Académique Documents

Professionnel Documents

Culture Documents

Iwikwbwb

Transféré par

Ganda PrajaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Iwikwbwb

Transféré par

Ganda PrajaDroits d'auteur :

Formats disponibles

Crosby® Bolt Type Shackles

• Capacities 1/3 thru 150 metric tons, grade 6.

• Working Load Limit and grade “6” permanently shown on every shackle.

• Forged – Quenched and Tempered, with alloy bolts.

• Hot Dip galvanized or self colored. (85, 120, and 150 metric ton shackles

are all hot dip galvanized bows and the bolts are Dimetcoted® and painted red)

Shackles

• Sizes 3/8 and below are mechanically galvanized.

• Fatigue rated (1/3t - 55t).

• Shackles 25t and larger are RFID EQUIPPED.

• Approved for use at -40° C (-40° F) to 204° C (400° F).

G-2130 / S-2130

Bolt Type Anchor shackles with • Meets or exceeds all requirements of ASME B30.26.

thin head bolt - nut with cotter pin.

Meets the performance requirements • Shackles 85 metric tons and larger are individually proof tested to 2.0 times the

of Federal Specification RR-C working load limit.

271G, Type IVA, Grade A, Class

3, except for those provisions • Type Approval certification in accordance with ABS 2016 Steel Vessel Rules

required of the contractor. For ABS Guide for Certification of Lifting Appliances available. Certificates available

additional information, see page 452.

when requested at time of order and may include additional charges.

• 3.1 Certification as standard available for charpy and statisti al proof test from 3.25t

up to 25 tons to DNV2.7-1 and EN13889.

• Crosby 3.25t through 25t G2130OC anchor shackles are type approved to DNV Certification

Notes 2.7-1- Offshore Containers. These Crosby shackles are statistical proof and impact

tested to 42 Joules (31 ft•lbf) min. avg. at -20° C (-4° F). The tests are conducted by Crosby

and 3.1 test certification is available upon request. Refer to page 87 for Crosby COLD

TUFF® shackles that meet the additional requirements of DNV rules for certification of lifting

applications - Loose Gear.

• All other 2130 shackles can meet charpy requirements of 42 Joules (31 ft•lbf) avg at -20° C

(-4° F) when requested at time of order.

• Look for the Red Pin® . . . the mark of genuine Crosby quality.

®

SEE APPLICATION INFORMATION

On Page 92 of the General Catalog

Para Español: www.thecrosbygroup.com

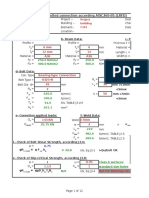

G-2130 / S-2130 Bolt Type Anchor Shackles

Stock Dimensions Tolerance

Nominal Working No. Weight (in) +/-

Size Load Limit Each

(in) (t)* G-2130 S-2130 G-2130OC (lb) A B C D E F H L M N C A

3/16 1/3 ‡ 1019464 – – .06 .38 .25 .88 .19 .60 .56 1.47 .98 1.29 .19 .06 .06

1/4 1/2 1019466 – – .11 .47 .31 1.13 .25 .78 .61 1.84 1.28 1.56 .25 .06 .06

5/16 3/4 1019468 – – .22 .53 .38 1.22 .31 .84 .75 2.09 1.47 1.82 .31 .06 .06

3/8 1 1019470 – – .33 .66 .44 1.44 .38 1.03 .91 2.49 1.78 2.17 .38 .13 .06

7/16 1-1/2 1019471 – – .49 .75 .50 1.69 .44 1.16 1.06 2.91 2.03 2.51 .44 .13 .06

1/2 2 1019472 1019481 – .79 .81 .64 1.88 .50 1.31 1.19 3.28 2.31 2.80 .50 .13 .06

5/8 3-1/4 1019490 1019506 1262013 1.68 1.06 .77 2.38 .63 1.69 1.50 4.19 2.94 3.56 .69 .13 .06

3/4 4-3/4 1019515 1019524 1262022 2.72 1.25 .89 2.81 .75 2.00 1.81 4.97 3.50 4.15 .81 .25 .06

7/8 6-1/2 1019533 1019542 1262031 3.95 1.44 1.02 3.31 .88 2.28 2.09 5.83 4.03 4.82 .97 .25 .06

1 8-1/2 1019551 1019560 1262040 5.66 1.69 1.15 3.75 1.00 2.69 2.38 6.56 4.69 5.39 1.06 .25 .06

1-1/8 9-1/2 1019579 1019588 1262059 8.27 1.81 1.25 4.25 1.13 2.91 2.69 7.47 5.16 5.90 1.25 .25 .06

1-1/4 12 1019597 1019604 1262068 11.71 2.03 1.40 4.69 1.29 3.25 3.00 8.25 5.75 6.69 1.38 .25 .06

1-3/8 13-1/2 1019613 1019622 1262077 15.83 2.25 1.53 5.25 1.42 3.63 3.31 9.16 6.38 7.21 1.50 .25 .13

1-1/2 17 1019631 1019640 1262086 19.00 2.38 1.66 5.75 1.53 3.88 3.63 10.00 6.88 7.73 1.62 .25 .13

1-3/4 25 1019659 1019668 1262095 33.91 2.88 2.04 7.00 1.84 5.00 4.19 12.34 8.80 9.68 2.25 .25 .13

2 35 1019677 1019686 – 52.25 3.25 2.30 7.75 2.08 5.75 4.81 13.68 10.15 10.81 2.40 .25 .13

2-1/2 55 1019695 1019702 – 98.25 4.13 2.80 10.50 2.71 7.25 5.69 17.90 12.75 13.58 3.13 .25 .25

3 † 85 1019711 – – 154.00 5.00 3.30 13.00 3.12 7.88 6.50 21.50 14.62 15.13 3.62 .25 .25

3-1/2 † 120 ‡ 1019739 – – 265.00 5.25 3.76 14.63 3.62 9.00 8.00 24.88 17.02 17.00 4.38 .25 .25

4 † 150 ‡ 1019757 – – 338.00 5.50 4.26 14.50 4.00 10.00 9.00 25.68 18.00 17.75 4.56 .25 .25

* NOTE: Maximum Proof Load is 2 times the Working Load Limit. Minimum Ultimate Strength is 6 times the Working Load Limit. For Working Load Limit reduction due to side loading ap-

plications, see page 94. † Individually Proof Tested with certification. ‡ Furnished in Anchor style only and furnished with eyebolts for handling.

Copyright © 2019 The Crosby Group LLC All Rights Reserved 79

Vous aimerez peut-être aussi

- Request For QuotationDocument13 pagesRequest For QuotationGanda PrajaPas encore d'évaluation

- 2017 Catalogue: DistributorsDocument26 pages2017 Catalogue: DistributorsGanda PrajaPas encore d'évaluation

- A New Textiles Economy Full Report Updated 1-12-17Document150 pagesA New Textiles Economy Full Report Updated 1-12-17Iulia SoiganPas encore d'évaluation

- Baby Products: - and Their Meaning For The New Mothers inDocument94 pagesBaby Products: - and Their Meaning For The New Mothers inParul KhannaPas encore d'évaluation

- Product Catalogue: Eco Friendl y Childr En's WearDocument16 pagesProduct Catalogue: Eco Friendl y Childr En's WearGanda PrajaPas encore d'évaluation

- 0 R 1 Us 893 IzbbzkskDocument8 pages0 R 1 Us 893 IzbbzkskGanda PrajaPas encore d'évaluation

- Sanket Safety Equipments LLP.: Since 1999Document12 pagesSanket Safety Equipments LLP.: Since 1999Ganda PrajaPas encore d'évaluation

- Your Favourite Recipe Made Easier and Healthier: Oven Toast GrillDocument23 pagesYour Favourite Recipe Made Easier and Healthier: Oven Toast GrillGanda PrajaPas encore d'évaluation

- Your Favourite Recipe Made Easier and Healthier: Oven Toast GrillDocument23 pagesYour Favourite Recipe Made Easier and Healthier: Oven Toast GrillGanda PrajaPas encore d'évaluation

- Jayco Safety Products Pvt. Ltd. OverviewDocument10 pagesJayco Safety Products Pvt. Ltd. OverviewGanda PrajaPas encore d'évaluation

- Tender Document For Purchase Of: Safety Items Tender Number: 6000012593/SAFETYITEMS/463/, Dated: 03.06.2019Document37 pagesTender Document For Purchase Of: Safety Items Tender Number: 6000012593/SAFETYITEMS/463/, Dated: 03.06.2019Ganda PrajaPas encore d'évaluation

- Crosby Lebus Mckissick NationalDocument20 pagesCrosby Lebus Mckissick NationalGanda PrajaPas encore d'évaluation

- Risqmcidkp 86543Document104 pagesRisqmcidkp 86543Ganda PrajaPas encore d'évaluation

- Sanket Safety Equipments LLP.: Since 1999Document12 pagesSanket Safety Equipments LLP.: Since 1999Ganda PrajaPas encore d'évaluation

- Tecumseh Service ManualDocument123 pagesTecumseh Service Manualmasterviking82% (85)

- WEKSLERDocument46 pagesWEKSLERKevin IllescasPas encore d'évaluation

- Babikautsuhddb 6728Document1 pageBabikautsuhddb 6728Ganda PrajaPas encore d'évaluation

- Crosby Series BP OMNI-TRIM Pressure Relief Valves For Applications Involving Variable Back PressureDocument12 pagesCrosby Series BP OMNI-TRIM Pressure Relief Valves For Applications Involving Variable Back PressureGanda PrajaPas encore d'évaluation

- Rokokbdjdjje PDFDocument52 pagesRokokbdjdjje PDFGanda PrajaPas encore d'évaluation

- Cibai 638 UehdjsiieDocument52 pagesCibai 638 UehdjsiieGanda PrajaPas encore d'évaluation

- Essential guide for caring for baby girls and boysDocument43 pagesEssential guide for caring for baby girls and boysGanda PrajaPas encore d'évaluation

- Mi 39297 FFJNDJSKDocument12 pagesMi 39297 FFJNDJSKGanda PrajaPas encore d'évaluation

- Baby Checklist PDFDocument8 pagesBaby Checklist PDFDarwin Fajardo100% (1)

- Essential guide for caring for baby girls and boysDocument43 pagesEssential guide for caring for baby girls and boysGanda PrajaPas encore d'évaluation

- Sumitomo Consumables Listing Parts GuideDocument137 pagesSumitomo Consumables Listing Parts GuidesuriantoPas encore d'évaluation

- 2 Ride Holding Accelerates Its Development With The Financial Support of Eurazeo PME and Acquires Italian Company NolanDocument2 pages2 Ride Holding Accelerates Its Development With The Financial Support of Eurazeo PME and Acquires Italian Company NolanGanda PrajaPas encore d'évaluation

- 2 Ride Holding Signs An Acquisition Agreement With NOLAN Group To Create A Leader in Protective Equipment For Motorcycle and Outdoor MarketsDocument2 pages2 Ride Holding Signs An Acquisition Agreement With NOLAN Group To Create A Leader in Protective Equipment For Motorcycle and Outdoor MarketsGanda PrajaPas encore d'évaluation

- Hydraulic Excavator: - 5G - 5G - 5G - 5G - 5G - 5GDocument15 pagesHydraulic Excavator: - 5G - 5G - 5G - 5G - 5G - 5GDt NamdinhPas encore d'évaluation

- 2 Ride Holding Accelerates Its Development With The Financial Support of Eurazeo PME and Acquires Italian Company NolanDocument2 pages2 Ride Holding Accelerates Its Development With The Financial Support of Eurazeo PME and Acquires Italian Company NolanGanda PrajaPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Oculus: Free Plan: Oculus Supercap FFDocument68 pagesOculus: Free Plan: Oculus Supercap FFDarren-Edward O'NeillPas encore d'évaluation

- DeWalt 7730 Radial Arm Saw Manual PDFDocument20 pagesDeWalt 7730 Radial Arm Saw Manual PDFDan100% (1)

- Saudi Aramco Oil Company: SECTION 05520 Handrails Railings & Bollard Part 1 GeneralDocument12 pagesSaudi Aramco Oil Company: SECTION 05520 Handrails Railings & Bollard Part 1 GeneralAbid HussainPas encore d'évaluation

- AISC-Connections in SteelDocument45 pagesAISC-Connections in SteelDesi RamadhaniPas encore d'évaluation

- FDI Distribution-PDocument39 pagesFDI Distribution-PElias ZabanehPas encore d'évaluation

- P17-1TS-KBR Bolting Types Carbon & Alloy SteelDocument2 pagesP17-1TS-KBR Bolting Types Carbon & Alloy Steelyulianus_sr100% (1)

- Plant Plucker: Department of Mechanical EngineeringDocument15 pagesPlant Plucker: Department of Mechanical EngineeringASWATHY V RPas encore d'évaluation

- Amua Water Sysems ProductsDocument2 pagesAmua Water Sysems Productsevelyne_kiambatiPas encore d'évaluation

- Mechanical Setting Procudere of CR & Bridge PlugDocument7 pagesMechanical Setting Procudere of CR & Bridge PlugChandra FadhillahPas encore d'évaluation

- Manual de Taller Lambretta Tv175Document81 pagesManual de Taller Lambretta Tv175serferraPas encore d'évaluation

- AISC360-05 LRFD Shear Bolted Connection CheckDocument12 pagesAISC360-05 LRFD Shear Bolted Connection CheckMario FeghaliPas encore d'évaluation

- Maintenance BFPDocument28 pagesMaintenance BFPYulianto Kartono100% (1)

- Dss - Question BankDocument10 pagesDss - Question Bankapi-306484475Pas encore d'évaluation

- ANEVAZO BIOPLASTICS, INC. Machinery and EquipmentDocument21 pagesANEVAZO BIOPLASTICS, INC. Machinery and EquipmentAlyssa Sarah ArenasPas encore d'évaluation

- GRAPADORADocument36 pagesGRAPADORARafaelChochoaPas encore d'évaluation

- Lysaght Custom Blue Orb Bullnose Verandah Construction Guide September 2016Document6 pagesLysaght Custom Blue Orb Bullnose Verandah Construction Guide September 2016Stephen MaartenszPas encore d'évaluation

- EN CLIPLINE Complete Quality LoResDocument60 pagesEN CLIPLINE Complete Quality LoRes姜桐Pas encore d'évaluation

- S40 Instruction and MaintenanceDocument33 pagesS40 Instruction and Maintenancelavankumar_nuthalapatiPas encore d'évaluation

- 53007-San FranciscoDocument32 pages53007-San Franciscomarcial rubioPas encore d'évaluation

- Preambles To Method of MeasurementDocument20 pagesPreambles To Method of MeasurementMiguel EllaPas encore d'évaluation

- M-AJT2-000000-CR00-MSS-000001 - 003 Method Statement For Plinth Work On ViaductDocument160 pagesM-AJT2-000000-CR00-MSS-000001 - 003 Method Statement For Plinth Work On ViaductAnup PandeyPas encore d'évaluation

- Eng MmountDocument38 pagesEng MmountIbrahimElKelanyPas encore d'évaluation

- Cobra & Vaal Medical Catalogue IntroductionDocument24 pagesCobra & Vaal Medical Catalogue IntroductionKamlesh Kamlesh EtwaroPas encore d'évaluation

- Lista Standarde ASME B18-In VigoareDocument8 pagesLista Standarde ASME B18-In Vigoare2601220150379Pas encore d'évaluation

- ZXSDR BS8900A Quick Installation Guide R2.0 - CH - ENDocument37 pagesZXSDR BS8900A Quick Installation Guide R2.0 - CH - ENMuhammad AliPas encore d'évaluation

- MERCURY 30 40 HP Instruktsiya Po Zamene Svechey Zazhiganiya I Rem - Komplekta Pompy Sistemy OhlazhdeniyaDocument4 pagesMERCURY 30 40 HP Instruktsiya Po Zamene Svechey Zazhiganiya I Rem - Komplekta Pompy Sistemy OhlazhdeniyaScott BakerPas encore d'évaluation

- General Information: Workshop ManualDocument56 pagesGeneral Information: Workshop ManualRowan CorneliusPas encore d'évaluation

- Hager Weatherstrip CatalogDocument20 pagesHager Weatherstrip Catalogmarchus09Pas encore d'évaluation

- CC Marine 2013-14 Catalogue - Interior HardwareDocument20 pagesCC Marine 2013-14 Catalogue - Interior HardwareGregGGHPas encore d'évaluation

- GMD 44 / 55 / 66 Multidisc Mower: Assembly / Operator'S ManualDocument48 pagesGMD 44 / 55 / 66 Multidisc Mower: Assembly / Operator'S Manualtgpinto100% (1)