Académique Documents

Professionnel Documents

Culture Documents

Us2028776 PDF

Transféré par

Teleson Marques0 évaluation0% ont trouvé ce document utile (0 vote)

10 vues3 pagesTitre original

US2028776.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

10 vues3 pagesUs2028776 PDF

Transféré par

Teleson MarquesDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

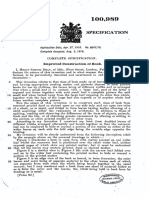

Patented Jan.

28, 1936 2,028,776

UNITED STATES 2,028,776

PATENT OFFICE

CELLULOSC ARTICLES AND METEOD OF

PREPARNG THE SAME

Harold Hibbert, Montreal, Quebec, Canaia, as

signor to Celanese Corporation of America, a

corporation of Delaware

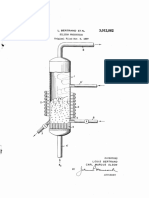

No Drawing. Application April 23, 1932,

Serial No. 60229

10 Claims, (C. 91-0)

This invention relates to the preparation of ization, whereby a layer of relatively impervious

foils, films and other articles made of cellulose polymerization product is formed.

or its derivatives, and relates more particularly . Articles to be treated in accordance with this

to rendering the same more impervious to mois invention may be of any suitable form. This in

tre. vention is particularly applicable to the treat

ment of foils Or transparent paper having a thick

An object of my invention is to render articles

and particularly sheet-like articles made of Cel neSS of the Order of 0.001' to 0.003' to be used

ulosic material more impermeable by condensing for Wrapping articles Or for any other suitable

thereon a liquid capable of polymerization to form purpose. The articles to be treated by this in

solid or semi-solid resinous material and then Sub vention on the other hand may be in the form of 10

jecting the same to polymerization, whereby a films to be used for photographic, cinemato

layer of resinous material is formed on the Sur graphic or other purposes, or other sheet-like ma

faces of said articles to render the Sane more in terials, which may be made by casting or fiawing

pervious or waterproof. A further object of my a Solution of the cellulose or cellulose derivative

s invention is to employ a volatile vinyl compound on to smooth metallic or glass surfaces, such as 15

as the polymerizable liquid in Such process. Oth film. Wheels, drums, bands, tables, etc. as is well

er objects of this invention will appear from the known in the art.

folloying detailed description. Other articles such as yarns, fabrics or articles

Articles made of, or containing on the Surface made of plastic compositions containing deriva

thereof, cellulose, regenerated cellulose or ceilu tives of cellulose may be treated by this invention. 20

lose derivatives are not as impervious to Water, In its broad a Spects this invention includes the

either in liquid or vapor state, as is often de treatment of paper, cardboard, cotton fabrics and

sired. For instance, it has been found that thin other articles made of cellulose ibres.

foils made of regenerated cellulose or cellulose The articles to be treated by this invention may

25 acetate plastics to be used in the Wrapping of be made of or contain on at least the surface 25

tobacco products or foodstuffs are more or eSS thereof any Suitable cellulosic material, such as

permeable so that moisture in the form of vapors cellulose itself, regenerated cellulose, or deriva

may pass through the same, whereby the original tives of cellulose. The derivatives of cellulose in

humidity of the wrapped articles in tine becomes clude besides nitrocellulose, organic derivatives of

3. altered. cellulose such as organic esters of cellulose and 30

I have found that if Such articles are Subjected cellulose ethers. Examples of organic esters of

to the vapors of yolatile liquids capable of be cellulose are cellulose acetate, cellulose formate,

coming polymerized to a solid or semi-solid con cellulose butyrate and cellulose propionate while

sistency under such conditions as to cause at examples of cellulose ethers are ethyl cellulose,

35 least part of the vapors to become condensed or methyl cellulose and benzyl cellulose. Generally 35

absorbed on the surfaces of Such articles, and the if the articles are made of cellulose derivatives,

same are then subjected to a process causing there will be present plasticizers such as triacetin,

polymerization, the resulting layer of polymerized diethyl phthalate, dibutyl phthaliate, diethyl tar

compound renders the articles more impervious trate, dibutyl tartrate and any other desired ma

40 to moisture, air or other gases. The condensing terials. Such as pigments and effect materials, as is 40

or absorbing of the Vapors is of great advantage well known in the cellulose derivative plastic art.

over the application of the material as a liquid, This invention is of general application to the

since much more uniform thin layers may be de treatment of the articles with the vapors of a

posited in this manner, and the use of a diluent polymerizable liquid. Such liquid may be a sub

45 or solvent to make the necessary dilute solution stantially unpolymerized vinyl compound, such 45

of the liquid, if it is to be applied as a liquid, is as the unpolymerized divinyl ether, vinyl acetate,

avoided. styrene, which is the vinyl benzene, vinyl ethyl

In accordance with my invention I render ar ether, vinyl ethyl carbonol, etc. Polymerizable

ticles made of, or containing cellulosic materials liquids other than vinyl compounds may be

50 at least on the surface thereof, more impervious used, examples of which are glycide or glycidol 50

or waterproof by subjecting the same to the va C2H3O.CH2.OH, or other glycides, which poly

pors of a liquid capable of polymerization under merize at elevated temperatures in the presence

such conditions that part of the same becomes of catalysts such as alkalies or zinc chloride.

condensed or is absorbed on the surface of the Conveniently in order to deposit the vinyl com

55 article and then subjecting the same to polymer pound onto the Surface to be treated, the surface 55

2 2,028,776

is exposed to the vapors of the vinyl compound. duce a rubber-like, water-resistant surface, thus

In the case when the foil or surface of the arti imparting greatly increased impermeability and

cle to be treated is made of derivatives of cellu . Waterproofness to the foil.

lose, some of the vinyl compounds are mutually It is to be understood that the foregoing de

soluble with the derivative of cellulose and there tailed description is given merely by way of illus

fore are absorbed on the Surface of the Same. tration and that many variations may be made

In order to promote the condensation of the therein, without departing from the spirit of my

vinyl compound on to the surfaces of the article invention.

to be treated, such surfaces are preferably kept Having described my invention, what I claim.

10 at a low temperature. and desire to Secure by Letters Patent is: O

The polymerization of the polymerizable con 1. Method of rendering surfaces of non-metal

pound after it has been applied to the surface lic articles more impermeable, which comprises

may be conducted in any suitable manner. Thus

in the case of vinyl compounds, the polymeriza exposing surfaces of articles to vapors of a vola

tile polymerizable material selected from the

15 tion may be accomplished by heating to tempera group consisting of Substantially unpolymerized 5

tures of 70 to 100° C. or more, by exposure to light vinyl compounds and glycides to deposit the poly

rays, particularly sunlight or light rich in ultra merizable material on said surfaces, and then

violet rays, such as emitted from a mercury vapor polymerizing said polymerizable material to form

lamp. If desired, catalysts such as benzoyl per a surface coating.

20 oxide or other organic peroxides, uranium salts 2. Method of rendering surfaces of cellulosic

and the like, promoting the polymerization of material more impermeable, which comprises ex

the vinyl compound may be employed, and Small posing surfaces of cellulosic material to vapors

quantities of these catalysts may be incorporated of a volatile polymerizable material selected from

in or coated on the cellulosic films, foils Or other the group consisting of substantially unpoly

25 articles, either during their manufacture or after merized vinyl compounds and glycides, to deposit 25

their formation. the polymerizable material on said surfaces, and

If desired, a thin layer of paraffin wax, teresin then polymerizing said polymerizable material to

wax, beeswax or other wax may be incorporated form a surface coating.

in or applied to the surface of the foils or other

30 articles, either before or after application and of3.cellulose

Method of rendering surfaces of derivative

material more impermeable, which 30

polymerization of the vinyl compound. If the comprises exposing surfaces of derivatives of cel

foil is made of regenerated cellulose, a thin So lulose to vapors of a volatile polymerizable ma

lution containing the wax, nitroCellulose and a terial Selected from the group consisting of sub

plasticizer such as triphenyl phosphate, dissolved stantially unpolymerized vinyl compounds and

35 in a suitable solvent may be applied to the foil glycides, to deposit the polymerizable material 35

to coat the same with verythin coatings of these On Said Surfaces, and then polymerizing said

materials, in order to increase their impermeabil polymerizable material to form a surface coating.

ity either before or after the application and 4. Method of rendering surfaces of cellulose

polymerization of the vinyl compound. acetate material more impermeable, which com

40 Thin foils, films, sheets or other articles made prises exposing surfaces of cellulose acetate to 40

or treated in accordance with this invention have vapors of a volatile polymerizable material se

greatly increased impermeability to moisture or

other liquids. Thin foils prepared in accordance lected from the group consisting of substantially

unpolymerized vinyl compounds and glycides, to

with this invention are eminently suitable for deposit the polymerizable material on said sur

45 the wrapping of cigars, cigarettes Or other t0 faces, and then polymerizing said polymerizable 45

bacco articles and confectionary, cakes and other material to form a surface coating.

foodstuffs.

By way of an example of a method of carrying to 5.foilsMethod of imparting greater impermeability

or films containing cellulosic material,

out my invention the following is given. Thin which comprises exposing the same at low tem

50 foils of a thickness of 0.00' to 0.003' made of a peratures to the vapors of a volatile polymeriz 50

plastic composition containing cellulose acetate

and plasticizer, is passed around a drum within ableof

material selected from the group consisting

substantially unpolymerized vinyl compounds

a closed chamber. Cold brine is circulated with and glycides, whereby the polymerizable material

in the drum to maintain its temperature be

55 low 10, say 0° C. Wapors of divinyl ether, is deposited on the surface of said foils or films,

(CH2:CH)2O, are passed into the chamber and and then polymerizing Said polymerizable mate 55

a portion of the vinyl ether is condensed on or rial to form a coating on the surface of said foils

absorbed in the Surface of the cool foil. If it or films.

is so desired to cause the divinyl ether to be de 6. Method of imparting greater impermeability

60 posited on both sides of the foil, two cooled to foils or films containing cellulose acetate, 60

drums may be provided either in one chamber or which comprises exposing the same at low tem

peratures to the vapors of a volatile polymeriz

in separate chambers, the drums being so ar able material selected from the group consisting

ranged that on One of the drums, one side of the

foil is exposed to the vapors, while the other of substantially unpolymerized vinyl compounds

65 side of the foil is exposed to the vapors while and glycides, whereby, the polymerizable material 65

on the other drum. 1. is deposited on the surface of said foils or films,

The foil with the vinyl ether condensed on the and then polymerizing said polymerizable mate

surface thereof is then passed into another rial to form a coating on the surface of said foils

chamber to cause the polymerization thereof. Or films. . . . . ,w

70 This chamber may be heated to 80 to 100° C. to 7. Method of imparting greater impermeability 70

cause polymerization of the vinyl compound, or to foils or films containing cellulosic material

the chamber may be flooded with ultra-violet comprising exposing the same to the vapors of a

light and be maintained at ordinary temperatures substantially unpolymerized vinyl compound to

or elevated temperatures up to 100° C. In this deposit a layer of the vinyl compound on at least

75 manner, the divinyl ether polymerizes to pro one surface of the foil or film and then poly- is

2,028,776 3

inerizing the vinyl compound to form a solid to compound to deposit a layer of the divinyl ether

semi-solid resin material. compound on at least one surface of the foll or

8. Method of imparting greater impermeability film and then polymerizing the divinyl ether com

pound to form a solid to semi-Solid resin material.

to foils or films containing cellulose acetate Com

prising exposing the same to the vapors of a Sub 10. Method of imparting greater imperime

stantially unpolymerized vinyl compound to de ability to foils or films containing cellulose ace

posit a layer of the vinyl compound on at least tate comprising exposing the same to the Vapors

One surface of the foil or film and then polymer of a substantially unpolymerized divinyl ether

izing the vinyl compound to form a solid to semi compound to deposit a layer of the divinyl ether

0 Solid resin material. compound on at least one surface of the film or 10

9. Method of imparting greater impermeabil foil and then polymerizing the divinyl ether to

ity to foils Or films containing cellulosic mate form a Solid to Semi-Solid resin material.

rial comprising exposing the same to the vapors

of a SubStantially unpolymerized divinyl ether HAROLD HIBBERT.

Vous aimerez peut-être aussi

- United States Patent Office: Polyurethane ElastomersDocument10 pagesUnited States Patent Office: Polyurethane ElastomersZarathos SinghPas encore d'évaluation

- United States Patent Office: Patented Nov. 9, 1943Document4 pagesUnited States Patent Office: Patented Nov. 9, 1943Teleson MarquesPas encore d'évaluation

- Us2932251 PDFDocument4 pagesUs2932251 PDFchecolonoskiPas encore d'évaluation

- Sept. L2, 1972 V - Mahe L-Rral 3,690,910: Filed Jan. 19, 1971 2 Sheets-Sheet 1Document5 pagesSept. L2, 1972 V - Mahe L-Rral 3,690,910: Filed Jan. 19, 1971 2 Sheets-Sheet 1Abha SinghPas encore d'évaluation

- H3T Ooo: J. R. Crawford Drying Method and Apparatus Filed June 8, 1961Document7 pagesH3T Ooo: J. R. Crawford Drying Method and Apparatus Filed June 8, 1961Nur Aina Ramadhani PurbaPas encore d'évaluation

- United States Patent: 6, 1989 Patent Number: Date of Patent: Shimuzu Et AlDocument8 pagesUnited States Patent: 6, 1989 Patent Number: Date of Patent: Shimuzu Et AlEsat KostakPas encore d'évaluation

- Water Repellent FinishesDocument5 pagesWater Repellent FinishesKevin MeonkPas encore d'évaluation

- Us 5362842Document7 pagesUs 5362842giovanniPas encore d'évaluation

- Coal Miners SuitDocument4 pagesCoal Miners SuitSudipta BainPas encore d'évaluation

- Man-Made Fibres GLDocument5 pagesMan-Made Fibres GLLinh NguyenPas encore d'évaluation

- Rayon Tre Cord Finish OilDocument4 pagesRayon Tre Cord Finish OilLoganathan MurugadassPas encore d'évaluation

- Iec 16 1125 1924Document1 pageIec 16 1125 1924Jeff ZabolotneyPas encore d'évaluation

- Modified Silica Sol Coatings For Water-Repellent TextilesDocument10 pagesModified Silica Sol Coatings For Water-Repellent TextilesJhorma jose Medina AltahonaPas encore d'évaluation

- BuckEye ProcessDocument8 pagesBuckEye ProcessDindaTamaraPas encore d'évaluation

- Dec. 26, 1950 N. L. Cox 2,535,044: Filed April 26, 1947Document8 pagesDec. 26, 1950 N. L. Cox 2,535,044: Filed April 26, 1947udinPet0tPas encore d'évaluation

- US4999869Document4 pagesUS4999869omer reisPas encore d'évaluation

- United States Patent Office: Patented June 16, 1964Document3 pagesUnited States Patent Office: Patented June 16, 1964Vansala GanesanPas encore d'évaluation

- Process For Surface Sizing PaperDocument7 pagesProcess For Surface Sizing PaperRakeshPas encore d'évaluation

- BM Adhesives and SealantsDocument3 pagesBM Adhesives and SealantsErnesto CabuyadaoPas encore d'évaluation

- Feb-5, 1973 K. W. Pope 3,7153": Cellular Polyureth' Filed Aug. 31. 1967 - 5 Sheets-Sheet 1Document8 pagesFeb-5, 1973 K. W. Pope 3,7153": Cellular Polyureth' Filed Aug. 31. 1967 - 5 Sheets-Sheet 1Khoi Nguyen DangPas encore d'évaluation

- Solvent Cast Technology - A Versatile ToolDocument14 pagesSolvent Cast Technology - A Versatile ToolsggdgdPas encore d'évaluation

- United States Patent 0. ": Patented Def. 5, 1965Document6 pagesUnited States Patent 0. ": Patented Def. 5, 1965Ersa Nurul YarizsaPas encore d'évaluation

- TR Guide Multilayers v6Document4 pagesTR Guide Multilayers v6Thuận LêPas encore d'évaluation

- Plastic Wiki 2Document2 pagesPlastic Wiki 2WolfMensch1216Pas encore d'évaluation

- CH3331 CC01 ZeoliteDocument32 pagesCH3331 CC01 ZeoliteNhư LêPas encore d'évaluation

- United States Patent Office: Patented Feb. 6, 1951Document3 pagesUnited States Patent Office: Patented Feb. 6, 1951karmilaPas encore d'évaluation

- Franklin Institute: Bakelite, A Condensation Product of Phenols and Formaldehyde, A N D Its UsesDocument6 pagesFranklin Institute: Bakelite, A Condensation Product of Phenols and Formaldehyde, A N D Its UsesAhmad Dwi ArgaPas encore d'évaluation

- United States Patent 0: Patented Apr. 9, 1974 2Document5 pagesUnited States Patent 0: Patented Apr. 9, 1974 2lauraPas encore d'évaluation

- Beeswax-Chitosan Emulsion Coated Paper With Enhanced Water Vapor Barrier EfficiencyDocument6 pagesBeeswax-Chitosan Emulsion Coated Paper With Enhanced Water Vapor Barrier EfficiencyJustineTimbolÜPas encore d'évaluation

- Coatings With Solar Reflective Properties: - Nouryon Chemicals International B.VDocument41 pagesCoatings With Solar Reflective Properties: - Nouryon Chemicals International B.VChris BothaPas encore d'évaluation

- Us 4058649Document6 pagesUs 4058649yigitilgazPas encore d'évaluation

- Regular Rayon (Or Viscose) Is The Most Widely Produced Form of Rayon. This Method of RayonDocument11 pagesRegular Rayon (Or Viscose) Is The Most Widely Produced Form of Rayon. This Method of RayonManda Ramesh BabuPas encore d'évaluation

- Us 4371639Document5 pagesUs 4371639atnmmm100Pas encore d'évaluation

- July 19, 1960: ObjectDocument3 pagesJuly 19, 1960: ObjectVansala GanesanPas encore d'évaluation

- Plastic IndustriesDocument4 pagesPlastic IndustriesJustin Paul CongePas encore d'évaluation

- 01Document5 pages01sochincPas encore d'évaluation

- Roofing SBSDocument6 pagesRoofing SBSfredyPas encore d'évaluation

- Wayne, C. Et Al. Silicone Oil. A New Technique Preserving Waterlogged RopeDocument13 pagesWayne, C. Et Al. Silicone Oil. A New Technique Preserving Waterlogged RopeTrinidad Pasíes Arqueología-ConservaciónPas encore d'évaluation

- Material AntifogginDocument11 pagesMaterial AntifogginJavier BecerraPas encore d'évaluation

- Polyvinylchloride (PVC) : Eco-Profiles of The European Plastics IndustryDocument15 pagesPolyvinylchloride (PVC) : Eco-Profiles of The European Plastics IndustryGuillianPas encore d'évaluation

- Plastics N RubbDocument10 pagesPlastics N Rubbmickyraycon45Pas encore d'évaluation

- Sintex Part 2Document29 pagesSintex Part 2payalmalayPas encore d'évaluation

- US2942991Document3 pagesUS2942991Kerem BPas encore d'évaluation

- United States Patent (19) : SouthwickDocument6 pagesUnited States Patent (19) : SouthwickEdgar hernandezPas encore d'évaluation

- WaterproofingDocument38 pagesWaterproofingPranay GandhiPas encore d'évaluation

- Thermal Paper CoatingDocument4 pagesThermal Paper CoatingSintong Leonardo Situngkir100% (1)

- Process For Producing Granular Triple Superphosphate: F. DunbarDocument5 pagesProcess For Producing Granular Triple Superphosphate: F. DunbarOscar SobradosPas encore d'évaluation

- Us 3464121 PNEUMATIC DRYDocument4 pagesUs 3464121 PNEUMATIC DRYCesar EnochPas encore d'évaluation

- Xue Et Al, 2008 Superhydrophobic Cotton FabricsDocument6 pagesXue Et Al, 2008 Superhydrophobic Cotton FabricsemtetePas encore d'évaluation

- U.S. Patent 1,780,844, Applying Nitrocellulose Varnishes, Issued 1930.Document2 pagesU.S. Patent 1,780,844, Applying Nitrocellulose Varnishes, Issued 1930.Anonymous a7S1qyXPas encore d'évaluation

- Us 2975151Document4 pagesUs 2975151Clinton ThomsonPas encore d'évaluation

- Penggunaan Sodium Polyacrylate Untuk Proses Demulsifikasi Minyak-AirDocument6 pagesPenggunaan Sodium Polyacrylate Untuk Proses Demulsifikasi Minyak-AirRahmi Nur Anisah Nasution 2003114489Pas encore d'évaluation

- Electrospinning Cellulose and Cellulose Derivatives: Margaret W. FreyDocument15 pagesElectrospinning Cellulose and Cellulose Derivatives: Margaret W. FreyDanielle JuaisPas encore d'évaluation

- Handbook of Package Engineering 2edDocument18 pagesHandbook of Package Engineering 2edAlain Krlyn100% (1)

- US2417090Document7 pagesUS2417090خبر عاجل وتحليلاتPas encore d'évaluation

- Thompson 2015Document12 pagesThompson 2015MartinaPas encore d'évaluation

- A Brief Overview of Theories of PVC Plasticization andDocument5 pagesA Brief Overview of Theories of PVC Plasticization andMahmood BhaiPas encore d'évaluation

- Processes: Novel Technique For Coating of Fine Particles Using Fluidized Bed and Aerosol AtomizerDocument18 pagesProcesses: Novel Technique For Coating of Fine Particles Using Fluidized Bed and Aerosol AtomizerDenis Crispin IrazabalPas encore d'évaluation

- US3012862 Si Halide With Hydrogen PatentDocument7 pagesUS3012862 Si Halide With Hydrogen PatentLiya Elizabeth JacobPas encore d'évaluation

- CA749964A ClathrateDocument36 pagesCA749964A ClathrateTeleson MarquesPas encore d'évaluation

- Us4728376 PDFDocument9 pagesUs4728376 PDFTeleson MarquesPas encore d'évaluation

- Us4728376 PDFDocument9 pagesUs4728376 PDFTeleson MarquesPas encore d'évaluation

- US20120020871 PerchlorateDocument41 pagesUS20120020871 PerchlorateTeleson MarquesPas encore d'évaluation

- US878726 Ammonium PicrateDocument1 pageUS878726 Ammonium PicrateTeleson MarquesPas encore d'évaluation

- GB100989A Improved Construction of BookDocument3 pagesGB100989A Improved Construction of BookTeleson MarquesPas encore d'évaluation

- US4548660A - Water-In-Oil Emulsion Explosive - Google PatentsDocument2 pagesUS4548660A - Water-In-Oil Emulsion Explosive - Google PatentsTeleson MarquesPas encore d'évaluation

- 2011 - Manual - Compressed EsteDocument14 pages2011 - Manual - Compressed EsteTeleson MarquesPas encore d'évaluation

- Field Expedient Methods For Explosives Preparations Desert Publications PDFDocument28 pagesField Expedient Methods For Explosives Preparations Desert Publications PDFpeter.gomes20087216Pas encore d'évaluation

- US243432Document2 pagesUS243432Teleson MarquesPas encore d'évaluation

- Thunder Flash Report Potassium ChlorateDocument1 pageThunder Flash Report Potassium ChlorateTeleson MarquesPas encore d'évaluation

- US1240272Document2 pagesUS1240272Teleson MarquesPas encore d'évaluation

- US2223964 Naoum PhokionDocument1 pageUS2223964 Naoum PhokionTeleson MarquesPas encore d'évaluation

- Thunder Flash Report Potassium ChlorateDocument1 pageThunder Flash Report Potassium ChlorateTeleson MarquesPas encore d'évaluation

- Thunder Flash Report Potassium ChlorateDocument1 pageThunder Flash Report Potassium ChlorateTeleson MarquesPas encore d'évaluation

- Field Expedient Methods For Explosives Preparation - 5ac3733a1723dd9445078f1bDocument9 pagesField Expedient Methods For Explosives Preparation - 5ac3733a1723dd9445078f1bTeleson MarquesPas encore d'évaluation

- Solubility Table 2Document14 pagesSolubility Table 2Teleson MarquesPas encore d'évaluation

- US2776965 Magnesium Nitrate Used in Nitrocellulose NitrationDocument6 pagesUS2776965 Magnesium Nitrate Used in Nitrocellulose NitrationTeleson MarquesPas encore d'évaluation

- Cellulose NitrateDocument7 pagesCellulose NitrateTeleson MarquesPas encore d'évaluation

- United States Patent (10) Patent N0.: US 8,899,217 B2Document7 pagesUnited States Patent (10) Patent N0.: US 8,899,217 B2Teleson MarquesPas encore d'évaluation

- Field Expedient Methods For Explosives Preparations Desert Publications PDFDocument28 pagesField Expedient Methods For Explosives Preparations Desert Publications PDFpeter.gomes20087216Pas encore d'évaluation

- Single and Double Base Propellant Composition TablesDocument1 pageSingle and Double Base Propellant Composition TablesTeleson MarquesPas encore d'évaluation

- Preparation of Picramic AcidDocument3 pagesPreparation of Picramic AcidTeleson MarquesPas encore d'évaluation

- US2969638 Urea PicrateDocument6 pagesUS2969638 Urea PicrateTeleson MarquesPas encore d'évaluation

- US1440063 Guanidine NitrateDocument1 pageUS1440063 Guanidine NitrateTeleson MarquesPas encore d'évaluation

- US2797979 Manufacture of CyanamidesDocument5 pagesUS2797979 Manufacture of CyanamidesTeleson MarquesPas encore d'évaluation

- Us 9175933Document22 pagesUs 9175933Teleson MarquesPas encore d'évaluation

- US2773911 Manufacture of NitrobenzeneDocument3 pagesUS2773911 Manufacture of NitrobenzeneTeleson MarquesPas encore d'évaluation

- US2208934 Trimethylene Trinitramine Hexogen RDXDocument1 pageUS2208934 Trimethylene Trinitramine Hexogen RDXTeleson MarquesPas encore d'évaluation

- Us2103926 DDNPDocument3 pagesUs2103926 DDNPTeleson MarquesPas encore d'évaluation

- Lubricants For PVCDocument4 pagesLubricants For PVCvongoctu2016Pas encore d'évaluation

- BioChem - LipidsDocument41 pagesBioChem - LipidsKYLE ANDREW SAWITPas encore d'évaluation

- Ceridust® 3920 FDocument2 pagesCeridust® 3920 Fquangga10091986Pas encore d'évaluation

- The Anatomy of A TonerDocument12 pagesThe Anatomy of A TonerOndineSelkiePas encore d'évaluation

- Clover Leaf Candles Sept2011 CatalogDocument15 pagesClover Leaf Candles Sept2011 Catalogmonique5617Pas encore d'évaluation

- The Leather Chemical Company: Research and ManufactureDocument10 pagesThe Leather Chemical Company: Research and Manufactureoscar_bcnPas encore d'évaluation

- 2020-Clariant Brochure High Performance Waxes For The Plastics Industry EN FinalDocument32 pages2020-Clariant Brochure High Performance Waxes For The Plastics Industry EN Finaljaviera1983Pas encore d'évaluation

- Chemistry Investigatory Project On FOOD ADULTERATIONDocument21 pagesChemistry Investigatory Project On FOOD ADULTERATIONDinesh Gupta0% (1)

- 95-1132-01 - Formulation Dowanol PDFDocument40 pages95-1132-01 - Formulation Dowanol PDFNeli Arias100% (1)

- Dental WaxDocument5 pagesDental WaxNajla IsmailPas encore d'évaluation

- LIP Cosmetics: Patricia G. EngasserDocument9 pagesLIP Cosmetics: Patricia G. EngasserCarlos CastilloPas encore d'évaluation

- Smart Formulating For Coatings enDocument32 pagesSmart Formulating For Coatings enPalanethra B100% (2)

- Asphalt Concrete With Encapsulated CbsDocument13 pagesAsphalt Concrete With Encapsulated CbsMariaNilaZaragozaPalacioPas encore d'évaluation

- 13 WaxDocument67 pages13 Waxak4sevenPas encore d'évaluation

- Astm D87Document3 pagesAstm D87Hammada AlfafaPas encore d'évaluation

- DXIAMETER Emulsion FormulaDocument42 pagesDXIAMETER Emulsion Formulasandersperfumes brPas encore d'évaluation

- Knitted FabricsDocument67 pagesKnitted Fabrics郭哲宏100% (1)

- WaxesDocument943 pagesWaxesKatrina Miller100% (5)

- Catenex S Paraffinic Process Oils TDSDocument6 pagesCatenex S Paraffinic Process Oils TDScallingoutukPas encore d'évaluation

- Chemistry of Fats Oils and Waxes PDFDocument33 pagesChemistry of Fats Oils and Waxes PDFShai VillalbaPas encore d'évaluation

- Chapter 3 Wax Processing and PurificationDocument40 pagesChapter 3 Wax Processing and Purificationjiva100% (8)

- US20030075077A1Document12 pagesUS20030075077A1Kyaw Kyaw LinnPas encore d'évaluation

- WaxDocument6 pagesWaxSuiko22Pas encore d'évaluation

- Chapter 25Document34 pagesChapter 25Betty Weiss100% (2)

- Oil Fat and WaxesDocument20 pagesOil Fat and WaxesShariful IslamPas encore d'évaluation

- Chemistry ProjectDocument20 pagesChemistry ProjectakshabhiPas encore d'évaluation

- Coconut Cocos Nucifera As An Alternative To Paraffin FloorwaxDocument7 pagesCoconut Cocos Nucifera As An Alternative To Paraffin FloorwaxMiguel Piquero67% (9)

- Nail Care 9 Periodical TestDocument7 pagesNail Care 9 Periodical Testvanessa cabangPas encore d'évaluation

- Safdar Chemistry - Project - On - STUDY - OF - ADULTERANTDocument15 pagesSafdar Chemistry - Project - On - STUDY - OF - ADULTERANTSAFDAR HafizPas encore d'évaluation

- KL2 Ver.2.1Document2 pagesKL2 Ver.2.1Atawit SomsiriPas encore d'évaluation