Académique Documents

Professionnel Documents

Culture Documents

Liquid Epoxy Type E: Force-Cure Epoxy For Superior 3-Layer Corrosion Protection

Transféré par

amirhossein0 évaluation0% ont trouvé ce document utile (0 vote)

139 vues2 pagesCanusa type e primer tds

Titre original

PDS_NA_Type_E

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentCanusa type e primer tds

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

139 vues2 pagesLiquid Epoxy Type E: Force-Cure Epoxy For Superior 3-Layer Corrosion Protection

Transféré par

amirhosseinCanusa type e primer tds

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

Liquid Epoxy Type E

Force-cure epoxy for superior

3-layer corrosion protection

Canusa Liquid Epoxy Type E is a force cured, two part epoxy

used as the primary layer with Canusa 3-layer systems, such as

GTS-PE and GTS-65. Usage of Canusa’s proven method of force

curing enables the installer to “pre-inspect” the joint prior to sleeve

application. This provides the assurance that the pipe is fully

protected and it will not be displaced and exposed to corrosive

contaminates during the aligning and shrinking stages of the sleeve

installation. It is composed of a specially formulated 100% solids

epoxy system, which does not use any volatile solvents. This ensures

that the thickness of the epoxy layer does not change as it cures.

Applications

Coating Continuity Oil & Gas

• The Liquid Epoxy Type E layer offers equivalent corrosion protection

to the FBE primary layer in 3 layer polyethylene and 3 layer

polypropylene mainline coated pipelines Offshore Pipelines

Improved Cathodic Disbondment Resistance

• Liquid Epoxy Type E will improve the Cathodic Disbondment Repair & Rehab

resistance results for hotmelt type adhesives when compared

against bare steel substrate.

Superior Force Cured Epoxy High Temperature

• Using Canusa’s proven method of force curing the epoxy to the

steel allows the installer to “pre-inspect” the joint prior to sleeve

installation.

Saves Time

• The improved chemical bonding that is achieved from the adhesive

to the force cured epoxy layer allows for reduced sleeve installation

times due to lower heat requirements.

PRODUCT DATA SHEET canusacps.com

The product information

shown here is intended as a guide

Liquid Epoxy Type E for standard products.

Consult your Canusa

Force-cure epoxy for superior 3-layer corrosion representative for specific

projects or unique applications.

protection

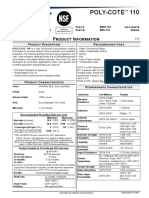

Performance Characteristics E E-HB

Mixing Ratio 4:1 (by volume) 3:1 (by volume)

Percent Solids 100% 100%

1.57 ± 0.05 (Base) 1.49 ± 0.05 (Base)

Specific Gravity

1.04 ± 0.05 (Cure) 1.04 ± 0.05 (Cure)

14,000 ± 10% cps (Base) 68,000 ± 20% cps (Base)

Viscosity

800 ± 20% cps (Cure) 18,000 ± 20% cps (Cure)

Typical Coating Thickness 6 mils 10 mils

Number of coats One One

18 minutes @ 23°C 10 minutes @ 23°C Canusa-CPS

Pot Life Pot life decreases with Pot life decreases with A division of Shawcor Ltd.

temperature. temperature.

Head Office

3 years @ 23°C, out of direct sunlight.

Shelf Life 25 Bethridge Road

Shelf life decreases with temperature. Toronto, ON, Canada M9W 1M7

Tel: +1 416 743 7111

Minimum Curing Temperature 10°C 10°C Fax: +1 416 743 5927

Canada

Calculation of Liquid Epoxy Type E Quantity Required

Dome Tower St. 2200, 333-7th Avenue SW

Calgary, AB, Canada T2P 2Z1

Bare Steel Surface Area

Circumference (m) * Cutback length (mm) / 1000 Tel: +1 403 218 8207

(square meter)

Fax: +1 403 264 3649

Required Volume of Bare Steel Surface Area * Thickness (microns) / 1000000 *

Americas

Liquid Epoxy Type E (Liter) [(1+Wastage Factor¹/100) * 1000]

5875 N. Sam Houston Pkwy W., Suite 200

Houston, TX, USA 77086

Total Required Number of Kits Required Volume of Liquid Epoxy Type E / 0.170

Tel: +1 281 886 2350

Fax: +1 281 886 2353

Typical Quantity of 170 ml Liquid Epoxy Type E kits required by Pipe Size²

Middle East

ADPC - Mussafah Port, P.O. Box 2621

4.5” to 22” One Abu Dhabi, UAE

Tel: +971 2 496 3500

24” to 42” Two Fax: +971 2 496 3501

Europe, Africa & Russia

44” to 60” Three Dellaertweg 9-E, Gebouw “Le Carrefour”

2316 WZ Leiden, The Netherlands (NL)

¹ Typical Wastage Factor: 25-50% Tel: +31 71 80 802 70

² Based on a 300 mm wide cut back with 6 mils average thickness and typical wastage Fax: +31 71 80 802 71

Asia-Pacific

Epoxy Consumption is based on the following variables and will differ

101 Thomson Road, #11-03 United Square

between applications: 307591 Singapore

Tel: +65 6749 8918

• Applicator Type (roller or sponge) • Surface Profile Fax: +65 6749 8919

• Applicator Skill • Pipeline Layout Quality Management system

registered to ISO 9001

Safety Canusa warrants that the product conforms to its

chemical and physical description and is appropriate

for the use stated on the product data sheet when

Handle with care. Before and during use, observe all safety labels on packaging used in compliance with Canusa’s written instructions.

Since many installation factors are beyond our control,

containers, consult with Canusa-CPS Material Safety Data Sheets and abide by all the user shall determine the suitability of the products

for the intended use and assume all risks and liabilities

local or national safety regulations. in connection therewith. Canusa’s liability is stated

in the standard terms and conditions of sale. Canusa

makes no other warranty either expressed or implied.

Since 1967, Canusa-CPS has been a leading developer and manufacturer of specialty pipeline coatings All information contained in this data sheet is to be

used as a guide and is subject to change without

for the sealing and corrosion protection of pipeline joints and other substrates. Canusa-CPS high notice. This data sheet supersedes all previous data

sheets on this product. E&OE

performance products are manufactured to the highest quality standards and are available in a number

of configurations to accommodate many specific project applications. PDS_Epoxy(E)_rev020

Vous aimerez peut-être aussi

- Parche CRP 65 - Ficha Técnica - en InglesDocument2 pagesParche CRP 65 - Ficha Técnica - en IngleserwinvillarPas encore d'évaluation

- Cote LDocument1 pageCote Lalvarado.hdez05Pas encore d'évaluation

- Pds Covalence Htlp60 v1 Oct14 Aarps 0193Document2 pagesPds Covalence Htlp60 v1 Oct14 Aarps 0193pepePas encore d'évaluation

- Scotchweld EC 2216BADocument8 pagesScotchweld EC 2216BAbenPas encore d'évaluation

- PDS - NA - PRP Repair Data SheetDocument2 pagesPDS - NA - PRP Repair Data SheetHendra AwanPas encore d'évaluation

- Reinforcekit Beam Fiche TechniqueDocument24 pagesReinforcekit Beam Fiche TechniqueAmel RADJEFPas encore d'évaluation

- Description Features and CharacteristicsDocument2 pagesDescription Features and CharacteristicsPranpath NarupantawartPas encore d'évaluation

- INDUSTRIAL FLOORING SOLUTIONSDocument24 pagesINDUSTRIAL FLOORING SOLUTIONSchengkkPas encore d'évaluation

- PDS - Na - Klon-KlnnDocument2 pagesPDS - Na - Klon-Klnndemi bajakanPas encore d'évaluation

- Brushable CeramicDocument2 pagesBrushable CeramicDivyanshu GuptaPas encore d'évaluation

- Technical Data Sheet: Epoguard EnamelDocument3 pagesTechnical Data Sheet: Epoguard Enameltrường phạmPas encore d'évaluation

- Sherwin Williams - Heatflex Hi-Temp 1200 DatasheetDocument4 pagesSherwin Williams - Heatflex Hi-Temp 1200 DatasheetAce AcePas encore d'évaluation

- Plastic Steel Putty (A) : Technical Data SheetDocument3 pagesPlastic Steel Putty (A) : Technical Data SheetsanjayPas encore d'évaluation

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraPas encore d'évaluation

- AERC8 Ramset-EpconC8 PDSDocument11 pagesAERC8 Ramset-EpconC8 PDSZilong ZhangPas encore d'évaluation

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAIPas encore d'évaluation

- FBE PowderDocument8 pagesFBE PowderJoseph CortezPas encore d'évaluation

- Hbe-Os: High Build Epoxy Coating For Offshore Corrosion ProtectionDocument2 pagesHbe-Os: High Build Epoxy Coating For Offshore Corrosion Protectionsamkarthik47Pas encore d'évaluation

- HDPE-100 Catalogue PDFDocument9 pagesHDPE-100 Catalogue PDFkumar sandeepPas encore d'évaluation

- EPS Pipe InsulationDocument1 pageEPS Pipe InsulationAlankar Nana Ambwade/Infrastructure Solutions-MEP/MUMBAIPas encore d'évaluation

- 3X-TDS-R4D-ECHT-technical Note PDFDocument2 pages3X-TDS-R4D-ECHT-technical Note PDF今夕何夕Pas encore d'évaluation

- HojaTecnica Heat Flex Hi Temp 1200Document4 pagesHojaTecnica Heat Flex Hi Temp 1200NANCY JASMIN MORENOPas encore d'évaluation

- Urethane Coating 165 PWDocument2 pagesUrethane Coating 165 PWANIBALLOPEZVEGAPas encore d'évaluation

- Ceramic Repair Putty: Technical Data SheetDocument2 pagesCeramic Repair Putty: Technical Data SheetNiku SamarthPas encore d'évaluation

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cPas encore d'évaluation

- Flexcrete 400: Epoxy Polysulfide Elastomeric Coating For Potable Water TanksDocument2 pagesFlexcrete 400: Epoxy Polysulfide Elastomeric Coating For Potable Water TanksSuresh YadavPas encore d'évaluation

- Hbe-Cw: High Build Liquid Coating For Low Temperature ApplicationsDocument2 pagesHbe-Cw: High Build Liquid Coating For Low Temperature ApplicationsMohammad Mehdi JafariPas encore d'évaluation

- DEVCON® Fasmetal 10 HVAC Repair (Special F)Document2 pagesDEVCON® Fasmetal 10 HVAC Repair (Special F)mohamed hamedPas encore d'évaluation

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahPas encore d'évaluation

- Macropoxy 646 PW 2021Document4 pagesMacropoxy 646 PW 2021Jeisson BravoPas encore d'évaluation

- WWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinDocument2 pagesWWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinVinodKandukuriPas encore d'évaluation

- Wrapidcoat PVC: Superior Mechanical ProtectionDocument2 pagesWrapidcoat PVC: Superior Mechanical ProtectioncocoaPas encore d'évaluation

- Carbozinc 608 HB-ProductFlyer - 112817Document2 pagesCarbozinc 608 HB-ProductFlyer - 112817Muhammad Prima JayaPas encore d'évaluation

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisPas encore d'évaluation

- 11 3367 01 Dowsil TC 2035 Adhesive TdsDocument5 pages11 3367 01 Dowsil TC 2035 Adhesive TdsClausio MeloPas encore d'évaluation

- Technical Information: (BR) (WR-2) (Special F)Document1 pageTechnical Information: (BR) (WR-2) (Special F)johnPas encore d'évaluation

- ShaliPoxy CTE 103Document4 pagesShaliPoxy CTE 103Prashant BaruaPas encore d'évaluation

- Ceiling Insulation-k FlexDocument1 pageCeiling Insulation-k FlexdesignPas encore d'évaluation

- 226NDocument2 pages226NUmaibalanPas encore d'évaluation

- Doctor and Roll Cleaning BladesDocument1 pageDoctor and Roll Cleaning BladesbdfeduardoPas encore d'évaluation

- Pricelist: Name TGL UpdateDocument2 pagesPricelist: Name TGL UpdateVina SopianiPas encore d'évaluation

- Dfense Blok™: Technical Data SheetDocument1 pageDfense Blok™: Technical Data SheetjohnPas encore d'évaluation

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthPas encore d'évaluation

- Wrapidcoat PVC: Superior Mechanical ProtectionDocument2 pagesWrapidcoat PVC: Superior Mechanical ProtectionsenthilkumarPas encore d'évaluation

- Wrapidcoat PVC: Superior Mechanical ProtectionDocument2 pagesWrapidcoat PVC: Superior Mechanical ProtectionHendra AwanPas encore d'évaluation

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02Pas encore d'évaluation

- Duraplate 301K - Sherwin WilliamsDocument4 pagesDuraplate 301K - Sherwin WilliamsJardenson CésarPas encore d'évaluation

- Clock Spring Diamond Wrap BrochureDocument2 pagesClock Spring Diamond Wrap BrochuremuhammadxpPas encore d'évaluation

- Web ProductSheet DiamondWrap 2018 PDFDocument2 pagesWeb ProductSheet DiamondWrap 2018 PDFRiankwnPas encore d'évaluation

- HBE-HT High Build Epoxy Coating 150°C PipelinesDocument2 pagesHBE-HT High Build Epoxy Coating 150°C PipelinesdakidofdaboomPas encore d'évaluation

- 1.9.1.2-75B - BondArc WireDocument6 pages1.9.1.2-75B - BondArc WireGiovanni Cervera FerriolPas encore d'évaluation

- CANUSA E Primer PDFDocument2 pagesCANUSA E Primer PDFZainudin100% (1)

- Dfense Blok™: Technical Data SheetDocument1 pageDfense Blok™: Technical Data SheetjohnPas encore d'évaluation

- Industrial Aluminum Paint: Protective & Marine CoatingsDocument4 pagesIndustrial Aluminum Paint: Protective & Marine CoatingsAna CabreraPas encore d'évaluation

- Macropoxy 646 SEDocument4 pagesMacropoxy 646 SESleyda MunozPas encore d'évaluation

- Canusa Flanş Izolasyonu Için Isı Ile Büzüşen Levha Çözümü PDS - NA - HSDocument2 pagesCanusa Flanş Izolasyonu Için Isı Ile Büzüşen Levha Çözümü PDS - NA - HSozcanPas encore d'évaluation

- Cavityrock Cavity Wall and Rainscreen Applications TechdataDocument2 pagesCavityrock Cavity Wall and Rainscreen Applications TechdatadeepscubPas encore d'évaluation

- Plastic Steel 5 Minute PuttyDocument3 pagesPlastic Steel 5 Minute PuttyDivyanshu GuptaPas encore d'évaluation

- Raychem Shrink SleevesDocument12 pagesRaychem Shrink SleevesislamakthamPas encore d'évaluation

- Geotextiles and Geomembranes HandbookD'EverandGeotextiles and Geomembranes HandbookT.S. IngoldÉvaluation : 5 sur 5 étoiles5/5 (1)

- D869 2015Document2 pagesD869 2015mithileshPas encore d'évaluation

- M TP 210Document9 pagesM TP 210amirhosseinPas encore d'évaluation

- Astm D6677-18 6.02Document2 pagesAstm D6677-18 6.02amirhossein100% (3)

- RZ 5215 1Document2 pagesRZ 5215 1amirhosseinPas encore d'évaluation

- @tspkco: Construction: 6x19 / 6x36 Group IWRC Construction: 6x19 / 6x36 Group Fibre Core (Document1 page@tspkco: Construction: 6x19 / 6x36 Group IWRC Construction: 6x19 / 6x36 Group Fibre Core (amirhosseinPas encore d'évaluation

- A 160Document2 pagesA 160amirhosseinPas encore d'évaluation

- Raoult's Law Is A DeceptionDocument2 pagesRaoult's Law Is A DeceptionCarlos VelascoPas encore d'évaluation

- Hard-Wear Concrete FloorsDocument5 pagesHard-Wear Concrete FloorsDimas SaputraPas encore d'évaluation

- Purity of A SubstanceDocument13 pagesPurity of A SubstanceAlly Bin AssadPas encore d'évaluation

- BigMike's PH ManifestoDocument31 pagesBigMike's PH ManifestodalbanwaitPas encore d'évaluation

- Corrosion & Non-Ferrous MetalDocument21 pagesCorrosion & Non-Ferrous Metalsiraphat.bmPas encore d'évaluation

- Flexible PKG Abhay Mulay 19092003Document76 pagesFlexible PKG Abhay Mulay 19092003Ahmad FirdausPas encore d'évaluation

- UNIT III Bulk Deformation ProcessDocument67 pagesUNIT III Bulk Deformation ProcessvigneshPas encore d'évaluation

- Glass Production: From Wikipedia, The Free EncyclopediaDocument10 pagesGlass Production: From Wikipedia, The Free EncyclopediaMahfuzur Rahman SiddikyPas encore d'évaluation

- Encyclopedia of Textile Finishing PDFDocument2 777 pagesEncyclopedia of Textile Finishing PDFFERNANDO JOSE NOVAES100% (1)

- Advance Computational Tools For Cement PlantsDocument16 pagesAdvance Computational Tools For Cement PlantsJomarie GañalongoPas encore d'évaluation

- EXPERIMENT 1.0: Factors Affecting Rate in A Chemical ReactionDocument2 pagesEXPERIMENT 1.0: Factors Affecting Rate in A Chemical ReactionElla NanaPas encore d'évaluation

- Chemical Safety Following The Globally Harmonized System (GHS)Document6 pagesChemical Safety Following The Globally Harmonized System (GHS)Hazel Sanne CachaperoPas encore d'évaluation

- Spalling - KhouryDocument11 pagesSpalling - KhouryMouhaPas encore d'évaluation

- Degafloor NZ Why Degadur Brochure2 PDFDocument8 pagesDegafloor NZ Why Degadur Brochure2 PDFslantsyhimPas encore d'évaluation

- Relationship between Reflux Ratio and Number of PlatesDocument4 pagesRelationship between Reflux Ratio and Number of PlatesAbsar BaigPas encore d'évaluation

- Cold Rolling Mill For Aluminium Sheet: Dr. P. Mallesham, V.V. Ram BabuDocument5 pagesCold Rolling Mill For Aluminium Sheet: Dr. P. Mallesham, V.V. Ram BabuerpublicationPas encore d'évaluation

- Optimal AgricultureDocument9 pagesOptimal AgriculturesamPas encore d'évaluation

- Welding Workshop ManualDocument28 pagesWelding Workshop ManualMADHAV GUPTA 10814-07Pas encore d'évaluation

- Gel RiteDocument12 pagesGel RiteAlonso PomaPas encore d'évaluation

- Manufacturing Processes Lecture: Introduction to Joining TechniquesDocument233 pagesManufacturing Processes Lecture: Introduction to Joining TechniquesThasarathan Ravichandran100% (2)

- GDGT PaperDocument25 pagesGDGT PaperjackPas encore d'évaluation

- Different Proof Methods of Daltons Partial VolumeDocument6 pagesDifferent Proof Methods of Daltons Partial VolumeMuhammad FurqanPas encore d'évaluation

- Chem T6 HLQDocument23 pagesChem T6 HLQStudy TipsPas encore d'évaluation

- A Timeline of Atomic Spectroscopy: Volker ThomsenDocument11 pagesA Timeline of Atomic Spectroscopy: Volker ThomsencamiloPas encore d'évaluation

- Mole Concept Practice Question PaperDocument13 pagesMole Concept Practice Question PaperYasir MohammedPas encore d'évaluation

- June 2015 (IAL) QP - Unit 1 Edexcel Chemistry A-LevelDocument21 pagesJune 2015 (IAL) QP - Unit 1 Edexcel Chemistry A-LevelNabindra RuwaliPas encore d'évaluation

- Bioplastic Foam Net MadeDocument12 pagesBioplastic Foam Net MadeYumi Jackylyn CrimonaPas encore d'évaluation

- Fibre Reinforced ConcreteDocument26 pagesFibre Reinforced ConcreteIswaryaPas encore d'évaluation

- Evaluation of Concrete Structures Affected by Alkali-Silica ReactionDocument59 pagesEvaluation of Concrete Structures Affected by Alkali-Silica ReactionCarlos Augusto Sánchez RondónPas encore d'évaluation

- Eau de Cologne ConcentrationsDocument1 pageEau de Cologne ConcentrationsImma OlayanPas encore d'évaluation