Académique Documents

Professionnel Documents

Culture Documents

2017 HV Training Brochure - 2GNM110108

Transféré par

shahzTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

2017 HV Training Brochure - 2GNM110108

Transféré par

shahzDroits d'auteur :

Formats disponibles

2017 High Voltage Service Training

Courses & Schedule

High Voltage Products: 38 - 800 kV

DTB, OCB, Mechanisms, GIS, Monitoring

Devices, Surge Arresters, & SF 6 Handling

& Safe Practices

Introduction to High Voltage Training

In order to maintain a skilled and

knowledgeable workforce, it is

imperative for service personnel,

engineers, and their respective

supervisors to receive the best

training possible.

ABB set the standard for quality

training on high voltage products. 1.

By combining classroom theory

and hands-on application in our

training lab, students gain real-

world knowledge on everything

from mechanism and circuit 2.

breaker troubleshooting and

maintenance to how they are

built. After a training course,

students are readily equipped to

troubleshoot, diagnose, maintain,

and overhaul high voltage

3.

equipment relevant to the class

he /she attended.

1. Students inspect a single pole 245 kV dead tank breaker during

class.

2. Students overhaul AHMA/HMB mechanisms in the training lab.

3. Students learn the latest circuit breaker troubleshooting methods and

tips before working on equipment in the training lab.

4. Students learn diagnostic testing done in the control cabinet during

on site training. 4.

2 Schedule | ABB HV Service Training Brochure

Contents

Every high voltage product needs an Topic Page

expert to maximize its reliability and Introduction to High Voltage Training 2

lifespan. ABB High Voltage Service’s Training Benefits 4

training courses will give you the skills Schedule 5

needed to increase your equipment’s 38 / 72 / 145 / 170 PM / PMI/-B O&M Maintenance 6

availability and keep it operating longer. 242 PMR / PMRI O&M Maintenance 7

345 / 362 PM / PME / PMI / PMI-B O&M 8

Maintenance

550 / 800 PM O&M Maintenance 9

245 / 242 PMG / PMI / PMG-B / PMI-B O&M 10

Maintenance

145 / 242 PA O&M Maintenance 11

LTB / HPL / ELF (live tank) O&M Maintenance 12

Operating Mechanisms (ABB, BBC, Westinghouse) 13

O&M Maintenance

SCU / SCS / CBS / CBS Lite / CBS Lite CSA / 14

Utilities are facing an aging asset base. For CBS-F 6 / Asset Optimization / Monitoring Systems

example, the average age of HV breakers in Oil Circuit Breaker 101 15

North America is approximately 30 years old. SF 6 Handling and Safe Practices 16

Utilities also have an aging workforce with Surge Arresters 101 17

nearly 36% of technical employees eligible GIS O&M Maintenance 18

to retire within five years. At the same time, Customized Training Course 19

utilities must meet grid reliability requirements Frequently Asked Questions 20

and asset performance goals with increasing

Registration Form & Important Information 21

pressure on O&M expenses. At this critical

Contact Us 22

juncture, workforce training has become an

even more important resource for utilities

managing vital power equipment.

ABB HV Service Training Brochure | Schedule 3

Training Advantages

- Stay up-to-date on the latest products and services available in the marketplace to help improve the performance and reliability of your

high voltage equipment.

- Gain technical knowledge needed to reduce the time and cost associated with maintenance of your equipment.

- Develop the skills needed to lengthen your equipment’s operating life.

- Improve your troubleshooting skills through training by experienced ABB field service technicians.

- Develop business contacts with ABB personnel.

- Bring knowledge and expertise to your business through an improved understanding of your high voltage equipment.

- Work first-hand with functioning circuit breakers and life-size models in a training lab as ABB experts demonstrate maintenance and

trouble shooting techniques.

- Get answers to all of your questions related to ABB’s wide range of high voltage products from our experienced staff of engineers and

service technicians.

- Earn CEU’s (continuing education credits) or PDH’s (professional development hours) for courses completed. All attendees receive a

certificate of completion.

- State-of-the-are training center opened improves the classroom experience

- Remodeled workshop enhances hands-on sessions.

- Customized curriculum available to meet specific customer needs.

Factory training On-site training

ABB’s Greensburg, PA factory location is ideal for circuit breaker ABB offers the convenience of on-site training courses to make

training, providing a state-of-the-art manufacturing facility for the most of your training budget. For a set price, our experienced

hands-on experience. Our factory features a fully-equipped instructors will present customer-specific courses at your location.

classroom setting adjacent to the training lab, complete with several As an additional benefit, we can provide our state-of-the art

fully-functional training circuit breakers, interrupter models, and product trailer for hands-on demonstration. The price includes

operating mechanisms. Additionally, attendees will have access to instruction for up to 10 students, and our ABB instructors will work

ABB specialists as well as our shop floor in order to see the circuit with you to tailor the course to your particular needs. With on-site

breakers being manufactured first-hand. training you can maximize the number of participants, or optimize

your budget by combining field maintenance with a training class.

Pricing will be provided on a case-by-case basis depending on the

customer’s specifications.

Hotel and transportation options as well as a registration form

can be found on page 21. Contact your local ABB representative at 724-696-1300 for more

information about on-site training.

*ABB reserves the right to cancel the course in the event of insufficient enrollment.

4 Schedule | ABB HV Service Training Brochure

Schedule

ABB High Voltage Service is pleased to announce the 2017 schedule for “hands on” training seminars at our Greensburg, PA training

center. Please note that courses can be designed and scheduled for specific customer needs.

Online Training: HV Training via webinar (Contact highvoltageservice@us.abb.com for a schedule and course options.)

Hone maintenance, diagnostic,

and troubleshooting skills

− Improve equipment reliability

− Develop maintenance skills

− Reduce repair time

− Extend equipment life

− And much more!

Click here to register online

(Applies to classes held in our Greensburg

Training Center only)

Seminar dates

38 / 72 / 145 / 170 PM / PMI/-B / C

January 17-19 June 6-8 September 12-14

242 PMR / PMRI

January 24-26 June 20-22 September 19-21

362 PM / PME / PMI / PMI-B

March 7-9 August 22-24 Oct 31-Nov 2

550 / 800 PM

February 7-9 August 8-10 October 10-12

242 PMG / PMI / PMG-B / PMI-B

February 21-23 August 29-31 December 5-7

145 / 242 PA

July 11-13 October 17-19

LTB / HPL / ELF (live tank)

April 25-27 November 7-9

Operating Mechanisms (ABB, BBC, Westinghouse)

(AHMA, HMB, FSA, BLK, BLG, AA-7/10/14) March 21-23 May 2-4 December 12-14

SCU / SCS / CBS / CBS Lite / CBS Lite CSA / CBS-F 6 / Asset Optimization / Monitoring Systems (*classes range from 1 to 3 days)

April 18-20* May 9-11*

Oil Circuit Breaker 101

March 29-30

ELK-04 GIS

August 15-17

SF 6 Handling & Safe Practices

April 4-5 June 13-14 November 14-15

Surge Arrester 101

October 24-25

For registration or information, contact:

Art Schultz, Training Coordinator

ABB Inc.

Click here to register online

231 Theobold Avenue

Greensburg, PA 15601

724-696-1397 *ABB reserves the right to cancel the course in the event of insufficient enrollment.

art.schultz@us.abb.com

ABB HV Service Training Brochure | Schedule 5

Course syllabi

38 / 72 / 145 / 170 PM / PMI/-B / C General Operation & Maintenance

Training

Duration 3 days

Professional 24 PDH / 2.4 CEU Eligible

Development Hours /

Continuing Education

Units

Included 38 / 72 / 145 / 170 PM/-B information manuals

3 continental breakfasts

3 lunches

1 group dinner

certificate of completion

Who would benefit Direct maintenance personnel

Substation maintenance engineers

Engineering managers

Substation supervisors

Asset Managers

Training Coordinators or Managers

Course summary ABB High Voltage Service is pleased to offer the following three (3) day training course consisting of classroom and hands-on

instruction in ABB’s Greensburg, PA facility. The course is aimed to provide a general understanding of operations and maintenance of

38 / 72 / 145 / 170 PM power circuit breakers. During the classroom portion, experienced instructors will share their knowledge and

expertise through interactive, engaging classroom instruction. To add further understanding, each main category of instruction will be

followed by hands-on activity where students can interact with the breaker first-hand.

Course Agenda Day 1 Day 2 Day 3

Introduction to Breaker Fundamentals Operating Mechanism (FSA, HMB, BLK, Installation and Commissioning

- Breaker safety & MSD) - Lifting the breaker

- Switching - Principles of operation - - Mounting to foundation

- Grounding spring mechanism - Electrical controls & alarms / lockouts

- Pole assembly hydraulic mechanism - Breaker timing

- Removal of bushings - Maintenance procedures / schedules - Leak detection

- Bushing lifting points - Charging system - Moisture analysis

- Through-rod connection - Trip / close coils - CT ratio and polarity

- Maintenance procedures / schedules - Trip / close latches - Contact resistance

- Auxiliary switches

38 / 72 / 145 / 170 PM and PMI Interrupter - Duty cycle SF6 Handling Procedures

Theory and Maintenance / Interrupter - Troubleshooting - Gas filling and vacuum procedures

Removal - Spare parts - SF6 by-products

- Interrupter overview

- Contact inspection

- Interrupter installation

Examination Quiz

6 Course syllabi | ABB HV Service Training Brochure

242 PMR / PMRI General Operation & Maintenance Training

Duration 3 days

Professional 24 PDH / 2.4 CEU Eligible

Development Hours /

Continuing Education

Units

Included 242 PMR / PMRI information manuals

3 continental breakfasts

3 lunches

1 group dinner

certificate of completion

Who would benefit First line maintenance managers

Direct maintenance personnel

Substation maintenance engineers

Engineering managers

Substation supervisors

Asset Managers

Training Coordinators or Managers

Course summary ABB High Voltage Service is pleased to offer the following three (3) day training course consisting of classroom and hands-on

instruction in ABB’s Greensburg, PA facility. The course is aimed to provide a general understanding of operations and maintenance

of 242 PMR / PMRI power circuit breakers. During the classroom portion, experienced instructors will share their knowledge and

expertise through interactive, engaging classroom instruction. To add further understanding, each main category of instruction will be

followed by hands-on activity where students can interact with the breaker first-hand.

Course Agenda Day 1 Day 2 Day 3

Introduction to Breaker Fundamentals Operating Mechanism (HMB) Installation and Commissioning

- Breaker safety - Principles of operation - - Lifting the breaker

- Switching hydraulic mechanism - Mounting to foundation

- Grounding - Maintenance procedures / schedules - Electrical controls & alarms / lockouts

- Pole assembly - Charging system - Breaker timing

- Removal of bushings - Trip / close coils - Leak detection

- Bushing lifting points - Trip / close latches - Moisture analysis

- Through-rod connection - Auxiliary switches - CT ratio and polarity

- Maintenance procedures / schedules - Duty cycle - Contact resistance

- Troubleshooting

242 PMR and PMRI Interrupter Theory and - Spare parts SF6 Handling Procedures

Maintenance / Interrupter Removal - Gas filling and vacuum procedures

- Interrupter overview - SF6 by-products

- Contact inspection

- Interrupter installation

Examination Quiz

ABB HV Service Training Brochure | Course syllabi 7

345 / 362 PM / PME / PMI / PMI-B General Operation & Maintenance

Training

Duration 3 days

Professional 24 PDH / 2.4 CEU Eligible

Development Hours /

Continuing Education

Units

Included 362 PM / PMI information manuals

3 continental breakfasts

3 lunches

1 group dinner

certificate of completion

Who would benefit First line maintenance managers

Direct maintenance personnel

Substation maintenance engineers

Engineering managers

Substation supervisors

Asset Managers

Training Coordinators or Managers

Course summary ABB High Voltage Service is pleased to offer the following three (3) day training course consisting of classroom and hands-on

instruction in ABB’s Greensburg, PA facility. The course is aimed to provide a general understanding of operations and maintenance of

362 PM / PMI power circuit breakers. During the classroom portion, experienced instructors will share their knowledge and expertise

through interactive, engaging classroom instruction. To add further understanding, each main category of instruction will be followed

by hands-on activity where students can interact with the breaker first-hand.

Course Agenda Day 1 Day 2 Day 3

Introduction to Breaker Fundamentals Operating Mechanism (AHMA-8 & HMB-8) Installation and Commissioning

- Breaker safety - Principles of operation - - Lifting the breaker

- Switching hydraulic mechanism - Mounting to foundation

- Grounding - Maintenance procedures / schedules - Electrical controls & alarms / lockouts

- Pole assembly - Charging system - Breaker timing

- Removal of bushings - Trip / close coils - Leak detection

- Bushing lifting points - Trip / close latches - Moisture analysis

- Through-rod connection - Auxiliary switches - CT ratio and polarity

- Maintenance procedures / schedules - Duty cycle - Contact resistance

- Troubleshooting

362 PM/PME/PMI Interrupter Theory and - Spare parts SF6 Handling Procedures

Maintenance / Interrupter Removal - Gas filling and vacuum procedures

- Interrupter overview - SF6 by-products

- Contact inspection

- Interrupter installation

Examination Quiz

8 Course syllabi | ABB HV Service Training Brochure

550 / 800 PM General Operation & Maintenance Training

Duration 3 days

Professional 24 PDH / 2.4 CEU Eligible

Development Hours /

Continuing Education

Units

Included 500 / 800 PM information manuals

3 continental breakfasts

3 lunches

1 group dinner

certificate of completion

Who would benefit First line maintenance managers

Direct maintenance personnel

Substation maintenance engineers

Engineering managers

Substation supervisors

Asset Managers

Training Coordinators or Managers

Course summary ABB High Voltage Service is pleased to offer the following three (3) day training course consisting of classroom and hands-on

instruction in ABB’s Greensburg, PA facility. The course is aimed to provide a general understanding of operations and maintenance of

550 / 800 PM power circuit breakers. During the classroom portion, experienced instructors will share their knowledge and expertise

through interactive, engaging classroom instruction. To add further understanding, each main category of instruction will be followed

by hands-on activity where students can interact with the breaker first-hand.

Course Agenda Day 1 Day 2 Day 3

Introduction to Breaker Fundamentals Operating Mechanism (AHMA-8/11 & Installation and Commissioning

- Breaker safety HMB-8/11)) - Lifting the breaker

- Switching - Principles of operation - - Mounting to foundation

- Grounding hydraulic mechanism - Electrical controls & alarms / lockouts

- Pole assembly - Maintenance procedures / schedules - Breaker timing

- Removal of bushings - Charging system - Leak detection

- Bushing lifting points - Trip / close coils - Moisture analysis

- Through-rod connection - Trip / close latches - CT ratio and polarity

- Maintenance procedures / schedules - Auxiliary switches - Contact resistance

- Duty cycle

550 / 800 PM Interrupter Theory and - Troubleshooting SF6 Handling Procedures

Maintenance / Interrupter Removal - Spare parts - Gas filling and vacuum procedures

- Interrupter overview - SF6 by-products

- Contact inspection

- Interrupter installation

- Grading capacitors

- Closing resistor

Examination Quiz

ABB HV Service Training Brochure | Course syllabi 9

245 / 242 PMG / PMI / PMG-B / PMI-B General Operation &

Maintenance Training

Duration 3 days

Professional 24 PDH / 2.4 CEU Eligible

Development Hours /

Continuing Education

Units

Included 242 PMG / PMI information manuals

3 continental breakfasts

3 lunches

1 group dinner

certificate of completion

Who would benefit First line maintenance managers

Direct maintenance personnel

Substation maintenance engineers

Engineering managers

Substation supervisors

Asset Managers

Training Coordinators or Managers

Course summary ABB High Voltage Service is pleased to offer the following three (3) day training course consisting of classroom and hands-on

instruction in ABB’s Greensburg, PA facility. The course is aimed to provide a general understanding of operations and maintenance of

242 / 245 PMG / PMI /-B power circuit breakers. During the classroom portion, experienced instructors will share their knowledge and

expertise through interactive, engaging classroom instruction. To add further understanding, each main category of instruction will be

followed by hands-on activity where students can interact with the breaker first-hand.

Course Agenda Day 1 Day 2 Day 3

Introduction to Breaker Fundamentals Operating Mechanism (AHMA-4/8 & Installation and Commissioning

- Breaker safety HMB-4/8) - Lifting the breaker

- Switching - Principles of operation - - Mounting to foundation

- Grounding hydraulic mechanism - Electrical controls & alarms / lockouts

- Pole assembly - Maintenance procedures / schedules - Breaker timing

- Removal of bushings - Charging system - Leak detection

- Bushing lifting points - Trip / close coils - Moisture analysis

- Through-rod connection - Trip / close latches - CT ratio and polarity

- Maintenance procedures / schedules - Auxiliary switches - Contact resistance

- Duty cycle

242 PMG and PMI Interrupter Theory and - Troubleshooting SF6 Handling Procedures

Maintenance / Interrupter Removal - Spare parts - Gas filling and vacuum procedures

- Interrupter overview - SF6 by-products

- Contact inspection

- Interrupter installation

Examination Quiz

10 Course syllabi | ABB HV Service Training Brochure

145 / 242 PA General Operation & Maintenance Training

Duration 3 days

Professional 24 PDH / 2.4 CEU Eligible

Development Hours /

Continuing Education

Units

Included 145 / 242 PA information manuals

3 continental breakfasts

3 lunches

1 group dinner

certificate of completion

Who would benefit First line maintenance managers

Direct maintenance personnel

Substation maintenance engineers

Engineering managers

Substation supervisors

Asset Managers

Training Coordinators or Managers

Course summary ABB High Voltage Service is pleased to offer the following three (3) day training course consisting of classroom and hands-on

instruction in ABB’s Greensburg, PA facility. The course is aimed to provide a general understanding of operations and maintenance of

145 / 242 PA power circuit breakers. During the classroom portion, experienced instructors will share their knowledge and expertise

through interactive, engaging classroom instruction. To add further understanding, each main category of instruction will be followed

by hands-on activity where students can interact with the breaker first-hand.

Course Agenda Day 1 Day 2 Day 3

Introduction to Breaker Fundamentals Operating Mechanism (AHMA-8/11 & Installation and Commissioning

- Breaker safety HMB-8/11)) - Lifting the breaker

- Switching - Principles of operation - - Mounting to foundation

- Grounding hydraulic mechanism - Electrical controls & alarms / lockouts

- Pole assembly - Maintenance procedures / schedules - Breaker timing

- Removal of bushings - Charging system - Leak detection

- Bushing lifting points - Trip / close coils - Moisture analysis

- Through-rod connection - Auxiliary switches - CT ratio and polarity

- Maintenance procedures / schedules - Duty cycle - Contact resistance

- Troubleshooting

145 and 242 PA Interrupter Theory and - Spare parts SF6 Handling Procedures

Maintenance / Interrupter Removal - Gas filling and vacuum procedures

- Interrupter overview - SL & SP - SF6 by-products

- Contact inspection

- Interrupter installation

Examination Quiz

ABB HV Service Training Brochure | Course syllabi 11

LTB / HPL / ELF General Operation & Maintenance Training

Duration 3 days

Professional 24 PDH / 2.4 CEU Eligible

Development Hours /

Continuing Education

Units

Included information manuals

3 continental breakfasts

3 lunches

1 group dinner

certificate of completion

Who would benefit First line maintenance managers

Direct maintenance personnel

Substation maintenance engineers

Engineering managers

Substation supervisors

Asset Managers

Training Coordinators or Managers

Course summary ABB High Voltage Service is pleased to offer the following three (3) day training course consisting of classroom and hands-on

instruction in ABB’s Greensburg, PA facility. The course is aimed to provide a general understanding of operations and maintenance

of HPL / ELF power circuit breakers. The course will cover a variety of voltage classes, depending on the equipment types the course

attendees encounter in the field. During the classroom portion, experienced instructors will share their knowledge and expertise

through interactive, engaging classroom instruction. To add further understanding, each main category of instruction will be followed

by hands-on activity where students can interact with the breaker first-hand.

Course Agenda Day 1 Day 2 Day 3

Introduction to Breaker Fundamentals Operating Mechanism (BLG1002/1002A, Installation and Commissioning

- Breaker safety PKA & AHMA-8) - Lifting the breaker

- Switching - Principles of operation - - Mounting to foundation

- Grounding spring / spring, pneumatic and hydraulic - Electrical controls & alarms / lockouts

- Maintenance procedures / schedules / spring mechanism - Breaker timing

- Maintenance procedures / schedules - Leak detection

HPL / ELF Interrupter Theory and ◊ Changeout and adjustments of: - Moisture analysis

Maintenance / Interrupter Removal • Coils - CT ratio and polarity

- Interrupter overview • Dashpots (BLG only) - Contact resistance

• Spur gear (BLG only)

Disassembly and Reassembly of • Charging motor SF6 Handling Procedures

Interrupter Chambers • Trip and close latches (BLG only) - Gas filling and vacuum procedures

- Inspection of nozzles and arching • Adjustment of clutch and limit - SF6 by-products

contacts switches

- Interrupter installation • Control valve (PKA & AHMA only)

- Auxiliary switches

- Duty cycle

- Troubleshooting

- Spare parts

Examination Quiz

12 Course syllabi | ABB HV Service Training Brochure

Operating Mechanisms (ABB, BBC & Westinghouse) General Operation

& Maintenance Training

Duration 3 days

Professional 24 PDH / 2.4 CEU Eligible

Development Hours /

Continuing Education

Units

Included operating mechanism information manuals

3 continental breakfasts

3 lunches

1 group dinner

certificate of completion

Who would benefit First line maintenance managers

Direct maintenance personnel

Substation maintenance engineers

Engineering managers

Substation supervisors

Asset Managers

Training Coordinators or Managers

Course summary ABB High Voltage Service is pleased to offer the following three (3) day training course consisting of classroom and hands-on

instruction in ABB’s Greensburg, PA facility. The course is aimed to provide a general understanding of operations and maintenance

of ABB legacy mechanisms. During the classroom portion, experienced instructors will share their knowledge and expertise through

interactive, engaging classroom instruction. To add further understanding, each main category of instruction will be followed by hands-

on activity where students can interact with the breaker first-hand.

Course Agenda Day 1 Day 2 Day 3

Operating Mechanism (FSA, BLG, BLK, Operating Mechanism (HMB, AHMA & Westinghouse Mechanisms Background

& MSD) PKA) - Preceding Westinghouse mechanism

- Principles of operation - - Principles of operation - designs

spring / spring mechanisms hydraulic / spring mechanisms

- Maintenance procedures / schedules - Maintenance procedures / schedules Type AA-7, AA-10 & AA-14 Pneumatic

- Charging system - Charging system Mechanisms

- Trip / close coils - Trip / close coils - Design objectives and advantages

- Trip / close latches - Trip / close latches - Operating system function

- Auxiliary switches - Auxiliary switches - Basic mechanism theory and operation

- Duty cycle - Duty cycle - Changes and interchangeability

- Troubleshooting - Troubleshooting

- Spare parts - Spare parts Field Maintenance

BBC Mechanisms (PKA & HKA) Factory Remanufacturing

- Principles of operation -

pneumatic mechanisms Field Replacement

- Principles of operation -

hydraulic / nitrogen mechanisms Troubleshooting

- Troubleshooting

- Spare parts

Hydraulic Mechanism

- Maintenance procedures / schedules

- Charging system

- Trip / close coils

- Trip / close latches

- Auxiliary switches

- Duty cycle

- Troubleshooting

- Spare parts

Examination Quiz

ABB HV Service Training Brochure | Course syllabi 13

SCU / SCS / CBS / CBS Lite / CBS Lite CSA / CBS-F6 / Asset

Optimization / Monitoring Systems Fundamentals Training

Duration 1, 2, or 3 days

Professional 24 PDH / 2.4 CEU Eligible for three days

Development Hours / 16 PDH / 1.6 CEU Eligible for three day

Continuing Education

Units 8 PDH / 0.8 CEU Eligible for one day

Included SCU / SCS / CBS / Asset Insight information manuals

1 - 3 continental breakfasts

1 - 3 lunches

1 group dinner

certificate of completion

Who would benefit First line maintenance managers

Direct maintenance personnel

Substation maintenance engineers

Engineering managers

Substation supervisors

Course summary ABB High Voltage Service is pleased to offer the following training course consisting of classroom and hands-on instruction in ABB’s

Greensburg, PA facility. The course is aimed to provide a general understanding of operations and maintenance of ABB’s SCU, SCS, CBS,

CBS Lite, CBS Lite CSA, and CBS-F6 circuit breaker monitoring systems as well as asset optimization remote monitoring software. The

course will cover a variety of voltage classes, depending on the equipment types the course attendees encounter in the field. During the

classroom portion, experienced instructors will share their knowledge and expertise through interactive, engaging classroom instruction.

To add further understanding, each main category of instruction will be followed by hands-on activity where students can interact with the

units first-hand.

Course Agenda 1 Day - SCU/SCS 1 Day - CBS / CBS Line of Devices 1 Day - Asset Optimization

Introduction to the SCU/SCS Introduction to the CBS Devices Asset Optimization Operational Training

− Capacitor bank energization − Sensors − Asset Optimization architecture

− Equipment stress − Hardware − Operate objects

− Transient migration methods − Monitoring concepts − Object Aspect navigation

− Pre-insertion resistors − Alarms handling

− CB Insight

− What is synchronous closing? − Asset monitors & reporters

− Setup and configuration

− Point-on-wave control

− Factory test − Trend displays

− Transient control with synchronous closing

− Responding to alarms − Asset reports

− Advancements in technology

− Synchronous closing design goals − CBS communication concepts − Monitoring applications (e.g. CB Insight)

− Interrupter issues

− Control algorithm - compensation CBS Hands-on Commissioning Note: Customized training sessions can be

− Control algorithm - adaptation − Wiring and sensor installation offered upon request.

− Control hardware requirements ◊ Wiring of the RS485 bus

− Timing considerations ◊ Installation of clamp-on transformers

◊ Customer specific wiring

SCU Hands-on Commissioning − Field commissioning with CB Insight

− SCU control software software

− Setup of breaker for test ◊ Establish Communication wizard

− SCU connections ◊ Field Commissioning Wizard

− Why commission the SCU?

− Troubleshooting the CBS devices

− Verify communication

− Temperature Compensation Wizard

− Verifying parameters

− Changing parameters

− Point-on-wave control

− Event diagrams - grounded

− Event diagrams - ungrounded

− Closing time compensation

− Adaptation adjustment

− Event status report

− Breaker operations

− Troubleshooting sync problems

− Finalizing settings

− Create commissioning report and log file

− Lightbulb tests/Hot sync

− SCU tester

SCS Hands-on Commissioning

− Connections and Wiring

− Verifying SCS Connections

− Phase Rotation (A-B-C or A-C-B)

− Location of Phases with Respect to CB Poles

− CB Insight download

− CB Insight and settings

− Establish and verify Communication

− Alarm Conditions & Panel Lights

− Device Settings Tab

− Event Summary Tab

− Commissioning wizard

− SCS Light-Bulb Test

− Troubleshooting Sync Problems

− Data download

− Creating CBI file

14 Course syllabi | ABB HV Service Training Brochure

Oil Circuit Breaker 101 - Applications, Operations and Maintenance

Fundamentals Training

Duration 2 days

Professional 16 PDH / 1.6 CEU Eligible

Development Hours /

Continuing Education

Units

Included OIl circuit breaker information manuals

2 continental breakfasts

2 lunches

1 group dinner

certificate of completion

Who would benefit First line maintenance managers

Direct maintenance personnel

Those customers who have oil circuit breakers in their population of high voltage breakers

Course summary The course will cover the basic applications, operations and maintenance fundamentals of oil circuit breakers. Emphasis will

be placed on Westinghouse breakers, but the course will also touch on other popular designs of the era. Knowledgeable

ABB instructors will present in their individual areas of expertise, ranging from the major components of the breaker, to

maintenance and troubleshooting. The course will comprise of classroom instruction, demonstrations and hands-on training.

During the hands-on portion of the course, participants will be broken into small groups and rotated through stations for face-

to-face interaction with ABB experts and first-hand experience.

Course Agenda Day 1 Day 2

ABB Greensburg Facility ABB Greensburg Facility

Classroom Instruction - Main Conference Classroom Instruction

Room - Field maintenance

- Greeting / introductions - Control / schematics

- Fundamentals - Troubleshooting

- Mechanisms - Questions

- Linkage

Lunch

Lunch

Hands-on Session

Classroom Instruction - Stations

- Interrupters ◊ Control cabinet

- Bushings ◊ Mechanisms - pnuematic and sole-

- Current transformers noid

◊ Linkages

Dinner ◊ Interrupters

Discussion / Wrap-up

ABB HV Service Training Brochure | Course syllabi 15

SF6 Handling and Safe Practices Training

Duration 2 days

Professional 16 PDH / 1.6 CEU Eligible

Development Hours /

Continuing Education

Units

Included SF6 Handling Guide (Recycling and Re-use)

2 continental breakfasts

2 lunches

1 group dinner

certificate of completion

Who would benefit Direct maintenance personnel

Substation maintenance engineers

Substation Supervisors

Environmental personnel that report SF6 gas usage and emissions to government agencies

Course summary ABB High Voltage Service is pleased to offer the following two (2) day training course consisting of classroom and hands on instruction

in ABB’s Greensburg, PA facility. The course is aimed to provide to you a safe and environmentally responsible methodology while

handling SF6 gas. During the classroom portion, experienced instructors will share their knowledge and experience through interactive,

engaging classroom instruction. To add further understanding, a hands on activity where students can interact with the SF 6 handling

equipment, including gas carts, analyzers, fittings, and hoses will be employed on the second day.

Course Agenda Day 1 Day 2

Introduction SF6 switchgear

SF6 background and applications Inventory management and record keeping

Environmental impact and government Leak management and live monitoring

regulation

SF6 chemistry, by-products and testing

SF6 safety

Transport and storage

SF6 Recycling

SF6 Field Analyzers and Equipment

Equipment Decommissioning

Examination Quiz

16 Course syllabi | ABB HV Service Training Brochure

Surge Arresters 101 Fundamentals Training

Duration 1.5 days

Professional 12 PDH / 1.2 CEU Eligible

Development Hours /

Continuing Education

Units

Included Surge Arrester information manuals

2 continental breakfasts

2 lunches

1 group dinner

certificate of completion

Who would benefit First line maintenance managers

Direct maintenance personnel

Substation maintenance engineers

Engineering managers

Substation supervisors

Asset Managers

Course summary ABB High Voltage Service is pleased to offer the following two (2) day training course consisting of classroom and hands-on instruction

in ABB’s Greensburg, PA facility. The course is aimed to provide a general understanding of operations and maintenance of surge

arresters. During the classroom portion, experienced instructors will share their knowledge and expertise through interactive, engaging

classroom instruction. To add further understanding, a guided walk-through of the surge arrester manufacturing line in the Mt.

Pleasant facility will be provided.

Course Agenda Day 1 Day 2

Why Use Surge Arresters? Review and Summarization of Day 1

Types of Overvoltages Question and Answer Session

Surge Arrester Applications & Installation Factory Tour - Surge Arrester Production

Line

How do Surge Arresters Work?

Surge Arrester Ratings

Selecting the Proper Surge Arresters for

your System

Types of System Connections

Continuous Operating Voltages

Insulation Withstand and Arrester Protec-

tion Levels

Examination Written examination

ABB HV Service Training Brochure | Course syllabi 17

GIS General Operation & Maintenance Training

Duration 3 days

Professional 24 PDH / 2.4 CEU Eligible

Development Hours /

Continuing Education

Units

Included ELK-04 GIS information manuals

3 continental breakfasts

3 lunches

1 group dinner

certificate of completion

Who would benefit Direct maintenance personnel

Substation maintenance engineers

Substation Supervisors

Asset Managers

Training Coordinators or Managers

Course summary ABB High Voltage Service is pleased to offer the following three (3) day training course consisting of classroom and hands-on

instruction in ABB’s Greensburg, PA facility. The course is aimed to provide a general understanding of operations and maintenance of

high voltage gas insulated switchgear. The specific type covered in this course is ELK-04. During the classroom portion, experienced

instructors will share their knowledge and expertise through interactive, engaging classroom instruction. To add further understanding,

each main category of instruction will be followed by hands-on activity where students can interact with the GIS and mechanisms first-

hand

Course Agenda Day 1 Day 2 Day 3

Introduction to GIS fundamentals Operating Mechanism (AHMA & HMB) Installation and Commissioning

- Flange connection

- GIS safety - Principles of operation - hydraulic

- GIS components mechanism - Rupture disc and desiccant

- Switching disconnects and grounds - Maintenance procedures / schedules - Transversal dismantling unit

- Outdoor vs indoor application - Charging system

- Testing from Fast Acting Ground

- Interlocking - Trip / close coils

- Maintenance procedures / schedules - Trip / close latches Switches

- Auxiliary switches

GIS Interrupter Theory and Maintenance / - Duty cycle

SF6 Procedures

Interrupter Removal - Troubleshooting

- Spare parts - Gas filling and vacuum procedures

- Interrupter Removal - SF6 by-products

- Contact inspection

- Interrupter instalation

- SF6 Handling

Examination Quiz

18 Course syllabi | ABB HV Service Training Brochure

Customized Training Course

Duration Varies, 1 to 3 days

Professional Variable PDH / Variable CEU Eligible

Development Hours /

Continuing Education

Units

Included Subject-related nformation manuals

Variable continental breakfasts

Variable lunches

1 group dinner

certificate of completion

Who would benefit First line maintenance managers

Direct maintenance personnel

Substation maintenance engineers

Engineering managers

Substation supervisors

Asset Managers

Course summary ABB High Voltage Service is pleased to offer a one to three day training course with subject matter and content developed per the

customer request and assets in their fleet. Subject matter may be a combination of courses in this training catalog or customzed

subject matter. Contact ABB for options and to discuss specific material to be covered. This course may be offered at the customer

site or in ABB’s HV training facility. During the classroom and/or interactive hands-on portions, experienced instructors will share their

knowledge and expertise. To add further understanding, actual equipment, or demo equipment may be used to aid in learning by

interacting with actual equipment or solutions.

Course Agenda Day 1 Day 2 (Optional) Day 3 (Optional)

Course outline developed per customer Course outline developed per customer

Course outline developed per customer

request / assets in fleet request / assets in fleet

request / assets in fleet

Examination Quiz

ABB HV Service Training Brochure | Course syllabi 19

Frequently Asked Questions

Q What do I need to bring?

A Personal protective equipment (PPE). A portable computer (laptop / tablet is not needed but may be helpful. Each desk

has an electrical outlet. To provide the highest level of learning possible, the training center and hands-on workshop is

located inside ABB’s High Voltage Service remanufacturing facility. Trainees must wear PPE. Steel toe boots and safety

glasses are required. Gloves may be worn during the hands-on portion at the attendee’s personal discretion.

Q What do I need to know / study beforehand?

A There is no pre-training studying or coursework required. We recommend you have at least two years of high voltage or

power equipment experience.

Q Is there are cafeteria on site?

A Lunch will be provided. Vending machines are also located on site.

Q Will I get to see any circuit breakers in production?

A Yes, training includes two tours. ABB North America’s dead tank circuit breaker production facility where a full portfolio of

72 - 800 kV high voltage breakers are built every year, along with the production of high voltage switchgear mechanisms,

surge arresters, and capacitors. ABB High Voltage Service’s remanufacturing facility produces custom built high voltage

switchgear, rebuilds dead tank breakers, live tank breakers, oil breakers, and gas insulated switchgear, in addition to

stocking the largest OEM inventory in the high voltage industry.

Q Will I get experience working on a circuit breaker? (Operations & Maintenance courses)

A Training includes classroom explanation and hands-on experience, dis- and re-assembling a high voltage circuit breaker

interrupter and performing general maintenance procedures on an operating mechanism.

Q Will I be eligible to earn Professional Development Hours (PDH’s) or Continuing Education Units (CEU’s)?

A Yes, ABB will provide you with a certificate of completion for 24 PDH’s (equivalent to 2.4 CEU’s). This is based on our

standard three-day training course. Customized courses, shorter or longer courses, will earn PDH’s/CEU’s on a sliding

scale. The trainee is responsible for administering PDH and/or CEU requirements.

Q Do you hold training courses in a language other than English?

A ABB can make accommodations for bi-lingual training courses. Contact your ABB High Voltage Service marketing

representative for details.

Q What travel arrangements are available for individuals unfamiliar with driving in the US?

A There are several public transportation options for commuting to and from the training center.

Q Where are the training classes held?

A Training is held at High Voltage’s Service’s remanufacturing and training center: 231 Theobold Avenue, Greensburg,

PA 15601 (except for Surge Arrester courses, SA 101 is held at the Surge Arrester factory: 100 Distribution Circle, Mt.

Pleasant, PA 15666.)

Q What time does training start?

A Classes run from 8 AM to 5 PM each day.

For registration or information, contact:

Art Schultz, Training Coordinator

ABB Inc.

231 Theobold Avenue

Greensburg, PA 15601

724-696-1397

art.schultz@us.abb.com

20 Course syllabi | ABB HV Service Training Brochure

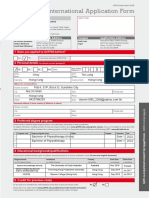

Registration & Important Information

Personal data

First Name ____________________________________ Last Name __________________________________

Company ____________________________________ Title _______________________________________

Street _______________________________________ City / State __________________________________

Country / Zip Code _______________________________ Office Phone _________________________________

Mobile _______________________________________ Email _____________________________________

Training course _________________________________ Dates _____________________________________

Complete entire form and fax to 724-696-1379 or email to art.schultz@us.abb.com.

Copy this page for additional attendees. Attach purchase order to this form. Please

contact your marketing representative if paying by credit card. Keep a copy of each page

for your records.

PO No. ______________________________________ Date ______________________________________

Signature _____________________________________ Printed Name ________________________________

Conditions for participation:

- Attendees must wear steel toe shoes / boots and safety glasses. Safety glasses can be provided. Attendees must obey safety rules of

instructor at all times.

- Attendees must have basic technical knowledge of high voltage power equipment.

- Courses run from 8 AM to 5 PM EST.

- Courses are conducted in English. Attendees will incur the cost of a translator to conduct courses in an alternative language.

- Registration and purchase order / payment must be received before each class begins.

- Attendees must notify ABB of special dietary needs.

Hotel Accomodations Hotel Accomodations International & Local Airports

Holiday Inn Express Ramada Greensburg Hotel Pittsburgh International Airport

250 Bessimer Road 100 Ramada Inn Drive Pittsburgh, PA 15231

Mount Pleasant, PA 15666 Greensburg, PA 15601 (412) 472-3500

(724) 547-2095

(724) 836-6060

Arnold Palmer Regional Airport

Courtyard by Marriott Greensburg

Hampton Inn Greensburg Aviation Lane

700 Power Line Drive

1000 Towne Square Drive Latrobe, PA 15650

Greensburg, PA 15601

Greensburg, PA 15601 (724) 539-8100

(724) 834-3555 (724) 838-8800

For registration or information, contact:

Holiday Inn Express & Suites Four Points by Sheraton Pittsburgh Airport Art Schultz, Training Coordinator

ABB Inc.

137 Blair street One Industry Lane 231 Theobold Avenue

Greensburg, PA 15601 Pittsburgh, PA 15108 Greensburg, PA 15601

724-696-1397

724-837-1400 (724) 695-0002 art.schultz@us.abb.com

ABB HV Service Training Brochure | Course syllabi 21

Contact us

Document Number 2GNM110108 / November 2015

ABB High Voltage Training Center & Click here to register online

Remanufacturing Facility (Greensburg Training Center classes only)

231 Theobold Avenue Contact us to register for on-site or customized

Greensburg, PA 15601 classes.

(Courses held here)

US High Voltage Service Headquarters

ABB Inc.

High Voltage Service

100 Distribution Circle

Mount Pleasant, Pennsylvania, USA

Phone +1 (724) 696-1300

Fax: +1 (724) 696-1379

highvoltageservice@us.abb.com

www.abb.us/hvservice

Interested in learning more? Scan the above QR code

with your phone or other mobile device to sign up for

our newsletter. Be the first to know about future training,

events, white papers, and more!

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Teaching Arts in The Elementary Grades: OgdimalantaDocument12 pagesTeaching Arts in The Elementary Grades: OgdimalantaDiana Rose SimbulanPas encore d'évaluation

- GE Jack Welch Case StudyDocument30 pagesGE Jack Welch Case StudyEqraChaudhary100% (1)

- Math 7 Summative Test: - Read The Questions Carefully. Choose The Letter of Your Answer and Write It in YourDocument4 pagesMath 7 Summative Test: - Read The Questions Carefully. Choose The Letter of Your Answer and Write It in Youretheljoy agpaoaPas encore d'évaluation

- Griffith Application Form UgpgDocument2 pagesGriffith Application Form UgpgDenise SummerPas encore d'évaluation

- Preservice ESP Teacher Training in An African French-Speaking Country - RevisitedDocument17 pagesPreservice ESP Teacher Training in An African French-Speaking Country - RevisitedZoumana KonePas encore d'évaluation

- S4 Mitotic Cell Division Lesson Plan PDFDocument4 pagesS4 Mitotic Cell Division Lesson Plan PDFShiella Mae Baltazar BulauitanPas encore d'évaluation

- Duxbury Clipper 2010 - 12 - 05Document48 pagesDuxbury Clipper 2010 - 12 - 05Duxbury ClipperPas encore d'évaluation

- Beliefs, Practices, and Reflection: Exploring A Science Teacher's Classroom Assessment Through The Assessment Triangle ModelDocument19 pagesBeliefs, Practices, and Reflection: Exploring A Science Teacher's Classroom Assessment Through The Assessment Triangle ModelNguyễn Hoàng DiệpPas encore d'évaluation

- Cambridge Primary Maths Curriculum OutlineDocument2 pagesCambridge Primary Maths Curriculum OutlineMike Serge Razafi0% (1)

- Department of Education: Weekly Learning Activity PlanDocument2 pagesDepartment of Education: Weekly Learning Activity PlanSaz RobPas encore d'évaluation

- Exam For Real Estate in CaliforniaDocument230 pagesExam For Real Estate in Californiaharpay100% (9)

- IGCSE Science (Double Award) TSM Issue 2Document52 pagesIGCSE Science (Double Award) TSM Issue 2frogfloydPas encore d'évaluation

- Frontlearn 2021 Fee StructureDocument1 pageFrontlearn 2021 Fee StructureNjihiaPas encore d'évaluation

- KIG 2020 Final ReportDocument107 pagesKIG 2020 Final ReportCitizen Matters100% (1)

- Father ManualDocument5 pagesFather Manualapi-355318161Pas encore d'évaluation

- Valley Cultural Center - Concerts On The Green 2011 ProgramDocument80 pagesValley Cultural Center - Concerts On The Green 2011 ProgramvalleyculturalcenterPas encore d'évaluation

- B. SPT Memo TOR MAESDocument8 pagesB. SPT Memo TOR MAESEVA NOEMI ABAYONPas encore d'évaluation

- Annual Report 2010Document72 pagesAnnual Report 2010Yan-Lin Jubi LeePas encore d'évaluation

- Planting Our Own SeedsDocument6 pagesPlanting Our Own Seedsapi-612470147Pas encore d'évaluation

- 16 Ombudsman v. GaliciaDocument21 pages16 Ombudsman v. GaliciaMark De JesusPas encore d'évaluation

- Lac Sessions: General Tinio National High SchoolDocument1 pageLac Sessions: General Tinio National High SchoolFrancis JosePas encore d'évaluation

- Ya'qūb Ibn Is Āq Al-Kindī, Alfred L. Ivry-Al-Kindi's Metaphysics - A Translation of Ya'qūb Ibn Is Āq Al-Kindī's Treatise On First Philosophy (Fī Al-Falsafah Al-Ūlā) - SUNY (1974) PDFDocument215 pagesYa'qūb Ibn Is Āq Al-Kindī, Alfred L. Ivry-Al-Kindi's Metaphysics - A Translation of Ya'qūb Ibn Is Āq Al-Kindī's Treatise On First Philosophy (Fī Al-Falsafah Al-Ūlā) - SUNY (1974) PDFDwi Afrianti50% (2)

- Dissertation Peut On Se Connaitre Soi Meme IntroductionDocument6 pagesDissertation Peut On Se Connaitre Soi Meme IntroductionCanadaPas encore d'évaluation

- MG Rolly Dela Torre: Certificate of AppreciationDocument15 pagesMG Rolly Dela Torre: Certificate of AppreciationMajoy TibayPas encore d'évaluation

- Nov2017 GeotechnicalEngineering JGB Part1Document121 pagesNov2017 GeotechnicalEngineering JGB Part1Kim Dionald EimanPas encore d'évaluation

- 11 2f9 6th Grade PLC Agenda and MinutesDocument2 pages11 2f9 6th Grade PLC Agenda and Minutesapi-365464044Pas encore d'évaluation

- Final Score Card For MBA Jadcherla (Hyderabad) Program - 2021Document3 pagesFinal Score Card For MBA Jadcherla (Hyderabad) Program - 2021Jahnvi KanwarPas encore d'évaluation

- RUTAGDocument3 pagesRUTAGRidwan AhmedPas encore d'évaluation

- Detailed Lesson Plan FINAL 4asDocument3 pagesDetailed Lesson Plan FINAL 4asLENY SILAGAN TEJANOPas encore d'évaluation