Académique Documents

Professionnel Documents

Culture Documents

en-GB PDF

Transféré par

niyasTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

en-GB PDF

Transféré par

niyasDroits d'auteur :

Formats disponibles

Product Data

HEMPEL'S GALVOSIL 15780

15780: LIQUID 15789: HEMPEL’S ZINC METAL PIGMENT 97170

Description: HEMPEL’S GALVOSIL 15780 is a two-component, medium-zinc, solvent-borne, selfcuring inorganic

zinc silicate coating. Applicable by airless spray.

Hempel's Zinc metal pigment 97170 is in full compliance with ISO 3549 and ASTM D520 type II.

Recommended use: As a general purpose rust-preventing primer in paint systems for long-life protection of steel exposed to

moderately to severely corrosive environment. In compliance with SSPC-Paint 20, type 1, level 2.

Service temperature: Resistant to permanent (non-cyclic) dry temperatures as well as occasionally dry peak temperatures up

to maximum: 500°C/932°F.

It is of advantage to apply a topcoat of HEMPEL'S SILICONE ALUMINIUM 56914 in case of service

temperatures above: 400°C/752°F.

Resistant to cyclic dry temperatures up to 400°C/752°F.

Availability: Part of Group Assortment. Local availability subject to confirmation.

PHYSICAL CONSTANTS:

Shade nos/Colours: 19840 / Metal grey

Finish: Flat

Volume solids, %: 62 ± 1

Theoretical spreading rate: 12.4 m2/l [497.2 sq.ft./US gallon] - 50 micron/2 mils

Flash point: 14 °C [57.2 °F]

Specific gravity: 2.4 kg/litre [20 lbs/US gallon]

Surface-dry: 15 minute(s) 20°C/68°F

Through-dry: 20 minute(s) 20°C/68°F

Fully cured: 16 approx. hour(s) 20°C/68°F (65% RH)

VOC content: 442 g/l [3.7 lbs/US gallon]

Shelf life: 6 months for the LIQUID and 3 years for HEMPEL'S ZINC METAL PIGMENT (stored in closed

container) (25°C/77°F) from time of production.

Shelf life is dependent on storage temperature. Shelf life is reduced at storage temperatures above

25°C/77°F. Do not store above 40°C/104°F. Shelf life is exceeded if the liquid is gelled or if the mixed

product forms gels before application.

- The physical constants stated are nominal data according to the HEMPEL Group's approved formulas.

APPLICATION DETAILS:

Version, mixed product: 15780

Mixing ratio: LIQUID 15789: HEMPEL’S ZINC METAL PIGMENT 97170

4.1 : 5.9 by weight

(by volume - see REMARKS overleaf)

Application method: Airless spray / Air spray / Brush (touch up)

Thinner (max.vol.): [08700 (30%) and/or 0870M (30%) see REMARKS overleaf ]/ 08700 (50%) / 08700 (10%)

Pot life: 4 hour(s) 20°C/68°F

Nozzle orifice: 0.019 - 0.023 "

Nozzle pressure: 100 bar [1450 psi]

(Airless spray data are indicative and subject to adjustment)

Cleaning of tools: HEMPEL'S THINNER 08700

Indicated film thickness, dry: 50 micron [2 mils] see REMARKS overleaf

Indicated film thickness, wet: 75 micron [3 mils]

Overcoat interval, min: According to separate APPLICATION INSTRUCTIONS

Overcoat interval, max: According to separate APPLICATION INSTRUCTIONS

-

Safety: Handle with care. Before and during use, observe all safety labels on packaging and paint containers,

consult HEMPEL Safety Data Sheets and follow all local or national safety regulations.

Date of issue: January 2019 Page: 1/2

Product Data

HEMPEL'S GALVOSIL 15780

SURFACE PREPARATION: Remove oil and grease etc. thoroughly with suitable detergent. Remove salts and other contaminants

by high pressure fresh water cleaning. Abrasive blasting with sharp abrasive to minimum Sa 2½ (ISO

8501-1:2007) with a surface profile equivalent to Rugotest No. 3, BN10, Keane-Tator Comparator, min.

3.0 G/S, or ISO Comparator rough Medium (G). In case of new steel to be exposed to no more than

medium aggressive (industrial) environment and without any extraordinary demands to lifetime, a

surface preparation degree of SSPC-SP6 may suffice.

See separate APPLICATION INSTRUCTIONS

APPLICATION CONDITIONS: The surface must be completely clean and dry at the time of application and its temperature must be

above the dew point to avoid condensation. At temperatures ranging from 0°C/32°F to 40°C/105°F,

curing needs minimum 65% relative humidity and is significally retarded at lower temperatures.

Curing is retarded at lower temperature and lower humidity.

See separate APPLICATION INSTRUCTIONS

SUBSEQUENT COAT: According to specification.

REMARKS: Local adjustments:

Local conditions (e.g. application equipment, climatic application conditions) may require local

adjustments in solvent composition, degree of pre-thinning and degree of pre-hydrolysis for the primer

as supplied. As such adjustments may influence flash point, Hempel’s quality control system requires

separate product numbers and Material safety Data Sheets to be issued, even though the adjustments

have no influence on the properties and performance of the final and cured primer film.

The following product numbers represent such adjustments: HEMPEL'S GALVOSIL 15780K

Induction time: For application at high temperatures, a special thinner is available.

Application(s): When mixing part of the content in a can the mixing ratio on volume should be made as follows: 8.0

parts of the BASE and then add HEMPEL'S ZINC METAL PIGMENT up to a total of 10.00 parts by

volume.

Note: HEMPEL'S GALVOSIL 15780 For professional use only.

ISSUED BY: HEMPEL A/S 1578019840

This Product Data Sheet supersedes those previously issued.

For explanations, definitions and scope, see “Explanatory Notes” available on www.hempel.com. Data, specifications, directions and recommendations given in this data sheet

represent only test results or experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appropriateness under the actual conditions

of any intended use of the Products herein must be determined exclusively by the Buyer and/or User.

The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed

in writing. The Manufacturer and Seller disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence, except as expressed in said

GENERAL CONDITIONS for all results, injury or direct or consequential losses or damages arising from the use of the Products as recommended above, on the overleaf or otherwise.

Product data are subject to change without notice and become void five years from the date of issue.

Date of issue: January 2019 Page: 2/2

Vous aimerez peut-être aussi

- Gel Electrophoresis Lab ReportDocument10 pagesGel Electrophoresis Lab Reportapi-31150900783% (6)

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualD'EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualPas encore d'évaluation

- Mitsubishi Evo Vii Workshop ManualDocument1 471 pagesMitsubishi Evo Vii Workshop ManuallimaynardPas encore d'évaluation

- Syllabus 2012 Singing 20190122Document91 pagesSyllabus 2012 Singing 20190122suzypienaarPas encore d'évaluation

- BC C Punmia BeamDocument14 pagesBC C Punmia BeamvikrantgoudaPas encore d'évaluation

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsD'EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Gulliver's Travels Misogyny or MisanthropyDocument3 pagesGulliver's Travels Misogyny or MisanthropyKingshuk MondalPas encore d'évaluation

- Waste Management in the Chemical and Petroleum IndustriesD'EverandWaste Management in the Chemical and Petroleum IndustriesPas encore d'évaluation

- Filipino Catholic Wedding Ceremony LiturgyDocument8 pagesFilipino Catholic Wedding Ceremony LiturgyHoney Joy ChuaPas encore d'évaluation

- Gas Sweetening and Processing Field ManualD'EverandGas Sweetening and Processing Field ManualÉvaluation : 4 sur 5 étoiles4/5 (7)

- Geotextiles and Geomembranes HandbookD'EverandGeotextiles and Geomembranes HandbookT.S. IngoldÉvaluation : 5 sur 5 étoiles5/5 (1)

- GX Audit Internal Audit Risk and Opportunities For 2022Document26 pagesGX Audit Internal Audit Risk and Opportunities For 2022Muhammad SamiPas encore d'évaluation

- She Walks in BeautyDocument6 pagesShe Walks in Beautyksdnc100% (1)

- Metamath: A Computer Language For Mathematical ProofsDocument247 pagesMetamath: A Computer Language For Mathematical ProofsJohn DoePas encore d'évaluation

- Theories & Models of LearningDocument33 pagesTheories & Models of LearningAna Paulina Suárez CervantesPas encore d'évaluation

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsD'EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsPas encore d'évaluation

- Eight Directions Feng ShuiDocument6 pagesEight Directions Feng Shuifree_scribdPas encore d'évaluation

- Industrial Training (Tarun Kumar) - Final ReprtDocument46 pagesIndustrial Training (Tarun Kumar) - Final ReprtSaumya GargPas encore d'évaluation

- Pds Hempadur Glass Flake 35851 En-GbDocument2 pagesPds Hempadur Glass Flake 35851 En-Gbkalpesh parmarPas encore d'évaluation

- Hempel'S Galvosil 15780: DescriptionDocument2 pagesHempel'S Galvosil 15780: DescriptionEngTamer100% (1)

- Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlD'EverandTheory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlPas encore d'évaluation

- Hempadur 15570Document2 pagesHempadur 15570Edwin HarrisPas encore d'évaluation

- Revit Mep Vs Autocad MepDocument4 pagesRevit Mep Vs Autocad MepAbdelhameed Tarig AlemairyPas encore d'évaluation

- VFTO DocumentationDocument119 pagesVFTO DocumentationSheri Abhishek ReddyPas encore d'évaluation

- Hempadur 85531 PDFDocument2 pagesHempadur 85531 PDFvitharvan0% (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesD'EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- PDS Hempel's Galvosil 15700 en-GBDocument2 pagesPDS Hempel's Galvosil 15700 en-GBbayuPas encore d'évaluation

- Hempels Galvosil 15780Document7 pagesHempels Galvosil 15780Yosses Sang NahkodaPas encore d'évaluation

- Galvosil 15700 DSDocument2 pagesGalvosil 15700 DSIssam TrikiPas encore d'évaluation

- HEMPEL'S GALVOSIL 15790 Product Data SheetDocument2 pagesHEMPEL'S GALVOSIL 15790 Product Data SheetRoberto_PrrPas encore d'évaluation

- PDS 15700Document2 pagesPDS 15700altipatlarPas encore d'évaluation

- Galvosil 15680 Data SheetDocument2 pagesGalvosil 15680 Data Sheetn00b1810Pas encore d'évaluation

- Hempel Shopprimer 15890ZSDocument2 pagesHempel Shopprimer 15890ZSAnuar SalehPas encore d'évaluation

- Hempel Galvosil 1570019840Document2 pagesHempel Galvosil 1570019840Jj OredinaPas encore d'évaluation

- Pds Hempel's Silicone Acrylic 56940 En-GbDocument2 pagesPds Hempel's Silicone Acrylic 56940 En-GbsenthilkumarPas encore d'évaluation

- Pds Hempel's Silicone Aluminium 56914 En-GbDocument2 pagesPds Hempel's Silicone Aluminium 56914 En-GbMatej ZirdumPas encore d'évaluation

- Pds Hempel's Silicone Aluminium 56910 En-GbDocument2 pagesPds Hempel's Silicone Aluminium 56910 En-GbjakelowPas encore d'évaluation

- Product Data: Hempel'S Silicone Zinc 16900Document2 pagesProduct Data: Hempel'S Silicone Zinc 16900Anuar SalehPas encore d'évaluation

- PDS HEMPATHANE ENAMEL 55100 en-GBDocument2 pagesPDS HEMPATHANE ENAMEL 55100 en-GBMohamed NouzerPas encore d'évaluation

- Hempel's Epoxy Resin 05500 Product Data SheetDocument2 pagesHempel's Epoxy Resin 05500 Product Data SheetaymannasserPas encore d'évaluation

- 15780Document7 pages15780khalid764Pas encore d'évaluation

- Hempadur XP 87550: DescriptionDocument2 pagesHempadur XP 87550: DescriptionEngTamer50% (4)

- Hempathane Hs 55610 55610 En-GbDocument2 pagesHempathane Hs 55610 55610 En-GbfaizalPas encore d'évaluation

- PDS Hempel's Silicone Aluminium 56910 en-GBDocument2 pagesPDS Hempel's Silicone Aluminium 56910 en-GBdanishPas encore d'évaluation

- HEMPADUR 47140: DescriptionDocument2 pagesHEMPADUR 47140: DescriptionMashudi FikriPas encore d'évaluation

- HEMPADUR 15400: DescriptionDocument2 pagesHEMPADUR 15400: Descriptionherysyam1980Pas encore d'évaluation

- HEMPADUR 15400: DescriptionDocument2 pagesHEMPADUR 15400: Descriptionherysyam1980Pas encore d'évaluation

- 457GB en-GBDocument2 pages457GB en-GBIbrahim MahranPas encore d'évaluation

- Pds Hempel's 174de En-GbDocument2 pagesPds Hempel's 174de En-GbMark InnesPas encore d'évaluation

- Product DataDocument2 pagesProduct DataVentas SA TabPas encore d'évaluation

- Hempadur 15590Document2 pagesHempadur 15590Yosses Sang NahkodaPas encore d'évaluation

- Fast-Drying Epoxy Primer DataDocument2 pagesFast-Drying Epoxy Primer Datadkdkdkdkdkdk_Pas encore d'évaluation

- HempadurDocument2 pagesHempadurLuciano SalituriPas encore d'évaluation

- Protect Steel Surfaces in Acidic EnvironmentsDocument2 pagesProtect Steel Surfaces in Acidic EnvironmentsJuanda Mardohar Dantec SitompulPas encore d'évaluation

- Hempadur Quattro InglesDocument3 pagesHempadur Quattro InglesElizabeth Maria Bazán MoralesPas encore d'évaluation

- Product DataDocument2 pagesProduct DataegomoPas encore d'évaluation

- Hempel 15700 PDS Promain 24 08 2022Document4 pagesHempel 15700 PDS Promain 24 08 2022Dimitris VythoulkasPas encore d'évaluation

- Defend 740Document2 pagesDefend 740Mohamed NouzerPas encore d'évaluation

- Heavy-Duty Epoxy Coating Product DataDocument2 pagesHeavy-Duty Epoxy Coating Product DataKhyle Laurenz DuroPas encore d'évaluation

- PDFDocument2 pagesPDFMuhammad AsifPas encore d'évaluation

- PDS Hempel's Antifouling Basic 71950 en-GBDocument2 pagesPDS Hempel's Antifouling Basic 71950 en-GBFahri SofianPas encore d'évaluation

- PDS Hempel's Antifouling Olympic 72950 en-GBDocument2 pagesPDS Hempel's Antifouling Olympic 72950 en-GBFahri SofianPas encore d'évaluation

- Hempadur 15130Document2 pagesHempadur 15130MuthuKumarPas encore d'évaluation

- Pds Hempadur Glass Flake 35851 En-GbDocument2 pagesPds Hempadur Glass Flake 35851 En-GbIlham NugrohoPas encore d'évaluation

- Hempadur 15570 15570 En-GbDocument2 pagesHempadur 15570 15570 En-GbgabyorPas encore d'évaluation

- PDS HEMPADUR EASY 47700 en GBDocument3 pagesPDS HEMPADUR EASY 47700 en GBharshana divankaPas encore d'évaluation

- Product DataDocument2 pagesProduct DatapoerwntiPas encore d'évaluation

- PDS HEMUCRYL ENAMEL HI-BUILD 58030 en-GBDocument2 pagesPDS HEMUCRYL ENAMEL HI-BUILD 58030 en-GBFreddy Carl FredricksenPas encore d'évaluation

- Hempadur 85530Document2 pagesHempadur 85530kumarnowabuPas encore d'évaluation

- Product Data: Hempel's Antifouling Olympic Protect+Document2 pagesProduct Data: Hempel's Antifouling Olympic Protect+ululPas encore d'évaluation

- Pds Hempathane Topcoat 55210 En-GbDocument2 pagesPds Hempathane Topcoat 55210 En-GbDoni HardiPas encore d'évaluation

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Applications of Ionic Liquids in the Oil Industry: Towards A Sustainable IndustryD'EverandApplications of Ionic Liquids in the Oil Industry: Towards A Sustainable IndustryPas encore d'évaluation

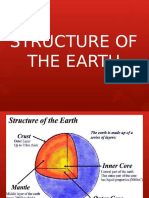

- Earth's StructureDocument10 pagesEarth's StructureMaitum Gemark BalazonPas encore d'évaluation

- Lab No.7: Measurement of Coupling Coefficient, Directivity and Insertion Loss of A Directional CouplerDocument3 pagesLab No.7: Measurement of Coupling Coefficient, Directivity and Insertion Loss of A Directional CouplerM. Ahmad RazaPas encore d'évaluation

- Rebecca A. Endaya Beed-Iii Art Education: ExploreDocument5 pagesRebecca A. Endaya Beed-Iii Art Education: ExploreBhecca Endaya0% (1)

- Rabuddha HarataDocument67 pagesRabuddha HaratasagggasgfaPas encore d'évaluation

- ICJ Judgment on Philippines' Bid to Intervene in Indonesia-Malaysia Maritime Boundary CaseDocument8 pagesICJ Judgment on Philippines' Bid to Intervene in Indonesia-Malaysia Maritime Boundary CaseZayd Iskandar Dzolkarnain Al-Hadrami100% (1)

- FDocument109 pagesFssissaaPas encore d'évaluation

- Analyzing Visual TextsDocument4 pagesAnalyzing Visual Textsapi-582845240Pas encore d'évaluation

- Odoo Video Conference User GuidesDocument12 pagesOdoo Video Conference User GuidesZeus TitanPas encore d'évaluation

- MirazDocument1 pageMirazTatat PatrianiPas encore d'évaluation

- Literature Review BUS 507 PDFDocument18 pagesLiterature Review BUS 507 PDFtanmoy8554Pas encore d'évaluation

- Optimize Your Portfolio With Modern TheoriesDocument65 pagesOptimize Your Portfolio With Modern Theoriesastro9jyotish9asim9mPas encore d'évaluation

- Data Sheet 6EP1457-3BA00: InputDocument4 pagesData Sheet 6EP1457-3BA00: InputSeyyed Amir MohmmadiPas encore d'évaluation

- Oracle Fusion Middleware: CloningDocument25 pagesOracle Fusion Middleware: CloningSwathiPatluriPas encore d'évaluation

- Anselm's Ontological Argument ExplainedDocument8 pagesAnselm's Ontological Argument ExplainedCharles NunezPas encore d'évaluation

- Key-Words: - Techniques, Reflection, Corporal Punishment, EffectiveDocument7 pagesKey-Words: - Techniques, Reflection, Corporal Punishment, EffectiveManawPas encore d'évaluation

- IT Department - JdsDocument2 pagesIT Department - JdsShahid NadeemPas encore d'évaluation