Académique Documents

Professionnel Documents

Culture Documents

Product Information: Tectyl™ 121-LV

Transféré par

Ravi GurugeTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Product Information: Tectyl™ 121-LV

Transféré par

Ravi GurugeDroits d'auteur :

Formats disponibles

PRODUCT INFORMATION

Valvoline Performance Products – Tectyl

Version: TE016/01

Tectyl™ 121-LV

Premium wax/asphaltic based, corrosion preventive underbody coating.

TECTYL 121-LV is a filled, solvent cutback wax/asphaltic base, thixotropic, corrosion

preventive compound.

TECTYL 121-LV is suitable for the complete undercoating of undersides of autos, trucks,

buses, truck trailers, camp trailers, heavy construction equipment and cargo containers.

TECTYL 121-LV is very suitable as a coating in industrial constructions of ovens and

chimneys, where high temperatures and in between periods under the dew point can occur.

TECTYL 121-LV dries to a firm, black, resilient, tough and abrasion resistant film .

Approvals/Performance levels Applications

Tectyl 121-LV Surface preparation:

The maximum performance of TECTYL 121-LV can

Accelerated Corrosion tests: be achieved only when the metal surfaces to be

@ Average recommended DFT protected are clean, dry and free of rust, oil and mill

scale. Avoid direct contact of the product with PVC

Accelerated Corrosion tests: due to possible material incompatibility.

Salt Spray; 5 % NaCl @ 35°C; ISO 9227 NSS

(Q-Panels, Type R, ASTM A1008) Application:

40+ days TECTYL 121-LV is formulated to be used as

Humidity; 100 % RH; @ 40°C; ISO 6270-2 CH supplied. It is recommended that the ambient and

(Q-Panels, Type R, ASTM A1008) product temperature be 10-35 °C at the time of

100+ days product application. TECTYL 121-LV can be applied

by airless spray or brush.

Estimated Protection Period

Removal:

TECTYL 121-LV can be removed with mineral spirits

Indoor: 36 months or any similar petroleum solvent, vapor degreasing,

Outdoor: 21 months hot alkaline wash or low pressure steam. Also Tectyl

Biocleaner can be used to remove Tectyl 121-LV.

Features & Benefits

Protection at high temperatures Processing

Tectyl 121-LV is very suitable as a protective coating in Tectyl 121-LV is an easy to apply, elastic,

areas where high temperatures in combination with protective underbody coating.

periods under the dew point occur.

Multiple substrates

Multi-functional The underbody coating can also be used on

Tectyl 121-LV can be applied on many different vehicles, different substrates, such as the wooden

such as cars, trucks, busses, campers and construction underside of a camper of caravan.

equipment, but also trailers and caravans.

PRODUCT INFORMATION

Trusted since 1930 Health & Safety

Since 1930, Tectyl™ protective coatings have This product is not likely to present any

been extending the operational life of cars, significant health or safety hazards when properly

trucks, buses and other vehicles and equipment. used in the recommended application and good

The Tectyl name is synonymous with quality standards of personal hygiene are maintained.

coatings that are easy to apply, long-lasting and Reference is made to the Safety Data Sheet

easy to remove when no longer required. (SDS) which is available on request via your local

sales office or via the internet

For more information on Tectyl products, http://sds.valvoline.com

programs and services please visit

www.tectyl-europe.com Protect the environment

Comply with local regulations. Comply with local

regulations. Do not discharge into drains, soil or

Typical properties water.

Typical property characteristics are based on

current production. Whilst future production will Storage

conform to Tectyl specifications, variations in Tectyl 121-LV should be stored at temperatures

these characteristics may occur. between 10-35 °C. Mild agitation is

recommended prior to use. Due to its

Tectyl 121-LV composition Tectyl 121-LV can be subject to

Flash Point, PMCC [ºC] 40 postproduction viscosity changes during storage.

Density @ 20°C [kg/ltr] 1,03 Under proper storage conditions Tectyl 121-LV is

Recommended Dry Film best before 36 months after production date.

Thickness over metal profile 250

Caution

[microns]

Adequate ventilation is required for cure and to

Theoretical coverage @ 2,1 ensure against formation of combustible liquid.

recommended DFT [m²/ltr] THE PARTIALLY CURED FILM SHOULD NOT

Non Volatile [weight %] 65 BE EXPOSED TO IGNITION SOURCES

Drop melting Point (non volatile > 200 SUCH AS FLARES, FLAMES, SPARKS,

part) [°C] EXCESSIVE HEAT OR TORCHES. Refer to

Viscosity; Brookfield @ 25°C The Safety Data Sheet for additional handling

@ 2 RPM [mPa.s] [cP] 30.000 and first aid information.

@ 20 RPM [mPa.s] [cP] 8.000

Note

Dry to touch time @ 20°C [hours] 3 The addition of any product over or under this

Cure time @ 20°C [hours] 24 coating is not recommended. The use of

additional coatings could result in chemical

Volatile Organic Compound

incompatibility, thus affecting the performance of

Content ISO 11890-2 (10.4) [g/ltr] 354 this coating as stated in the Typical Properties

section. If a primer, other than a Valvoline

This information only applies to products recommended product is required, written

manufactured in the following location(s): authorization must be obtained from Valvoline.

Europe

Replaces –

™ Trademark of Valvoline, registered in various countries © 2017

All statements, information and data presented herein are believed to be accurate and reliable, but are not to be taken as a guarantee, an express warranty,

or an implied warranty of merchantability or fitness for a particular purpose, or representation, express or implied, for which Ellis Enterprises B.V. and its

affiliates assume legal responsibility.

Vous aimerez peut-être aussi

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesD'EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Shelf Life ControlDocument7 pagesShelf Life ControlRushikesh Deshpande100% (1)

- Eur Val Tectyl502c CTG Tec enDocument2 pagesEur Val Tectyl502c CTG Tec ennathansta61Pas encore d'évaluation

- Produktinformation Tectyl 506 G TE033 01Document2 pagesProduktinformation Tectyl 506 G TE033 01HDSC ChemicalsPas encore d'évaluation

- Product Information: Tectyl™ 502-CDocument2 pagesProduct Information: Tectyl™ 502-CnicusebpPas encore d'évaluation

- PI - Tectyl 506 WD - TE034 01Document2 pagesPI - Tectyl 506 WD - TE034 01jlplazaolaPas encore d'évaluation

- PI Tectyl-506 TE031-01Document2 pagesPI Tectyl-506 TE031-01nicusebpPas encore d'évaluation

- Eur Val Tectyl506eh CTG Tec enDocument2 pagesEur Val Tectyl506eh CTG Tec ennathansta61Pas encore d'évaluation

- Product Information: Tectyl™ 506-EHDocument2 pagesProduct Information: Tectyl™ 506-EHrakeshPas encore d'évaluation

- EUR Val TectylMultiPurpose506 CTG TEC ENDocument2 pagesEUR Val TectylMultiPurpose506 CTG TEC ENbouwersPas encore d'évaluation

- Tectyl 502CDocument2 pagesTectyl 502Cmoinu85Pas encore d'évaluation

- Tectyl 121 LVDocument2 pagesTectyl 121 LVRafiPas encore d'évaluation

- CC-3122 Conformal CoatingDocument3 pagesCC-3122 Conformal Coatingquang trinhPas encore d'évaluation

- Tds Polybit-Polypoxy-Ct en MeaDocument2 pagesTds Polybit-Polypoxy-Ct en Meakhaleejdubai jubailPas encore d'évaluation

- Hyperdesmo Polyurea 2K HCDocument3 pagesHyperdesmo Polyurea 2K HCmeena nachiyarPas encore d'évaluation

- Rooftite AC5Document2 pagesRooftite AC5Anas SalamaPas encore d'évaluation

- Shell Tellus S2 M 100: Performance, Features & BenefitsDocument3 pagesShell Tellus S2 M 100: Performance, Features & BenefitsMuhtiar DarjaPas encore d'évaluation

- Tectyl 502c c2 TdsDocument2 pagesTectyl 502c c2 TdspoklePas encore d'évaluation

- MOLYKOTE 112 High Consistency Valve SealantDocument2 pagesMOLYKOTE 112 High Consistency Valve SealantLuz Angela GuerreroPas encore d'évaluation

- Printed in FranceDocument9 pagesPrinted in FranceYusron AzharyPas encore d'évaluation

- Tectyl 472 PDFDocument2 pagesTectyl 472 PDFMichiel HuijgenPas encore d'évaluation

- CRC 2-26Document2 pagesCRC 2-26saranPas encore d'évaluation

- Product Information Navisyn De: DescriptionDocument2 pagesProduct Information Navisyn De: DescriptionGabriel NogueiraPas encore d'évaluation

- Interline 1012+ds+engDocument4 pagesInterline 1012+ds+engSUBHOMOYPas encore d'évaluation

- TDS Loctite Nickel LB 771-EnDocument2 pagesTDS Loctite Nickel LB 771-EnGregory Alan Francisco IIPas encore d'évaluation

- Tectyl 400 CDocument2 pagesTectyl 400 CAdeniyiPas encore d'évaluation

- Loctite 596™: SurfacesDocument2 pagesLoctite 596™: Surfaces楼淼森Pas encore d'évaluation

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsMuthuKumarPas encore d'évaluation

- Sikasil RTV Gasket PdsDocument2 pagesSikasil RTV Gasket PdsAhmad Ikhsan KurniantoPas encore d'évaluation

- Loctite 595-EN PDFDocument2 pagesLoctite 595-EN PDFDhananjay LimayePas encore d'évaluation

- 32 Tectyl 502 CDocument2 pages32 Tectyl 502 CMani Rathinam RajamaniPas encore d'évaluation

- Tectyl 502 C PDFDocument2 pagesTectyl 502 C PDFVăn Trường LêPas encore d'évaluation

- Gpcdoc Gtds Shell Diala s3 Zx-I (En) TdsDocument2 pagesGpcdoc Gtds Shell Diala s3 Zx-I (En) TdsSecret64Pas encore d'évaluation

- BASF MasterProtect 8000 CIDocument4 pagesBASF MasterProtect 8000 CIHJPas encore d'évaluation

- Chembloc Series 239Sc: Product ProfileDocument2 pagesChembloc Series 239Sc: Product ProfileSky MoonPas encore d'évaluation

- Shell Tivela S 220: Advanced Synthetic Gear OilsDocument2 pagesShell Tivela S 220: Advanced Synthetic Gear OilsViruzfhmPas encore d'évaluation

- Masterseal TC 257 TdsDocument2 pagesMasterseal TC 257 TdsfirozembrayilPas encore d'évaluation

- DAOTAN VTW 1265/36WA: Technical Datasheet Liquid Coating Resins and AdditivesDocument2 pagesDAOTAN VTW 1265/36WA: Technical Datasheet Liquid Coating Resins and Additives8612106535Pas encore d'évaluation

- Tectyl 506 PDFDocument4 pagesTectyl 506 PDFjaskaran singhPas encore d'évaluation

- 6 2 1 6 1 Polyflex PDFDocument2 pages6 2 1 6 1 Polyflex PDFFourier MakambioPas encore d'évaluation

- Chevron Texclad PDS1 LoDocument1 pageChevron Texclad PDS1 LoAustin UdofiaPas encore d'évaluation

- Protectosil CIT PDFDocument3 pagesProtectosil CIT PDFFrancois-Pas encore d'évaluation

- Shell Tellus S2 V LeafletDocument2 pagesShell Tellus S2 V Leafletluismanuel.g10Pas encore d'évaluation

- GPCDOC Local TDS United Kingdom Shell Tellus S4 VX 32 en-GB TDS PDFDocument3 pagesGPCDOC Local TDS United Kingdom Shell Tellus S4 VX 32 en-GB TDS PDFcorsini999Pas encore d'évaluation

- Shell Tellus S2 MX 100: Performance, Features & BenefitsDocument3 pagesShell Tellus S2 MX 100: Performance, Features & BenefitsJose Cabrera ChakongPas encore d'évaluation

- Elastuff 102Document3 pagesElastuff 102pravi3434Pas encore d'évaluation

- DELMON ProfileDocument77 pagesDELMON ProfileFAIYAZ AHMEDPas encore d'évaluation

- X-Tech CrystalClear 3Document2 pagesX-Tech CrystalClear 3EGO AnimationPas encore d'évaluation

- Technical Data Sheet Chemitac 28: DescriptionDocument3 pagesTechnical Data Sheet Chemitac 28: DescriptionPhuong The NguyenPas encore d'évaluation

- Henk Loctite Superflex Red TdsDocument2 pagesHenk Loctite Superflex Red TdsMariano DomenechPas encore d'évaluation

- Interclene 245: TBT Free AntifoulingDocument4 pagesInterclene 245: TBT Free AntifoulingTrịnh Minh KhoaPas encore d'évaluation

- Tectyl 502 CDocument2 pagesTectyl 502 CKARTHIGEYAN.RPas encore d'évaluation

- 308Document4 pages308lacsmm982Pas encore d'évaluation

- Ceilcote 2000 Flakeline+ds+engDocument4 pagesCeilcote 2000 Flakeline+ds+englivefreakPas encore d'évaluation

- Shell Tellus S2 MX 100: Performance, Features & BenefitsDocument4 pagesShell Tellus S2 MX 100: Performance, Features & BenefitsDesta 77Pas encore d'évaluation

- Shell Tellus Oils PBLAD - 2Document3 pagesShell Tellus Oils PBLAD - 2Ard SaleelPas encore d'évaluation

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsD'EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965D'EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Pas encore d'évaluation

- Water-Based Paint Formulations, Vol. 3D'EverandWater-Based Paint Formulations, Vol. 3Évaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Geotextiles and Geomembranes HandbookD'EverandGeotextiles and Geomembranes HandbookT.S. IngoldÉvaluation : 5 sur 5 étoiles5/5 (1)

- Cryogenics Safety Manual: A Guide to Good PracticeD'EverandCryogenics Safety Manual: A Guide to Good PracticePas encore d'évaluation

- Study On The Heat Transfer CharacteristicsDocument22 pagesStudy On The Heat Transfer CharacteristicsRavi GurugePas encore d'évaluation

- Numerical Simulation of Frosting Behavior and Its Effect On A Direct-Contact Ambient Air VaporizerDocument10 pagesNumerical Simulation of Frosting Behavior and Its Effect On A Direct-Contact Ambient Air VaporizerRavi GurugePas encore d'évaluation

- Stresses in Large Horizontal CylindricalDocument12 pagesStresses in Large Horizontal CylindricalRavi GurugePas encore d'évaluation

- Designing and Analysis of Cryogenic Storage Vessels: January 2016Document13 pagesDesigning and Analysis of Cryogenic Storage Vessels: January 2016Hassan HabibPas encore d'évaluation

- Cibse Nabic CPD 10 20Document4 pagesCibse Nabic CPD 10 20Ravi GurugePas encore d'évaluation

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocument8 pagesDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeYakubu100% (1)

- Plate Checkered 02 FinalDocument1 pagePlate Checkered 02 FinalRavi GurugePas encore d'évaluation

- Potential For Hydrogen DDT With Ambient Vaporizers: October 2018Document16 pagesPotential For Hydrogen DDT With Ambient Vaporizers: October 2018Ravi GurugePas encore d'évaluation

- Simulation and Performance AnalysisDocument7 pagesSimulation and Performance AnalysisRavi GurugePas encore d'évaluation

- Steel PlateDocument38 pagesSteel PlatejazhmanPas encore d'évaluation

- The Dynamical Thermal Stress and Temperature of The Main Member of LNG Carrier During Pre-Cooling ProcessDocument5 pagesThe Dynamical Thermal Stress and Temperature of The Main Member of LNG Carrier During Pre-Cooling ProcessRavi GurugePas encore d'évaluation

- Energies 10 00310Document21 pagesEnergies 10 00310HarmanPas encore d'évaluation

- Energies 15 00280Document14 pagesEnergies 15 00280Ravi GurugePas encore d'évaluation

- Plate Checkered 02 FinalDocument1 pagePlate Checkered 02 FinalRavi GurugePas encore d'évaluation

- Science: (Subject Code - 086) Syllabus For Purpose of Examination 2021-22 CLASS - IX and X (2021-22)Document10 pagesScience: (Subject Code - 086) Syllabus For Purpose of Examination 2021-22 CLASS - IX and X (2021-22)AmberPas encore d'évaluation

- SGL Datasheet SIGRACELL Bipolar Plates enDocument2 pagesSGL Datasheet SIGRACELL Bipolar Plates enRavi GurugePas encore d'évaluation

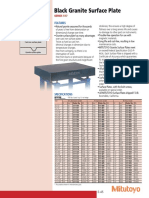

- Black Granite Surface Plate: FeaturesDocument2 pagesBlack Granite Surface Plate: FeaturesRavi GurugePas encore d'évaluation

- Art and Design Art and Design: A Comprehensive Guide For Creative Artists A Comprehensive Guide For Creative ArtistsDocument128 pagesArt and Design Art and Design: A Comprehensive Guide For Creative Artists A Comprehensive Guide For Creative ArtistsWaiyan Phonemyint100% (1)

- Handbook of DrawingDocument302 pagesHandbook of DrawingTucc195% (22)

- C1e 001Document44 pagesC1e 001Dhananjay KumarPas encore d'évaluation

- What Is ScienceDocument22 pagesWhat Is SciencerebeccabarrowPas encore d'évaluation

- 1 s2.0 S1876610214004925 MainDocument9 pages1 s2.0 S1876610214004925 MainsuyogbhavePas encore d'évaluation

- Thermal Stress Analysis of Process Piping System Installed On LNG Vessel Subject To Hull Design LoadsDocument16 pagesThermal Stress Analysis of Process Piping System Installed On LNG Vessel Subject To Hull Design LoadsprakashPas encore d'évaluation

- SGL Datasheet SIGRACELL Bipolar Plates enDocument2 pagesSGL Datasheet SIGRACELL Bipolar Plates enRavi GurugePas encore d'évaluation

- Cleaning of Equipment For Oxygen ServiceDocument56 pagesCleaning of Equipment For Oxygen ServicenovdicPas encore d'évaluation

- Grammar Essentials 3eDocument224 pagesGrammar Essentials 3eOrangeSister100% (24)

- Volvo FM Specifications UKDocument18 pagesVolvo FM Specifications UKLuqman Cuopreakt'zPas encore d'évaluation

- Weld Topic - Welding Symbols PDFDocument7 pagesWeld Topic - Welding Symbols PDFRavi GurugePas encore d'évaluation

- Creating A Positive Impression Lesson 4Document10 pagesCreating A Positive Impression Lesson 4Ravi GurugePas encore d'évaluation

- Insulation Technical DetailsDocument16 pagesInsulation Technical DetailsRavi GurugePas encore d'évaluation

- Commented (JPF1) : - The Latter Accused That Rizal HasDocument3 pagesCommented (JPF1) : - The Latter Accused That Rizal HasLor100% (1)

- Doka H20 BeamDocument20 pagesDoka H20 Beamshoaib100% (1)

- Banaag Reflective Journal BlsDocument3 pagesBanaag Reflective Journal BlsR Hornilla ArcegaPas encore d'évaluation

- The Modern Fire Attack - Phil Jose and Dennis LegearDocument7 pagesThe Modern Fire Attack - Phil Jose and Dennis LegearTomPas encore d'évaluation

- 50-Article Text-116-1-10-20191113Document6 pages50-Article Text-116-1-10-20191113Annisa FauziahPas encore d'évaluation

- (Clinical Sociology - Research and Practice) Howard M. Rebach, John G. Bruhn (Auth.), Howard M. Rebach, John G. Bruhn (Eds.) - Handbook of Clinical Sociology-Springer US (2001) PDFDocument441 pages(Clinical Sociology - Research and Practice) Howard M. Rebach, John G. Bruhn (Auth.), Howard M. Rebach, John G. Bruhn (Eds.) - Handbook of Clinical Sociology-Springer US (2001) PDFMuhammad AliPas encore d'évaluation

- Transaction AnalysisDocument34 pagesTransaction AnalysisSunil Ramchandani100% (1)

- Steel Scrap Recycling Policy 06.11.2019 PDFDocument31 pagesSteel Scrap Recycling Policy 06.11.2019 PDFAnshul SablePas encore d'évaluation

- Pre-Feasibility Report: at Plot No. 15/B-3, Jigani Industrial Area Anekal Taluk, Bangalore South District Karnataka byDocument41 pagesPre-Feasibility Report: at Plot No. 15/B-3, Jigani Industrial Area Anekal Taluk, Bangalore South District Karnataka by12mchc07Pas encore d'évaluation

- Lord You Know All Things, You Can Do All Things and You Love Me Very MuchDocument4 pagesLord You Know All Things, You Can Do All Things and You Love Me Very Muchal bentulanPas encore d'évaluation

- Hydraulic Fluid CategoriesDocument3 pagesHydraulic Fluid CategoriesJako MishyPas encore d'évaluation

- Physical Fitness TestDocument1 pagePhysical Fitness TestGiessen Fran RamosPas encore d'évaluation

- Impact of Textiles and Clothing Industry On EnvironmentDocument15 pagesImpact of Textiles and Clothing Industry On Environmentranjann349Pas encore d'évaluation

- Assessment in The Affective DomainDocument19 pagesAssessment in The Affective DomainChano MorenoPas encore d'évaluation

- TinyEYE Online Speech Therapy Media GuideDocument4 pagesTinyEYE Online Speech Therapy Media GuideTinyEYE Therapy ServicesPas encore d'évaluation

- People v. Jerry BugnaDocument1 pagePeople v. Jerry BugnaRey Malvin SG PallominaPas encore d'évaluation

- Solved Rail Chapter 1Document7 pagesSolved Rail Chapter 1spectrum_48Pas encore d'évaluation

- Recipe Booklet PRINT VERSIONDocument40 pagesRecipe Booklet PRINT VERSIONjtsunami815100% (1)

- Comparative Study of Financial Statements of Company, Oil and Gas.Document105 pagesComparative Study of Financial Statements of Company, Oil and Gas.Ray Brijesh AjayPas encore d'évaluation

- I. Choose The Meaning of The Underlined Words Using Context CluesDocument4 pagesI. Choose The Meaning of The Underlined Words Using Context CluesMikko GomezPas encore d'évaluation

- User's Manual Eco Friendly Park BenchDocument35 pagesUser's Manual Eco Friendly Park BenchAmirulHanif AlyahyaPas encore d'évaluation

- Bandura Social Cognitive TheoryDocument93 pagesBandura Social Cognitive TheoryВикторияPas encore d'évaluation

- Magnesium L Threonate For Depression and Anxiety PDFDocument6 pagesMagnesium L Threonate For Depression and Anxiety PDFRocco LamponePas encore d'évaluation

- Job Vacancy Kabil - Batam April 2017 RECARE PDFDocument2 pagesJob Vacancy Kabil - Batam April 2017 RECARE PDFIlham AdePas encore d'évaluation

- Asking and Showing Rooms in Hospital2Document17 pagesAsking and Showing Rooms in Hospital2Roland DelPas encore d'évaluation

- Remote Control RC902V1 ManualDocument3 pagesRemote Control RC902V1 ManualdezdoPas encore d'évaluation

- Elasticity, Plasticity Structure of Matter: by DR R. HouwinkDocument9 pagesElasticity, Plasticity Structure of Matter: by DR R. HouwinkKhlibsuwan RPas encore d'évaluation

- Baseline Capacity Assessment For OVC Grantee CSOsDocument49 pagesBaseline Capacity Assessment For OVC Grantee CSOsShahid NadeemPas encore d'évaluation

- Jurnal RustamDocument15 pagesJurnal RustamRustamPas encore d'évaluation