Académique Documents

Professionnel Documents

Culture Documents

Half Elevation of P.S.C.Girder: Islamabad National Highway Authority

Transféré par

Zubair MuhammadTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Half Elevation of P.S.C.Girder: Islamabad National Highway Authority

Transféré par

Zubair MuhammadDroits d'auteur :

Formats disponibles

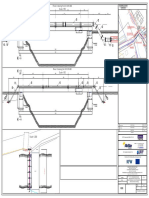

CL OF PSC GIRDER

SYMMETRICAL ABOUT LC

44275 150

38

22137.5 22137.5

217 235

1500 750

CL OF DIAPHRAGM

600

600

433

13/0.5" CABLE

217

NO 1

SHADED PORTION

13/0.5" CABLE

NO 2 TO BE CONCRETED

217

AFTER PRESTRESSING

2600

433

13/0.5" CABLE NO AND GROUTING

3

217

13/0.5" CABLE NO

4

217

13/0.5" CABLE NO 5

433

217

LIFT HOLE

217

100 I.D. G.I. PIPE,750 LONG CABLE NO.5 CABLE NO.4 CABLE NO.3 CABLE NO.2 CABLE NO.1

HALF ELEVATION OF P.S.C.GIRDER

433

217

44275

22137.5 22137.5

198 208

433

27

1100

1,2,

750

3,4 & 5 100

ANCHORAGE PIT DETAIL

HALF PLAN OF P.S.C.GIRDER

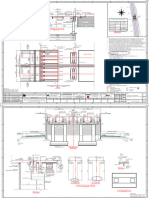

1100 1100 1100 1100 1100 NOTES:

1. TOTAL EXTENSION SHOWN IN THE TABLE IS INCLUSIVE OF 6mm SETBACK.

170

2. PRESTRESSING CABLES SHALL BE BASED ON SEVEN WIRES MULTI STRAND SYSTEM

225

CONFORMING TO AASTHTO M203 GRADE 270.

1 3. ALL STEEL SHALL BE HIGH YIELD GRADE 60 CONFORMING TO ASTM A615 UNLESS OTHERWISE

455 MENTIONED.

4. CLASS 'D1' (350Kg/sq.cm) (5000PSI) CONCRETE SHALL BE USED.

2 5. PROFILE OF CABLE CORRESPONDS TO THE CENTRE OF CABLE i.e. CENTROID OF STRANDS AND

SHALL BE ACHIEVED AFTER STRESSING.

2600

2165

1625

1 190 6. ALL CABLES SHALL BE STRESSED AND LOCKED IF ANCHORAGE PULL IN EXCEEDS 6mm, THE CABLE

2600

3

SHALL BE DE-STRESSED AND SHALL BE PRESTRESSED.

7. PRESTRESSED GIRDERS SHALL NOT BE CAST ON CONCRETE OR MASONRY PLASTERED

1732

2

4 20 PLATFORMS CONSTRUCTED ON GROUND. BOTTOM FORM WORK SHALL BE PROPERLY

1299

DESIGNED STEEL PLATES. THE SKIN PLATES SHALL NOT BE LESS THAN 3mm THICK AND

1

1314

3 STIFFENED TO ENSURE CONCRETE SURFACES FREE FROM WRINKLES, WARPS AND OFFSETS. SIDE

866

2 9090 FORM WORK PLANKS SHALL BE SECURED BY STEEL TIES IN CONCRETE OR STEEL FERRULES.

991

300 280

5

4 20 1 PLASTIC PIPES ARE PROHIBITED.

706

627

498

3 2 1 2

433

5 8. TENDONS SHALL BE GROUTED AFTER PRESTRESS ING WITH NEAT CEMENT GROUT OF 0.55

369

342

4 3 5 3 5

251

224

220

5 4 4

176

121

WATER CEMENT RATIO. NO ADDITIVES SHALL BE USED.

90

90

90

30 30 120 120 130 130 130 130 9. ANCHORAGE POCKETS SHALL BE FILLED WITH CONCRETE (f'c=165kg/sq cm) USING 10mm

375 375 750 750 750 750 DOWN AGGREGATES, AFTER GROUTING AND TRIMMING TENDONS.

10. ALL CONCRETE SHALL BE FAIR-FACED USING STEEL FORM WORK AND PLATES OF NOT LESS

END VIEW SEC. AT 16613 SEC. AT 11075 SEC. AT 5538 SEC. AT 0000 THAN 3mm THICKNESS. TIMBER OR STEEL CLAD TIMBER FORM SHALL NOT BE ALLOWED.

11. OVERLAP IN STEEL WHERE REQUIRED SHALL BE STAGGERED.

CABLE PROFILE

DIA OF SHEATHING (mm) 12. PRESTRESS ALONG WITH ITS COMPLETE FIXTURES WILL BE ACCORDING TO STRONGHOLD

COORDINATES OF CABLES PROFILE FROM C/L OF GIRDER (mm) CABLE /STRANDS (13/0.5”)

JACKING

SYSTEM OR EQUIVALENT.

THREADING THREADING

X=0 FORCE IN TOTAL EXTENSION** CABLE

BEFORE

13. GIRDER TOP WILL BE ROUGHENED TO FULL AMPLITUDE OF 6 mm.

CABLE 2769 5538 8306 11075 13844 166 13 19381 22150 ORDER OF AFTER

(mm) METRIC AT JACKING END STRANDS

CONCRETING CONCRETING 14. THE FOLLOWING PARAMETERS HAVE BEEN USED IN DESIGN:-

NO 1/8 L 2/8L 3/8 L 4/8 L 5/8 L 6/8 L 7/8 L END PRESTRESSING

C.L TONNES OF CABLE (mm)

(ACTUAL)

8

63 51 a. ANCHORAGE SLIP = 5mm

Y 220 250 342 494 706 980 1314 1709 2165

9

1 210.8 152.2+152.2=304.4 B b. FRICTION CURVATURE COEFF ICIENT 0.300 PER RAD.

Z -130 -130 -90 -40 -20 -10 0 0 0 10

Y 220 220 251 343 498 714 99 1 1331 1732 c. FRICTION WOBBLE COEFFICIENT 0.0020/m.

2 210.8 151.6+151.6=303.2 C 11 75 63

Z 130 130 90 40 20 10 0 0 0 d. MODULUS OF ELASTICITY OF STEEL 193MPa (28.00Ksi).

12

Y 90 90 90 124 224 392 62 7 930 1299 e. JACKING SHOULD BE DONE FROM BOTH ENDS.

3 210.8 151.4+151.4=302.8 D 13

Z -130 -130 -130 -130 -120 -80 -30 -10 0

Y 90 90 90 90 121 214 36 9 587 866 14 81 75

4 210.8 151.3+151.3=302.7 E 15

Z 130 130 130 130 120 80 30 10 0

Y 90 90 90 90 90 111 17 6 283 433 16

5 210.8 151.6+151.6=303.2 A

Z 0 0 0 0 0 0 0 0 0 17

* INCLUDING HYDRAULIC PUMP LOSSES OF 2 %. 90 81

18 DATE

** IT INCLUDES PULL IN OF 6mm.

*** JACKING SHOULD BE DONE FROM BOTH ENDS. 19 REVISED

DEC, 2017

04 DESIGNED BY Dr. M IQBAL

SCALE

03 DRAWN BY ARIF RAO

NATIONAL HIGHWAY AUTHORITY 02 CHECKED BY HASSAM ULLAH

SWAN BRIDGE (NBC) AS SHOWN

ISLAMABAD 01 RECOMMENDED Km: 1534 (N-5) DATE DWG. NO.

A-017

Vous aimerez peut-être aussi

- SM 74 Specs PDFDocument97 pagesSM 74 Specs PDFLODELBARRIO RD100% (10)

- Employee Details Gross SalaryDocument1 110 pagesEmployee Details Gross Salaryghanpreet arora100% (1)

- Get Published Workbook - The Busy Persons Guide To Writing A Book PDFDocument13 pagesGet Published Workbook - The Busy Persons Guide To Writing A Book PDFwintermute57Pas encore d'évaluation

- Valhalla Schematic PDFDocument1 pageValhalla Schematic PDFelekoss100% (1)

- Fender Rumble 75Document2 pagesFender Rumble 75GustavoTfLaPas encore d'évaluation

- 60 M.bow String Girder 10411 3 RDocument1 page60 M.bow String Girder 10411 3 RkesharinareshPas encore d'évaluation

- The Five People You Meet in HeavenDocument11 pagesThe Five People You Meet in HeavenXstffn Membrere SalapangPas encore d'évaluation

- Pen and Ink Drawing Techniques PDFDocument4 pagesPen and Ink Drawing Techniques PDFDiwas ChauhanPas encore d'évaluation

- 4 Nysdtsea Unit 4 Traffic Control Devices and LawsDocument68 pages4 Nysdtsea Unit 4 Traffic Control Devices and Lawsapi-24869537750% (2)

- 10-01-2022 - IN201007-FLD-T35-FL-0007 Sheet-2Document1 page10-01-2022 - IN201007-FLD-T35-FL-0007 Sheet-2Debasis BarmanPas encore d'évaluation

- 3x2000kVA DG SYNCRONISING + OUTGOING PANEL - JSPL - GA+Control+Bom - AS BUILT - 02.07.11Document76 pages3x2000kVA DG SYNCRONISING + OUTGOING PANEL - JSPL - GA+Control+Bom - AS BUILT - 02.07.11RITENDRA GHOSHPas encore d'évaluation

- 22.5 KL Check PrintDocument1 page22.5 KL Check PrintparveshPas encore d'évaluation

- IyyyyyyyyyyyyyyykDocument3 pagesIyyyyyyyyyyyyyyykrim dePas encore d'évaluation

- L&T Hospital SLD - PDF R1Document1 pageL&T Hospital SLD - PDF R1subhankar ghoshPas encore d'évaluation

- Gamabar DepanDocument1 pageGamabar Depananugerahjaya elektrindoPas encore d'évaluation

- Ground Beams Arrangements: 225 2-R12 BRC Mesh No. A142Document1 pageGround Beams Arrangements: 225 2-R12 BRC Mesh No. A142Yaw KrahPas encore d'évaluation

- SX6 SchematicsDocument14 pagesSX6 SchematicsSugeng AriyadiPas encore d'évaluation

- Cable Epc Girder ReinforDocument1 pageCable Epc Girder Reinforshshank guptaPas encore d'évaluation

- Specifications:: Section DDDocument1 pageSpecifications:: Section DDBharani Madamanchi100% (1)

- Detail Z (1: 5) : Rabigh 3 Independent Water ProjectDocument1 pageDetail Z (1: 5) : Rabigh 3 Independent Water ProjectrenjithyesodharanPas encore d'évaluation

- E.D. Etnyre & Co.: OREGON, IL. 61061Document3 pagesE.D. Etnyre & Co.: OREGON, IL. 61061Wily WayerPas encore d'évaluation

- Elevation: CCCC Water Transportation Consultants Co - LTDDocument1 pageElevation: CCCC Water Transportation Consultants Co - LTDJoel MontoyaPas encore d'évaluation

- Plan at Ground Floor: A-08 W.V. CoscolluelaDocument1 pagePlan at Ground Floor: A-08 W.V. CoscolluelaEljoy C. AgsamosamPas encore d'évaluation

- Beam Schedule: 250 3Rd FloorDocument1 pageBeam Schedule: 250 3Rd FloorNhel AlbrechtPas encore d'évaluation

- Front Elevation Left Side Elevation Stair Section: StairsDocument1 pageFront Elevation Left Side Elevation Stair Section: StairsAiza lhie VenturaPas encore d'évaluation

- 4Document1 page4Richard AkelaPas encore d'évaluation

- Crate V33H SchematicDocument2 pagesCrate V33H SchematicDanielo ErréPas encore d'évaluation

- 239 Albert Replacement Cladding PanelsDocument4 pages239 Albert Replacement Cladding PanelsmeghadurganPas encore d'évaluation

- R Dis GR 01Document1 pageR Dis GR 01Constantin ConstantaPas encore d'évaluation

- Gad 2Document1 pageGad 2Aerotide InfrastructuresPas encore d'évaluation

- Thermo IEC Multi RF Series Service ManualDocument83 pagesThermo IEC Multi RF Series Service ManualystlovePas encore d'évaluation

- Parts and Assemblies Simpson and Shipton Short Stroke Steam EngineDocument2 pagesParts and Assemblies Simpson and Shipton Short Stroke Steam EngineThanh VuPas encore d'évaluation

- Ground Floor Plan: Sheet TitleDocument1 pageGround Floor Plan: Sheet TitleEmrys MhaykucePas encore d'évaluation

- (Applicable in Only Beam Fin Plate) : Tack Weld TYP Stud Weld TYPDocument1 page(Applicable in Only Beam Fin Plate) : Tack Weld TYP Stud Weld TYPKhelen ThoudamPas encore d'évaluation

- 240K C2 3100 25J 001 3Document1 page240K C2 3100 25J 001 3Benny Gomez CPas encore d'évaluation

- Positive Voltage Line: Negative Voltage Line:Audio Signal LineDocument1 pagePositive Voltage Line: Negative Voltage Line:Audio Signal LineAranaya WayaPas encore d'évaluation

- Positive Voltage Line: Negative Voltage Line:Audio Signal LineDocument1 pagePositive Voltage Line: Negative Voltage Line:Audio Signal LinelargosoftPas encore d'évaluation

- IRN90-160k-Of AC-WC Electric SchematicDocument3 pagesIRN90-160k-Of AC-WC Electric Schematicsachin JoshiPas encore d'évaluation

- MeeeeDocument1 pageMeeeeRamces AsisiPas encore d'évaluation

- LO AD 2 LOWW 9-4-1 enDocument8 pagesLO AD 2 LOWW 9-4-1 enjoseph.mangan1892Pas encore d'évaluation

- Crate V33H Schematic 1Document2 pagesCrate V33H Schematic 1Danielo ErréPas encore d'évaluation

- Elevation: CCCC Water Transportation Consultants Co - LTDDocument1 pageElevation: CCCC Water Transportation Consultants Co - LTDJoel MontoyaPas encore d'évaluation

- 1C38 Column 1 Req'D As Drawn MKD' No: JSW Severfield Structures LTDDocument1 page1C38 Column 1 Req'D As Drawn MKD' No: JSW Severfield Structures LTDKhelen ThoudamPas encore d'évaluation

- PE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZPas encore d'évaluation

- Section A-A Section B-B Section C-C: Table Ii - Option Suffixes Available For This E.DDocument1 pageSection A-A Section B-B Section C-C: Table Ii - Option Suffixes Available For This E.DEduardo ZamoranoPas encore d'évaluation

- For Praveen SirDocument1 pageFor Praveen SirArushi SharmaPas encore d'évaluation

- Ele Schematic With Links PDFDocument25 pagesEle Schematic With Links PDFPeter JohnPas encore d'évaluation

- VUP - AT CH.217+160 (Recovered 1) (Recovered)Document2 pagesVUP - AT CH.217+160 (Recovered 1) (Recovered)Aerotide InfrastructuresPas encore d'évaluation

- RRPR-OPR-PRB-BR1-SB78 - Rev 1Document1 pageRRPR-OPR-PRB-BR1-SB78 - Rev 1sanjeev sharmaPas encore d'évaluation

- 10 723711 4800000299 PCC Ict DRG 102403 - DWG - 05 PS06Document1 page10 723711 4800000299 PCC Ict DRG 102403 - DWG - 05 PS06Zeeshan YasinPas encore d'évaluation

- Crate V33-212Document7 pagesCrate V33-212Danielo ErréPas encore d'évaluation

- Companion 5 - DSP SCH PDFDocument4 pagesCompanion 5 - DSP SCH PDFManimaran MaranPas encore d'évaluation

- G.F Wall Electrical DetailDocument1 pageG.F Wall Electrical Detailaditya sagarPas encore d'évaluation

- 0K6 PotDocument1 page0K6 PotcbsomtecladosPas encore d'évaluation

- Schematic - BO ĐIỀU HÒA - 2023-07-26Document1 pageSchematic - BO ĐIỀU HÒA - 2023-07-26Sơn NguyễnPas encore d'évaluation

- Evh® 5150iii LBXDocument3 pagesEvh® 5150iii LBXДмитрийPas encore d'évaluation

- Atlantic Version: Revisions CDocument4 pagesAtlantic Version: Revisions Cjuan lopezPas encore d'évaluation

- Flue Gas Outlet DamperDocument1 pageFlue Gas Outlet Damperprth valvePas encore d'évaluation

- SssssssssssssssssssssDocument1 pageSsssssssssssssssssssskhraieric16Pas encore d'évaluation

- Ground Floor Plan: Scale 1:100Document2 pagesGround Floor Plan: Scale 1:100CSEC Uganda Ltd.Pas encore d'évaluation

- Carvin 8 BusDocument1 pageCarvin 8 BusRobby AhyanaPas encore d'évaluation

- Electrical Room: 2041.44 kVA 1219.938 kVA Rated Load Peak Load 2455.471 A 1467.357 ADocument3 pagesElectrical Room: 2041.44 kVA 1219.938 kVA Rated Load Peak Load 2455.471 A 1467.357 ARodrigo Pedraza GalazPas encore d'évaluation

- Skema FullDocument1 pageSkema FullZubaidin ChannelPas encore d'évaluation

- Telecommunication Tower Design & Implementation Technical SpecificationDocument30 pagesTelecommunication Tower Design & Implementation Technical SpecificationJohn MelvinPas encore d'évaluation

- SNBC App Slab Detail PDFDocument1 pageSNBC App Slab Detail PDFZubair MuhammadPas encore d'évaluation

- SNBC Typical Detal PDFDocument1 pageSNBC Typical Detal PDFZubair MuhammadPas encore d'évaluation

- SNBC Piers Details PDFDocument1 pageSNBC Piers Details PDFZubair MuhammadPas encore d'évaluation

- SNBC Elevation Plan PDFDocument1 pageSNBC Elevation Plan PDFZubair MuhammadPas encore d'évaluation

- Bridge Working DWGDocument1 pageBridge Working DWGZubair MuhammadPas encore d'évaluation

- SNBC Abt#2 Detail PDFDocument1 pageSNBC Abt#2 Detail PDFZubair MuhammadPas encore d'évaluation

- Fichas HE 2017Document21 pagesFichas HE 2017redaPas encore d'évaluation

- Oas Community College: Republic of The Philippines Commission On Higher Education Oas, AlbayDocument11 pagesOas Community College: Republic of The Philippines Commission On Higher Education Oas, AlbayYram GambzPas encore d'évaluation

- New Microsoft Word DocumentDocument13 pagesNew Microsoft Word DocumentSagar PadekarPas encore d'évaluation

- 21528029whquestions Reported Speech Grammar Drills - 88620Document1 page21528029whquestions Reported Speech Grammar Drills - 88620Co conutPas encore d'évaluation

- HealerDocument1 pageHealerrheldtPas encore d'évaluation

- Gatsby Chapter Questions Ruk5s2 PDFDocument6 pagesGatsby Chapter Questions Ruk5s2 PDFAndrea SantoPas encore d'évaluation

- My Dear FriendsDocument5 pagesMy Dear FriendsНастя Семенчук100% (1)

- Hora Practica Listening SpeakingDocument2 pagesHora Practica Listening SpeakingBurgos MiguelPas encore d'évaluation

- 1000 Books To ReadDocument76 pages1000 Books To Readdarkdarkhbk100% (1)

- Campania FountainsDocument413 pagesCampania FountainsthegodivaPas encore d'évaluation

- Queer Theory Analysis in Chapter 1 of Jeffrey Eugenides's "Middlesex"Document5 pagesQueer Theory Analysis in Chapter 1 of Jeffrey Eugenides's "Middlesex"Fitrie GoesmayantiPas encore d'évaluation

- Creo Design Essentials Brochure (English)Document6 pagesCreo Design Essentials Brochure (English)Victor MitovPas encore d'évaluation

- Adda247 - No. 1 APP For Banking & SSC PreparationDocument8 pagesAdda247 - No. 1 APP For Banking & SSC PreparationAjithPas encore d'évaluation

- Demo Version: Cho Ral She Eet Mus Sic - PR Ractice Mp3'S Sandb Backtra AckDocument0 pageDemo Version: Cho Ral She Eet Mus Sic - PR Ractice Mp3'S Sandb Backtra Acktribus2512Pas encore d'évaluation

- 210 Uzduotys 2002 VBE Anglu PDFDocument17 pages210 Uzduotys 2002 VBE Anglu PDFAusteja kusaitePas encore d'évaluation

- Xyra's Photography - Bridal PackagesDocument3 pagesXyra's Photography - Bridal PackagesalihummadPas encore d'évaluation

- Textual Analysis of PoemDocument4 pagesTextual Analysis of Poemzebra_t00Pas encore d'évaluation

- Catalogue Leatherman 2019 PDFDocument32 pagesCatalogue Leatherman 2019 PDFEsteban Zumbado AcevedoPas encore d'évaluation

- CL 1 Module 4TH Quarter Lesson 19Document9 pagesCL 1 Module 4TH Quarter Lesson 19Cleofe SobiacoPas encore d'évaluation

- Clase 5 InglesDocument5 pagesClase 5 InglesYenssyPas encore d'évaluation

- The Self From Various Philosophical PerspectivesDocument2 pagesThe Self From Various Philosophical PerspectivesGwyneth MorcoPas encore d'évaluation

- Human Rights Bible VersesDocument8 pagesHuman Rights Bible VersesEymardMoisesMabutasEstalillaPas encore d'évaluation

- Owls by Mary OliverDocument1 pageOwls by Mary OliverSamantha DeLardPas encore d'évaluation

- Chet FakerDocument10 pagesChet FakerGiovanni CantúPas encore d'évaluation