Académique Documents

Professionnel Documents

Culture Documents

WPSGMAW90 102011ExamplePDF PDF

Transféré par

Bhanu Pratap ChoudhuryTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

WPSGMAW90 102011ExamplePDF PDF

Transféré par

Bhanu Pratap ChoudhuryDroits d'auteur :

Formats disponibles

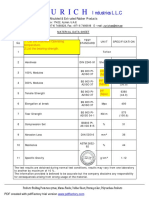

WELDING PROCEDURE SPECIFICATON (WPS) BTC GMAW 90-10 2011

PREQUALIFIED Per AWS D1.1 2010 QUALIFIED BY TESTING

Identification # GMAW 90-10 2011

Revision 1 Date Oct 28, By Robert Rutile

2011

Company Name: Slagboy Enterprises Authorized by Samuel Slaghammer Oct 28, 2011

Welding Process(es) GMAW Type—Manual Semi-Automatic

JOINT DESIGN USED Butt Machine Automatic

Type Single Double Weld Position

Backing Yes No Position of Groove Flat

Backing Material ASTM A-36 Fillet Position/s Flat and Horizontal

Root Opening 1/4 in.

Root Face Dimension1/16 +0 -1/16" Vertical Progression N/A

Back Gouging No

BASE METALS ELECTRICAL CHARACTERISTICS

Material Spec ASTM A 36 Transfer Mode (GMAW) N/A

Type or Grade Current DCEP

Thickness: Groove 1/8" to 1" Fillet . Tungsten Electrode Size (GTAW)

Diameter (Pipe) Size N/A

Type N/A

FILLER METALS TECHNIQUE

AWS Specification AWS A5.18 Stringer or Weave Bead Stringer

AWS Classification ER70S-6 Multi-pass or Single Pass (per side) Multi

Number of Electrodes 1

SHIELDING Gas 90/10 Ar/Co2 Contact Tube to Work Distance 5/8 to 3/4 in.

Flux: N/A Flow Rate 35 Cfh Peening None

Electrode-Flux (Class): N/A Cup Size 5/8 in

Interpass Cleaning Oxide Removal (mechanical)

Composition: N/A

PREHEAT POST WELD HEAT TREATMENT

Preheat Temp Min., 50F Temp N/A

Interpass Temp., Min Max 500F Time N/A

Special instructions:

GMAW B-U2a-GF (D1.1 2010) 1. No grinding on cover pass

α 70 degrees 2. Inter-pass grinding must be approved by

R ¼” instructor and done in test position

Hold points:

1. Inspect bevels

2. Inspect tack-up

3. Inspect root pass

4. Inspect cover pass

5. Inspect backing strip removal prior to cutting

straps

WELDING PROCEDURE

Pass or Weld Layers Process Filler Metals Current Volts Travel

GMAW Class Dia. Speed

ER70S-6 Type & Amps or Wire Feed speed 24-27

………...0.35 in Polarity (IPM) 14 IPM

DCEP 400-550 ipm + or –

15%

Vous aimerez peut-être aussi

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document1 pageIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Bhanu Pratap ChoudhuryPas encore d'évaluation

- NF7WQFT2AN7C8X218109 ETicketDocument2 pagesNF7WQFT2AN7C8X218109 ETicketBhanu Pratap ChoudhuryPas encore d'évaluation

- Astm D4541 22Document7 pagesAstm D4541 22Bhanu Pratap ChoudhuryPas encore d'évaluation

- 07.01.05 Fabrication Galvanizing R1Document11 pages07.01.05 Fabrication Galvanizing R1Bhanu Pratap ChoudhuryPas encore d'évaluation

- QW 217 - Clad Plata Joining PDFDocument1 pageQW 217 - Clad Plata Joining PDFBhanu Pratap ChoudhuryPas encore d'évaluation

- Format InvoiceDocument1 pageFormat InvoiceBhanu Pratap ChoudhuryPas encore d'évaluation

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document1 pageIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Bhanu Pratap ChoudhuryPas encore d'évaluation

- INCONEL 686 - INCO-WELD 686CPT Application List For IndiaDocument10 pagesINCONEL 686 - INCO-WELD 686CPT Application List For IndiaBhanu Pratap ChoudhuryPas encore d'évaluation

- TUV India Online Training Program With Fees and Registration LinksDocument3 pagesTUV India Online Training Program With Fees and Registration LinksBhanu Pratap ChoudhuryPas encore d'évaluation

- Hot-Dip Zinc Coatings On Structural Steel and Other Allied Products - SpecificationDocument9 pagesHot-Dip Zinc Coatings On Structural Steel and Other Allied Products - SpecificationBhanu Pratap ChoudhuryPas encore d'évaluation

- (First Revision) : Indian StandardDocument8 pages(First Revision) : Indian StandardBhanu Pratap ChoudhuryPas encore d'évaluation

- ADANII QAP 316L Npdf-SignedDocument3 pagesADANII QAP 316L Npdf-SignedBhanu Pratap ChoudhuryPas encore d'évaluation

- Subject: Handling of Public Grievances Received in Cpgrams On Covid-19 in States/Uts GovernmentsDocument1 pageSubject: Handling of Public Grievances Received in Cpgrams On Covid-19 in States/Uts GovernmentsBhanu Pratap ChoudhuryPas encore d'évaluation

- Manufacturing Quality Plan For Tank: FGD Sysyem, 2X550 MW TpsDocument4 pagesManufacturing Quality Plan For Tank: FGD Sysyem, 2X550 MW TpsBhanu Pratap ChoudhuryPas encore d'évaluation

- Reaffirmed 2006Document23 pagesReaffirmed 2006Bhanu Pratap ChoudhuryPas encore d'évaluation

- Special Alloys and Overmatched Welding Products SolveDocument14 pagesSpecial Alloys and Overmatched Welding Products SolveBhanu Pratap ChoudhuryPas encore d'évaluation

- FGD Sheet Lining LiteratureDocument8 pagesFGD Sheet Lining LiteratureBhanu Pratap ChoudhuryPas encore d'évaluation

- QW 217 - Clad Plata Joining PDFDocument1 pageQW 217 - Clad Plata Joining PDFBhanu Pratap ChoudhuryPas encore d'évaluation

- Separator - Company ProfileDocument1 pageSeparator - Company ProfileBhanu Pratap ChoudhuryPas encore d'évaluation

- Separator - Type Test ReportDocument1 pageSeparator - Type Test ReportBhanu Pratap ChoudhuryPas encore d'évaluation

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocument10 pagesFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- Roll-Bonded Clad Plates: Our Cost-Efficient Answer To CorrosionDocument40 pagesRoll-Bonded Clad Plates: Our Cost-Efficient Answer To CorrosionRoyster CabralPas encore d'évaluation

- CTC To Tata - 100320Document1 pageCTC To Tata - 100320Bhanu Pratap ChoudhuryPas encore d'évaluation

- CTC To Tata - 100320Document1 pageCTC To Tata - 100320Bhanu Pratap ChoudhuryPas encore d'évaluation

- Yahoo Mail - Booking Confirmation On IRCTC, Train - 12802, 23-Aug-2019, SL, TATA - CTCDocument1 pageYahoo Mail - Booking Confirmation On IRCTC, Train - 12802, 23-Aug-2019, SL, TATA - CTCBhanu Pratap ChoudhuryPas encore d'évaluation

- Separator PODocument1 pageSeparator POBhanu Pratap ChoudhuryPas encore d'évaluation

- Separator QAPDocument1 pageSeparator QAPBhanu Pratap ChoudhuryPas encore d'évaluation

- Separator - Performance CertificatesDocument1 pageSeparator - Performance CertificatesBhanu Pratap ChoudhuryPas encore d'évaluation

- Ola - Tata Station To Adityapur - 110320Document3 pagesOla - Tata Station To Adityapur - 110320Bhanu Pratap ChoudhuryPas encore d'évaluation

- Yahoo Mail - Booking Confirmation On IRCTC, Train - 18477, 11-Mar-2020, 3A, CTC - TATA PDFDocument1 pageYahoo Mail - Booking Confirmation On IRCTC, Train - 18477, 11-Mar-2020, 3A, CTC - TATA PDFBhanu Pratap ChoudhuryPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Api RP 571 (B) 51-100Document6 pagesApi RP 571 (B) 51-100alvaedison00100% (1)

- 1 Hot Tap MKSR Dec 2018 003Document137 pages1 Hot Tap MKSR Dec 2018 003Billy KurniawanPas encore d'évaluation

- ECG Interpretation Made Incredibly Easy! (5th Edition)Document29 pagesECG Interpretation Made Incredibly Easy! (5th Edition)Freisan Chen0% (1)

- Table 1A (Cont'd) Section I Section III, Classes 2 and 3 Section VIII, Division 1 and Section XII Maximum Allowable Stress Values ( See Maximum Temperature Limits For Restrictions On Class)Document3 pagesTable 1A (Cont'd) Section I Section III, Classes 2 and 3 Section VIII, Division 1 and Section XII Maximum Allowable Stress Values ( See Maximum Temperature Limits For Restrictions On Class)Latif RadwanPas encore d'évaluation

- Maraging Steel: Maraging Steels (A Portmanteau of "Martensitic" and "Aging") Are Steels (Iron Alloys) That Are KnownDocument5 pagesMaraging Steel: Maraging Steels (A Portmanteau of "Martensitic" and "Aging") Are Steels (Iron Alloys) That Are KnownVysakh VasudevanPas encore d'évaluation

- Munro c301Document8 pagesMunro c301m4x4rtPas encore d'évaluation

- GF-304CR Dossier.Document35 pagesGF-304CR Dossier.suria qaqcPas encore d'évaluation

- Teflon MDSDocument1 pageTeflon MDSSajir ThiyamPas encore d'évaluation

- Chemrite - 520Document2 pagesChemrite - 520ICPL-RWPPas encore d'évaluation

- Advantages of Steel As A Structural MaterialDocument3 pagesAdvantages of Steel As A Structural MaterialIrfan MunirPas encore d'évaluation

- API 5l Practice Questions Doc r2Document4 pagesAPI 5l Practice Questions Doc r2Anonymous SLI4aGPas encore d'évaluation

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandPas encore d'évaluation

- Washbasins: Selector Pedestal/Wall Hung Semi-Countertop Countertop Under-Countertop Vessel Handrinse FittingsDocument39 pagesWashbasins: Selector Pedestal/Wall Hung Semi-Countertop Countertop Under-Countertop Vessel Handrinse FittingsNaveen NtrPas encore d'évaluation

- Irc107 2013Document24 pagesIrc107 2013rahulPas encore d'évaluation

- Case Studies Catalogue: Lik HungDocument22 pagesCase Studies Catalogue: Lik HungE DaePas encore d'évaluation

- Eternia Brochure PDFDocument16 pagesEternia Brochure PDFmathew1965Pas encore d'évaluation

- Y Strainer 50 MM DiaDocument27 pagesY Strainer 50 MM Diamudassir mPas encore d'évaluation

- Bas CatDocument31 pagesBas Catanwer_ahsanPas encore d'évaluation

- BoQ - FSHDocument273 pagesBoQ - FSHsrs_ce05Pas encore d'évaluation

- Positive Material Identification Report: PMI - Just in CaseDocument1 pagePositive Material Identification Report: PMI - Just in CaseJuan CarlosPas encore d'évaluation

- Sample Electrical PlanDocument1 pageSample Electrical PlanAl DrinPas encore d'évaluation

- Blanking and PiercingDocument5 pagesBlanking and Piercingm9966822Pas encore d'évaluation

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremPas encore d'évaluation

- Section 02820 Ornamental Metal Fences and GatesDocument14 pagesSection 02820 Ornamental Metal Fences and GatesMØhãmmed ØwięsPas encore d'évaluation

- Analysis of Tapping Process in Three Types of Cast Iron PDFDocument8 pagesAnalysis of Tapping Process in Three Types of Cast Iron PDFFlorin MilasPas encore d'évaluation

- 2014 - 68 - EU Pressure Equipment - Summary List of Harmonised Standards - Generated On 10.02.2021Document17 pages2014 - 68 - EU Pressure Equipment - Summary List of Harmonised Standards - Generated On 10.02.2021Bilel MahjoubPas encore d'évaluation

- Building Materials and Construction - Civil Engineering Questions and Answers PDF Free Download - Preparation For EngineeringDocument21 pagesBuilding Materials and Construction - Civil Engineering Questions and Answers PDF Free Download - Preparation For Engineeringjs kalyana rama75% (8)

- 4th International Conference On DURABILITY & SUSTAINABILITY OF FIBRE REINFORCED POLYMER (FRP) COMPOSITES FOR CONSTRUCTION & REHABILITATIONDocument21 pages4th International Conference On DURABILITY & SUSTAINABILITY OF FIBRE REINFORCED POLYMER (FRP) COMPOSITES FOR CONSTRUCTION & REHABILITATIONEgyptian ResearcherPas encore d'évaluation

- Aglomerasi Bijih BesiDocument44 pagesAglomerasi Bijih BesiAlfiansyah DarmawanPas encore d'évaluation

- Bohler Colour ChartDocument1 pageBohler Colour Chartscooba84Pas encore d'évaluation