Académique Documents

Professionnel Documents

Culture Documents

Into Plane Fuel Checklist

Transféré par

Husam FCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Into Plane Fuel Checklist

Transféré par

Husam FDroits d'auteur :

Formats disponibles

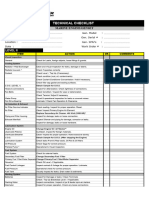

INTO PLANE FUEL CHECKLIST

INTO PLANE FUEL CHECKLIST Incomplete

Inspection score Failed items Created actions

0.00% 0 0

Document No.

000001

Audit Title

Unanswered

Client / Site

Unanswered

Conducted on

21st May, 2019 4:23 AM IST

Prepared by

Husam Farooq

Location

Unanswered

Personnel

Unanswered

Private & Confidential Page 1/5

Audit 0.00%

POLICY

Are the lastest revisions of the ATA 103, JIG, or Local Authority

Unanswered

Standards available?

Does the vendor maintain a file(s) of audit findings and corrective

actions for a minimum of 12 calendars months and is it (are they) Unanswered

accessible to the auditor?

Does the vendors have a Operations Manual (Airlines Manual) to help

Unanswered

ensure the safe and dependable flow of quality fuel to aircraft?

If a person[s initials or employee number is (are) used for signing off

Unanswered

paperwork, is there a roster showing name, number and/or initials?

Does the vendor have a documented training program and records for

all personnel under their direction or control, qualifying them to to Unanswered

properly perform their assignedtasks?

Do training records include Aviation Fuel Knowledge, Safety

(Emergency Procedures(SPILL)), Fuel Quality Management, Aircraft

Unanswered

Fuel Servicing, Drive Safety (Driving License, UAEAC Approval, only for

CM*).

Does the Airline and then Vendors provide initial and recurrent training

respectively to their personnel on an interval not less than once during Unanswered

every 36 months period?

Does the vendor have a pre-employment and post accident

drug/alcohol program for personnel dealing with the handling and Unanswered

dispensing of fuel?

Are fuels handing personnel given a color blindness test? Unanswered

Fuel Farm use the same pipeline for differents products? (JET A1,

Unanswered

GAS, Biodiesel)

If Biodiesel is used, there is procedures for measure FAME (Fatty Acid

Unanswered

Methyl Ester)?

FUELING EQUIPMENT INSPECTIONS

DAILY CHECKS: General condition, Filter sumps, Filter DPI Pressures,

Safety Interlocks, Nozzle pressures, Static reels, cables (less than 10

Unanswered

ohms), Hoses, Nozzles, Swivels, Deadman , Lift Platforms , Fire

extinguishers , Air Tanks, Surge/Rel

Private & Confidential Page 2/5

MONTHLY CHECKS: Millipore, Static System Continuity Test,

Corrected Filter DP, Emergency Shutdown System, Nozzle Screens,

Unanswered

Signs, Labels, Placards, Meter seals, Tanker Interiors, Deadman

Controls, Lift Platforms, Fire Extinguishers, Free

QUARTERLY CHECKS: Water defense system external, Pressure

Controls Primary and Secundary Pressure, Vehicle inspection, Unanswered

Interlock Override function check

SEMI-ANNUALLY CHECKS: Periodic Hose Pressure and certifications Unanswered

ANNUALLY CHECKS: Filter Element change, Filter and DPI Pressure

Gauge Calibration, Meter Calibration, Water defense system insp. and Unanswered

test

Do the records indicate when any equipment was not in service? Unanswered

Does the data on the filter conversion placards compliment the

Unanswered

original filter unit specifications?

PHYSICAL FUELING EQUIPMENT CHECKS

Check the vehicle for general condition Unanswered

Check condition of boding, reels, cables and clamps Unanswered

Check minimum 20 LBS B, C rated fire extinguishers for accessibility,

intact seal, and current inspection tag. There must be a minimum of Unanswered

one (1) on a Hydrant unit and two (2) on a tanker truck

FILTER/SEPARATOR IS USED, CHECK THE FOLLOWING

Has filter vessel been converted? If so, is there an up to date

Unanswered

conversion data placardon vessel?

Air elimination provision? Unanswered

Direct reading DPI gauges? Unanswered

Manual sump drain? Unanswered

Upstream and downstream menbrane sampling ports, and caps? Unanswered

Over pressure or thermal relief device? Unanswered

Is a nameplate attached to the filter vessel, complete with the required

Unanswered

information?

Water defense sytem? Unanswered

FULL FLOW IS USED, CHECK THE FOLLOWING

Air elimination provision? Unanswered

Private & Confidential Page 3/5

Direct reading DPI gauges? Unanswered

Manual sump drain? Unanswered

Upstream and downstream menbrane sampling ports, and caps? Unanswered

Over pressure or thermal relief device? Unanswered

Is a nameplate attached to the filter vessel, complete with the required

Unanswered

information?

Check for the following sign and placards

JET A (each side and rear) -- FLAMMABLE (each side and rear) -- NO

SMOKING (two sides and in cab vehicle) -- EMERGENCY SHUTOFF by Unanswered

each shutoff control and placard indicating it operations(both side

tanker, one sid

Placard identified FILTER DPI -- Placards identifying tanks drain valve

-- Placard showing last date (month/year) filter was changed or single

Unanswered

element change performed -- Placard showing filter sump drain --

Placard showing normal/override position of bra

Check for presence of emergency shutoff switch on lift, if lift present Unanswered

Check for presence of deadman control system Unanswered

Check condition of hoses, swivels and nozzles Unanswered

Check fo intack calibratror/adjuster cover seal Unanswered

Check for hose/dust covers and proper attachment Unanswered

Perform tank and filter sump fuel appareance test for each

Unanswered

compartment

Is there a three way valve or other effective means of detecting a

Unanswered

failure of the DPI gauge?

Check to ensure emergency shutoff cuts off fuel flow at a level of less

Unanswered

than 5% when activated?

Perform downstream free water test (15 PPM), Test result

Unanswered

acceptable?, Testing procedures acceptables?

Does the brake (safety) interlock system operate properly? Check

Unanswered

interlock override warning light.

Perform stastic system continuity check. Unanswered

Check condition of 100 mesh nozzle screens Unanswered

Check to ensure deadman cuts off fuel flow at a level of less than 5%

Unanswered

when de-activated

Private & Confidential Page 4/5

Check for fuel leaks on plumbing hose reels and hoses. Unanswered

OBSERVING AIRCRAFT FUELING ACTIVITY

If the truck/carts chocked properly? Unanswered

If the fueling vehicle bonded to the aircraft prior to hose hook up? Unanswered

If the vehicle positioned clear of the wing? Unanswered

Private & Confidential Page 5/5

Vous aimerez peut-être aussi

- Impac Vehicle Maintenance Sheet - C, D, EDocument6 pagesImpac Vehicle Maintenance Sheet - C, D, EFranklyn MunroePas encore d'évaluation

- Automotive Actuators and EVAP System TestingD'EverandAutomotive Actuators and EVAP System TestingÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Hydraulic System Inspection SOPDocument6 pagesHydraulic System Inspection SOPZev ZekPas encore d'évaluation

- Hydraulic System Inspection SOPDocument6 pagesHydraulic System Inspection SOPGovinda RaiPas encore d'évaluation

- 0298 199 0 SV en 300Document56 pages0298 199 0 SV en 300andis_a100% (1)

- InspeccionDocument5 pagesInspeccionwaveletPas encore d'évaluation

- 050 Diagnosis and Testing Vehicle Dynamic SuspensionDocument23 pages050 Diagnosis and Testing Vehicle Dynamic SuspensionsailorporPas encore d'évaluation

- Engstrom CarestationDocument24 pagesEngstrom CarestationmaruthaiPas encore d'évaluation

- MS-FIRE-001 - Automatic Sprinkler Circuit TestingDocument8 pagesMS-FIRE-001 - Automatic Sprinkler Circuit TestingKo KoPas encore d'évaluation

- JH FRM Pae 001 15 Drum Roller Plant Pre Acceptance ChecklistDocument2 pagesJH FRM Pae 001 15 Drum Roller Plant Pre Acceptance ChecklistStansilous Tatenda NyagomoPas encore d'évaluation

- Hydrostatic TestDocument4 pagesHydrostatic TestStanley RascalPas encore d'évaluation

- Service 38559Document2 pagesService 38559Sumeet SawlaniPas encore d'évaluation

- Milton Cat Preventive Maintenance PM 1 and PM 2 Marketing PieceDocument2 pagesMilton Cat Preventive Maintenance PM 1 and PM 2 Marketing PieceEdwin AlexPas encore d'évaluation

- Aim of Procedure: Daily Operations Checks - Franna CranesDocument5 pagesAim of Procedure: Daily Operations Checks - Franna CranesakhmadbayPas encore d'évaluation

- Leakfinder Wv622nvwkitDocument20 pagesLeakfinder Wv622nvwkitPaul ZiddyPas encore d'évaluation

- JH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistDocument2 pagesJH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistAnwar DeenPas encore d'évaluation

- PropertyRiskEngineering GAPS FireProtection InspectionMaintFrequency Chart XL Catlin USDocument9 pagesPropertyRiskEngineering GAPS FireProtection InspectionMaintFrequency Chart XL Catlin USSteve VelardePas encore d'évaluation

- 12.4 Performance Qualification Protocol For Laminar Air Flow UnitDocument13 pages12.4 Performance Qualification Protocol For Laminar Air Flow UnituzairPas encore d'évaluation

- Service Guide: Section TwoDocument78 pagesService Guide: Section TworemguPas encore d'évaluation

- EV PDI PDS Sheet - v2Document2 pagesEV PDI PDS Sheet - v2yonatan solomon100% (1)

- 8.4 Performance Qualification Protocol For Dispensing BoothDocument13 pages8.4 Performance Qualification Protocol For Dispensing BoothArej Ibrahim AbulailPas encore d'évaluation

- 63 Leak TesterDocument6 pages63 Leak Testersystacare remediesPas encore d'évaluation

- Air Handling Units GuidelineDocument5 pagesAir Handling Units GuidelineImam MansyurPas encore d'évaluation

- Fd4.25f Alegria Maintance Checklist 3 2012-01Document1 pageFd4.25f Alegria Maintance Checklist 3 2012-01Mosab BabikirPas encore d'évaluation

- General InformationDocument111 pagesGeneral Informationkhaledserag23Pas encore d'évaluation

- VS - VPSP - DVL - DVSP - SSV - MSP - MVL Vertical Lift - Pre-Delivery and Frequent Inspection Report PDFDocument1 pageVS - VPSP - DVL - DVSP - SSV - MSP - MVL Vertical Lift - Pre-Delivery and Frequent Inspection Report PDFMaria Alejandra Peña LeonPas encore d'évaluation

- ESCALATOR-Bk Gulf OnlyDocument3 pagesESCALATOR-Bk Gulf OnlySHARAFUDHEEN TKPas encore d'évaluation

- Audit Checklist - Department Wise in Pharmaceuticals - Pharma BeginnersDocument32 pagesAudit Checklist - Department Wise in Pharmaceuticals - Pharma Beginnersisrael afolayan mayomiPas encore d'évaluation

- 320CDocument77 pages320COveis YPas encore d'évaluation

- Ust Monitoring PlanDocument5 pagesUst Monitoring PlanAhmedA.HassanPas encore d'évaluation

- ARC Property Inspection Maintenance FPEDocument7 pagesARC Property Inspection Maintenance FPEsanaPas encore d'évaluation

- SamsonDocument2 pagesSamsonIñaki EseberriPas encore d'évaluation

- Microsoft Word - Tire Handler Owners Manual PDFDocument195 pagesMicrosoft Word - Tire Handler Owners Manual PDFPlanificador MantencionPas encore d'évaluation

- PM ProgramDocument29 pagesPM Programemad youssefPas encore d'évaluation

- Mac25 Maintenance Section 2Document27 pagesMac25 Maintenance Section 2Wahyu SriharjaPas encore d'évaluation

- Ewp Annual or Third Party Inspection ChecklistDocument5 pagesEwp Annual or Third Party Inspection ChecklistScott BoogemansPas encore d'évaluation

- INS201 6.0 FUELSTAT InstructionsDocument4 pagesINS201 6.0 FUELSTAT InstructionsFotis AndrianopoulosPas encore d'évaluation

- PSSR ChecklistDocument5 pagesPSSR ChecklistzhangjiePas encore d'évaluation

- Sprinkler Report NFPA 25 03.27.13Document8 pagesSprinkler Report NFPA 25 03.27.13redbire100% (1)

- Diesel Generator Prestart Checklist - SafetyCultureDocument4 pagesDiesel Generator Prestart Checklist - SafetyCultureaman khanPas encore d'évaluation

- Aerial Lift Pre Use Inspection ChecklistDocument1 pageAerial Lift Pre Use Inspection ChecklistSigit PratiknoPas encore d'évaluation

- MS4 Certification - Verification ProcedureDocument4 pagesMS4 Certification - Verification ProcedureBrahmananda ChakrabortyPas encore d'évaluation

- Nissan Certified Pre-Owned Inspection ChecklistDocument2 pagesNissan Certified Pre-Owned Inspection Checklistnuryakhin sePas encore d'évaluation

- NDTAudit ChecklistDocument5 pagesNDTAudit ChecklistReinaldo Orejuela100% (7)

- Technical Report Checklist - MARINE ENGINESDocument2 pagesTechnical Report Checklist - MARINE ENGINESsary qasimPas encore d'évaluation

- Jim Gammon Petroleum Quality ControlDocument67 pagesJim Gammon Petroleum Quality ControlSandeep PrasadPas encore d'évaluation

- Air Compressor Maintenance - Reciprocating Compressor - SafetyCultureDocument6 pagesAir Compressor Maintenance - Reciprocating Compressor - SafetyCulturematthew kagurabadzaPas encore d'évaluation

- Jig 4 SmallerAirportsJIG4 - CHECK LISTDocument26 pagesJig 4 SmallerAirportsJIG4 - CHECK LISTgulfpipinggmailcom100% (5)

- Fire Pumps - Inspection, Testing and MaintenanceDocument2 pagesFire Pumps - Inspection, Testing and Maintenancesunilarora9999Pas encore d'évaluation

- SLPG - HV Transformer-1wDocument2 pagesSLPG - HV Transformer-1wAshraf MohammedPas encore d'évaluation

- Greenheck DOAS Start-Up Report June2019Document19 pagesGreenheck DOAS Start-Up Report June2019DurgaPas encore d'évaluation

- (Page Name Not Set) Audit: Say Goodbye To Paper Checklists!Document2 pages(Page Name Not Set) Audit: Say Goodbye To Paper Checklists!Viraj GhatgePas encore d'évaluation

- Installation and Commisioning of Servo & Propotional Control ValvesDocument3 pagesInstallation and Commisioning of Servo & Propotional Control ValvesIdehen KelvinPas encore d'évaluation

- Rig Condition Monitoring 1Document27 pagesRig Condition Monitoring 1exergicPas encore d'évaluation

- Vapor Recovery Test Procedure: Adopted: February 1, 2001 Amended: July 3, 2002 Amended: October 8, 2003Document10 pagesVapor Recovery Test Procedure: Adopted: February 1, 2001 Amended: July 3, 2002 Amended: October 8, 2003ObaidUrRehmanPas encore d'évaluation

- Service Schedule: Outstanding Field Service Actions. Please Ensure They Are CompletedDocument2 pagesService Schedule: Outstanding Field Service Actions. Please Ensure They Are CompletedHotel ConfortPas encore d'évaluation

- Konsep PMDocument154 pagesKonsep PMHellow HellowPas encore d'évaluation

- Heavy Equipment Maintenance Checklist: Pre-Start Checks (Walk Around)Document3 pagesHeavy Equipment Maintenance Checklist: Pre-Start Checks (Walk Around)Nihad ZainPas encore d'évaluation

- Maintenance - Inspection Intervals Group 75 Aircraft Rescue and Fire Fighting Vehicle Maintenance - Inspection IntervalsDocument8 pagesMaintenance - Inspection Intervals Group 75 Aircraft Rescue and Fire Fighting Vehicle Maintenance - Inspection IntervalsJordan RaveloPas encore d'évaluation

- What You See Here Is An Electro-Mechanical Actuator' or For Short EMA. There Are 4 EMA's On The Boeing 787. We Had To Replace TDocument1 pageWhat You See Here Is An Electro-Mechanical Actuator' or For Short EMA. There Are 4 EMA's On The Boeing 787. We Had To Replace THusam FPas encore d'évaluation

- British Airways - Reserve SeatsDocument1 pageBritish Airways - Reserve SeatsHusam FPas encore d'évaluation

- What Is Carbon Solid Laminate Construction - Google SearchDocument1 pageWhat Is Carbon Solid Laminate Construction - Google SearchHusam FPas encore d'évaluation

- Easa-Icaa Sms m5Document13 pagesEasa-Icaa Sms m5Husam FPas encore d'évaluation

- Easa-Icaa QMSDocument36 pagesEasa-Icaa QMSHusam F100% (1)

- SMS/QMS Awareness Course: Icaa/Easa Amman, May 2017Document5 pagesSMS/QMS Awareness Course: Icaa/Easa Amman, May 2017Husam FPas encore d'évaluation

- Dangerous Goods Regulations No 24Document21 pagesDangerous Goods Regulations No 24Husam F100% (1)

- Transmission Hydraulic Control 966Document3 pagesTransmission Hydraulic Control 966Walid Houran100% (1)

- Materials System SpecificationDocument9 pagesMaterials System SpecificationFAPM1285Pas encore d'évaluation

- GovernorDocument43 pagesGovernorVIJIOCL100% (2)

- D758-Et Minipurge ManualDocument48 pagesD758-Et Minipurge Manualziad atfePas encore d'évaluation

- Boiler Operator Study GuideDocument30 pagesBoiler Operator Study GuideSantiago DuranPas encore d'évaluation

- DOOWIN-Bilk Liquid Bladder TanksDocument7 pagesDOOWIN-Bilk Liquid Bladder TanksSetiadi MargonoPas encore d'évaluation

- Simulation of Water Distribution Networks The Use of EPANETDocument31 pagesSimulation of Water Distribution Networks The Use of EPANETMohammad Risky Na100% (2)

- Ec 160 Service ManualDocument32 pagesEc 160 Service ManualNatalia MontañaPas encore d'évaluation

- Nordstrom Valves: Sealants and Sealant EquipmentDocument12 pagesNordstrom Valves: Sealants and Sealant EquipmentHrushikesh ReddyPas encore d'évaluation

- Bhel LP-HP Bypass OrderDocument32 pagesBhel LP-HP Bypass OrderGiriDharanPas encore d'évaluation

- Underwater Hammer Drill: SpecificationsDocument2 pagesUnderwater Hammer Drill: SpecificationsmatrixianuPas encore d'évaluation

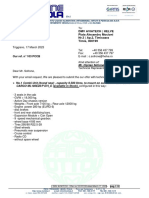

- DMV Aviatech - Helve Piata Alexandru Mocioni Nr.3 - Ap.2, Timisoara Timis, 300199Document12 pagesDMV Aviatech - Helve Piata Alexandru Mocioni Nr.3 - Ap.2, Timisoara Timis, 300199endless gravePas encore d'évaluation

- Valve pv98 EngDocument2 pagesValve pv98 EngGerald Leon Flores100% (1)

- Fluid Flow Basiics of Throttliing ValvesDocument56 pagesFluid Flow Basiics of Throttliing Valvesdanne_ePas encore d'évaluation

- Types of PipesDocument23 pagesTypes of PipesgautamPas encore d'évaluation

- Gas Breaker: The Mechanical Traveling Valve That Ends Gas Lock ProblemsDocument5 pagesGas Breaker: The Mechanical Traveling Valve That Ends Gas Lock ProblemsSayed Afg HashimiPas encore d'évaluation

- Chemical ProcessDocument43 pagesChemical ProcesstavolenPas encore d'évaluation

- Parts Manual For ISL98, ISL03, ISL07, ISC07Document4 pagesParts Manual For ISL98, ISL03, ISL07, ISC07LUIS LAHUASIPas encore d'évaluation

- Flexible Jumper Design PremiseDocument12 pagesFlexible Jumper Design PremiseAgus BudionoPas encore d'évaluation

- Aluminum Extrusion PlantDocument21 pagesAluminum Extrusion PlantRam sevakPas encore d'évaluation

- Air Conditioning and Refrigeration Exam PaperDocument9 pagesAir Conditioning and Refrigeration Exam PaperYean Ghing Tong100% (1)

- GRACO King 45-1 PartsDocument10 pagesGRACO King 45-1 Partssamgivp2869Pas encore d'évaluation

- 185H-260 Cat-JD 02250156-375Document144 pages185H-260 Cat-JD 02250156-375masanmartinf100% (3)

- Modine V - VN-212Document16 pagesModine V - VN-212Enrique Escobar PérezPas encore d'évaluation

- Marvac CatalogueDocument40 pagesMarvac CataloguedhavaleshPas encore d'évaluation

- Cat Dumper 773 E Valve Setting ToolDocument12 pagesCat Dumper 773 E Valve Setting Toolfinx786Pas encore d'évaluation

- Regulador EQA-99Document3 pagesRegulador EQA-99Ronan CristhiamPas encore d'évaluation

- Selectomat PL: Premium Line - Steam SterilizerDocument11 pagesSelectomat PL: Premium Line - Steam SterilizerAdolfo SalazarPas encore d'évaluation

- Firedos Stationary Proportioners - ENDocument16 pagesFiredos Stationary Proportioners - ENJoshPas encore d'évaluation