Académique Documents

Professionnel Documents

Culture Documents

BARZAN Onshore EPC Project: Breathing Air Quality and Use Inspection

Transféré par

Mohamed NouzerTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

BARZAN Onshore EPC Project: Breathing Air Quality and Use Inspection

Transféré par

Mohamed NouzerDroits d'auteur :

Formats disponibles

BARZAN Onshore EPC Project

BREATHING AIR QUALITY AND USE INSPECTION

Number of Unit Inspected: 01

Sub-contractor: Location:

Date: Time:

QCON Painting & Blasting Area(BD 41)

09/09/2013 0330H

A. Equipment Used: Drager Pump x-act 5000 w/ detector tubes

General

PARTICULARS ACCEPTED COMMENTS

Compress breathing air meets the requirements for Grade D breathing air.

SAMPLING STANDARDS Oxygen levels measured using SCTR

PARTICULARS READING REMARKS

TIME (OSHA) BW- Gas Alert Multi-gas tester.

Serial: MA211-028A57

Oxygen 20.9% - 19.5%- 23.5% PASSED Calibration Due date: 20-Dec.-2013

5 mg/m3 or NONE

Oil Mist 0 mg/m3 30 min DETECTED

less

Carbon 10 ppm or NONE

0 ppm 4 min DETECTED

Monoxide less

Carbon 1,000 ppm or YES

01 500 ppm 4 min PASSED

Dioxide less

Water 24 ppm or NO

< 1 ppm 1.5 min PASSED

Vapour less

No

Noticeable NONE - NONE PASSED

odor

COMPRESSOR BRAND: SERIAL # : WUX563961

ATLAS COPCO COMPRESSOR #: 21

Note: Measurement was done using Air Investigation inside the blasters hood.

Compressors

Are constructed and situated to prevent contaminated air from getting into the

system.

YES

06

Is the compressor free from combustion exhaust from vehicles or the

compressor itself? NO

Is the compressor free from contaminated air from hazardous work areas?

YES

Are equipped with in-line air purifying sorbent beds and filters that are

07

maintained or replaced following manufacturer’s instructions.

NO

YES

Are tagged with information on the most recent change date of the filter and an

08

authorizing signature.

NO

Carbon monoxide alarms are used on oil-lubricated compressors; monitor the YES Clean Air Box is use

Calibration due date: 22 – Sept. – 2013

09 air often enough to ensure that carbon monoxide does not exceed 10 ppm if

Serial: 1203125313

only a high-temperature alarm is used. NO

RT ZAMUCO NEXT MEASUREMENT: 09/12/2013

Evaluated by:

JGC - INDUSTRIAL HYGIENIST

Page 1 of 1

Vous aimerez peut-être aussi

- Profiler 8 Tutorial Rev 10Document93 pagesProfiler 8 Tutorial Rev 10Mohamed NouzerPas encore d'évaluation

- Calibration Procedure Crowcon Xgard Gas Detectors - 5720273 - 01Document16 pagesCalibration Procedure Crowcon Xgard Gas Detectors - 5720273 - 01Daniel Rolando Gutierrez FuentesPas encore d'évaluation

- The Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995D'EverandThe Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995Évaluation : 5 sur 5 étoiles5/5 (1)

- Versant ModifiedDocument57 pagesVersant ModifiedAryan Kharadkar100% (3)

- 600 Manual v7.0Document16 pages600 Manual v7.0Le Duy ThangPas encore d'évaluation

- PARKER Air Purity Test KitDocument2 pagesPARKER Air Purity Test KitestabejaPas encore d'évaluation

- Executive Report Demo Controll Parex Desorbent PTT GCDocument7 pagesExecutive Report Demo Controll Parex Desorbent PTT GCArie PanjunanPas encore d'évaluation

- M070062 XgardIQ Ammonia Low Range Sensor Module Iss 1 April 16Document2 pagesM070062 XgardIQ Ammonia Low Range Sensor Module Iss 1 April 16carlos perezPas encore d'évaluation

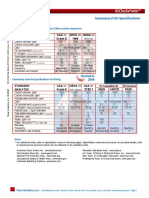

- Aircheck4Notes™: Summary of Air SpecificationsDocument4 pagesAircheck4Notes™: Summary of Air SpecificationsDaniel LagosPas encore d'évaluation

- Niosh 6604 PDFDocument3 pagesNiosh 6604 PDFDiana CruzPas encore d'évaluation

- Zero-Calibration-Kit-2022-Stage-01Document2 pagesZero-Calibration-Kit-2022-Stage-01Alfabi Muhlisin SaktiPas encore d'évaluation

- Rev 01 Mud Gas Separator of Oil ServiceDocument3 pagesRev 01 Mud Gas Separator of Oil ServiceKanti LakhankarPas encore d'évaluation

- Fire Monitors DatasheetsDocument1 pageFire Monitors DatasheetsmoodydoodyPas encore d'évaluation

- Gas AnalyserDocument3 pagesGas AnalyserviahulPas encore d'évaluation

- Air Quality Meter Gasman-H2S Hydrogen Sulfide - PCE InstrumentsDocument3 pagesAir Quality Meter Gasman-H2S Hydrogen Sulfide - PCE InstrumentsSalman HaroonPas encore d'évaluation

- Attachment 2 - ESP+Bag Filter Technical SpecificationDocument48 pagesAttachment 2 - ESP+Bag Filter Technical SpecificationEky Aditya PutraPas encore d'évaluation

- 2.ananlyzar - 20230729121304.633 - XDocument1 page2.ananlyzar - 20230729121304.633 - XDon't MindPas encore d'évaluation

- Competitive Comparison – Diagnostic MonitorsDocument21 pagesCompetitive Comparison – Diagnostic MonitorsDatNguyenPas encore d'évaluation

- ACM2000一氧化碳传感器英文说明书 A0 20220427Document6 pagesACM2000一氧化碳传感器英文说明书 A0 20220427SamPas encore d'évaluation

- Different Gas Detection Meters Used On ShipDocument6 pagesDifferent Gas Detection Meters Used On ShipWilliam GonzalezPas encore d'évaluation

- Clip SGD Iss1 Sep17 GBDocument4 pagesClip SGD Iss1 Sep17 GBAnonymous h9kxYJf3NPas encore d'évaluation

- ManualDocument7 pagesManualAsri GaniPas encore d'évaluation

- Sulfur Dioxide (SO ) Sensor: Technical Data SheetDocument1 pageSulfur Dioxide (SO ) Sensor: Technical Data SheetAnonymous X3PnFL6Pas encore d'évaluation

- Sultanate's ultrasonic flowmeter standardsDocument3 pagesSultanate's ultrasonic flowmeter standardsaltipatlarPas encore d'évaluation

- 5b - Pump ExampleDocument48 pages5b - Pump ExampleIslam SolimanPas encore d'évaluation

- Gas Alert Extreme Data Sheet 555812 enDocument2 pagesGas Alert Extreme Data Sheet 555812 enAlvaro Muñoz BaezaPas encore d'évaluation

- Environment Monitoring Monthly Report - Aug'22Document1 pageEnvironment Monitoring Monthly Report - Aug'22Mohit Kumar DasPas encore d'évaluation

- Arde Respiraçãoe HospitalarDocument4 pagesArde Respiraçãoe HospitalarSuprimentos IndaloPas encore d'évaluation

- ST13-22136Document1 pageST13-22136Luis mendezPas encore d'évaluation

- Chlorine Gas DetectorDocument3 pagesChlorine Gas Detectormohamad chaudhariPas encore d'évaluation

- GasAlert XT Datasheet (5558 10 En)Document2 pagesGasAlert XT Datasheet (5558 10 En)nkouhiPas encore d'évaluation

- 2 +artis PDFDocument25 pages2 +artis PDFkikorrasPas encore d'évaluation

- Manager'S Instructions Ref No. 031 /2021Document3 pagesManager'S Instructions Ref No. 031 /2021ShanmugamoorthyPas encore d'évaluation

- Fire Hydrants DatasheetsDocument1 pageFire Hydrants DatasheetsmoodydoodyPas encore d'évaluation

- CORRECTION FOR TEMPERATURE, HUMIDITY AND PRESSUREDocument1 pageCORRECTION FOR TEMPERATURE, HUMIDITY AND PRESSUREJohn Anthony DanaPas encore d'évaluation

- Gasalertextreme Datasheet 5558-10-EnDocument2 pagesGasalertextreme Datasheet 5558-10-Enapi-433779908Pas encore d'évaluation

- Gcem4011 Co Analyser DocsDocument11 pagesGcem4011 Co Analyser DocsmukurshahPas encore d'évaluation

- Chlorine Dioxide 5ppm Sensor Specs - 823-0239-42rFDocument2 pagesChlorine Dioxide 5ppm Sensor Specs - 823-0239-42rFakshay varmaPas encore d'évaluation

- Low Voc Tdi FoamsDocument8 pagesLow Voc Tdi FoamsMuhammad SaadPas encore d'évaluation

- Kwik-Draw Air-Tester-KitDocument2 pagesKwik-Draw Air-Tester-Kitdhruvit_159737548Pas encore d'évaluation

- Click-On Inline Super Clean Purifiers: GC, Gc/Ms Gas ManagementDocument2 pagesClick-On Inline Super Clean Purifiers: GC, Gc/Ms Gas Managementveronica880Pas encore d'évaluation

- Daily Painting Inspection Report 01Document1 pageDaily Painting Inspection Report 01Oussama Ben AbbesPas encore d'évaluation

- LQC STDDocument2 pagesLQC STDAstronPas encore d'évaluation

- Arde Respira Ç ÃoDocument8 pagesArde Respira Ç ÃoSuprimentos IndaloPas encore d'évaluation

- FM200 Fire FightingDocument54 pagesFM200 Fire Fightinganiket100% (1)

- Natural Gas Moisture MeasurementDocument2 pagesNatural Gas Moisture MeasurementJaime Andres Villegas MansillaPas encore d'évaluation

- 6f Pacific PG EngDocument4 pages6f Pacific PG EngForum PompieriiPas encore d'évaluation

- COC Ar30 40L 02-03-XII-14 Icl QC Check PDFDocument2 pagesCOC Ar30 40L 02-03-XII-14 Icl QC Check PDFTirtana PrasetiaPas encore d'évaluation

- CO AnalyzerDocument1 pageCO AnalyzeruzairPas encore d'évaluation

- Condumax II: Hydrocarbon Dew-Point AnalyzerDocument6 pagesCondumax II: Hydrocarbon Dew-Point AnalyzerJessePas encore d'évaluation

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliPas encore d'évaluation

- Novec Flux RemoverDocument2 pagesNovec Flux Removerquang trinhPas encore d'évaluation

- Witness analysis reportDocument1 pageWitness analysis reportHafiz DaudPas encore d'évaluation

- Gas Leak Checker: SP-220 SeriesDocument2 pagesGas Leak Checker: SP-220 SeriesFerli YansyahPas encore d'évaluation

- Document-2 HIDRAULIC PDFDocument1 pageDocument-2 HIDRAULIC PDFCorina StanculescuPas encore d'évaluation

- Gas Analyzer Measuremnt Sensitivity - GFM42Document3 pagesGas Analyzer Measuremnt Sensitivity - GFM42esraPas encore d'évaluation

- PDF USKBS BreathingAirSystem 07-2018 46-37001Document4 pagesPDF USKBS BreathingAirSystem 07-2018 46-37001Vara PrasadPas encore d'évaluation

- Leak Test Report. 1Document3 pagesLeak Test Report. 1Hanuman RaoPas encore d'évaluation

- 51-Msds Planigrout 310 CDocument8 pages51-Msds Planigrout 310 CJanella ChancanPas encore d'évaluation

- WDI 812 Cal ReportDocument1 pageWDI 812 Cal Reporttabish_khattakPas encore d'évaluation

- Test Qualità Dell'Aria Air Quality Test: Tester DRAGER AEROTEST SIMULTAN HP S/N 6665-12-353-8016Document1 pageTest Qualità Dell'Aria Air Quality Test: Tester DRAGER AEROTEST SIMULTAN HP S/N 6665-12-353-8016camiPas encore d'évaluation

- Gas Sweetening and Processing Field ManualD'EverandGas Sweetening and Processing Field ManualÉvaluation : 4 sur 5 étoiles4/5 (7)

- VOC compliant polyurethane topcoat for corrosive environmentsDocument2 pagesVOC compliant polyurethane topcoat for corrosive environmentsCarlos Andrés Pérez ValientePas encore d'évaluation

- PDS STRATA EPOXY MT 45520 en-GB PDFDocument2 pagesPDS STRATA EPOXY MT 45520 en-GB PDFMohamed NouzerPas encore d'évaluation

- Hempaline Defend en GroupDocument10 pagesHempaline Defend en GroupMohamed NouzerPas encore d'évaluation

- PDS STRATA EPOXY HT 35590 en-GB PDFDocument3 pagesPDS STRATA EPOXY HT 35590 en-GB PDFMohamed Nouzer0% (1)

- Ral ChartDocument10 pagesRal ChartShravan ThangallapalliPas encore d'évaluation

- Hempaline External FlyerDocument2 pagesHempaline External FlyerMohamed NouzerPas encore d'évaluation

- Hempaline Folder PDFDocument3 pagesHempaline Folder PDFMohamed NouzerPas encore d'évaluation

- Hempaline Internal Use OnlyDocument2 pagesHempaline Internal Use OnlyMohamed NouzerPas encore d'évaluation

- PDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFDocument3 pagesPDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFMohamed NouzerPas encore d'évaluation

- Advanced oil tank corrosion protection solutionDocument2 pagesAdvanced oil tank corrosion protection solutionMohamed NouzerPas encore d'évaluation

- Chersterton Arc S4+ PDFDocument1 pageChersterton Arc S4+ PDFMohamed NouzerPas encore d'évaluation

- Hempaline Middle East Case StudyDocument3 pagesHempaline Middle East Case StudyMohamed NouzerPas encore d'évaluation

- Chemical Resistance GuideDocument11 pagesChemical Resistance GuideMohamed NouzerPas encore d'évaluation

- Ral Chart PDFDocument3 pagesRal Chart PDFErunerPas encore d'évaluation

- PDS STRATA EPOXY MT 45520 en-GB PDFDocument2 pagesPDS STRATA EPOXY MT 45520 en-GB PDFMohamed NouzerPas encore d'évaluation

- Chersterton Arc 858 PDFDocument1 pageChersterton Arc 858 PDFMohamed NouzerPas encore d'évaluation

- RAL & British Standard Colour Charts PDFDocument5 pagesRAL & British Standard Colour Charts PDFMohamed NouzerPas encore d'évaluation

- Product Specification Sheet BELZONA 5831: General InformationDocument4 pagesProduct Specification Sheet BELZONA 5831: General InformationMohamed NouzerPas encore d'évaluation

- Hempel's Tank Lining CRG Brochure - v9Document11 pagesHempel's Tank Lining CRG Brochure - v9togentongPas encore d'évaluation

- Chersterton Arc S2 PDFDocument1 pageChersterton Arc S2 PDFMohamed NouzerPas encore d'évaluation

- PDS MAESTRO PRO FILLER 38810 en-GB PDFDocument1 pagePDS MAESTRO PRO FILLER 38810 en-GB PDFMohamed NouzerPas encore d'évaluation

- Chersterton Arc 982 PDFDocument2 pagesChersterton Arc 982 PDFMohamed NouzerPas encore d'évaluation

- Hempel'S Topaz Matt Emulsion 588meDocument2 pagesHempel'S Topaz Matt Emulsion 588meMohamed NouzerPas encore d'évaluation

- Product Specification Sheet BELZONA 1321: General InformationDocument3 pagesProduct Specification Sheet BELZONA 1321: General InformationMohamed NouzerPas encore d'évaluation

- bs4800 Colour Chart PDFDocument4 pagesbs4800 Colour Chart PDFMohamed NouzerPas encore d'évaluation

- 588ME - Fire Rating PDF J176617-SR090305BS 476 PT 7 AirGap PDF 1 PDFDocument13 pages588ME - Fire Rating PDF J176617-SR090305BS 476 PT 7 AirGap PDF 1 PDFMohamed NouzerPas encore d'évaluation

- Hempaline Defend 630 AI (Cure 24) v3Document3 pagesHempaline Defend 630 AI (Cure 24) v3Mohamed NouzerPas encore d'évaluation

- Pitt-Char XP - TdsDocument4 pagesPitt-Char XP - TdsMohamed NouzerPas encore d'évaluation

- Advanced oil tank corrosion protection solutionDocument2 pagesAdvanced oil tank corrosion protection solutionMohamed NouzerPas encore d'évaluation

- Desiderata: by Max EhrmannDocument6 pagesDesiderata: by Max EhrmannTanay AshwathPas encore d'évaluation

- Binge-Eating Disorder in AdultsDocument19 pagesBinge-Eating Disorder in AdultsJaimeErGañanPas encore d'évaluation

- Business PlanDocument63 pagesBusiness PlanKristine BalanayPas encore d'évaluation

- Fajar Secondary Sec 3 E Math EOY 2021Document16 pagesFajar Secondary Sec 3 E Math EOY 2021Jayden ChuaPas encore d'évaluation

- Dahua Pfa130 e Korisnicko Uputstvo EngleskiDocument5 pagesDahua Pfa130 e Korisnicko Uputstvo EngleskiSaša CucakPas encore d'évaluation

- CV1000 CV2000 CV3000 Ice Cube Machines SpecsDocument12 pagesCV1000 CV2000 CV3000 Ice Cube Machines SpecsAriel Godoy100% (1)

- Principle Harmony RhythmDocument16 pagesPrinciple Harmony RhythmRosalinda PanopioPas encore d'évaluation

- Surface Hardening enDocument20 pagesSurface Hardening engtm1207Pas encore d'évaluation

- Art-App-Module-12 Soulmaking, Improvisation, Installation, & TranscreationDocument4 pagesArt-App-Module-12 Soulmaking, Improvisation, Installation, & TranscreationJohn Mark D. RoaPas encore d'évaluation

- Ch3 XII SolutionsDocument12 pagesCh3 XII SolutionsSaish NaikPas encore d'évaluation

- Palm Wine SpecificationDocument10 pagesPalm Wine SpecificationUday ChaudhariPas encore d'évaluation

- المحاضرة الرابعة المقرر انظمة اتصالات 2Document31 pagesالمحاضرة الرابعة المقرر انظمة اتصالات 2ibrahimPas encore d'évaluation

- 841 Specific GravityDocument1 page841 Specific GravityJam SkyPas encore d'évaluation

- Supply Chain Management: Tata Tea's Global OperationsDocument15 pagesSupply Chain Management: Tata Tea's Global OperationsAmit Halder 2020-22Pas encore d'évaluation

- JSW Energy Plant Maintenance BBPDocument46 pagesJSW Energy Plant Maintenance BBPSandeep Kumar PraharajPas encore d'évaluation

- The Baptismal Liturgy in The Easter Vigil According To The Sacramentary of Fulda (10th Century)Document7 pagesThe Baptismal Liturgy in The Easter Vigil According To The Sacramentary of Fulda (10th Century)Henry DonascoPas encore d'évaluation

- Gerovital anti-aging skin care product guideDocument10 pagesGerovital anti-aging skin care product guideכרמן גאורגיהPas encore d'évaluation

- EiaDocument14 pagesEiaRamir FamorcanPas encore d'évaluation

- UPSC IFS Botany Syllabus: Paper - IDocument3 pagesUPSC IFS Botany Syllabus: Paper - IVikram Singh ChauhanPas encore d'évaluation

- Weber Grills - FinalDocument12 pagesWeber Grills - FinalDIVYANSHU SHEKHARPas encore d'évaluation

- Blood Group 3Document29 pagesBlood Group 3Hamirie JoshuaPas encore d'évaluation

- Combustion Cat 2008Document32 pagesCombustion Cat 2008Miguel LinaresPas encore d'évaluation

- Grade 11 Holiday Homework Part 1Document7 pagesGrade 11 Holiday Homework Part 1Jashfa SaboorPas encore d'évaluation

- Presentation 123Document13 pagesPresentation 123Harishitha ManivannanPas encore d'évaluation

- Cooling System Exhaust System: RadiatorDocument2 pagesCooling System Exhaust System: RadiatorMd ShPas encore d'évaluation

- TP5 W9 S9 R0Document2 pagesTP5 W9 S9 R0DickiEffendy0% (1)

- 18 Butterfly Valves A Disc BrayDocument10 pages18 Butterfly Valves A Disc BrayAli FananiPas encore d'évaluation

- Mycbseguide: Cbse Class 10 Social Science Sample Paper - 08 (MCQ Based)Document10 pagesMycbseguide: Cbse Class 10 Social Science Sample Paper - 08 (MCQ Based)Abdul MuqsitPas encore d'évaluation

- Science Section A UPSRDocument2 pagesScience Section A UPSRvinno8556% (9)