Académique Documents

Professionnel Documents

Culture Documents

VT Acceptance (ASME B31.1-2012) PDF

Transféré par

Phan Minh PhungTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

VT Acceptance (ASME B31.1-2012) PDF

Transféré par

Phan Minh PhungDroits d'auteur :

Formats disponibles

ASME B31.

1-2012

(B) on-the-job training to familiarize the NDE person- performed to verify that all completed welds in pipe

nel with the appearance and interpretation of indica- and piping components comply with the acceptance

tions of weld defects. The length of time for such training standards specified in (A) below or with the limitations

shall be sufficient to ensure adequate assimilation of the on imperfections specified in the material specification

knowledge required. under which the pipe or component was furnished.

(C) an eye examination performed at least once each (A) Acceptance Standards. The following indications

year to determine optical capability of NDE personnel are unacceptable:

to perform the required examinations. (A.1) cracks — external surface.

(D) upon completion of (A) and (B) above, the NDE (A.2) undercut on the surface that is greater than

1

personnel shall be given an oral or written examination ⁄32 in. (1.0 mm) deep, or encroaches on the minimum

and performance examination by the employer to deter- required section thickness.

mine if the NDE personnel are qualified to perform the (A.3) weld reinforcement greater than specified in

required examinations and interpretation of results. Table 127.4.2.

(E) certified NDE personnel whose work has not (A.4) lack of fusion on surface.

included performance of a specific examination method (A.5) incomplete penetration (applies only when

for a period of 1 yr or more shall be recertified by success- inside surface is readily accessible).

fully completing the examination of (D) above and also (A.6) any other linear indications greater than 3⁄16 in.

passing the visual examination of (C) above. Substantial (5.0 mm) long.

changes in procedures or equipment shall require recer- (A.7) surface porosity with rounded indications

tification of the NDE personnel. having dimensions greater than 3⁄16 in. (5.0 mm) or four

As an alternative to the preceding program, the or more rounded indications separated by 1⁄1 6 in.

requirements of the ASME Boiler and Pressure Vessel (2.0 mm) or less edge to edge in any direction. Rounded

Code, Section V, Article 1 may be used for the qualifica- indications are indications that are circular or elliptical

tion of NDE personnel. Personnel qualified to AWS QC1 with their length less than three times their width.

may be used for the visual examination of welds.

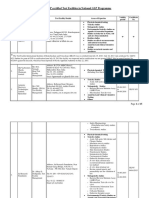

136.4.3 Magnetic Particle Examination. Whenever

136.4 Examination Methods of Welds required by this Chapter (see Table 136.4), magnetic

particle examination shall be performed in accordance

136.4.1 Nondestructive Examination. Nondestruc- with the methods of Article 7, Section V, of the ASME

tive examinations shall be performed in accordance with Boiler and Pressure Vessel Code.

the requirements of this Chapter. The types and extent (A) Evaluation of Indications

of mandatory examinations for pressure welds and (A.1) Mechanical discontinuities at the surface will

welds to pressure retaining components are specified be indicated by the retention of the examination

in Table 136.4. For welds other than those covered by medium. All indications are not necessarily defects;

Table 136.4, only visual examination is required. Welds however, certain metallurgical discontinuities and mag-

requiring nondestructive examination shall comply with netic permeability variations may produce similar indi-

the applicable acceptance standards for indications as cations that are not relevant to the detection of

specified in paras. 136.4.2 through 136.4.6. As a guide, unacceptable discontinuities.

the detection capabilities for the examination method

(A.2) Any indication that is believed to be nonrele-

are shown in Table 136.4.1. Welds not requiring examina-

vant shall be reexamined to verify whether or not actual

tion (i.e., RT, UT, MT, or PT) by this Code or the engi-

defects are present. Surface conditioning may precede

neering design shall be judged acceptable if they meet

the reexamination. Nonrelevant indications that would

the examination requirements of para. 136.4.2 and the

mask indications of defects are unacceptable.

pressure test requirements specified in para. 137. NDE

(A.3) Relevant indications are those that result from

for P-Nos. 3, 4, 5A, 5B, and 15E material welds shall be

unacceptable mechanical discontinuities. Linear indica-

performed after postweld heat treatment unless directed

tions are those indications in which the length is more

otherwise by engineering design. Required NDE for

than three times the width. Rounded indications are

welds in all other materials may be performed before

indications that are circular or elliptical with the length

or after postweld heat treatment.

less than three times the width.

(12) 136.4.2 Visual Examination. Visual examination as (A.4) An indication of a discontinuity may be larger

defined in para. 100.2 shall be performed in accordance than the discontinuity that causes it; however, the size

--`,,`,`,,`,`,,,,``,``,,,,,``,,,-`-`,,`,,`,`,,`---

with the methods described in Section V, Article 9, of of the indication and not the size of the discontinuity

the ASME Boiler and Pressure Vessel Code. Visual exam- is the basis of acceptance or rejection.

inations may be conducted, as necessary, during the (B) Acceptance Standards. Indications whose major

fabrication and erection of piping components to pro- dimensions are greater than 1⁄16 in. (2.0 mm) shall be

vide verification that the design and WPS requirements considered relevant. The following relevant indications

are being met. In addition, visual examination shall be are unacceptable:

104

Vous aimerez peut-être aussi

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsD'EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsÉvaluation : 5 sur 5 étoiles5/5 (1)

- 136.4.2 Visual ExaminationDocument1 page136.4.2 Visual ExaminationrohimPas encore d'évaluation

- Visual Examination B31.1Document2 pagesVisual Examination B31.1PamungkasPas encore d'évaluation

- Mandatory Appendix 6 MTDocument2 pagesMandatory Appendix 6 MTTahar DabbarPas encore d'évaluation

- Páginas Desde ASME VIII - DIV.1Document2 pagesPáginas Desde ASME VIII - DIV.1daniel_break_1Pas encore d'évaluation

- UT Acceptance Criteria 10062019Document1 pageUT Acceptance Criteria 10062019Balkishan DyavanapellyPas encore d'évaluation

- Asme B 31.1Document4 pagesAsme B 31.1Md Ashikur Rahman100% (1)

- Art 6 - MTDocument2 pagesArt 6 - MTcosme fulanitoPas encore d'évaluation

- B31.1 Weld Insp.Document3 pagesB31.1 Weld Insp.Ivan AlanizPas encore d'évaluation

- Asme Viii - MT Apendix 6Document2 pagesAsme Viii - MT Apendix 6abu faizPas encore d'évaluation

- Asme Viii - Mandatoryappendix 6 - MTDocument2 pagesAsme Viii - Mandatoryappendix 6 - MTDjamelPas encore d'évaluation

- Asme Sec Viii D1 Ma App 6Document2 pagesAsme Sec Viii D1 Ma App 6ADRIANPas encore d'évaluation

- 2013 Asme VIII Acceptance CriteriaDocument8 pages2013 Asme VIII Acceptance CriteriaSiggy LaiPas encore d'évaluation

- Mandatory Appendix 12 Ultrasonic Examination of Welds (Ut) : 12-1 SCOPEDocument1 pageMandatory Appendix 12 Ultrasonic Examination of Welds (Ut) : 12-1 SCOPESefa yıldızPas encore d'évaluation

- Asme Sec Viii D1 Ma App 12Document1 pageAsme Sec Viii D1 Ma App 12Marco100% (1)

- Asme VIII d1 Ma Appendix 8 PDFDocument2 pagesAsme VIII d1 Ma Appendix 8 PDFedisjdavPas encore d'évaluation

- Asme Viii - Mandatoryappendix 12 - UtDocument1 pageAsme Viii - Mandatoryappendix 12 - UtDjamelPas encore d'évaluation

- Asme B31 1 PDFDocument331 pagesAsme B31 1 PDFjulian100% (2)

- 6.ASME Section VIII, Man App 8 (2010)Document2 pages6.ASME Section VIII, Man App 8 (2010)NDT GMFPas encore d'évaluation

- A 903 A 903M 99 R03 Qtkwmy9botaztq PDFDocument2 pagesA 903 A 903M 99 R03 Qtkwmy9botaztq PDFaliodormanoleaPas encore d'évaluation

- Sa 435Document3 pagesSa 435KHALED OSMANPas encore d'évaluation

- ASME Sec VIII d1 Ma App 8Document2 pagesASME Sec VIII d1 Ma App 8fuihiufhPas encore d'évaluation

- A 903 - A 903M - 99 Qtkwmy05oqDocument2 pagesA 903 - A 903M - 99 Qtkwmy05oqrolando cuadro blancoPas encore d'évaluation

- Paut - Articulo en El Nbic Magazine - Wi2021Document4 pagesPaut - Articulo en El Nbic Magazine - Wi2021Martin Urriza VelazquezPas encore d'évaluation

- RESSUAGEDocument2 pagesRESSUAGELNCI MEHDI EL MIRPas encore d'évaluation

- Es 48Document6 pagesEs 48Chris SchnurchPas encore d'évaluation

- Astm 903Document2 pagesAstm 903MIRAmira100% (1)

- ASME BPVC Section V (526-530)Document5 pagesASME BPVC Section V (526-530)Reza Elang HangkosoPas encore d'évaluation

- ASTM D 4417-14 Medicion de Rugosidad PDFDocument4 pagesASTM D 4417-14 Medicion de Rugosidad PDF1zorro1Pas encore d'évaluation

- Closure Weld RequirementsDocument1 pageClosure Weld RequirementsManzar Khan0% (1)

- Asme2a Sa 388Document8 pagesAsme2a Sa 388Dipankar ChakrabortyPas encore d'évaluation

- Codecase 181 2Document4 pagesCodecase 181 2enemesioPas encore d'évaluation

- PFI - ES - 48 - 2008 - Random ExaminationsDocument5 pagesPFI - ES - 48 - 2008 - Random Examinationsespluisjavier100% (1)

- Use of The Ultrasonic Time of Flight Diffraction (TOFD) TechniqueDocument12 pagesUse of The Ultrasonic Time of Flight Diffraction (TOFD) TechniqueDavidMontillaPas encore d'évaluation

- Straight-Beam Ultrasonic Examination of Steel Plates: Standard Specification ForDocument2 pagesStraight-Beam Ultrasonic Examination of Steel Plates: Standard Specification ForRod RoperPas encore d'évaluation

- Astm D 4417-14Document4 pagesAstm D 4417-14Renato100% (1)

- Standard Practice For Ultrasonic Examination of Austenitic Steel ForgingsDocument6 pagesStandard Practice For Ultrasonic Examination of Austenitic Steel ForgingssyyouPas encore d'évaluation

- Api 510 - Vol 4 - Part 1 - Asme Sec.v-ExtractsDocument39 pagesApi 510 - Vol 4 - Part 1 - Asme Sec.v-Extractsmohamed nasrPas encore d'évaluation

- Ac43.13-1b Eddy CurrentDocument4 pagesAc43.13-1b Eddy CurrentByronPas encore d'évaluation

- 101391t 6537cf10c27f4Document6 pages101391t 6537cf10c27f4Cristian MendozaPas encore d'évaluation

- ASME VIII - DIV.3 (2019) PAUT-ToFDDocument16 pagesASME VIII - DIV.3 (2019) PAUT-ToFDMubeenPas encore d'évaluation

- Sspc-Pa 17-2012Document7 pagesSspc-Pa 17-2012ALEXIS MARTINEZ100% (1)

- AstmDocument6 pagesAstmBagas Bayu BharataPas encore d'évaluation

- Nepalese Civil Airworthiness Requirements Section D Approval ProceduresDocument3 pagesNepalese Civil Airworthiness Requirements Section D Approval ProceduresSantosh SahPas encore d'évaluation

- Sa 388Document8 pagesSa 388Widya widyaPas encore d'évaluation

- Sep 1922 enDocument7 pagesSep 1922 enIngo Becker100% (2)

- General Requirements For Ultrasonic ExaminationsDocument11 pagesGeneral Requirements For Ultrasonic ExaminationsmaheshPas encore d'évaluation

- ASME Sec Viii MTDocument2 pagesASME Sec Viii MTrashid isaarPas encore d'évaluation

- SB 548Document5 pagesSB 548Edson Julio S RPas encore d'évaluation

- Standard Practice For Ultrasonic Examination of Heavy Steel ForgingsDocument6 pagesStandard Practice For Ultrasonic Examination of Heavy Steel ForgingsSTRUCPIPE CALIDAD100% (1)

- Standard Specification F R ST Aight - Beam Ultrasonic Exa Ination of Steel PlatesDocument3 pagesStandard Specification F R ST Aight - Beam Ultrasonic Exa Ination of Steel Platesanon_935140585Pas encore d'évaluation

- Asme B31.3-2016 CC 181Document3 pagesAsme B31.3-2016 CC 181MubeenPas encore d'évaluation

- QW-191.2 Ultrasonic ExaminationDocument1 pageQW-191.2 Ultrasonic ExaminationJuan ortega castellarPas encore d'évaluation

- Flexural Strength of Concrete (Using Simple Beam With Center-Point Loading)Document3 pagesFlexural Strength of Concrete (Using Simple Beam With Center-Point Loading)RajuNSanaboinaPas encore d'évaluation

- Article 9 Visual ExaminationDocument3 pagesArticle 9 Visual Examinationpriesblack12Pas encore d'évaluation

- Asme Section 8 Div 1 - RTDocument12 pagesAsme Section 8 Div 1 - RTGulfnde Industrial ServicePas encore d'évaluation

- Asme Sec Viii Div 1 Uw-51Document1 pageAsme Sec Viii Div 1 Uw-51ALEXIS MORALESPas encore d'évaluation

- NASA PRC-6503 Rev C Radiographic InspectionDocument8 pagesNASA PRC-6503 Rev C Radiographic InspectionLi-chung JeaPas encore d'évaluation

- ASME 2017 - Section V ARTICLE4 CALIFDocument2 pagesASME 2017 - Section V ARTICLE4 CALIFJ.CarrascoPas encore d'évaluation

- Introduction To Pharmacy ReviewerDocument4 pagesIntroduction To Pharmacy ReviewerMaiah Dinglasan0% (1)

- NMDTM PhosphoricAcidDocument10 pagesNMDTM PhosphoricAcidacas35Pas encore d'évaluation

- Ijbs 4 89Document8 pagesIjbs 4 89Francisco SalgadoPas encore d'évaluation

- Purlin LysaghtDocument6 pagesPurlin LysaghtAnonymous MHMqCrzgTPas encore d'évaluation

- Seperator Design, K C Foong PDFDocument7 pagesSeperator Design, K C Foong PDFpomaukPas encore d'évaluation

- Crystallography and Mineralogy NotesDocument220 pagesCrystallography and Mineralogy NotesSyed Aquib ShamshadPas encore d'évaluation

- A2H Actuator CatalogDocument6 pagesA2H Actuator CatalogahnafPas encore d'évaluation

- United States Patent (10) Patent No.: US 7,806,945 B2: The To In... TDocument21 pagesUnited States Patent (10) Patent No.: US 7,806,945 B2: The To In... TesiPas encore d'évaluation

- Body FluidsDocument10 pagesBody FluidsShashwat Jindal100% (1)

- New List of GLP Approved LabsDocument15 pagesNew List of GLP Approved LabsMulayam Singh YadavPas encore d'évaluation

- Preparation of Reagents & Aseptic TechniquesDocument21 pagesPreparation of Reagents & Aseptic TechniquesReylen OracionPas encore d'évaluation

- Phenguard™ 935: Product Data SheetDocument6 pagesPhenguard™ 935: Product Data SheetMuthuKumarPas encore d'évaluation

- Additives in Australian FoodsDocument11 pagesAdditives in Australian FoodsSarah AnnesleyPas encore d'évaluation

- Safety and Health Topics - Hydrogen Sulfide - Evaluating and Controlling ExposureDocument3 pagesSafety and Health Topics - Hydrogen Sulfide - Evaluating and Controlling ExposurehazopmanPas encore d'évaluation

- STD 154 PDFDocument55 pagesSTD 154 PDFDiwakar Nigam100% (1)

- Reverse Osmosis R12-Wall Mount Installation InstructionsDocument15 pagesReverse Osmosis R12-Wall Mount Installation InstructionsWattsPas encore d'évaluation

- ವಿಜ್ಞಾನ ಪ್ರಯೋಗಾಲಯ ಉಪಕರಣಗಳುDocument4 pagesವಿಜ್ಞಾನ ಪ್ರಯೋಗಾಲಯ ಉಪಕರಣಗಳುghshmkadiwalinamPas encore d'évaluation

- Hdpe SK 6100Document1 pageHdpe SK 6100Le Minh TuanPas encore d'évaluation

- Ecomax Front Loading DishwashersDocument4 pagesEcomax Front Loading Dishwashersrichard9982Pas encore d'évaluation

- AC178 InterimCriteriaforInspectionandVerificationofConcreteandReinforcedandUnreinforcedMasonryusingFRPDocument7 pagesAC178 InterimCriteriaforInspectionandVerificationofConcreteandReinforcedandUnreinforcedMasonryusingFRPBayram AygunPas encore d'évaluation

- 40MF End Suction BrochureDocument4 pages40MF End Suction Brochurerhusseinpos4765Pas encore d'évaluation

- USP Betamethasone MMDocument5 pagesUSP Betamethasone MMThai HocPas encore d'évaluation

- 1267497350933Document18 pages1267497350933anon_166797875Pas encore d'évaluation

- 10 1016@j Apenergy 2019 114135 PDFDocument12 pages10 1016@j Apenergy 2019 114135 PDFKevin Solórzano MacénPas encore d'évaluation

- STRUCTURE OF ATOMS - DoneDocument16 pagesSTRUCTURE OF ATOMS - DoneRaghvendra ShrivastavaPas encore d'évaluation

- Mixture ProblemsDocument15 pagesMixture ProblemsAngelica BascoPas encore d'évaluation

- Coordination CompoundDocument76 pagesCoordination Compoundashok pradhanPas encore d'évaluation

- NCERT Exemplar Problems For Solid State Class XIIDocument16 pagesNCERT Exemplar Problems For Solid State Class XIISuparnaPas encore d'évaluation

- Eucalyptus CamadulensisDocument12 pagesEucalyptus Camadulensismagdy edreesPas encore d'évaluation

- Saxophone Mouthpiece Materials - Part 1: by Theo WanneDocument7 pagesSaxophone Mouthpiece Materials - Part 1: by Theo WanneAprillePas encore d'évaluation