasan100% (1)

- Plate Hydraulic Design Procedure111Document17 pagesPlate Hydraulic Design Procedure111Gebrekiros ArayaPas encore d'évaluation

- MSDS Accelerator MBT 2-Mercaptobenzothiazole KemaiDocument7 pagesMSDS Accelerator MBT 2-Mercaptobenzothiazole KemaicarlosPas encore d'évaluation

- Chemisty Book Notes For Class XI - Chemical Bond - Gases005628Document23 pagesChemisty Book Notes For Class XI - Chemical Bond - Gases005628Mukhtiar AhmedPas encore d'évaluation

- Non Aqueous TitrationDocument29 pagesNon Aqueous TitrationpharmaprvPas encore d'évaluation

- Sterilization or Depyrogenation Validation - Non ProductDocument2 pagesSterilization or Depyrogenation Validation - Non ProductananthPas encore d'évaluation

- Injection Wells - An Introduction To Their Use, Operation and RegulationDocument16 pagesInjection Wells - An Introduction To Their Use, Operation and RegulationrakicbgPas encore d'évaluation

- Model M05 Non-Metallic Design Level 2: Service & Operating ManualDocument33 pagesModel M05 Non-Metallic Design Level 2: Service & Operating ManualTrungGVPas encore d'évaluation

- Standard Thermo Data 298 KDocument12 pagesStandard Thermo Data 298 KRebecca FrancisPas encore d'évaluation