Académique Documents

Professionnel Documents

Culture Documents

Project Spec

Transféré par

Cyril J PadiyathTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Project Spec

Transféré par

Cyril J PadiyathDroits d'auteur :

Formats disponibles

Abu Dhabi Airports Company PJSC Specification, Section 124816

SECTION 124816

ENTRANCE FLOOR GRILLES

1 - GENERAL

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Supplementary

Conditions and Division 01 Specification Sections, apply to this Section.

1.2 SUMMARY

A. Contractor shall provide all labour, Materials, Contractor’s Equipment and Plant to fully

execute the requirements to furnish, deliver, and install the Works as expressly described in

the Drawings and Specification, or implied therefrom, and in accordance with the Contract.

It is the intent of this Specification section that the work performed pursuant hereto be

complete and acceptable in every respect for its intended purpose. It is further required that

the provisions of this Specification section shall be complementary to, and shall be

correlated with, the requirements of the Contract. Nothing in this Specification section shall

limit the scope of work as required by the Contract.

B. This Section includes the following:

1. Entrance floor grille (ref EFG-01): recessed entrance floor grilles and frames.

C. Related Sections include, but are not limited to, the following. This paragraph cross-

references requirements a reader might expect to find in this Section but are specified in

another section. It is not intended to be, and shall not be interpreted as, a listing of every

other section that has a relationship to this Section.

1. Division 03 Section "Cast-in-Place Concrete" for slab depression for recessed

entrance floor grilles and frames.

1.3 PERFORMANCE REQUIREMENTS

A. Structural Performance: Provide entrance floor grilles and frames capable of withstanding

the following loads and stresses:

1. Uniform floor load of not less than 780 kg/100 sq. cm.

1.4 SUBMITTALS

A. Product Data: Include construction details, material descriptions, dimensions of individual

components and profiles, and finishes for entrance floor grilles and frames.

B. Shop Drawings: Plans and sections, indicating site measurements. Show the following:

1. Items penetrating entrance floor grilles and frames, including door control devices.

2. Divisions between grille sections.

3. Perimeter floor moldings.

C. Samples for Initial Selection: For each type of product involving color selection.

D. Samples for Verification: For each type of product indicated.

1. Entrance floor grille: 300-mm-square assembled sections, including tread rails and

inserts.

Contract: Midfield Terminal Building - General Contractor, AUH.06.10.0401 Page 1 of 5

Construction Document: Volume 3 of 4 July 2012

Abu Dhabi Airports Company PJSC Specification, Section 124816

2. Frame Members: 300-mm-long Sample of each type and finish.

E. Certification: Signed and sealed by Contractor, certifying that products and systems to be

provided comply with performance requirements in the Contract Documents. Include

calculations and structural analysis including comprehensive engineering analysis (limited

to the extent of the defined Performance Requirements in this Section) signed and sealed by

the qualified professional engineer responsible for their preparation.

1. Should there be proposed deviations from specified requirements, submit

calculations, loads, standards and other factors used to establish compliance with

performance requirements, for review and acceptance by Engineer.

2. Should there be proposed deviations from aesthetic effects, submit drawings

indicating such proposed deviations, for review and acceptance by Engineer.

F. Maintenance Data: For entrance floor grilles and frames to include in maintenance manuals.

G. Warranty: Sample of warranty.

1.5 QUALITY ASSURANCE

A. Source Limitations:

1. Obtain entrance floor grilles and frames through one source from a single

manufacturer.

2. Obtain entrance floor grilles and frames, and external bi-parting doors, through one

source.

B. Accessibility Requirements: Provide installed floor mats that comply with Section 4.5 in

the U.S. Architectural & Transportation Barriers Compliance Board's "Americans with

Disabilities Act (ADA), Accessibility Guidelines for Buildings and Facilities (ADAAG)"

and Sections 302 and 303 in ICC A117.1.

C. In-Place Mockups: Build mockups of entrance floor grille assemblies, to verify selections

made under sample submittals and to demonstrate aesthetic effects and set quality standards

for execution.

1. Extent: One complete entrance floor grille assembly.

2. Obtain Engineer’s approval of mockups before proceeding with subsequent

construction or installation.

3. Approval of mockups does not constitute approval of deviations from the Contract

Documents contained in mockups, unless such deviations are specifically approved

by Engineer in writing.

4. Subject to compliance with requirements, approved mockups may become part of the

completed Work if undisturbed at time of Substantial Completion.

1.6 REFERENCES

A. Product manufacture, testing and installation shall comply with the following references

unless otherwise stated in the specification or otherwise approved by the Engineer.

B. German National Standards:

1. DIN 51130-05: Testing of Floor Coverings - Determination of the Anti-Slip Property

- Workrooms and Fields of Activities with Slip Danger, Walking Method - Ramp

Test:

C. International Code Council

1. ICC A117.1-2003: Accessible and Usable Buildings and Facilities (ANSI)

Contract: Midfield Terminal Building - General Contractor, AUH.06.10.0401 Page 2 of 5

Construction Document: Volume 3 of 4 July 2012

Abu Dhabi Airports Company PJSC Specification, Section 124816

1.7 PROJECT CONDITIONS

A. Site Measurements: Indicate measurements on Shop Drawings.

1. Established Dimensions: Where field measurements of adjoining construction cannot

be made without delaying the Work, establish dimensions for adjoining construction,

and proceed with fabricating floor grilles in accordance with established dimensions.

Allow for trimming at site to tolerances agreed upon in advance with Engineer, and

coordinate construction to ensure that actual dimensions of adjoining construction

correspond to established dimensions.

1.8 COORDINATION

A. Coordinate size and location of recesses in concrete to receive entrance floor grilles and

frames.

1.9 EXTRA MATERIALS

A. Furnish extra materials that match products installed and that are packaged with protective

covering for storage and identified with labels describing contents.

1. Rubber Inserts: Rolls of grooved rubber inserts for treads for floor grilles, equal to 3

percent of total amount installed.

1.10 WARRANTY

A. Warranty:

1. All materials, assemblies, components, parts, and workmanship shall be guaranteed

against defect, damage, or non-conformity for a period of one year.

2. During the warranty period the manufacturer shall make all necessary repairs or

replacement to achieve conformity to the requirements of the Contract Documents.

3. Warranty Period: See Division 01 Section “Warranties” for commencement date of

warranty period.

2 - PRODUCTS

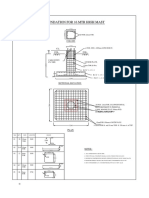

2.1 ENTRANCE FLOOR GRILLES

A. General: Provide manufacturer's standard roll-up foot-grille assemblies consisting of treads

of type and profile specified, interlocked or joined together by cross members, and with

support legs (if any) and other components needed to produce a complete installation.

B. Aluminum Entrance Floor Grilles: Provide manufacturer's standard entrance floor grilles

with extruded members, top-surfaced tread rails, and as follows:

1. Tread Rails: Extruded-aluminum tread channels, with impact sound insulation

underlay; approximately 29 mm wide by 22 mm deep.

2. Tread Rail Spacing: Approximately 34 mm o.c. with 5-mm-wide rubber spacers

between treads.

a. Connect tread rail sections using plastic-coated, galvanized steel wire.

3. Aluminum Finish: Mill.

4. Top Surface: Grooved rubber inserts; slip resistance of R9 in accordance with

DIN 51130.

a. Colors: Black.

Contract: Midfield Terminal Building - General Contractor, AUH.06.10.0401 Page 3 of 5

Construction Document: Volume 3 of 4 July 2012

Abu Dhabi Airports Company PJSC Specification, Section 124816

5. Grille Sizes and Configurations: As indicated on Drawings; multiple sizes and

configurations are required.

2.2 FRAMES

A. Provide manufacturer's standard frames of size and style for grille type, for permanent

recessed installation in subfloor, complete with installation anchorages and accessories.

Fabricate frame of same material and finish as grilles.

2.3 CONCRETE FILL

A. Provide concrete fill equivalent in strength to cast-in-place concrete slabs, to provide

leveling bed on top of screed to bring floor grilles to proper elevation. Use aggregate no

larger than one-third of fill thickness.

2.4 FABRICATION

A. Shop fabricate entrance floor grilles to greatest extent possible in sizes as indicated on

Drawings. Unless otherwise indicated, provide each grille as a single unit; do not exceed

manufacturer's recommended maximum sizes for units that are removed for maintenance

and cleaning. Where joints in grilles are necessary, space symmetrically and away from

normal traffic lanes.

B. Fabricate frame members in single lengths or, where frame dimensions exceed maximum

available lengths, provide minimum number of pieces possible, with hairline joints equally

spaced and pieces spliced together by straight connecting pins.

C. Fabricate to radii indicated on Drawings, using forming methods which maintain original

cross-section of members and provide smooth, uniform curves.

D. Coordinate fabrication of entrance floor grilles with external bi-parting doors, so that

dimensions and configurations of entrance floor grilles fit precisely with doors.

2.5 FINISHES

A. General: Protect mechanical finishes on exposed surfaces from damage by applying a

strippable, temporary protective covering before shipping.

B. Mill Finish: As fabricated; grind and buff as required to remove scratches, welding, or

abrasions produced in fabrication process.

3 - EXECUTION

3.1 EXAMINATION

A. Examine substrates and floor conditions for compliance with requirements for location, size,

minimum recess depth, and other conditions affecting installation of entrance floor grilles

and frames.

B. Examine roughing-in for drainage piping systems to verify actual locations of piping

connections before entrance floor grille and frame installation.

C. Proceed with installation only after unsatisfactory conditions have been corrected.

3.2 INSTALLATION

A. Install concrete fill to provide leveling bed on top of screed to bring floor grilles to proper

elevation, as indicated on Drawings.

Contract: Midfield Terminal Building - General Contractor, AUH.06.10.0401 Page 4 of 5

Construction Document: Volume 3 of 4 July 2012

Abu Dhabi Airports Company PJSC Specification, Section 124816

B. Install recessed entrance floor grilles and frames to comply with manufacturer's written

instructions at locations indicated on Drawings, and with top of entrance floor grilles and

frames in relationship to one another and to adjoining finished flooring as recommended by

manufacturer.

1. Provide Type 316 stainless steel baffle within depth of floor recess, under plane of

doors, so as to prevent short circuiting of exterior air into building interior.

2. Set foot-grille tops at height for most effective cleaning action.

3. Coordinate top of foot-grille surfaces with doors that swing across grilles to provide

clearance under door.

3.3 PROTECTION

A. After completing frame installations, provide temporary filler of plywood or fiberboard in

foot-grille recesses and cover frames with plywood protective flooring. Maintain protection

until construction traffic has ended and Project is near Substantial Completion.

END OF SECTION

Contract: Midfield Terminal Building - General Contractor, AUH.06.10.0401 Page 5 of 5

Construction Document: Volume 3 of 4 July 2012

Vous aimerez peut-être aussi

- Section 077129 - Manufactured Roof Expansion JointsDocument6 pagesSection 077129 - Manufactured Roof Expansion JointsWENDING HUPas encore d'évaluation

- Section 035440 - Cement-Based ScreedDocument11 pagesSection 035440 - Cement-Based ScreedWENDING HUPas encore d'évaluation

- SECTION 076200 Sheet Metal Flashing and Trim: 1 - GeneralDocument10 pagesSECTION 076200 Sheet Metal Flashing and Trim: 1 - GeneralCyril J PadiyathPas encore d'évaluation

- SECTION 03490 Glass Fiber Reinforced Concrete (GFRC)Document17 pagesSECTION 03490 Glass Fiber Reinforced Concrete (GFRC)SunilPas encore d'évaluation

- University of Houston Master Construction SpecificationsDocument9 pagesUniversity of Houston Master Construction SpecificationsParvez Syed RafiPas encore d'évaluation

- 09 2700 Plaster FabricationsDocument7 pages09 2700 Plaster FabricationsmordeauxPas encore d'évaluation

- FL - Aluminum Doors and WindowsDocument9 pagesFL - Aluminum Doors and WindowsAmro Ahmad AliPas encore d'évaluation

- SECTION 08331 Overhead Coiling Doors Part 1 - General 1.1Document3 pagesSECTION 08331 Overhead Coiling Doors Part 1 - General 1.1Im ChinithPas encore d'évaluation

- Aluminum WindowsDocument14 pagesAluminum Windowshayat49000Pas encore d'évaluation

- Entrance Floor Mats and FramesDocument4 pagesEntrance Floor Mats and FramesAWESDPas encore d'évaluation

- 033000-Cast-In-Place Concrete (Sanitized) PDFDocument47 pages033000-Cast-In-Place Concrete (Sanitized) PDFugurPas encore d'évaluation

- Glazed Aluminum Curtain WallsDocument22 pagesGlazed Aluminum Curtain Wallsnvdinh511Pas encore d'évaluation

- Section 034501 - Miscellaneous Architectural Precast ConcreteDocument6 pagesSection 034501 - Miscellaneous Architectural Precast ConcreteWENDING HUPas encore d'évaluation

- Section 10200 Louvers and VentsDocument3 pagesSection 10200 Louvers and VentsMØhãmmed ØwięsPas encore d'évaluation

- Connecting Details DWG 001Document9 pagesConnecting Details DWG 001Yadhu .msa17Pas encore d'évaluation

- ARCHITECTURAL JOINT SYSTEMS Rev.1Document8 pagesARCHITECTURAL JOINT SYSTEMS Rev.1mohdPas encore d'évaluation

- 03 4110 Precast Double Tees1Document11 pages03 4110 Precast Double Tees1M OdebrechtPas encore d'évaluation

- Section 07572 Athletic Surface 3Document4 pagesSection 07572 Athletic Surface 3bravo deltafoxPas encore d'évaluation

- Louvers CSI SpecificationDocument6 pagesLouvers CSI SpecificationRowdyRaheelPas encore d'évaluation

- Maintenance EquipmentDocument7 pagesMaintenance Equipmentwalid abou kachfePas encore d'évaluation

- Project Standard Specification: Metal Ducts 15815 - Page 1/12Document12 pagesProject Standard Specification: Metal Ducts 15815 - Page 1/12adel rihanaPas encore d'évaluation

- Section 32 1716 Manufactured Traffic-Calming DevicesDocument3 pagesSection 32 1716 Manufactured Traffic-Calming DevicesAnees RahmanPas encore d'évaluation

- ASTM Specs For Precast Concrete ProductsDocument9 pagesASTM Specs For Precast Concrete ProductsPrateek Mody100% (1)

- SECTION 09515 Matal Ceiling SystemsDocument4 pagesSECTION 09515 Matal Ceiling SystemsIm ChinithPas encore d'évaluation

- Aluminum Composite Pannel LimitsDocument7 pagesAluminum Composite Pannel LimitsRex SirilanPas encore d'évaluation

- Modifications/Changes in This UpdateDocument19 pagesModifications/Changes in This UpdateAdea CarolPas encore d'évaluation

- EWS Series 400 SpecsDocument11 pagesEWS Series 400 Specscancer24Pas encore d'évaluation

- SpecsDocument6 pagesSpecsTAHANIPas encore d'évaluation

- Pyramid PDFDocument7 pagesPyramid PDFAndriPas encore d'évaluation

- Steel Space Frame SpecDocument5 pagesSteel Space Frame SpecSusi SihombingPas encore d'évaluation

- Joint Sealants - MSTDocument9 pagesJoint Sealants - MSTwafikmh4Pas encore d'évaluation

- Section 08630 Metal-Framed SkylightDocument4 pagesSection 08630 Metal-Framed SkylightMØhãmmed ØwięsPas encore d'évaluation

- Air CurtainsDocument5 pagesAir Curtainsadel rihanaPas encore d'évaluation

- SECTION 08 63 00 Metal-Framed SkylightsDocument14 pagesSECTION 08 63 00 Metal-Framed SkylightsJuanPaoloYbañezPas encore d'évaluation

- 02b. SpecDocument19 pages02b. SpecAbdul LatheefPas encore d'évaluation

- 1 - . - Hot Dip Galvanizing AESS, Where Indicated, Is Specified in Section 05 05 156. - . - 1Document10 pages1 - . - Hot Dip Galvanizing AESS, Where Indicated, Is Specified in Section 05 05 156. - . - 1Jagatheesh RadhakrishnanPas encore d'évaluation

- Section 02870 Site FurnishingsDocument19 pagesSection 02870 Site FurnishingsMØhãmmed ØwięsPas encore d'évaluation

- FurnitureDocument4 pagesFurnitureLloyd R. PoncePas encore d'évaluation

- Key IWS CoatingDocument6 pagesKey IWS Coatingfaisal hanifPas encore d'évaluation

- Asphalt Shingles - MSTDocument13 pagesAsphalt Shingles - MSTwafikmh4Pas encore d'évaluation

- SECTION 03 45 00 Precast Architectural ConcreteDocument30 pagesSECTION 03 45 00 Precast Architectural ConcreteJuanPaoloYbañezPas encore d'évaluation

- Va 09 51 00Document16 pagesVa 09 51 00Hana KaedePas encore d'évaluation

- Signage Specifications SampleDocument4 pagesSignage Specifications SampleWenona Zamora DagcutaPas encore d'évaluation

- Crac Specification For CUCDocument12 pagesCrac Specification For CUCLi LiuPas encore d'évaluation

- I SteelDocument50 pagesI SteelsbunPas encore d'évaluation

- SECTION 07 24 00 Exterior Insulation and Finish SystemsDocument12 pagesSECTION 07 24 00 Exterior Insulation and Finish SystemsJuanPaoloYbañezPas encore d'évaluation

- Ref FRP Arch Guideline SpecDocument8 pagesRef FRP Arch Guideline SpecgeorgePas encore d'évaluation

- Section 09514Document7 pagesSection 09514motaz alzoubiPas encore d'évaluation

- Section 09680 CarpetDocument7 pagesSection 09680 CarpetMØhãmmed ØwięsPas encore d'évaluation

- Spec 092400 (Plastering Works)Document11 pagesSpec 092400 (Plastering Works)Ayman BadrPas encore d'évaluation

- Pipe and Tube RailingsDocument10 pagesPipe and Tube RailingssobhiPas encore d'évaluation

- Metal Framed SkylightsDocument13 pagesMetal Framed SkylightsLloyd R. PoncePas encore d'évaluation

- Volume Ii: Specifications (Stamped Concrete) : Issue: FINAL, 14th FEB 2013Document8 pagesVolume Ii: Specifications (Stamped Concrete) : Issue: FINAL, 14th FEB 2013Ahmad Saadeldin100% (1)

- Fixed Aerofoil Louver Brise Soleil SpecDocument4 pagesFixed Aerofoil Louver Brise Soleil Specpraveen0907Pas encore d'évaluation

- SECTION 08900 Glazed CurtainwallsDocument3 pagesSECTION 08900 Glazed CurtainwallsIm ChinithPas encore d'évaluation

- Section 055000 - Metal FabricationsDocument15 pagesSection 055000 - Metal FabricationsWENDING HUPas encore d'évaluation

- SECTION 08 56 53 Blast Resistant WindowsDocument10 pagesSECTION 08 56 53 Blast Resistant WindowsJuanPaoloYbañezPas encore d'évaluation

- Hollow Core SpecificationsDocument8 pagesHollow Core SpecificationsJohn Carpenter100% (1)

- Reinforced Concrete Buildings: Behavior and DesignD'EverandReinforced Concrete Buildings: Behavior and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- RN-02-00001-07-11-IR-NBH-MI-000145 (01) - M.Sub For Steel Elements For Irrigation Pump StationDocument2 pagesRN-02-00001-07-11-IR-NBH-MI-000145 (01) - M.Sub For Steel Elements For Irrigation Pump StationCyril J PadiyathPas encore d'évaluation

- Comments Resolution Sheet (CRS)Document27 pagesComments Resolution Sheet (CRS)Cyril J PadiyathPas encore d'évaluation

- Tokio QuoteDocument5 pagesTokio QuoteCyril J PadiyathPas encore d'évaluation

- FANR-RG-019 Radiation Safety in Industrial RadiographyDocument31 pagesFANR-RG-019 Radiation Safety in Industrial RadiographyCyril J PadiyathPas encore d'évaluation

- Inside WeldingDocument1 pageInside WeldingCyril J PadiyathPas encore d'évaluation

- FANR - RG007 Ver1Document64 pagesFANR - RG007 Ver1Cyril J PadiyathPas encore d'évaluation

- Stylish Teaching Cover LetterDocument1 pageStylish Teaching Cover LetterCyril J PadiyathPas encore d'évaluation

- Allianz Middle East Ship Mangament LLC: "WWE 210" 210ft Positioning (Crane) Barge 4PMDocument2 pagesAllianz Middle East Ship Mangament LLC: "WWE 210" 210ft Positioning (Crane) Barge 4PMCyril J PadiyathPas encore d'évaluation

- Queen Street Local Rules June 2011Document10 pagesQueen Street Local Rules June 2011Cyril J PadiyathPas encore d'évaluation

- V1 V2 Cal PRCDocument5 pagesV1 V2 Cal PRCCyril J PadiyathPas encore d'évaluation

- Form Radiation Work Permit Free TemplateDocument1 pageForm Radiation Work Permit Free TemplateCyril J PadiyathPas encore d'évaluation

- National Guard Epoxy Red Oxide PrimerDocument3 pagesNational Guard Epoxy Red Oxide PrimerCyril J PadiyathPas encore d'évaluation

- Sanitory Works SpecDocument10 pagesSanitory Works SpecCyril J PadiyathPas encore d'évaluation

- Emirates Steel BrochureDocument92 pagesEmirates Steel BrochureCyril J PadiyathPas encore d'évaluation

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data SheetCyril J PadiyathPas encore d'évaluation

- National Red Oxide Primer PDFDocument3 pagesNational Red Oxide Primer PDFCyril J Padiyath100% (1)

- SULB Product Catalogue PDFDocument46 pagesSULB Product Catalogue PDFCyril J PadiyathPas encore d'évaluation

- JSC "Zaporizhstal" (Ukraine) : Company's Business ProfileDocument8 pagesJSC "Zaporizhstal" (Ukraine) : Company's Business ProfileCyril J PadiyathPas encore d'évaluation

- General: SECTION 01 78 36 WarrantiesDocument3 pagesGeneral: SECTION 01 78 36 WarrantiesCyril J PadiyathPas encore d'évaluation

- 401 An e 07 Ge 0.00 LT SD 071 v00.c (Typical Lighting Detail Plan Lighting Fixture Type l2b & Xs1 S)Document1 page401 An e 07 Ge 0.00 LT SD 071 v00.c (Typical Lighting Detail Plan Lighting Fixture Type l2b & Xs1 S)Cyril J PadiyathPas encore d'évaluation

- TribologyDocument16 pagesTribologyKavya M BhatPas encore d'évaluation

- Workshop Manual Citea DAF Euro-5 EnglezaDocument466 pagesWorkshop Manual Citea DAF Euro-5 EnglezaIgor NistorPas encore d'évaluation

- High Mast Foundation Layout - DiagramDocument8 pagesHigh Mast Foundation Layout - DiagramTanveer Ahmad89% (9)

- Indeterminate StrussDocument44 pagesIndeterminate StrussMohan NaikPas encore d'évaluation

- PDIL JBsDocument7 pagesPDIL JBs9044nksPas encore d'évaluation

- Wall Panel SystemDocument32 pagesWall Panel SystemIrlPas encore d'évaluation

- Nca Code of ConductDocument15 pagesNca Code of ConductopulithePas encore d'évaluation

- Metric Hex Bolt ChartsDocument1 pageMetric Hex Bolt ChartsPraburamPas encore d'évaluation

- Forging AluminiumDocument3 pagesForging Aluminiumnadeem_mechPas encore d'évaluation

- Vol II KuchamanDocument556 pagesVol II Kuchamanrasun krPas encore d'évaluation

- Chapter 8Document25 pagesChapter 8aung0024Pas encore d'évaluation

- ART20195900Document9 pagesART20195900113- SandhyaPas encore d'évaluation

- Acoustic Emission Source LocationDocument176 pagesAcoustic Emission Source LocationCarlos Quiterio Gomez Muñoz100% (2)

- MDB Lesson 4 Poisson's Ratio-Biaxial and Triaxial DeformationsDocument12 pagesMDB Lesson 4 Poisson's Ratio-Biaxial and Triaxial DeformationsChan MirandaPas encore d'évaluation

- CIP Section 02Document14 pagesCIP Section 02viksofPas encore d'évaluation

- Calculating Design Loads For Residential Structures: Pdhonline Course S199 (4 PDH)Document34 pagesCalculating Design Loads For Residential Structures: Pdhonline Course S199 (4 PDH)Vincent De GuzmanPas encore d'évaluation

- Bearing Pad "A" Bearing Pad "B": Bd-Id1EDocument11 pagesBearing Pad "A" Bearing Pad "B": Bd-Id1EJUAN RULFOPas encore d'évaluation

- CA02 1819 Vol I PG - 303 - To - 355Document53 pagesCA02 1819 Vol I PG - 303 - To - 355KaranKikavatPas encore d'évaluation

- 9 BOQ Street Lights FINALDocument3 pages9 BOQ Street Lights FINALmooorthuPas encore d'évaluation

- Art 826Document1 pageArt 826MASOUDPas encore d'évaluation

- Zap Diy Old School Cable Kit Guide v1Document6 pagesZap Diy Old School Cable Kit Guide v1asdfhwegaPas encore d'évaluation

- Precast and Prestressed Folded Plate SlabsDocument10 pagesPrecast and Prestressed Folded Plate SlabsMuna ChiPas encore d'évaluation

- Pse 115a2512#dl PSDL D Com Proper 1 To 4Document4 pagesPse 115a2512#dl PSDL D Com Proper 1 To 4Rinowan PanggoariPas encore d'évaluation

- Induction Sheet A (002) (23163)Document1 pageInduction Sheet A (002) (23163)Vladut FaneaPas encore d'évaluation

- Selected Welding Application in Offshore IndustryDocument38 pagesSelected Welding Application in Offshore IndustryzuudeePas encore d'évaluation

- Standard Chain Link Design DetailDocument3 pagesStandard Chain Link Design Detailregkray01Pas encore d'évaluation

- Exhibitors ListDocument116 pagesExhibitors ListAuras TechnologyPas encore d'évaluation

- Gen TT Install InstructionsDocument25 pagesGen TT Install Instructionsspsperformance1Pas encore d'évaluation

- KSCST Project ReportDocument10 pagesKSCST Project ReportGururaj TavildarPas encore d'évaluation